Have you ever wondered how precision metal lathes work? These amazing machines can shape metal with incredible accuracy. But what happens when they need repairs or upgrades? Understanding the wiring is key!

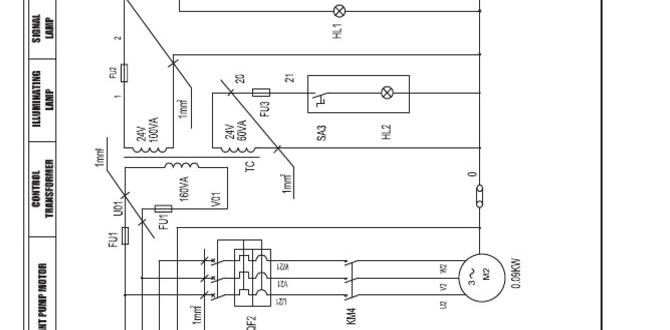

A precision metal lathe wiring diagram helps you see how all the parts fit together. It shows where every wire goes. For anyone who loves tinkering, a wiring diagram is like a treasure map.

Imagine being able to fix a glitch on your own lathe. With the right diagram, you can! This guide will help you understand these diagrams better. You’ll discover how to read them and use them for your projects.

Let’s dive into the world of precision metal lathe wiring. It’s not just technical; it’s also fun! You might just find your next hobby or passion here.

Precision Metal Lathe Wiring Diagram: A Comprehensive Guide

Understanding Precision Metal Lathe Wiring Diagrams

A precision metal lathe wiring diagram shows how to connect and use a lathe safely. Readers discover where to attach wires and what components to connect. This guide helps in troubleshooting and repairing lathes. Knowing these diagrams can also improve performance. Imagine being able to fix your machine without calling for help! Learning the basics of wiring diagrams can make the difference between a smooth operation and a frustrating day in the workshop.Understanding Precision Metal Lathes

