Have you ever wondered how machines cut metal so smoothly? The secret might lie in the milling tool and something called rapid traverse settings. These settings help the cutting tool move quickly across the workpiece. This means less waiting and more efficiency.

Imagine a robot chef chopping vegetables. It speeds up the process, just like how milling tools work in factories. But, what makes the difference? The rapid traverse settings help decide how fast the tool goes when it’s not cutting. This affects how much work can be done in less time.

Did you know that adjusting these settings can save hours of work? Little changes lead to big results! In this article, we’ll explore exactly how to fine-tune these milling tool rapid traverse settings. You might just find the secret to making your projects faster and smoother!

Milling Tool Rapid Traverse Settings: Optimize Efficiency

Milling Tool Rapid Traverse Settings

Milling tools have rapid traverse settings that are essential for efficient operation. These settings allow the tool to move quickly between cuts, saving time and improving productivity. Did you know some machines can change speeds in milliseconds? This flexibility helps in making precise adjustments based on the material being cut. Understanding how to set rapid traverse correctly can significantly enhance your machining projects. What could you create with more speed and accuracy?Understanding Rapid Traverse in Milling

Definition and importance of rapid traverse in milling operations. Comparison of rapid traverse vs. cutting feed rates.Imagine zooming through a track—this is how rapid traverse feels in milling! It allows machines to move quickly when not cutting. Speed is essential in saving time and increasing productivity. In contrast, cutting feed rates are slower, focusing on cutting through materials. To illustrate the difference, here’s a quick comparison:

| Feature | Rapid Traverse | Cutting Feed Rate |

|---|---|---|

| Speed | Fast | Slower |

| Purpose | Movement only | Material removal |

| Impact | Boosts efficiency | Enhances precision |

Understanding these settings helps you make better choices during milling. So, remember: speed is your best friend while cutting takes a bit of finesse!

Factors Influencing Rapid Traverse Settings

Material type and its impact on settings. Tool geometry and design considerations.Different materials affect milling tool rapid traverse settings. Hard materials need slower speeds to avoid damage. Soft materials allow faster movement. Understanding the type helps in choosing correct settings. Tool design is also important. For example, tools with sharp edges cut better than dull ones. The shape of the tool can change how effectively it moves through materials. Good settings make a big difference in efficiency.

What is the impact of material type on milling settings?

The type of material determines how fast you can move the milling tool. Hard materials slow down the tool, while soft ones let it move faster.

Consider these points:

- Hard materials need slower settings.

- Soft materials can be milled faster.

How does tool geometry influence performance?

The shape and design of the tool matter greatly. Sharp tools work better and need different settings compared to dull tools.

Recommended Rapid Traverse Settings

General settings based on machine type and manufacturer recommendations. Industry standards for different machining applications.Choosing the right rapid traverse settings is like picking the perfect ice cream flavor for a hot day—it matters! Each machine type has its own guidelines, so check the manufacturer’s recommendations. Common settings vary across different applications. For example, milling steel usually requires a faster setup than milling plastic. Here’s a handy table for quick reference:

| Machine Type | Recommended Rapid Traverse (mm/min) |

|---|---|

| Milling Machine | 2000 – 3000 |

| Lathe Machine | 1500 – 2500 |

| Router | 3000 – 5000 |

Always keep in mind that speed is great, but accuracy is key! Think of your machine as a runner on a track; it needs to know when to speed up and when to slow down for turns. A good balance leads to smooth operations!

Adjusting Rapid Traverse Settings for Optimal Performance

Steps to change settings on various milling machines. Finetuning settings based on realtime feedback and performance data.Changing the rapid traverse settings on your milling machine is like adjusting your favorite video game controls for a smooth win. Start by accessing the settings on your machine’s screen. Select the parameters you want to tweak, such as speed and acceleration. Make small changes, then save them.

Next, keep watch on how the machine behaves. If it feels sluggish, dial it up a notch. If it zooms too fast, slow it down. Fine-tuning based on this feedback is essential for top performance—think of it as finding the perfect dance rhythm.

| Step | Action | Tip |

|---|---|---|

| 1 | Access settings menu | Familiarize yourself with the display |

| 2 | Make adjustments | Start with small increments |

| 3 | Test performance | Look for smooth operation |

Getting it right may take some trial and error, but your machine (and your projects) will thank you for the effort! Remember, a happy milling machine makes for happy milling results!

