Ever watched a giant cookie cutter in action? That’s what a milling tool looks like. But how does it know the right way to slice through metal? The secret lies in torque. Torque is like the muscle of the tool. Think about twisting off a jar lid. You know how much force you need. Milling tool torque calculators help us figure this out for machines. Why is this important? Imagine your favorite toy breaking because you twisted too hard. The same could happen with machines. Knowing the right torque keeps things running smoothly. Dive in to explore how these calculators work their magic in the world of milling.

Understanding Milling Tool Torque Calculators

Milling Tool Torque Calculators

Milling tool torque calculators are like magic helpers for machinists. Ever wonder how much twist is needed to carve metal or wood? These cool calculators know! They keep machines from getting tired and breaking. Imagine riding a bike uphill; you need just the right push. That’s what these tools do for cutting machines. They help you find the perfect balance, making sure your project is smooth and safe. Want to cut metal without a hitch? Trust the torque calculator!Understanding Milling Tool Torque

Definition and importance of torque in milling.. How torque affects milling performance and tool life..Torque in milling is a bit like the secret sauce in a sandwich – it holds everything together in day-to-day, nothing falls apart during steps. Torque, simply put, is the force that twists and turns. It makes cutting tools move. This force is essential. It affects things like performance and how long the tools last.

More torque means better cutting at high speeds. But watch out! Too much can wear tools out faster than eating candy every day. Like Mother Hen, balance is the key. In fact, studies often show that balanced torque can improve tool life by up to 50%. Remember, a smooth sail is always better than rocky waters!

| Factor | Effect on Torque |

|---|---|

| Material | Harder materials need more torque |

| Speed | Higher speed increases torque needs |

| Tool Size | Larger tools require more torque |

A wise man once said, “Torque makes the world go round for milling tools.” Understanding and managing torque can ensure your tool not only lasts longer but also sings while it cuts away.

Components of a Torque Calculator

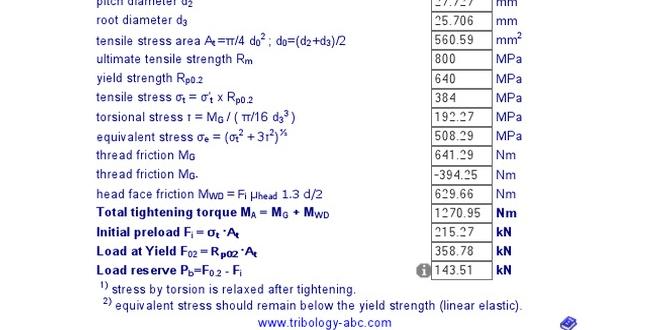

Key elements: motor power, speed, and load.. Explanation of formulae used in torque calculations..Milling tool torque calculators rely on some key components. First, you have motor power. This shows the strength of your tool. Next is speed. It tells how fast the tool is spinning. The last part is the load. This shows how much weight the tool can handle. When you combine these three, you can find the torque. To calculate, you use formulas that mix these parts in a smart way.

How do you calculate torque?

To calculate torque, use a simple formula: Torque = Motor Power x Speed x Load. By plugging in these values, you can see how strong your tool is. This helps in ensuring efficiency and avoiding overload in operations.- Motor Power: This is the energy your tool uses.

- Speed: It tells how fast the tool spins.

- Load: This shows the weight capacity of the tool.

Did you know? A good torque calculator helps tools work smoother and lasts longer. It’s like giving your tool a little brain power! With simple math, even kids can understand its magic. So, next time you see a tool, think of it as a superhero with a secret power called torque.

Choosing the Right Torque Calculator

Factors to consider: accuracy, usability, and features.. Popular brands and software for reliable calculations..Precision is key when choosing the right torque calculator. Look for accuracy, as even small errors can cause big problems. Usability is important too; you don’t want a tool that feels like a math test! Some calculators come with cool features, like real-time data and cloud storage. Popular brands include Bend-Tech and Machin3. Sure, they’re reliable, but also a bit pricey. In the end, it’s like choosing a pet—get one that suits your needs and licks your face, metaphorically speaking!

| Factor | Details |

|---|---|

| Accuracy | Ensures reliable and precise calculations. |

| Usability | Easy to understand and operate without frustration. |

| Features | Includes real-time data, cloud storage, and more. |

Step-by-Step Guide to Using a Torque Calculator

Inputting necessary parameters with examples.. Interpreting results for effective milling setup..Have you ever tried using a torque calculator for milling and felt like you were deciphering an ancient scroll? Fear not, dear reader! To begin, you’ll need some basic details like speed, feed rate, and diameters. Picture it as giving your calculator a recipe card–for success! For example, if the spindle speed is 1500 RPM and feed rate is 0.01 inches per tooth, pop those numbers in.

| Parameter | Example Value |

|---|---|

| Spindle Speed (RPM) | 1500 |

| Feed Rate (Inches/Tooth) | 0.01 |

Once entered, a calculated torque might stare back like a wise old owl. But don’t be fazed! Interpret these results to refine your milling techniques. Remember, optimal torque prevents tool disasters. Mastering this makes your milling smoother than a penguin on ice! Quoting machining experts: “Understanding torque is key to effective milling.” So, input correctly, and let the tool work smart, not hard.

