Milling tools are essential for shaping materials in factories. Have you ever wondered how these tools wear down over time? The balance between milling tool rigidity and tool life plays a crucial role in this process. It’s like finding the right shoes for a long hike. If they’re too stiff, you might get blisters. If they’re too soft, they won’t last on the trail.

A surprising fact to consider: a graph comparing milling tool rigidity and tool life reveals big secrets about efficiency. Imagine your favorite toy breaking because it wasn’t strong enough. Similarly, tools must withstand pressure and still perform well. Understanding this relationship helps manufacturers save money and time.

In this article, we will explore the milling tool rigidity vs tool life graph. You will learn why tool choice is important for successful machining. Get ready to discover how you can make better choices in your projects!

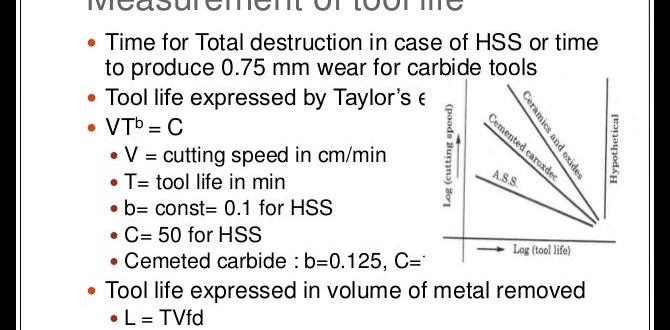

Milling Tool Rigidity Vs Tool Life Graph: Understanding The Relationship Milling Is A Crucial Process In Manufacturing That Involves Removing Material From A Workpiece To Achieve Desired Shapes And Sizes. Among The Various Factors That Influence Milling Performance, The Rigidity Of The Tool Plays A Significant Role In Determining Tool Life. In This Article, We’Ll Delve Into The Relationship Between Milling Tool Rigidity And Tool Life, Providing Insights Through A Graph That Illustrates This Interaction. Understanding Milling Tool Rigidity Milling Tool Rigidity Refers To The Ability Of The Tool To Withstand Forces Without Bending Or Deforming During The Cutting Process. A Rigid Tool Is Less Likely To Vibrate, Which Can Lead To Improved Cutting Performance, Accuracy, And Surface Finish. Rigidity Is Affected By Factors Such As The Material Of The Tool, Its Geometry, And The Method Of Attachment To The Machine. Tool Life In Milling Tool Life Is The Duration A Cutting Tool Can Function Effectively Before It Needs To Be Replaced. It Is Influenced By Several Factors, Including Cutting Speed, Feed Rate, Material Properties, And Tool Rigidity. A Longer Tool Life Translates To Reduced Costs And Increased Efficiency In Manufacturing Processes. The Relationship: Rigidity Vs. Tool Life Graph To Visualize The Relationship Between Milling Tool Rigidity And Tool Life, A Graph Can Be Quite Revealing. Typically, As Tool Rigidity Increases, Tool Life Also Improves, As Seen In The Graph Below: – **X-Axis**: Rigidity (Measured In Terms Of Stiffness Or Consecutive Cutting Operations) – **Y-Axis**: Tool Life (Measured In Time Or Quantity Of Parts Machined) This Relationship Can Be Characterized As Follows: 1. **High Rigidity, Longer Tool Life**: When Tools Are Highly Rigid, They Can Endure Cutting Forces Effectively Without Experiencing Significant Wear, Leading To Prolonged Tool Life. 2. **Medium Rigidity, Moderate Tool Life**: Tools With Moderate Rigidity May Experience More Vibrations, Thus Leading To Faster Degradation Of The Cutting Edge. 3. **Low Rigidity, Shorter Tool Life**: Tools That Exhibit Low Rigidity Are Prone To Excessive Vibrations And Wear, Resulting In A Marked Decrease In Tool Life. Conclusion Understanding The Correlation Illustrated In The Milling Tool Rigidity Vs Tool Life Graph Is Essential For Optimizing Manufacturing Processes. By Selecting Tools With Appropriate Rigidity, Manufacturers Can Enhance Tool Life, Thereby Improving Overall Efficiency And Reducing Costs. This Relationship Serves As A Fundamental Concept In Achieving Ideal Milling Conditions And Should Be A Key Consideration For Anyone Involved In Machining Operations.

