Have you ever wondered how machines cut metal with such skill? One key to this is the milling tool radius comp strategies. These strategies help machines make precise movements. They ensure that every cut is perfect.

Imagine trying to carve a smooth edge on a piece of wood. It’s tricky, right? You have to know how deep to cut and where to aim. The same goes for milling tools. If they don’t know their radius, the results can be messy.

Fun fact: The right milling tool can make the difference between a winning design and a total failure. Understanding milling tool radius comp strategies can boost your projects. It is like having a secret weapon in your toolbox!

Let’s dive deeper into these strategies and explore how they can enhance your work. The world of milling tools is fascinating and full of surprises!

Milling Tool Radius Compensation Strategies For Precision Cutting

Milling tool radius compensation strategies are essential for precise machining. These strategies adjust the tool path for the tool’s radius, ensuring accuracy in cutting. Understanding this can save time and material. Imagine a woodworker trying to carve a detailed design perfectly. Without the right radius adjustments, even the best tools can mislead! Through effective compensation, machinists improve efficiency and achieve better results. This knowledge enhances overall project success and helps avoid costly mistakes.

Understanding Tool Radius Compensation

Definition and importance of tool radius compensation in milling. How radius compensation impacts machining accuracy and surface finish.

Tool radius compensation is a method that helps machines cut materials accurately. It adjusts the path of the cutting tool to match the tool’s size. This is important because it enhances machining accuracy and improves the surface finish. Without compensation, the parts may not fit together well. This means a smoother and more precise final product.

- It helps in getting the right size of parts.

- Good surface finish means less time for polishing.

- Increases the lifespan of the cutting tools.

Why is tool radius compensation important?

Tool radius compensation is crucial because it ensures precision in machining. This leads to better quality in products and saves time!

Implementing Radius Compensation in CNC Programming

Stepbystep guide to programming radius compensation in CNC software. Common programming errors to avoid.

Using radius compensation in CNC programming is important for precision. Follow these steps for success:

- Define the radius value you need.

- Input the radius in your CNC software.

- Adjust the tool path to reflect the compensation.

- Run a simulation before actual operation.

- Check for errors in the setup.

Avoid these common mistakes:

- Not double-checking the radius value.

- Forgetting to adjust the toolpath.

- Skipping the simulation.

Mastering these points helps in achieving accurate cuts and avoiding costly mistakes.

What is radius compensation in CNC programming?

Radius compensation adjusts the tool path based on the tool’s radius, ensuring precise machining.

Choosing the Right Milling Tool for Effective Radius Compensation

Factors influencing tool selection (material, shape, application). Recommendations for optimal tool types based on compensation strategies.

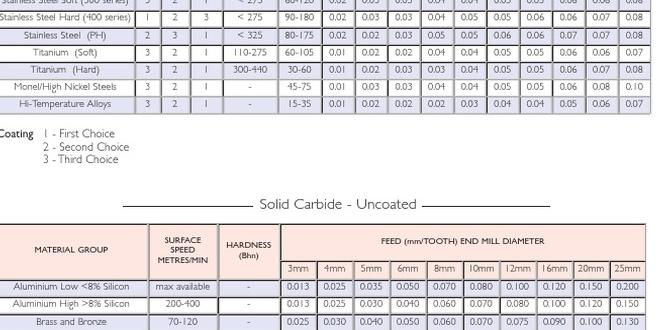

When picking a milling tool, several factors come into play. First, consider the material. Is it tough like steel or soft like butter? Next, look at the shape of the tool. Different shapes can create different radius effects. Lastly, think about the application. What are you making? Each task might need a special tool. Here’s a handy table to help you decide:

| Material | Shape | Application |

|---|---|---|

| Steel | Flat | Heavy Duty Cutting |

| Aluminum | Ball | Fine Detailing |

| Plastic | End Mill | General Tasks |

For optimal results based on compensation strategies, choosing the right tool type is key. Stick to materials and shapes that match your project’s needs. Happy milling!

Case Studies: Successful Radius Compensation in Manufacturing

Examples of industries that benefit from effective radius compensation. Analysis of improvements in production efficiency and quality.

Many industries gain from good radius compensation. For example, automotive, aerospace, and medical devices see great results. They enjoy better quality and speed in production. With radius compensation strategies, companies can reduce waste and make parts that fit perfectly.

- Automotive: Smoother edges lead to safer cars.

- Aerospace: Lighter parts mean better fuel efficiency.

- Medical Devices: Precise tools help save lives.

In fact, studies show that these strategies can boost production by as much as 30%. Successful radius compensation changes the game for manufacturing!

What are the benefits of radius compensation?

Radius compensation improves efficiency and quality in many ways. It helps make products that fit better. This leads to fewer mistakes and less wasted materials, keeping costs down.

Future Trends in Milling Tool Radius Compensation

Emerging technologies and innovations shaping radius compensation strategies. Impact of automation and AI on milling processes.

