Can you take a wood lathe when you travel? Yes, with a portable wood lathe designed for travel, you can! These compact machines let you continue your woodworking projects, demonstrations, or even teach classes wherever you go. This guide introduces you to the best options and what to consider.

Woodworking doesn’t have to stop when you leave your home workshop. Many woodturners dream of taking their passion on the road, whether for a demonstration at a club meeting, a woodworking festival, or even just for personal projects in a different location. The challenge? Traditional wood lathes are often bulky, heavy, and truly immobile. This can be frustrating if you want to share your skills or keep your hands busy while away from your permanent setup. But don’t worry! There are fantastic portable wood lathes designed precisely for these situations. We’ll explore what makes a lathe “portable,” what features to look for, and how to choose the right one for your travel woodworking adventures. Get ready to discover how you can turn anywhere!

What Makes a Wood Lathe “Portable”?

The term “portable wood lathe” can mean a few different things. Primarily, it refers to lathes that balance functionality with ease of transport. This usually involves:

Compact Size: Smaller overall dimensions that fit into vehicles or storage cases more easily.

Lightweight Construction: Using lighter materials like aluminum, or designing with minimal, yet sturdy, frames.

Collapsible or Foldable Components: Features like folding legs or detachable beds reduce the footprint for transport.

Integrated Handles or Cases: Designed with carrying in mind, sometimes including built-in handles or purpose-built storage solutions.

It’s important to note that “portable” is relative. While these lathes are much easier to move than their benchtop or floor-standing counterparts, they still involve moving equipment. A truly “travel wood lathe” is one that meets these criteria without sacrificing the core performance needed for enjoyable woodworking.

Key Features to Look For in a Portable Wood Lathe

When you’re shopping for a portable wood lathe, several features will significantly impact its usability and suitability for travel. Think about what you’ll be doing and where you’ll be going.

Size and Weight Considerations

This is the most obvious factor. A lathe that weighs 20 lbs and folds down smaller than a carry-on suitcase is vastly different from one that weighs 50 lbs and requires strapping to a dolly.

Weight: Aim for under 50 lbs if you plan to lift it frequently or move it by yourself. Some ultra-portable models are closer to 20-30 lbs.

Footprint: Check the actual dimensions when set up and when folded. Will it fit in your car trunk? Can it be stored easily in a small space?

Motor Power and Speed Control

Don’t let the size fool you; you still need enough power to turn the wood you intend to use and sufficient speed control for safety and versatility.

Horsepower (HP): For small to medium projects (pens, bowls up to 6-8 inches), a 1/2 HP to 1 HP motor is usually sufficient. Larger projects will require more.

Variable Speed Control: This is crucial! The ability to adjust the RPMs is vital for safety (slower speeds for rough turning and larger pieces) and for achieving a good finish (higher speeds for sanding). Look for electronic variable speed (EVS).

Swing and Distance Between Centers

These specifications determine the maximum size of workpiece you can turn.

Swing: This is the diameter of the largest workpiece you can turn, measured from the ways (the bed) to the center of the spindle. A typical portable lathe might offer a swing of 10-12 inches.

Distance Between Centers (or Bed Length): This is the maximum length of the workpiece you can turn between the headstock and tailstock. A distance of 16-18 inches is common for compact models, suitable for many smaller to medium-sized projects like bowls or spindles.

Bed Construction and Stability

Even a portable lathe needs a stable bed to reduce vibration.

Material: Cast iron offers the best vibration dampening but adds weight. Many portable lathes use sturdy steel tubing or extruded aluminum for a good balance of strength and portability.

Legs/Base: Look for stable legs that might be foldable for transport but firm when set up. Some models mount to a workbench, turning them into a stationary benchtop lathe when needed.

Tool Rest and Tool Kit

You’ll need a way to support your turning tools and a basic set of tools to start with.

Tool Rest: Ensure the tool rest is sturdy and easily adjustable. Standard industry sizes are often preferred for future upgrades.

Included Tools: Some portable lathes come with a basic set of turning chisels. While often entry-level, they can be enough to get started. You’ll likely want to invest in higher-quality tools as you progress.