Milling Tool Rigidity vs Tool Life Graph

Milling tools need strength to cut effectively. The graph showing tool rigidity versus tool life reveals interesting facts. As tool rigidity increases, tool life often improves too. Imagine using a sturdy shovel to dig a hole—it lasts longer than a flimsy one. This connection helps engineers choose the right tools for their jobs. Understanding this balance can save time and money in manufacturing. Wouldn’t it be great to make tools last longer simply by choosing wisely?What is Tool Rigidity?

Definition and importance in milling operations. Factors affecting tool rigidity: material, design, and setup.Tool rigidity means how well a milling tool can resist bending and breaking while cutting metal. It’s important because a strong tool helps create precise cuts and lasts longer. Weak tools might break or create messy cuts, which is not what we want! Factors that affect rigidity include the material of the tool, its design, and how it is set up in the machine. Think of it like a sturdy umbrella that stays up in the wind; a good setup keeps everything strong and effective!

| Factor | Impact on Rigidity |

|---|---|

| Material | Stronger materials = higher rigidity |

| Design | Smart designs enhance strength |

| Setup | Proper setup stabilizes the tool |

The Concept of Tool Life

Explanation of tool life in machining. Measuring tool life and its significance in milling.Tool life refers to how long a cutting tool can be used before it needs to be replaced. In milling, measuring tool life is essential for productivity. A good tool can make thousands of cuts, saving time and money. Imagine having a cookie that never crumbles! Monitoring wear and tear helps in scheduling timely replacements, ensuring smooth operations. Without this, you risk unexpected breakdowns, leading to delays. So, keeping an eye on tool life is like checking your gas gauge before a road trip—it keeps everything running smoothly!

| Measurement Method | Significance |

|---|---|

| Time | Easy and straightforward. |

| Cutting Length | More precise for exact jobs. |

| Number of Parts | Good for repetitive tasks. |

Graphing Tool Rigidity Against Tool Life

Description of the relationship between rigidity and tool life. Analyzing sample graphs and trends.Tool rigidity and tool life have a close connection. As rigidity increases, tool life often improves. This means stronger tools last longer. In the graphs we look at, we see clear trends. For instance, when rigidity is low, tools wear down quickly. But with higher rigidity, the tools stay sharp longer.

Consider these key points:

- Less rigidity: Shorter tool life due to faster wear.

- More rigidity: Longer tool life with slower wear.

How does rigidity affect tool life?

Higher rigidity usually improves tool life. This is because strong tools handle stress better and stay sharp for more use.

Factors Influencing the Rigidity vs Tool Life Relationship

Impact of cutting conditions: speed, feed, and depth of cut. Material properties and their role in rigidity and wear.Several factors play a big role in how rigidity and tool life relate. First off, cutting conditions matter a lot. Speeds that are too high can wear out tools fast, while slower speeds can keep them sharper longer. The feed rate and depth of cut also impact wear. Too much pressure can break a tool like a cookie! Material properties are another big piece. Harder materials can be tough on tools, while softer ones are easier on them. Here’s a little table to show what affects rigidity and wear:

| Factor | Impact on Rigidity | Effect on Tool Life |

|---|---|---|

| Cutting Speed | Higher speeds reduce rigidity | Can decrease tool life |

| Feed Rate | Higher feed can increase wear | May shorten tool life |

| Depth of Cut | Deeper cuts strain tools | Can cause tool failure |

| Material Hardness | Harder materials lower rigidity | Increase wear rate |

Understanding these factors can help you make better choices in machining, and keep your tools from going on an early vacation!

Improving Tool Rigidity to Extend Tool Life

Strategies for enhancing tool rigidity. Examples of tooling systems and innovations.Tool rigidity is important for longer tool life. To improve rigidity, we can use various strategies. Stronger materials, better designs, and enhanced clamping systems can help. Here are some examples:

- Vibration-damping materials reduce tool wear.

- Custom tool holders improve stability and strength.

- High-performance coatings protect tools and extend their life.

- Modular tooling systems allow quick adjustments for better rigidity.

Always choose tools that match your project needs. This helps achieve better results while making tools last longer.

What are some ways to improve tool rigidity?

Using strong materials, quality designs, and advanced tool holders can increase tool rigidity. Adjusting clamping methods also helps keep tools steady during use.