Cool new tech is reshaping how we think about milling tool radius compensation. Innovations like smart sensors are making adjustments quicker and more precise. Plus, automation and artificial intelligence are stepping in, making the whole milling process feel like a superhero movie—where machines save the day! Imagine tools that can learn and adapt as they work. This change can boost efficiency and keep humans out of the danger zone. It’s like having a sidekick that always knows the best moves!

| Technology | Description | Impact on Radius Compensation |

|---|---|---|

| Smart Sensors | Devices that measure tool wear and adjust settings. | Improves precision and reduces waste. |

| AI Algorithms | Programs that analyze data and make decisions. | Optimizes cutting paths and speeds up processes. |

| Robotic Automation | Machines that perform tasks without human help. | Reduces errors and enhances productivity. |

Common Challenges and Solutions in Radius Compensation

Identification of typical problems encountered. Strategies for troubleshooting and optimizing compensation.

Milling often faces annoying challenges. One common problem is getting the radius just right. If it’s not, it can ruin your cut and waste materials. Another trouble is tool wear; dull tools can make your work look like a bad haircut! To troubleshoot, check your settings and keep your tools sharp. You can also adjust your compensation settings to suit different materials.

| Challenge | Solution |

|---|---|

| Mismatched radius | Verify tool radius in settings |

| Dull tools | Replace or sharpen tools |

| Inconsistent cuts | Recheck compensation values |

Best Practices for Maximizing Milling Tool Efficiency

Guidelines for regular tool maintenance and replacement. Tips for optimizing feeds, speeds, and compensation settings.

Keeping milling tools in top shape helps them work better and last longer. Here are some useful tips for maintenance:

- Check tools regularly for wear and tear.

- Replace dull tools right away to avoid poor cuts.

Optimizing feeds and speeds is also important. Try these methods:

- Start with the recommended settings from the tool’s manual.

- Adjust settings based on the material you are using.

By following these guidelines, you can get more from your milling tools. Remember, a well-maintained tool is a happy tool!

How can I improve milling tool performance?

To improve performance, maintain regular checks and adjust feeds and speeds based on the material being used. Regular tool replacement also plays a key role.

Conclusion

In conclusion, milling tool radius compensation strategies help you improve precision in machining. By adjusting tool paths, you can enhance the quality of your work. You can explore different techniques to find what works best for you. Practice these strategies to boost your skills. For more details, consider looking at tutorials or guides online. Happy milling!

FAQs

Here Are Five Related Questions On The Topic Of Milling Tool Radius Compensation Strategies:

Milling tool radius compensation strategies help machines cut parts more accurately. When we use a tool, its size can affect the final shape. By adjusting for the tool’s size, we ensure the part is correct. This makes our work better and saves time too. It’s like making sure you have the right-sized cookie cutter for perfect cookies!

Sure! Just ask your question, and I’ll give you a simple answer!

What Are The Primary Advantages And Disadvantages Of Using Tool Radius Compensation In Cnc Milling Operations?

Using tool radius compensation in CNC milling helps you make better cuts. One big advantage is that it saves time because you don’t need to change your program for different tool sizes. It also helps keep parts accurate, so they fit together well. However, a downside is that it can be confusing at first, especially when you are learning. Sometimes, mistakes can happen if you don’t set it up right.

How Does Tool Radius Compensation Affect Machining Accuracy And Surface Finish During Milling Processes?

Tool radius compensation helps us make sure the cutting tool moves correctly. When we adjust for the tool’s round edge, we get better accuracy. This means the shapes we make are closer to what we want. Good accuracy also gives us a smoother surface on the final piece. So, using tool radius compensation helps us create better and nicer items.

What Differences Exist Between Manual And Automatic Tool Radius Compensation In Cnc Programming?

Manual tool radius compensation means you tell the machine how big the tool is by entering the size yourself. In automatic tool radius compensation, the machine figures it out for you using special sensors. With manual, you need to pay close attention and do it carefully. Automatic makes things easier by doing the hard work. Both help the machine cut correctly, but one needs you to help more than the other.

In What Scenarios Would A Machinist Choose To Implement Tool Radius Compensation Versus Making Physical Adjustments To Tool Dimensions?

A machinist might use tool radius compensation when they want to keep the same tool but change how it cuts. This helps to avoid stopping the machine and changing the tool. For example, if the tool gets dull, you can easily update the cutting path. It saves time and keeps everything running smoothly. If you need a quick fix, then radius compensation is the better choice.

How Can Tool Path Simulations Help In Visualizing The Effects Of Radius Compensation In Milling Programs?

Tool path simulations show us how a tool moves while cutting. We can see if the tool is too close or too far from a shape. Radius compensation helps adjust this distance based on the tool’s round edge. By watching the simulation, we can spot mistakes and fix them before we start working on real materials. This helps us make better and smoother cuts.