Portability Features

Look for specific design elements that aid in transport.

Carrying Handles: Integrated handles are a major plus.

Folding Legs: Legs that tuck away make storage and transport much easier.

Storage Cases: Some smaller models might even come with or offer optional hard cases.

Top Portable Wood Lathe Options for Travel

While the market for “true” portable wood lathes (like those you’d take cross-country on a bus) is niche, several manufacturers offer excellent, lightweight, and compact benchtop or small floor lathes that are highly portable for car travel and workshops. These are our top picks based on features, user reviews, and overall value.

1. Nova DVR Lathes (e.g., Nova 1624 II, Nova Comet II)

While not the absolute lightest, Nova’s DVR (Direct Variable Relationship) technology offers incredible power, smoothness, and features that make them surprisingly manageable for their capability. The smaller models are excellent for portability.

Pros: Powerful direct-drive motors, quiet operation, excellent electronic variable speed, robust construction, good support. The lighter models are very maneuverable.

Cons: Can be more expensive than basic models, might still be a bit heavy for some (depending on the specific model).

Portability Aspect: The Nova Comet II is particularly compact and lighter, making it a strong contender for portability for car travel. The 1624 II is larger but still manageable on a sturdy stand.

2. Jet Benchtop Lathes (e.g., Jet JWL-1015VS)

Jet offers a range of quality benchtop lathes that are more compact and lighter than full-sized models. The JWL-1015VS is a popular choice known for its solid performance and features.

Pros: Reputable brand, electronic variable speed, good build quality for its size, often comes with a stand.

Cons: The stand adds bulk when transporting; consider if you’ll mount it on a different portable workbench.

Portability Aspect: The lathe itself is manageable, and by detaching it from its stand, it becomes quite portable for car transport.

3. Rikon Mini Lathes (e.g., Rikon 70-105)

Rikon’s mini lathes are fantastic entry-level options that are genuinely easy to move. They are designed for smaller projects but punch above their weight in performance.

Pros: Very affordable, lightweight, compact, good for beginners and smaller projects, often variable speed.

Cons: Limited in terms of swing and distance between centers, motor power might be insufficient for larger or harder woods.

Portability Aspect: This is where Rikon mini lathes shine. They are designed to be easily carried and set up on any sturdy surface.

4. Specific “Travel” Lathe Models

Some manufacturers have produced very specialized, ultra-lightweight lathes specifically for demonstration or travel. These are less common but excellent if your primary need is maximum portabilty. Examples might include older or niche models designed with aluminum beds and very compact frames. Always check current availability and reviews for these.

Steps for Setting Up Your Portable Wood Lathe for Travel

Once you’ve chosen your portable wood lathe, setting it up for travel and then setting it up at your destination is straightforward. Safety and stability are paramount at each stage.

Step 1: Prepare the Lathe for Transport

Disassembly (if necessary): If your lathe has detachable legs or a removable headstock/tailstock, follow the manufacturer’s instructions for safe removal. Keep all bolts and small parts in a secure bag.

Secure Moving Parts: Ensure the tool rest assembly is removed or securely fastened. Lock the headstock and tailstock if your model has locking mechanisms.

Wrap and Protect: Consider wrapping the lathe in a moving blanket or bubble wrap to protect the finish during transit.

Choose a Sturdy Case or Dolly: For lighter lathes, a robust tool bag or a rolling tool chest might suffice. For heavier ones, a rolling dolly is essential. Make sure it can handle the weight and has straps to secure the lathe.

Step 2: Transporting Your Lathe

Load Safely: Use a ramp or ask for help when loading heavier items into vehicles. Place the lathe on a flat, stable surface in your vehicle, ensuring it won’t shift or tip during travel.

Secure in Vehicle: Use cargo straps to tie down the lathe and its case/dolly to prevent movement.

Step 3: Setting Up at Your Destination

Choose a Stable Location: Find a level, sturdy surface. This could be a workbench, a strong table, or the lathe’s own steady legs. Avoid soft or uneven surfaces that can cause vibration. A portable workbench designed for tools is an excellent companion.

