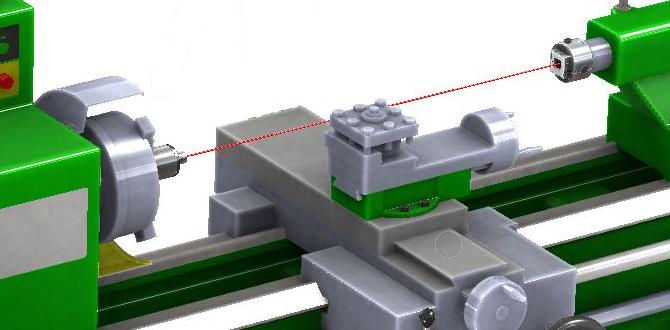

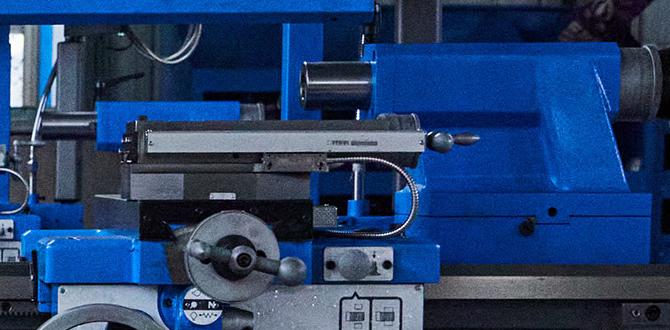

Have you ever wondered how metal parts are made with such precision? It all starts with a precision metal lathe. This amazing machine can create exact shapes from solid metal. But did you know that the secret lies in something called a gear train?

A gear train transfers power and helps control speed in the lathe. It connects different gears to ensure everything runs smoothly. Picture this: A team of well-organized people working together to complete a project. That’s how a gear train works in a lathe!

Understanding how a gear train functions can make you appreciate the art of metalworking even more. It’s not just about cutting metal. It’s about finding the right balance between speed and accuracy. Curious to dive deeper? Let’s explore the world of precision metal lathes and their incredible gear trains!

Precision Metal Lathe Gear Train: Understanding Its Importance

Precision Metal Lathe Gear Train

A precision metal lathe gear train is essential in machining. It helps control the movement of the lathe, giving users accurate cuts. Imagine a car engine; without gears, it wouldn’t run smoothly. These gear systems multiply torque and adjust speed, making tasks easier. Understanding how they work can improve your projects. Did you know even tiny adjustments can lead to big changes in your work? This gear train is a game-changer in the world of metalworking!What is a Precision Metal Lathe?

Definition and key features of precision metal lathes. Importance of precision in machining processes.A precision metal lathe is a machine that shapes metal into desired forms. It uses cutting tools to remove material. Key features include:

- High accuracy for detailed work

- Adjustable speeds for different tasks

- Robust construction to handle tough materials

Precision is vital in machining. It ensures parts fit perfectly. A small mistake can cause big issues. In industries, precision helps create safer and better products.

Why is precision important in machining?

Precision improves product quality. It reduces waste and saves time. In machines, fitting pieces tightly means they work better and last longer.

Types of Gear Trains in Precision Lathes

Simple gear trains and their applications. Compound gear trains and advantages.Gear trains play a big role in precision lathes, helping them run smoother than a buttered slide! There are mainly two types: simple gear trains and compound gear trains. Simple gear trains let you change speeds easily, which is great for basic tasks. In contrast, compound gear trains combine multiple gears, boosting strength and torque. This means they can tackle tougher jobs without breaking a sweat. Isn’t that neat? Check out the table below for a quick comparison!

| Type | Applications | Advantages |

|---|---|---|

| Simple Gear Train | Basic tasks and speed changes | Easy to understand and build |

| Compound Gear Train | Heavy-duty applications | Higher torque and efficiency |

How Gear Trains Affect Lathe Performance

Impact on speed and torque delivery. Relationship between gear ratio and machining precision.Gear trains play a big role in how well a lathe works. They affect speed and torque delivery. A higher gear ratio means faster speeds but less torque. This can help cut materials quickly. On the other hand, a lower gear ratio delivers more torque, which is great for tough jobs. This balance is key to precision machining. Good gear ratios lead to better accuracy in shapes and sizes.

- High gear ratios: Fast speed, less torque.

- Low gear ratios: More torque, slower speed.

- Precision improves with the right gear setup.

How does gear ratio impact machining precision?

The right gear ratio allows precise cuts, ensuring parts fit perfectly and work well together. Adjusting the gears can help match specific tasks, improving the overall lathe performance.

Selecting the Right Gear Train for Your Lathe

Key considerations when choosing a gear train. Common gear train configurations for different machining needs.Choosing the right gear train is important for your lathe. Think about what you need. Here are some key points:

- Speed: Faster gears cut quicker but may lack control.

- Power: Higher torque helps with tough materials.

- Size: Ensure your gear train fits your lathe model.

Common configurations include:

- Simple Gear Train: Good for basic tasks.

- Compound Gear Train: Offers more control and flexibility.

- Complex Gear Train: Best for advanced machining.

Pick wisely for better results!

What size gear train should I choose?

The size of the gear train depends on your lathe model. Check your lathe’s specifications to find the best fit. A proper match ensures smooth operation and better performance.

Maintenance Tips for Gear Trains in Lathes

Routine checks and maintenance practices. Common issues and troubleshooting methods.Keeping gear trains in lathes in good shape is easy with proper care. Here are some simple tips:

- Check for dirt and grime regularly.

- Lubricate moving parts to prevent wear.

- Look for loose connections or signs of damage.

- Listen for unusual noises when in operation.

