Have you ever wondered how metal parts are shaped with such precision? A metal lathe is a key tool in this process. But what makes it truly special is its ability to deliver the right torque. Torque is all about the twist force. It helps the lathe turn the metal smoothly and accurately.

Imagine a young inventor crafting a robot. They need perfectly shaped parts that fit together just right. That’s where a precision metal lathe comes into play. It ensures each piece is just as needed, thanks to its control over torque.

Did you know that the right torque can greatly improve the quality of your metalwork? Many metalworkers swear by it. They believe that a well-calibrated lathe can make or break a project.

In this article, we will dive into how precision metal lathe torque transforms the way we create. So, are you ready to explore the fascinating world of metal lathes and the magic of torque?

Understanding Precision Metal Lathe Torque For Optimal Performance

Precision Metal Lathe Torque Explained

Precision metal lathe torque is crucial for achieving high-quality machining. This measurement shows how much rotational force the lathe applies. Understanding torque helps you choose the right tools and settings for your projects. Did you know that too little torque can lead to poor cuts? Conversely, excessive torque may damage your materials. By mastering torque, you can enhance efficiency and accuracy in your metalworking tasks. It’s the secret ingredient for creating precision parts!What is Precision Metal Lathe Torque?

Definition and importance of torque in metal lathes. Impact of torque on machining performance and quality.Torque is the twisty power that drives metal lathes. Think of it as the muscle behind the machining magic! It helps the lathe turn metal smoothly and accurately, making precision a reality. Without enough torque, the machine might struggle, leading to poor quality pieces. A good torque level keeps cutting tools sharp and production flowing. When torque is just right, you get clean cuts that sing like a happy metal band!

| Torque Level | Effect on Machining |

|---|---|

| Low | Poor surface finish, rounding corners |

| Optimal | Clean cuts, accurate dimensions |

| High | Potential damage, tool wear |

Types of Torque in Metal Lathes

Static vs dynamic torque. Factors influencing torque levels during operation.There are two main types of torque in metal lathes: static and dynamic. Static torque is measured when the lathe is at rest, while dynamic torque kicks in during operation. It’s like waiting for popcorn to pop versus when you hear it popping away! Several factors can affect torque levels during use. These include material type, cutting speed, and tool sharpness. If the tool’s dull, it’s like trying to cut bread with a spoon—good luck!

| Type of Torque | Description |

|---|---|

| Static Torque | Torque measured at rest |

| Dynamic Torque | Torque measured during operation |

Calculating Torque for Precision Metal Lathes

Formulae and methods for torque calculation. Examples of torque calculations for different tasks.Understanding torque for precision metal lathes is easier than you think! First, the formula to find torque is: Torque = Force × Distance. This means you need the force applied and how far from the center it is. For example, if you use a 10-pound force at a 2-inch distance, your torque equals 20 inch-pounds. Let’s look at a quick comparison for different tasks:

| Task | Force (lbs) | Distance (in) | Torque (in-lbs) |

|---|---|---|---|

| Drilling | 8 | 3 | 24 |

| Tapping | 5 | 2 | 10 |

| Turning | 15 | 4 | 60 |

Calculating torque is like baking a cake: get the right ingredients, and you’ll have a sweet result! So, whether you’re drilling or turning, remember that torque is key to success!

Factors Affecting Torque in Metal Lathes

Material types and their influence on required torque. Cutting speed and feed rates impact on torque.Many things can change how much torque is needed in metal lathes. One big factor is the type of material. Harder materials need more torque to cut through them. Soft materials are easier, so they need less.

The speed you cut and how fast you feed the material also make a difference. Faster cutting speeds increase torque needs. Slower speeds and lower feed rates decrease it, making it easier to manage. Here’s a simple list:

- Material type impacts cutting force.

- Hard materials = more torque.

- Soft materials = less torque.

- Higher cutting speed = higher torque.

- Lower feed rates = lower torque.

Understanding these factors helps ensure good cuts and safe use of tools.

How does material type affect torque?

Harder materials require more torque to cut. Soft materials are easier and need less torque.

What impact do cutting speed and feed rates have?

Faster cutting and higher feed rates increase torque needs. Slower speeds lower the torque requirement.