Common Mistakes and How to Avoid Them

Typical errors when calculating torque.. Tips for ensuring precision and accuracy..Calculating torque in milling is like trying to dance in clown shoes—mistakes are possible! A big slip-up is faulty math. Watch out for wrong numbers sneaking in. Check your work so you don’t end up spinning in circles instead of milling smoothly. A digital calculator can be your best pal. For accuracy, double-check unit conversions. Also, keep your tools sharp, or they’ll misbehave like a stubborn mule.

| Common Mistakes | Solutions |

|---|---|

| Incorrect Measurements | Always double-check your input values |

| Ignoring Tool Wear | Regular maintenance and sharpening |

| Skipping Unit Conversions | Use calculators for precise conversions |

Think of precision like a superhero cape—you look cool, and it saves the day. Be wary of common math pitfalls by triple-checking numbers and tools. Remember, a watchful eye can save your workspace from chaos!

Practical Applications and Case Studies

Realworld examples of torque calculators in action.. Success stories from professional milling operations..How do torque calculators help in real-life milling?

Torque calculators make milling easier and safer. In a busy milling shop, they help workers choose the right tools. This means fewer mistakes and faster work. These calculators help workers save money and time. One worker said, “My work quality improved, and I feel more confident.” They are a vital tool for making sure everything runs smoothly.In real life, torque calculators are very useful. These tools help workers find the best tool for each job. For example, in a factory making car parts, the worker uses a torque calculator to find the right tool. It reduces errors and boosts efficiency, making the work faster and cheaper. In another case, a company saw a 15% increase in productivity after using these calculators. They help in making better choices, leading to success in projects.

Advancements and Future Trends in Torque Calculation

Emerging technologies and innovations in torque measurement.. Predictions for the future of milling torque calculators..Torque calculation is evolving fast. Innovative tools now make it easier. New digital sensors and AI help measure torque with precision. These technologies ensure smooth and safe milling operations. Here’s what’s coming:

- Smarter sensors detect and adjust torque in real-time.

- AI predicts torque needs before they happen.

- Online tools offer simple results instantly.

How will torque calculators improve milling in the future?

In the coming years, milling torque calculators will become even more essential. They will enhance precision and reduce errors. These tools will be smarter and simpler to use. They’ll offer **cloud connectivity** for easy updates and sharing.

Conclusion

Milling tool torque calculators help you choose the right tool by checking power and performance. They make sure your projects run smoothly and safely. By understanding these calculators, you can avoid mistakes and improve your skills. Keep exploring online resources and practice using these tools to become even more confident in your woodworking projects.FAQs

How Is Torque Calculated For A Milling Tool During A Machining Process?To calculate torque for a milling tool, you need to know how much force it uses to cut. Imagine using a pencil to draw. If you press hard, it needs more effort, just like the force in milling. You multiply that force by how far away it is from where you’re holding the tool. This gives you the torque, which tells you how much twisting power the tool needs to work.

What Factors Influence The Torque Requirements Of A Milling Tool?When using a milling tool, the size and shape of the tool matter. Bigger tools need more torque, or “twisting power.” The material you are cutting is important, too. Softer materials like wood need less torque than hard materials like metal. How fast you want to cut also affects torque needs. Going faster usually means you need more twisting power.

Are There Any Online Calculators Available To Estimate Milling Tool Torque, And How Reliable Are They?Yes, there are online calculators that help estimate milling tool torque. These tools are usually easy to use. They give you an idea but might not be 100% accurate. Always double-check with a grown-up or expert if you need to be sure.

How Does The Material Being Machined Affect The Torque Needed For Milling?When we are milling, the type of material affects how much power, or torque, is needed. Some materials, like soft plastic, are easy to cut and need less torque. Harder materials, like steel, are tougher to cut and need more torque. It’s like pushing a toy car on carpet vs. a smooth floor; the carpet needs more effort! This is how different materials change the effort needed in milling.

What Role Does Spindle Speed Play In Determining The Torque Of A Milling Tool?Spindle speed tells us how fast the tool spins. If it spins fast, the torque, which is the tool’s twisting power, can be less. When it spins slowly, the tool might twist harder into the material. So, finding the right speed helps us get enough power just right for cutting. It’s like how pedaling faster on a bike might make it easier to go fast downhill but harder uphill.