Assemble (if disassembled): Reattach legs or any removed components, following the manufacturer’s manual. Ensure all bolts are tightened securely.

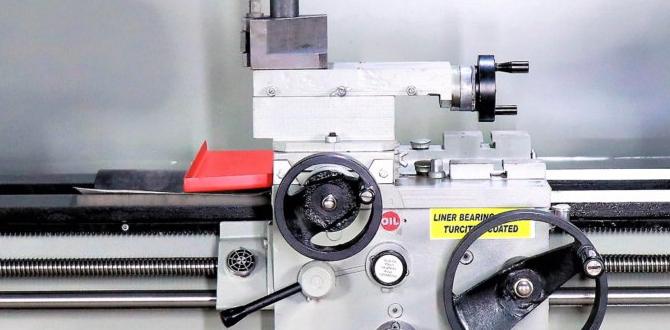

Proper Placement of Components: Position the headstock and tailstock correctly on the bed. Ensure they are aligned and locked firmly in place.

Attach Tool Rest: Securely mount the tool rest to its post. Adjust its height and position so it’s very close to the workpiece without touching it when spinning. This is critical for safety.

Check Power: Connect to a reliable power source. Ensure the power cord is not damaged and is routed safely away from your working area to prevent tripping hazards.

Pre-Operation Check: Before turning on the motor, manually spin the spindle to ensure it rotates freely and that nothing is rubbing or causing resistance. Check that the tool rest is secure and at the correct height.

Step 4: Wood Preparation and Mounting

Select Suitable Wood: For portable lathes, it’s best to stick to smaller logs or prepared blanks. Avoid very large, unbalanced, or heavy pieces that could overload the motor or be unsafe.

Mount the Wood Safely: Mount your wood securely between the headstock and tailstock centers, or using a chuck. Ensure all connections are tight. Always start turning at the slowest speed to check for balance and stability.

Portable Lathe Setup Checklist

Here’s a quick checklist to ensure your portable setup is safe and ready to go:

Lathe Unit: Securely assembled on a stable surface.

Tool Rest: Attached, at correct height (just below the center line of the workpiece) and distance (within 1/8″ of the workpiece).

Headstock Lock: Tight.

Tailstock Lock: Tight.

Workpiece: Securely mounted and balanced.

Power Cord: Inspected, properly connected, and routed safely.

Chisels/Tools: Sharp and ready for use, stored safely when not in hand.

Eye Protection: Worn at all times while operating the lathe.

Dust Mask/Respirator: Worn when creating dust.

Emergency Shut-off: Know where the power switch is and how to quickly stop the lathe.

Safety First: Essential Precautions for Portable Woodturning

Safety is non-negotiable, especially when operating machinery in less controlled environments. Portable setups require extra vigilance.

1. Eye Protection is Mandatory

This cannot be stressed enough. Always wear safety glasses or a full face shield. Wood chips, especially when breaking off unexpectedly, can cause serious eye injury. A full face shield offers more protection for your entire face. For more information on safety gear, check out resources from organizations like the Occupational Safety and Health Administration (OSHA) on personal protective equipment (https://www.osha.gov/).

2. Proper Clothing and Hair Control

Loose clothing, dangling jewelry, or long, uncontained hair can easily get caught in the spinning lathe. Always wear snug-fitting clothes, tie back long hair, and remove jewelry.

3. Sharp Tools

Dull tools require more force, making them more likely to catch and cause kickback. Keep your turning tools sharp. A sharp tool cuts cleanly with less effort.

4. Tool Rest Positioning

The tool rest should be positioned as close to the workpiece as possible – no more than 1/8 inch away – and just below the center line of the spindle. This prevents the tool from being pulled down into the wood and causing kickback.

5. Start Slow

Always start the lathe at its slowest speed, especially when mounting new material. Gradually increase speed as you confirm the piece is balanced and securely mounted. If you notice wobbles or unusual vibrations, stop immediately and re-check your setup.

6. Wood Stability

Be cautious when turning green wood or very wet wood, as pieces can become unbalanced as they dry unevenly. For portable setups, it’s often safer to turn dried, stabilized wood or smaller blanks.