If you notice any problems, address them quickly. Common issues include:

- Your lathe could be making strange sounds.

- It might not turn smoothly.

- Parts may show signs of rust.

Fixing these issues early can save time and money!

What are common issues with gear trains in lathes?

Common issues include strange noises, rough operation, and rust on parts. Addressing these quickly can help maintain performance and extend the life of your lathe.

Routine Checks:

- Daily: Look for dirt and loose parts.

- Weekly: Lubricate as needed and check for wear.

- Monthly: Inspect for rust or other damage.

Future Trends in Precision Metal Lathe Technology

Innovations and advancements in gear train design. Predictions for the future of precision machining tools.The future of precision metal lathe technology is bright and exciting! New gear train designs are popping up like popcorn. Innovations aim to make lathes faster and more efficient. Imagine a machine that can whip up parts in a blink! Experts predict that tools will get smarter, too, using AI to help machinists work better. This could mean fewer mistakes and more fun! Let’s keep an eye on these changes because they may just revolutionize the way we think about machining.

| Trend | Innovation | Prediction |

|---|---|---|

| Smart Technology | AI Integration | Reduced Errors |

| Advanced Materials | Stronger Gears | Increased Longevity |

| Energy Efficiency | Eco-Friendly Designs | Lower Costs |

Conclusion

In conclusion, a precision metal lathe gear train helps machines work smoothly and accurately. It converts motor power into precise movements. Understanding how it works can improve your projects. We encourage you to explore more about lathes and gear systems. This knowledge can enhance your skills and creativity in metalworking. Keep learning and experimenting!FAQs

Sure! Here Are Five Related Questions On The Topic Of Precision Metal Lathe Gear Trains:Precision metal lathe gear trains help machines work better. They change speeds and powers. This makes it easier for you to cut metal shapes. With the right gear train, you can make smooth and precise cuts. It’s like using different gears on a bicycle to go faster or slower!

Sure! Please provide the question you would like me to answer.

What Are The Main Components Of A Gear Train In A Precision Metal Lathe, And How Do They Function Together?A gear train in a precision metal lathe has a few main parts. First, there are gears that spin and change speed. We also find shafts that connect the gears and help them move. There are sometimes belts that link the gears together. All these components work together to control how fast or slow the lathe spins, helping you create precise shapes in metal.

How Does The Gear Train Configuration Affect The Accuracy And Surface Finish Of The Finished Metal Workpiece?The gear train configuration helps control how the machine moves. If the gears fit well, the machine works smoothly. This means the metal piece you create will be more accurate. A good setup also makes the surface of the metal piece smoother and nicer. So, using the right gears helps make better metal parts.

What Are The Advantages Of Using A Variable Speed Gear Train In Precision Metal Lathes Compared To Fixed-Speed Systems?Using a variable speed gear train in precision metal lathes is really cool! It lets you change the speed easily. This means you can work on different materials better. You can go slower for detailed work and faster for quick cuts. So, you get more control and can make better pieces!

How Can Gear Backlash In A Metal Lathe Gear Train Impact Machining Performance, And What Methods Are Used To Minimize It?Gear backlash in a metal lathe makes gears move a little away from each other before they catch. This can cause mistakes in the size of the pieces we make. To fix this, we can adjust the gears to fit better. We can also use special shims or tighteners to reduce the gaps. Keeping everything tight helps us make better and more accurate shapes.

What Maintenance Practices Are Essential For Ensuring The Longevity And Precision Of The Gear Train In Metal Lathes?To keep the gear train in metal lathes working well, we need to clean it often. Dirt and grease can slow it down. We should also check for any broken or worn parts. If something is wrong, we fix it right away. Finally, adding oil to the gears helps them move smoothly and last longer.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Precision Metal Lathe Gear Trains:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Precision metal lathe gear trains help machines work better. They change speeds and powers. This makes it easier for you to cut metal shapes. With the right gear train, you can make smooth and precise cuts. It’s like using different gears on a bicycle to go faster or slower!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Main Components Of A Gear Train In A Precision Metal Lathe, And How Do They Function Together?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A gear train in a precision metal lathe has a few main parts. First, there are gears that spin and change speed. We also find shafts that connect the gears and help them move. There are sometimes belts that link the gears together. All these components work together to control how fast or slow the lathe spins, helping you create precise shapes in metal.”}},{“@type”: “Question”,”name”: “How Does The Gear Train Configuration Affect The Accuracy And Surface Finish Of The Finished Metal Workpiece?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The gear train configuration helps control how the machine moves. If the gears fit well, the machine works smoothly. This means the metal piece you create will be more accurate. A good setup also makes the surface of the metal piece smoother and nicer. So, using the right gears helps make better metal parts.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Variable Speed Gear Train In Precision Metal Lathes Compared To Fixed-Speed Systems?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a variable speed gear train in precision metal lathes is really cool! It lets you change the speed easily. This means you can work on different materials better. You can go slower for detailed work and faster for quick cuts. So, you get more control and can make better pieces!”}},{“@type”: “Question”,”name”: “How Can Gear Backlash In A Metal Lathe Gear Train Impact Machining Performance, And What Methods Are Used To Minimize It?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Gear backlash in a metal lathe makes gears move a little away from each other before they catch. This can cause mistakes in the size of the pieces we make. To fix this, we can adjust the gears to fit better. We can also use special shims or tighteners to reduce the gaps. Keeping everything tight helps us make better and more accurate shapes.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Essential For Ensuring The Longevity And Precision Of The Gear Train In Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the gear train in metal lathes working well, we need to clean it often. Dirt and grease can slow it down. We should also check for any broken or worn parts. If something is wrong, we fix it right away. Finally, adding oil to the gears helps them move smoothly and last longer.”}}]}