Maintaining Optimal Torque for Performance

Tips for adjusting and calibrating lathe settings. Common issues leading to torque loss and how to prevent them.To keep your lathe running smoothly, regular adjustments are key. Start by checking the settings often to make sure they’re just right. Look out for issues like worn belts or loose bolts, which can cause torque loss. Remember, a happy lathe is a productive lathe! If things feel off, try recalibrating. Keep your tools clean and tight; no one likes a messy workspace! Even your lathe deserves some love, right? Below is a handy table to help:

| Issue | Tip |

|---|---|

| Worn belts | Replace them regularly |

| Loose bolts | Tighten them! |

| Dirty tools | Clean after each use |

Torque Specifications in Precision Metal Lathes

Standard torque specs for various metal lathe models. Importance of adhering to manufacturer specifications.Torque specifications are key for running metal lathes safely. Each lathe model may have different torque requirements. Following these specs helps avoid damage and ensures a smooth operation. For instance, a typical specification may include:

- Small lathes: 15-20 Nm

- Medium lathes: 25-40 Nm

- Large lathes: 50-80 Nm

Always check the manufacturer’s guidelines. Ignoring these can lead to serious problems. Remember, the right torque makes your work better and safer.

What are the consequences of ignoring torque specifications?

Ignoring torque specifications can lead to equipment failure and unsafe operations. This may cause injuries or costly repairs. Following the guidelines keeps everyone safe and machines running smoothly.

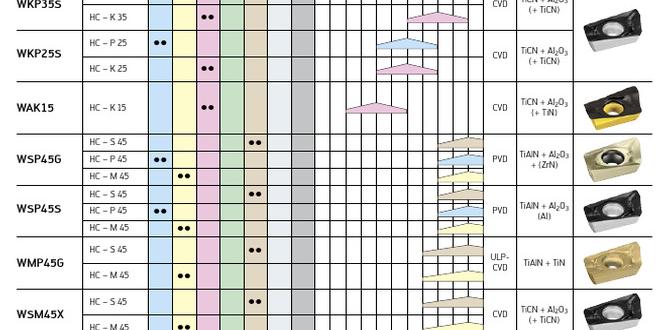

Technological Advances in Torque Management

Innovations in torque measurement tools. The role of CNC technology in enhancing torque control.New tools are changing how we measure torque. These tools are more accurate than ever. They help workers understand how much force is used. Precision is key for machines like lathes. CNC technology is a big part of this change. It allows for better control over torque. This means safer and more efficient work. Manufacturers use these advances to create better products.

What are the latest innovations in torque measurement tools?

The latest innovations include digital torque wrenches that provide real-time data and smart sensors that connect to apps for easy tracking.

- Digital torque wrenches

- Smart sensors

- Data-logging devices

The world of torque management is growing fast! These updates help everyone work smarter. Better tools lead to better machines and safer workplaces.

Applications of Torque in Metalworking Industries

Key industries relying on precision metal lathe torque. Case studies showcasing torque optimization success stories.Many industries depend on precision metal lathe torque for their operations. For example, the auto industry relies on this torque to make parts that fit perfectly, ensuring cars run smoothly. The aerospace sector also uses it, making sure planes are safe and reliable.

Case studies show that companies optimizing their torque often see big gains. One company cut its error rate by 30% simply by adjusting torque settings. That’s like winning the lottery of engineering! Check out the table below for more insights.

| Industry | Success Story | Improvement |

|---|---|---|

| Automotive | Torque Adjustments | 30% error reduction! |

| Aerospace | High Precision Machining | Increased safety with higher standards. |

Best Practices for Leveraging Torque Efficiency

Recommended practices for operators and machinists. Training resources for improving torque management skills.To boost torque efficiency, operators should embrace a few smart practices. First, always check your tools and parts; worn-out pieces can cause big problems! Next, calibrate your machines regularly. Think of it as giving your lathe a spa day. Training resources, like workshops or online courses, can help. They teach vital torque management skills, ensuring every operator shines like a star. Remember, “A lathe in good shape makes for happy machining!”

| Best Practices | Training Resources |

|---|---|

| Check tools for wear | Workshops |

| Calibrate machines often | Online courses |

| Follow safety protocols | Skill assessments |

Conclusion

In summary, precision metal lathes provide accurate torque for shaping metal. A good torque ensures smooth operation and better results. It’s important to understand torque settings to improve your projects. You can explore more about lathes and their uses in workshops. Remember, practice makes perfect, so don’t hesitate to dive in and start working!FAQs

Sure! Here Are Five Related Questions On The Topic Of Precision Metal Lathe Torque:Sure! Torque is the force that helps turn things, like a handle or a wheel. In a precision metal lathe, we need the right amount of torque to cut metal smoothly. If it’s too low, the tool might slip. If it’s too high, it can break the tool or the lathe itself. So, we have to find the perfect balance!

