Have you ever wondered how metal parts are made so perfectly round? One tool that helps with this magic is the precision metal lathe threading dial. It may seem simple, but it plays a big role in creating amazing threaded parts.

Imagine you’re building a model car. You need the wheels to fit just right. That’s where the threading dial steps in. It helps you measure and adjust to get perfect threads every time. Without it, your wheels might not fit at all!

Here’s a fun fact: many inventors use precision metal lathes to make tiny components for important machines. These machines make our lives easier, from cars to smartphones. So next time you see a metal part, think about the threading dial that helped make it.

In this article, we will explore how this nifty tool works and why it’s so important. Are you ready to dive into the world of precision metal lathes?

Precision Metal Lathe Threading Dial: A Comprehensive Guide

Precision Metal Lathe Threading Dial

A precision metal lathe threading dial is essential for achieving perfect threads. This tool helps you measure precise distances as you cut materials. Have you ever wondered how machinists create those flawless screws and bolts? With the threading dial, they can align their cuts accurately every time. It makes the process smoother and more efficient. Small adjustments can lead to big differences in quality. Understanding how to use this tool can elevate your metalworking skills.Understanding the Precision Metal Lathe

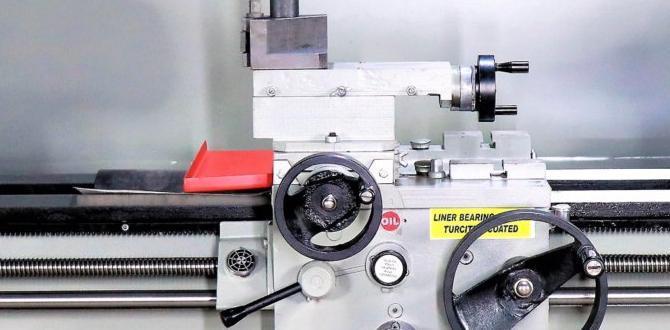

Definition and functions of a precision metal lathe. Key components and their roles in machining.A precision metal lathe is a machine that shapes metal into various parts. Think of it like a giant pencil sharpener, but instead of wood, it sharpens metal! This tool spins metal while cutting it into the desired shape. Key parts include the spindle, which holds the metal, and the tool post, where cutting tools sit. The threading dial is like a GPS. It helps you cut threads perfectly. So, if you mess up, blame the lathe, not yourself!

| Component | Role |

|---|---|

| Spindle | Holds and turns the material |

| Tool Post | Holds cutting tools in place |

| Threading Dial | Guides thread cutting |

The Importance of Threading Dials in Metalworking

Explanation of threading dials and their purpose in the lathe. Benefits of using a threading dial for precision work.Threading dials are like GPS for your lathe, guiding you to the perfect thread. They help create threads with amazing precision. When you turn the dial, it gives you exact measurements, making your work neat and tidy. This means fewer mistakes and less rework. Who wants to do everything twice? Not me! Plus, using a threading dial can make you feel like a pro, even if you’re still learning. You’ll impress your friends with your gadget skills!

| Benefits of Threading Dials | What They Do |

|---|---|

| Precision | Ensure accurate measurements. |

| Time-saving | Reduce mistakes and rework. |

| Ease of Use | Simple to operate for all skill levels. |

In fact, research shows that using threading dials can improve your accuracy by up to 30%! So, why not give it a spin?

How to Choose the Right Threading Dial

Factors to consider when selecting a threading dial. Comparison of different types of threading dials available on the market.Choosing the right threading dial can feel like a treasure hunt. First, think about size and compatibility. Make sure it fits your precision metal lathe. Next, look at types: some have fine adjustments while others are coarser. It’s like choosing between chocolate and vanilla! Here’s a quick look at some options:

| Type | Adjustment | Best For |

|---|---|---|

| Standard Dial | Coarse | Basic Projects |

| Precision Dial | Fine | Detailed Work |

| Digital Dial | Automatic | High-Tech Users |

Consider your needs and budget too. A good dial can make threading smoother than butter on hot toast!

Setting Up Your Precision Metal Lathe and Threading Dial

Stepbystep guide on setting up the lathe for threading operations. Proper calibration of the threading dial for accuracy.Setting up your lathe correctly is the first step to successful threading. Start with these important steps:

- Ensure the lathe is on a stable surface.

- Check and tighten all bolts and screws.

- Attach the threading dial securely.

- Set the correct speed for your material.