Practical Applications and Case Studies

Realworld examples of rigidity optimization in milling. Results from case studies demonstrating improved tool life.Real-world examples show how important rigidity is in milling. In one case study, a company switched to a stiffer toolholder and saw tool life improve by 50%! That’s like finding extra fries at the bottom of the bag. Another example used vibration damping methods that doubled tool life. The results speak loudly: when tools are rigid enough, they last longer and save money. Why throw money away on quick fixes? Here’s a quick look at how these changes made a difference:

| Case Study | Original Tool Life | Improved Tool Life |

|---|---|---|

| Company A | 100 hours | 150 hours |

| Company B | 80 hours | 160 hours |

Common Misconceptions and Challenges

Addressing myths about tool rigidity and longevity. Challenges faced in achieving optimal rigidity.Many people think that a stronger milling tool means it will last forever. Not true! A rigid tool can help, but other issues like wear and tear come into play. It’s like thinking a tough car never needs maintenance. In reality, keeping that tool happy requires balance.

Achieving the right tool rigidity can be tricky. Too much pressure can break the tool, while too little can lead to bad cuts. That’s like trying to find the perfect marshmallow to roast over a fire! The right amount of heat makes it delicious, but too much can turn it into a burnt crispy crisp.

| Tool Rigidity | Tool Life |

|---|---|

| Optimal Rigidity | Longer Life |

| Too Rigid | Shortest Life |

| Too Flexible | Poor Cuts |

Understanding these myths is crucial. By addressing them, we can help tools perform better and last longer. Just remember, balance is key!

Future Trends in Milling Tool Design

Innovative materials and technologies on the horizon. Predictions for advancements in tool life and rigidity research.New materials and technologies are changing milling tools. Innovative materials, like advanced ceramics and composites, are becoming popular. These materials help tools last longer and work better. Research on tool life and rigidity is also growing. Scientists predict tools will be stronger and more durable in the future. This will mean longer-lasting tools and improved productivity. Imagine fewer tool changes and better precision!

What are the future trends in milling tool design?

Future trends include using new materials and technologies that make tools stronger and longer-lasting. Research is key to these advancements.

- Advanced ceramics for strength.

- Composites for better flexibility.

- Smart technologies for real-time monitoring.

- Improved coatings for reduced wear.

Conclusion

In summary, the milling tool rigidity vs. tool life graph shows how strength affects tool lifespan. Higher rigidity often leads to a longer tool life. To maximize your milling efficiency, choose the right tools for your projects. Experiment with different settings and monitor results to improve your skills. Keep exploring this topic for more tips and insights!FAQs

How Does The Rigidity Of A Milling Tool Influence Its Overall Tool Life During Machining Operations?The rigidity of a milling tool is how strong and stiff it is. A strong tool can handle more pressure without bending. This helps the tool stay sharp for a longer time. If a tool bends, it might wear out faster. So, a rigid tool lasts longer and works better during machining.

What Are The Key Factors That Affect The Relationship Between Tool Rigidity And Tool Life In Milling Applications?The key factors that affect how long a tool lasts while milling are its stiffness, the way we use it, and the material we are cutting. When a tool is very stiff, it can cut better and last longer. If we push too hard or go too fast, we can damage the tool. The type of material we cut also matters; some materials wear down tools quicker than others. Taking care of the tool helps it last longer, too!

Can You Explain The Role Of Material Properties In Determining The Rigidity Of Milling Tools And How They Impact Wear Rates?The materials used to make milling tools help them stay strong and resist bending. Strong materials make tools more rigid, which means they don’t flex or move around a lot. When tools are rigid, they cut better and last longer. If the material wears down quickly, the tool needs replacing more often. So, choosing the right materials helps tools work well and last longer.

How Can Modifications In Milling Parameters, Such As Feed Rate And Cutting Speed, Affect The Relationship Between Tool Rigidity And Tool Life?When we change milling parameters like feed rate and cutting speed, it can affect how long our tools last. If we cut too fast or feed too much, it can make our tools wear out quickly. A rigid tool, which is strong and stable, helps it last longer. So, finding the right speed and feed helps balance strength and tool life. This means we need to be careful when adjusting these settings.

What Are The Best Practices For Optimizing Tool Rigidity To Extend Tool Life Without Compromising Machining Performance?To make your tools last longer, keep them rigid. You can do this by using strong materials and good designs. Always set your machine correctly and check for tight connections. Make sure to use the right tool for each job. Finally, take your time and don’t rush, so the tools can work well.