Sure! Please provide the question you would like me to answer.

What Is The Importance Of Torque Specifications In The Operation Of Precision Metal Lathes?Torque specifications are crucial for using precision metal lathes safely. They tell you how tight to make the bolts and screws. If they’re too loose, parts can move around. If they’re too tight, they can break or get damaged. Following these specs helps keep the lathe working correctly and prevents accidents.

How Does The Torque Output Of A Precision Metal Lathe Affect The Quality Of The Finished Workpiece?The torque output of a precision metal lathe is very important. Torque is the power that makes the machine turn. When the lathe has enough torque, it cuts metal smoothly. This helps make a better-quality workpiece. If the torque is low, the cuts can be rough and uneven.

What Are The Common Methods For Measuring Torque In Precision Metal Lathe Applications?To measure torque on a metal lathe, we can use a few common methods. One method is a torque wrench, which gives us a reading when we twist it. Another way is using a load cell, which measures the force and helps us calculate torque. We can also use a torque sensor attached to the lathe. These tools help us keep things safe and working well while we make metal parts.

How Can Improper Torque Settings Lead To Issues Such As Tool Wear Or Workpiece Deformation In Metal Lathing?If you don’t use the right torque settings, your tools can wear out quickly. This happens because too much or too little force can hurt them. Also, the piece you are working on might get bent or misshaped. It’s like if you press too hard on a cupcake, it squishes instead of holding its shape. So, always check your settings to keep everything safe and working well!

What Factors Should Be Considered When Selecting A Motor For A Precision Metal Lathe To Ensure Adequate Torque Performance?When choosing a motor for a precision metal lathe, we should think about several important factors. First, we need to check the torque, which is the turning force the motor can provide. Next, consider the speed of the motor, because different jobs need different speeds. We also have to make sure the motor fits well in the lathe space. Lastly, think about power supply; make sure we have the right electricity for the motor to work.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Precision Metal Lathe Torque:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Torque is the force that helps turn things, like a handle or a wheel. In a precision metal lathe, we need the right amount of torque to cut metal smoothly. If it’s too low, the tool might slip. If it’s too high, it can break the tool or the lathe itself. So, we have to find the perfect balance!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Is The Importance Of Torque Specifications In The Operation Of Precision Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Torque specifications are crucial for using precision metal lathes safely. They tell you how tight to make the bolts and screws. If they’re too loose, parts can move around. If they’re too tight, they can break or get damaged. Following these specs helps keep the lathe working correctly and prevents accidents.”}},{“@type”: “Question”,”name”: “How Does The Torque Output Of A Precision Metal Lathe Affect The Quality Of The Finished Workpiece?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The torque output of a precision metal lathe is very important. Torque is the power that makes the machine turn. When the lathe has enough torque, it cuts metal smoothly. This helps make a better-quality workpiece. If the torque is low, the cuts can be rough and uneven.”}},{“@type”: “Question”,”name”: “What Are The Common Methods For Measuring Torque In Precision Metal Lathe Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To measure torque on a metal lathe, we can use a few common methods. One method is a torque wrench, which gives us a reading when we twist it. Another way is using a load cell, which measures the force and helps us calculate torque. We can also use a torque sensor attached to the lathe. These tools help us keep things safe and working well while we make metal parts.”}},{“@type”: “Question”,”name”: “How Can Improper Torque Settings Lead To Issues Such As Tool Wear Or Workpiece Deformation In Metal Lathing?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you don’t use the right torque settings, your tools can wear out quickly. This happens because too much or too little force can hurt them. Also, the piece you are working on might get bent or misshaped. It’s like if you press too hard on a cupcake, it squishes instead of holding its shape. So, always check your settings to keep everything safe and working well!”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting A Motor For A Precision Metal Lathe To Ensure Adequate Torque Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a motor for a precision metal lathe, we should think about several important factors. First, we need to check the torque, which is the turning force the motor can provide. Next, consider the speed of the motor, because different jobs need different speeds. We also have to make sure the motor fits well in the lathe space. Lastly, think about power supply; make sure we have the right electricity for the motor to work.”}}]}