Have you ever watched a metal lathe turn raw metal into a smooth, shiny part? It’s fascinating, isn’t it? The heart of this machine is often the precision metal lathe chuck key. This small but mighty tool makes it safe and easy to secure workpieces. You may wonder, how can something so simple make such a big difference?

Imagine trying to hold onto a spinning piece of metal without the right tool. It would be risky and messy! The precision metal lathe chuck key helps keep everything in place. With this key, you can tighten or loosen the chuck, which holds the metal securely. That means you can work faster and safer.

Do you know what’s surprising? A precision metal lathe chuck key is used in many industries. From small workshops to huge factories, it’s everywhere! Understanding how this tiny tool works can improve your metalworking skills. So, let’s dive deeper into the world of precision metal lathe chuck keys and discover their importance together!

Precision Metal Lathe Chuck Key: Essential Tool Insights

Understanding the Precision Metal Lathe Chuck Key

The precision metal lathe chuck key is an important tool for machinists. It tightly secures workpieces on the lathe, ensuring accuracy during machining. Did you know that using the right chuck key prevents tool damage? A well-fitted key also enhances safety in the workshop. Whether you’re a beginner or a pro, knowing about this key can improve your skills. Next time you use a lathe, remember how vital this simple tool really is!What is a Precision Metal Lathe Chuck Key?

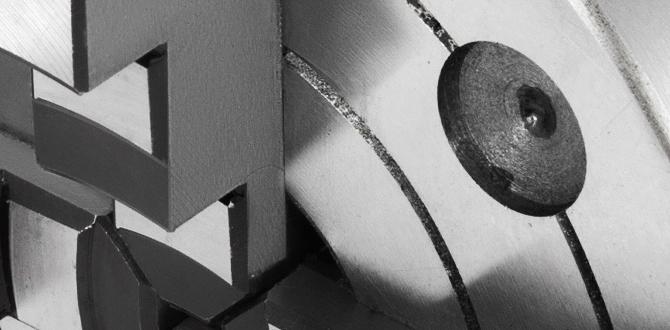

Definition and purpose of a chuck key in precision metal lathes. Types of chuck keys and their specific applications.A precision metal lathe chuck key is a small tool used to tighten or loosen chucks on lathe machines. Chucks hold materials securely while they are being shaped or cut. Without a chuck key, the process would be difficult and less safe. There are different types of chuck keys, each for specific uses:

- **Standard Chuck Key:** Used for general purposes.

- **T-handle Chuck Key:** Offers better grip and torque.

- **Keyless Chuck:** Allows quick changes without a key.

Each type helps machinists work more efficiently and safely.

What is a chuck key used for?

The main purpose of a chuck key is to ensure secure fastening of the chuck. This is important for safe and accurate machining.

How to Choose the Right Chuck Key for Your Lathe

Factors to consider: size, type, and compatibility. Importance of quality and durability in selecting a chuck key.Selecting a chuck key for your lathe is important and can be simple. Start by looking at the size. The key must fit your chuck snugly. Next, consider the type. Some are T-shaped, while others are simpler. Finally, ensure it’s compatible with your lathe model. A good chuck key should also be strong and long-lasting. Quality matters! Choose one made from tough materials, so it lasts longer. Remember, the right chuck key helps your work go smoothly!

What should I look for when buying a chuck key?

You should check the size, type, and compatibility. These factors ensure a good fit and easy use.

Key Points to Remember:

- Size: Must fit your chuck tightly.

- Type: Choose the shape that suits your work.

- Compatibility: Ensure it works with your specific lathe.

- Quality: Look for durable materials.

How to Properly Use a Chuck Key

Stepbystep guide on operating a chuck key effectively. Tips for maintaining safety while using a chuck key.Using a chuck key correctly is important for safety and effectiveness. Follow these steps:

- Choose the right chuck key for your lathe.

- Align the key with the chuck hole.

- Turn the key clockwise to tighten.

- For loosening, turn it counter-clockwise.

Remember these safety tips:

- Always wear safety goggles.

- Keep hands clear of moving parts.

- Never leave the key in the chuck when done.

Using the chuck key properly makes your work smoother and safer!

Why is using a chuck key important?

Using the chuck key is crucial because it ensures that the tool holds securely. Without proper tightening, the tool can slip, leading to accidents. Always use the key for safety!

Common Problems with Chuck Keys and Their Solutions

Frequent issues: slipping, wear, and incorrect size. Troubleshooting tips and preventative maintenance measures.Chuck keys can be tricky little gadgets. The most common problems are slipping, wear, and having the wrong size. When a key slips, it can feel like it’s doing a tap dance, but it’s not helpful! To fix it, check that your key fits snugly. If it’s worn out, it may be time for a new one—consider it a chuck key retirement party! Maintaining your chuck key helps avoid these issues. Clean it regularly and store it where it can’t get lost, or it’s off to the chuck key Bermuda Triangle!

| Problem | Solution |

|---|---|

| Slipping | Ensure a good fit |

| Wear | Replace old keys |

| Incorrect Size | Select the right key size |

Best Practices for Maintaining Your Chuck Key

Storage and care guidelines to prolong lifespan. Signs of wear and when to replace your chuck key.To take care of your chuck key, proper storage is key. Keep it in a dry place, away from moisture. Wipe it clean after each use to remove dirt and oil. Check it regularly for signs of wear, such as rust or cracks. If you notice any damage, it’s time to replace your chuck key. This will ensure your tools work well and last longer.

How do I know when to replace my chuck key?

Look for these signs:

- Rust: If you see rust, it can affect performance.

- Cracks: Any cracks can lead to breakage during use.

- Worn teeth: If the teeth are chipped or smooth, it’s time for a new one.