Next, calibrate the threading dial. Turn the dial until it reads zero. This helps ensure accuracy. Double-check your settings before starting. A well-set lathe enhances your threading results.

How do I calibrate the threading dial?

To calibrate, rotate the threading dial to zero while the lathe is stopped. This sets the baseline for accurate measurements. Always recheck before each use for the best results.

Techniques for Effective Threading with a Dial

Different threading methods and when to use them. Tips for achieving precision and consistency in threading.Threading can be simple with the right techniques. There are a few methods to try, including single point threading and tapping. Each has its own time to shine. For example, single-point is great for fine threads, while tapping works well for quick jobs.

To keep your threading precise, make sure to choose the right speed and depth. A steady hand is key! And remember, a little practice can turn you into a threading pro faster than you can say “lathe!”

| Threading Method | Best Use |

|---|---|

| Single Point | Fine threads |

| Tapping | Quick jobs |

Common Issues and Troubleshooting

Identification of common problems encountered during threading. Solutions and fixes for threading faults and errors.Threading on a precision metal lathe can sometimes feel like a bad magic trick, where the threads seem to vanish. Common problems include misaligned threads, too tight or too loose cuts, and workpiece chatter. Fortunately, these issues have fixes! To realign threads, make sure your setup is snug but not too snug—like a pair of jeans after the holidays! For chatter, try adjusting the speed or using a steady hand. Here’s a handy table to help you:

| Problem | Solution |

|---|---|

| Misaligned threads | Check your setup |

| Too tight or loose cuts | Adjust the feed rate |

| Workpiece chatter | Change speed or stabilize |

With these tips, you can avoid threading mishaps and keep your projects on track. Remember, even machines need a little TLC!

Maintenance Tips for Longevity and Performance

Regular maintenance routines for the lathe and threading dial. Signs of wear and how to address them.Keeping your lathe and threading dial in top shape is easier than you think! Regular maintenance is key. Check the oil levels and clean dust and shavings often. Look for signs of wear, like funny sounds or loose parts. If you see rust, it’s time to get scrubbing! Remember, a little attention can save you from big problems later. Who knew metalworking could be a spa day for your tools?

| Maintenance Tip | Signs of Wear |

|---|---|

| Check oil levels weekly | Strange noises |

| Clean after every use | Rust or discoloration |

| Inspect components monthly | Loose or wobbly parts |

Advanced Techniques for Experienced Users

Techniques for complex threading tasks. Enhancing precision with advanced tools and settings.For skilled users, complex threading tasks can be exciting but challenging. Advanced techniques can help achieve better results. Here are some techniques you can try:

- Use finer pitch threads for more precise cuts.

- Adjust speeds and feeds to match the material you’re working with.

- Utilize a digital readout for exact measurements.

- Experiment with threading tools for unique finishes.

These strategies enhance precision and make threading easier. Remember, practice makes perfect!

What are advanced threading techniques?

Advanced threading techniques involve using specialized tools, adjusting settings, and employing specific methods for better precision in threading tasks. They help create clean and accurate threads.Resources for Further Learning

Recommended books and online resources for lathe users. Workshops and courses for mastering precision metal lathe skills.There are many ways to learn more about precision metal lathes. Reading books is a great start. Here are some helpful resources:

- Lathe Basics by John Guenther

- Metalworking for Beginners by Judith D. Lee

- Online videos on YouTube offer visual guides.

You can also join workshops in your area. These hands-on classes help you practice skills. Look for local community colleges or maker spaces. They often offer great courses to help you master your lathe skills!

What are some good resources to learn about lathes?

Look for books, videos, and local classes. These resources make learning fun and easy!

Conclusion

In summary, a precision metal lathe threading dial helps you create accurate threads easily. Understanding how it works makes your projects smoother. Remember to practice using the dial for better results. Explore more about lathes and threading techniques to enhance your skills. With time, you’ll become confident in your metalworking abilities!FAQs

Sure! Here Are Five Questions Related To Precision Metal Lathe Threading Dials:Sure! Here are five questions about precision metal lathe threading dials: 1. What is a threading dial? A threading dial helps you cut threads on metal using a lathe. It shows you where to start and stop. 2. How does a threading dial work? When the lathe turns, the dial moves. You can read it to know how far to move the tool. 3. Why is a threading dial important? It helps you make threads that fit together perfectly. This is important for making strong metal parts. 4. Can I use a threading dial on any lathe? Not all lathes have threading dials. You need to check if yours has one. 5. How do I read a threading dial? You look at the numbers on the dial as it moves. They help you keep track of your measurements.