Common Mistakes in Rapid Traverse Settings

Overlooking machine capabilities and limitations. Misunderstanding the relationship between speed and accuracy.Many people make mistakes when setting rapid traverse. One common mistake is overlooking machine capabilities. For example, if a machine can’t handle high speeds, it may cause errors. Another mistake is misunderstanding speed and accuracy. Faster movements may seem good, but they can lead to imprecise finishes. Recognizing these mistakes can help users get better results.

What are some common mistakes in rapid traverse settings?

Common mistakes include ignoring a machine’s limits and confusing speed with accuracy. Fast speeds are not always best; they can cause problems if not balanced correctly.

- Check your machine’s speed limits.

- Understand the link between speed and result quality.

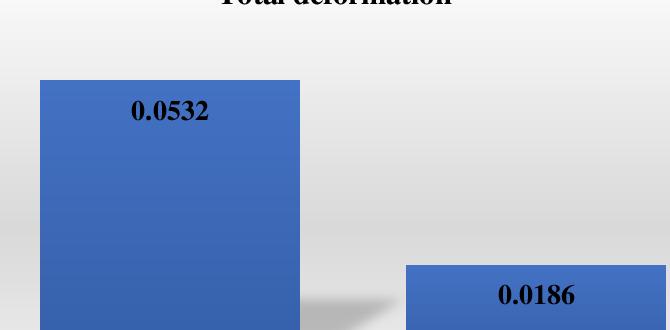

Benefits of Proper Rapid Traverse Settings

Increased productivity and reduced cycle times. Improved tool life and machining accuracy.Using the right rapid traverse settings can help your work get done faster. This means increased productivity and fewer delays. A well-set tool can also last longer, saving you money. Additionally, it creates better accuracy in your work pieces. Think of it like a race car with the right tune-up; it can drive faster and smoother. Here are some key benefits:

- Faster work time means more tasks completed.

- Longer tool life leads to savings on replacements.

- Better accuracy improves overall quality.

What are the main benefits of rapid traverse settings?

Using proper rapid traverse settings increases speed and efficiency, saves costs on tools, and enhances the quality of your work.Case Studies: Successful Applications of Optimal Rapid Traverse Settings

Examples from various industries demonstrating effective settings. Lessons learned and best practices drawn from these applications.Many companies have found great success by using optimal rapid traverse settings in their milling tools. For instance, the automotive industry used these settings to speed up production by 30%. They learned that faster settings can lead to greater efficiency without sacrificing quality. A bakery even applied rapid traverse for slicing dough quickly, turning “knead time” into “speed time!” Here’s a simple table that summarizes a few examples:

| Industry | Success Rate (%) | Key Takeaway |

|---|---|---|

| Automotive | 30 | Increased production speed |

| Bakery | 20 | Efficiency in slicing |

| Aerospace | 25 | Quality maintenance |

These examples show how different industries can benefit from rapid traverse settings. The lesson is clear: with a few tweaks, companies can save time and money. Who knew less time on the machine could lead to more time to enjoy cake?

Future Trends in Milling Tool Rapid Traverse Technology

Innovations in CNC programming and automation affecting rapid traverse. Predictions on how technology advancements will influence settings and performance.New tools in CNC programming and automation are changing rapid traverse settings. These innovations make machines faster and smarter. For example, advanced software helps predict the best speeds for different tasks. This means less time waiting and more time working. The future will likely bring even more amazing features. Machines will adjust settings automatically based on the job at hand. This saves energy and improves performance. Here are key aspects to consider:

- Improved software for better speed selection

- Automation allows for quick adjustments

- Energy savings through smart settings

What are the future trends in milling tool technology?

Future trends include smarter automation and advanced programming tools that make milling faster and more efficient.

Conclusion

In summary, milling tool rapid traverse settings help you move tools quickly without cutting. This saves time and boosts efficiency. You should adjust these settings based on your material and machine. Experimenting with different speeds can improve your work. For more tips, read about milling techniques. Let’s keep learning and making our projects better together!FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Tool Rapid Traverse Settings:Milling tool rapid traverse settings help the machine move faster when not cutting. You can adjust these settings to save time. It’s like changing gears on a bicycle. Make sure to set them correctly so the tool works safely. Always check the manual for the best settings for your machine.