Top Brands and Recommendations for Precision Metal Lathe Chuck Keys

Comparison of leading manufacturers in the market. Recommendations based on features, price, and user reviews.When choosing a precision metal lathe chuck key, looks matter. Top brands offer different features and prices. Some popular names are:

- Bison: Known for durability and excellent grip.

- SHARS: Offers good quality at budget prices.

- Grizzly: Great for beginners and has good reviews.

Based on features and user feedback, Bison comes highly recommended for its robust design. SHARS gives you value for money. Always check reviews to find the best fit for your needs.

What should I look for in a precision metal lathe chuck key?

Look for durability, ease of use, and size. These factors help you work better and safer!

FAQs About Precision Metal Lathe Chuck Keys

Answers to common questions and concerns from users. Additional resources for further reading and information.Many folks wonder about precision metal lathe chuck keys. Here are some common questions and amusing answers to help you out! If your key doesn’t fit, it’s like wearing shoes that are two sizes too small — all pain and no gain! Don’t force it! For deeper dives, plenty of resources are available online, like forums and tutorials. Check out the table below for quick answers to popular concerns.

| Question | Answer |

|---|---|

| Why is my key slipping? | Check the size and fit! A loose key can be a messy affair. |

| How do I clean it? | A gentle wipe with a cloth works wonders! No scrubbing like you’re washing a car! |

| Where can I buy a new one? | Local hardware stores and online shops have plenty to choose from. |

Conclusion

In summary, a precision metal lathe chuck key is essential for securing workpieces when machining. It helps you tighten or loosen the chuck easily and accurately. Understanding its function can improve your metalworking skills. If you’re looking to enhance your projects, consider reading more about lathe techniques or exploring different types of chucks. Let’s keep learning and creating!FAQs

What Are The Different Types Of Chuck Keys Used With Precision Metal Lathes, And How Do They Differ In Functionality?There are different types of chuck keys for metal lathes. The most common types are the pin key, the T-handle key, and the hex key. The pin key has a long stick with a pin that fits the chuck. The T-handle key looks like a T and gives you more grip. The hex key is a simple L-shape that fits into hexagonal screws. Each type helps you tighten or loosen the chuck, but they feel different in your hand.

How Do You Properly Use A Chuck Key To Ensure Secure Clamping Of Workpieces On A Precision Metal Lathe?To use a chuck key, first, find the key that fits your lathe’s chuck. You put the key into the holes around the chuck. Turn the key clockwise to tighten. Make sure it is snug but not too tight, so it holds the piece safely. Always remember to remove the key before starting the machine!

What Safety Precautions Should Be Taken When Using A Chuck Key On A Precision Metal Lathe?When using a chuck key on a metal lathe, make sure your hands are clear of the moving parts. Always remove the chuck key right after you finish turning the chuck. Wear safety glasses to protect your eyes from debris. Keep your workspace clean and tidy to avoid accidents. Finally, never reach into the lathe while it is running.

How Can You Troubleshoot Issues Related To A Chuck Key That Might Affect The Performance Of A Precision Metal Lathe?To troubleshoot a chuck key issue on your metal lathe, first check if the chuck key is fitting well. Make sure it’s the right size and not damaged. Next, look for any dirt or chips that might block the chuck. Clean it gently if you see any mess. Lastly, always remember to put the chuck key back safely after using it. This keeps everything working smoothly.

What Are Some Tips For Maintaining And Caring For A Chuck Key To Ensure Its Longevity And Effectiveness?To keep your chuck key in good shape, always store it in a safe place, so you don’t lose it. Clean it regularly with a cloth to remove dirt and oil. Check it for any damage, like cracks or rust, and replace it if needed. Always use it gently to avoid breaking it. With care, your chuck key will last a long time!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Different Types Of Chuck Keys Used With Precision Metal Lathes, And How Do They Differ In Functionality? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “There are different types of chuck keys for metal lathes. The most common types are the pin key, the T-handle key, and the hex key. The pin key has a long stick with a pin that fits the chuck. The T-handle key looks like a T and gives you more grip. The hex key is a simple L-shape that fits into hexagonal screws. Each type helps you tighten or loosen the chuck, but they feel different in your hand.”}},{“@type”: “Question”,”name”: “How Do You Properly Use A Chuck Key To Ensure Secure Clamping Of Workpieces On A Precision Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To use a chuck key, first, find the key that fits your lathe’s chuck. You put the key into the holes around the chuck. Turn the key clockwise to tighten. Make sure it is snug but not too tight, so it holds the piece safely. Always remember to remove the key before starting the machine!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Using A Chuck Key On A Precision Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a chuck key on a metal lathe, make sure your hands are clear of the moving parts. Always remove the chuck key right after you finish turning the chuck. Wear safety glasses to protect your eyes from debris. Keep your workspace clean and tidy to avoid accidents. Finally, never reach into the lathe while it is running.”}},{“@type”: “Question”,”name”: “How Can You Troubleshoot Issues Related To A Chuck Key That Might Affect The Performance Of A Precision Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot a chuck key issue on your metal lathe, first check if the chuck key is fitting well. Make sure it’s the right size and not damaged. Next, look for any dirt or chips that might block the chuck. Clean it gently if you see any mess. Lastly, always remember to put the chuck key back safely after using it. This keeps everything working smoothly.”}},{“@type”: “Question”,”name”: “What Are Some Tips For Maintaining And Caring For A Chuck Key To Ensure Its Longevity And Effectiveness? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your chuck key in good shape, always store it in a safe place, so you don’t lose it. Clean it regularly with a cloth to remove dirt and oil. Check it for any damage, like cracks or rust, and replace it if needed. Always use it gently to avoid breaking it. With care, your chuck key will last a long time!”}}]}