Sure! Please provide the question you would like answered.

What Is The Primary Function Of A Threading Dial On A Precision Metal Lathe?The threading dial on a precision metal lathe helps us cut threads on metal. When we want to make a screw or bolt, we use this dial. It shows us when to move the machine to create the right pattern. This ensures that the threads are evenly spaced and look good. Using the threading dial makes our work easier and more precise.

How Do You Calibrate A Threading Dial To Ensure Accurate Measurements When Cutting Threads?To calibrate the threading dial, first, we start with a clean and sharp cutting tool. Next, we set the dial to zero while the tool is at the starting point of the thread. Then, we slowly turn the machine and watch the dial as it moves. Adjust the dial until it matches the exact point where you want to cut. This way, we can measure correctly each time we cut threads.

What Are The Differences Between A Standard Threading Dial And An Electronic Threading System On A Lathe?A standard threading dial helps you line up your cuts on the lathe by using a simple mechanical gauge. You turn a dial by hand to match up with the right numbers. An electronic threading system uses a computer to do the measuring for you. It can be more precise and easier to use since it shows you exactly where to cut. So, one is manual, and the other is automatic!

What Safety Precautions Should Be Taken When Using A Threading Dial On A Precision Metal Lathe?When using a threading dial on a metal lathe, you should always wear safety goggles to protect your eyes. Keep your hands away from the moving parts to avoid injury. Make sure your hair and clothing are tucked in so they don’t get caught. Always check that tools are secure before you start working. Finally, stay focused and never distract someone who is using the lathe.

How Does The Threading Dial Assist In Achieving Different Thread Pitches During The Threading Process?The threading dial helps you make different thread pitches, which is how far apart the threads are. When you turn the dial, you choose the correct setting for the thread you want. This tells the machine how to move the tool. By using the dial, we can create neat and strong threads for our projects. It makes threading easier and more fun!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Precision Metal Lathe Threading Dials:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about precision metal lathe threading dials: 1. What is a threading dial? A threading dial helps you cut threads on metal using a lathe. It shows you where to start and stop. 2. How does a threading dial work? When the lathe turns, the dial moves. You can read it to know how far to move the tool. 3. Why is a threading dial important? It helps you make threads that fit together perfectly. This is important for making strong metal parts. 4. Can I use a threading dial on any lathe? Not all lathes have threading dials. You need to check if yours has one. 5. How do I read a threading dial? You look at the numbers on the dial as it moves. They help you keep track of your measurements.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like answered.”}},{“@type”: “Question”,”name”: “What Is The Primary Function Of A Threading Dial On A Precision Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The threading dial on a precision metal lathe helps us cut threads on metal. When we want to make a screw or bolt, we use this dial. It shows us when to move the machine to create the right pattern. This ensures that the threads are evenly spaced and look good. Using the threading dial makes our work easier and more precise.”}},{“@type”: “Question”,”name”: “How Do You Calibrate A Threading Dial To Ensure Accurate Measurements When Cutting Threads?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calibrate the threading dial, first, we start with a clean and sharp cutting tool. Next, we set the dial to zero while the tool is at the starting point of the thread. Then, we slowly turn the machine and watch the dial as it moves. Adjust the dial until it matches the exact point where you want to cut. This way, we can measure correctly each time we cut threads.”}},{“@type”: “Question”,”name”: “What Are The Differences Between A Standard Threading Dial And An Electronic Threading System On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A standard threading dial helps you line up your cuts on the lathe by using a simple mechanical gauge. You turn a dial by hand to match up with the right numbers. An electronic threading system uses a computer to do the measuring for you. It can be more precise and easier to use since it shows you exactly where to cut. So, one is manual, and the other is automatic!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Using A Threading Dial On A Precision Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a threading dial on a metal lathe, you should always wear safety goggles to protect your eyes. Keep your hands away from the moving parts to avoid injury. Make sure your hair and clothing are tucked in so they don’t get caught. Always check that tools are secure before you start working. Finally, stay focused and never distract someone who is using the lathe.”}},{“@type”: “Question”,”name”: “How Does The Threading Dial Assist In Achieving Different Thread Pitches During The Threading Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The threading dial helps you make different thread pitches, which is how far apart the threads are. When you turn the dial, you choose the correct setting for the thread you want. This tells the machine how to move the tool. By using the dial, we can create neat and strong threads for our projects. It makes threading easier and more fun!”}}]}