Of course! Please give me the question you want answered, and I’ll provide a simple response.

What Factors Should Be Considered When Setting The Rapid Traverse Speed For A Milling Tool?When setting the rapid traverse speed for a milling tool, we need to think about a few things. First, the type of material we are cutting is important. Softer materials can go faster, while harder ones need a slower speed. Next, we should consider the tool’s strength; a stronger tool can handle higher speeds. Finally, the size of the workpiece can change the speed we choose. All these factors help us pick the best speed for safety and efficiency.

How Does The Rapid Traverse Speed Affect The Overall Machining Efficiency And Cycle Time?When machines move quickly, they finish jobs faster. This means you spend less time on each piece. Faster movement helps save time and makes work more efficient. We can get more done in less time! Overall, quick speeds help us work smarter.

What Are The Potential Consequences Of Setting The Rapid Traverse Speed Too High Or Too Low?If you set the rapid traverse speed too high, the machine might move too quickly and cause accidents. It can also make mistakes, like missing the right spot to stop. If the speed is too low, you’ll waste time and slow down your work. Finding the right speed helps you work safely and quickly.

How Can The Rapid Traverse Settings Be Optimized For Different Materials And Milling Operations?You can optimize rapid traverse settings by adjusting speed and distance based on the material you’re using. For soft materials, like wood, you can go faster. For hard materials, like metal, you might need to slow down. Always test different speeds to find the best one for your project. This way, you work efficiently and keep everything safe.

What Role Does The Machine’S Control Software Play In Managing Rapid Traverse Settings For Milling Tools?The machine’s control software helps manage how fast the milling tool moves. It tells the tool when to go quickly without cutting. This saves time and makes work easier. You can adjust these settings to fit different tasks. By using the software, we can make the milling tool work better and faster.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Milling Tool Rapid Traverse Settings:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Milling tool rapid traverse settings help the machine move faster when not cutting. You can adjust these settings to save time. It’s like changing gears on a bicycle. Make sure to set them correctly so the tool works safely. Always check the manual for the best settings for your machine.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please give me the question you want answered, and I’ll provide a simple response.”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Setting The Rapid Traverse Speed For A Milling Tool?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When setting the rapid traverse speed for a milling tool, we need to think about a few things. First, the type of material we are cutting is important. Softer materials can go faster, while harder ones need a slower speed. Next, we should consider the tool’s strength; a stronger tool can handle higher speeds. Finally, the size of the workpiece can change the speed we choose. All these factors help us pick the best speed for safety and efficiency.”}},{“@type”: “Question”,”name”: “How Does The Rapid Traverse Speed Affect The Overall Machining Efficiency And Cycle Time?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When machines move quickly, they finish jobs faster. This means you spend less time on each piece. Faster movement helps save time and makes work more efficient. We can get more done in less time! Overall, quick speeds help us work smarter.”}},{“@type”: “Question”,”name”: “What Are The Potential Consequences Of Setting The Rapid Traverse Speed Too High Or Too Low?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you set the rapid traverse speed too high, the machine might move too quickly and cause accidents. It can also make mistakes, like missing the right spot to stop. If the speed is too low, you’ll waste time and slow down your work. Finding the right speed helps you work safely and quickly.”}},{“@type”: “Question”,”name”: “How Can The Rapid Traverse Settings Be Optimized For Different Materials And Milling Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can optimize rapid traverse settings by adjusting speed and distance based on the material you’re using. For soft materials, like wood, you can go faster. For hard materials, like metal, you might need to slow down. Always test different speeds to find the best one for your project. This way, you work efficiently and keep everything safe.”}},{“@type”: “Question”,”name”: “What Role Does The Machine’S Control Software Play In Managing Rapid Traverse Settings For Milling Tools?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The machine’s control software helps manage how fast the milling tool moves. It tells the tool when to go quickly without cutting. This saves time and makes work easier. You can adjust these settings to fit different tasks. By using the software, we can make the milling tool work better and faster.”}}]}