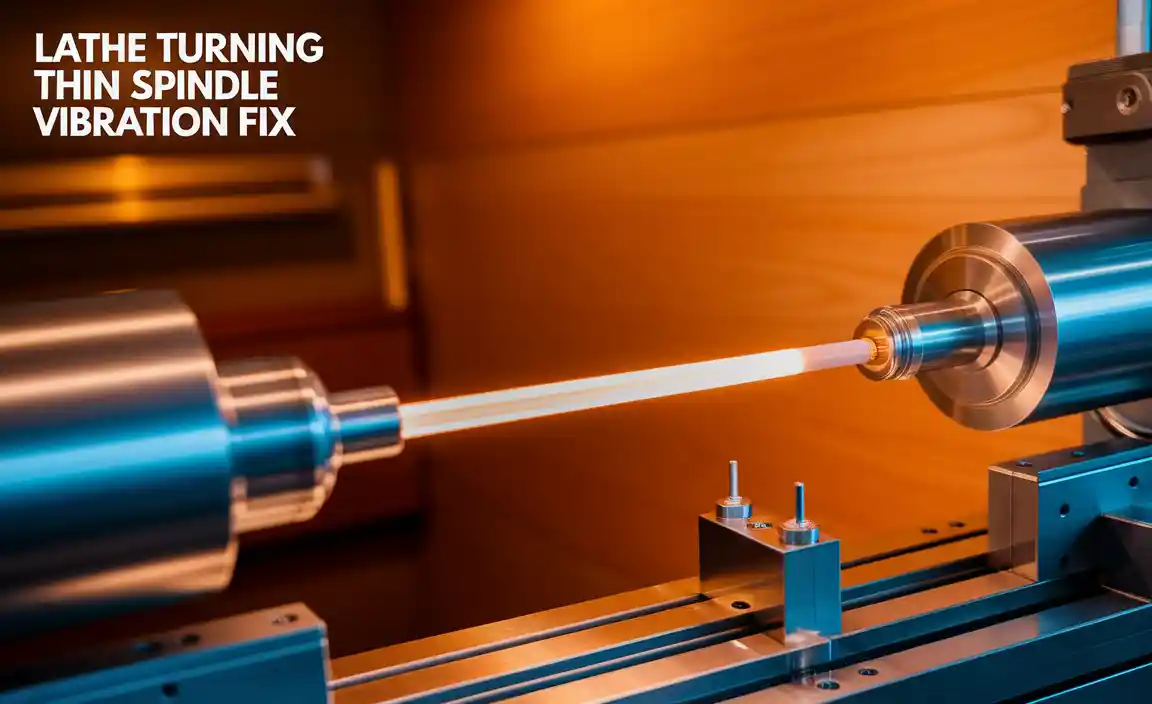

Definition and function of precision metal lathes. Importance of wiring in the operation of lathes.A precision metal lathe is a powerful tool that shapes metal into different forms. It spins metal pieces while a sharp tool cuts them. This process helps create precise parts for machines and devices. Good wiring is essential for the lathe to work correctly. The wiring connects the motor and controls, ensuring smooth operation. Without it, the lathe may not function properly.

- Definition: A tool that shapes metal accurately.

- Function: Spins and cuts metal to create parts.

- Wiring Importance: Connects parts to ensure proper operation.

Why is wiring important for precision metal lathes?

Wiring connects all the lathe’s parts, powering the machine and controlling movements. Without it, the machine may stall or run poorly.

Wiring Diagram Basics

Explanation of wiring diagrams: symbols and conventions. Importance of having a proper wiring diagram for troubleshooting.Wiring diagrams are like a treasure map for gadgets, showing how everything connects. They use symbols and conventions to make understanding easier. Think of wires as spaghetti and components as meatballs; without a map, dinner could get messy! Having a good wiring diagram is super important for troubleshooting. It helps find problems quickly, saving time and, let’s be honest, a few headaches.

| Symbol | Meaning |

|---|---|

| ⚫ | Connection point |

| 🔲 | Power supply |

| 🔥 | Switch |

How to Read a Precision Metal Lathe Wiring Diagram

Stepbystep guide on interpreting wiring diagrams. Common symbols found in lathe wiring diagrams.Reading a wiring diagram can feel like learning a secret code. First, find the power source; it’s like the heart of your lathe. Look for common symbols like switches and resistors—they’re the helpful road signs in this electrical maze. Here’s a fun tip: each line usually shows a wire, but twisty lines can play a game of hide and seek! Don’t worry, with practice, you’ll become a wiring pro. Just remember to keep your brain plugged in!

| Symbol | Description |

|---|---|

| ⚫ | Power Source |

| 🔘 | Switch |

| 📏 | Resistor |

| 📡 | Capacitor |

Common Wiring Schematics for Precision Metal Lathes

Examples of typical wiring diagrams for various lathe models. Comparison of different wiring configurations and their applications.Understanding wiring diagrams for lathes can be simple. Each model has its own unique configuration. For example, some common types include:

- **Single-phase wiring:** Used in small lathes. Simple and efficient.

- **Three-phase wiring:** Powerhouses in larger machines. Offers more torque.

- **DC motors:** Great for precision work, allowing smooth control.

These diagrams show how to connect motors, switches, and controls. Comparing these setups helps choose the right one for specific jobs. Make sure to pick the wiring scheme that fits your lathe model best!

What are typical examples of wiring diagrams for lathes?

Typical examples include single-phase and three-phase diagrams. **Single-phase** is simpler and common for smaller lathes, while **three-phase** suits larger machines needing more power.

Safety Precautions in Wiring a Metal Lathe

Essential safety tips when working with lathe wiring. Importance of proper grounding and circuit protection.Working with a metal lathe can be exciting. However, safety is very important. Always wear protective gear like gloves and goggles. Make sure the area is clean and free of clutter. Proper grounding is essential. This prevents electrical shocks. Also, use circuit protection to avoid overloads. It keeps you and the machine safe. Here are some key tips:

- Double-check all connections.

- Do not work with wet hands.

- Keep tools organized and stored safely.

What are essential safety tips for wiring a metal lathe?

Always check connections, wear protective gear, and ensure proper grounding.

Troubleshooting Wiring Issues in Metal Lathes

Common problems and their symptoms. Stepbystep troubleshooting guide.Wiring issues in metal lathes can be a puzzling riddle. Common problems include blown fuses, faulty switches, or damaged wires, all of which can make your lathe as quiet as a mime. Symptoms might show up as strange noises, sparks, or even a complete shutdown. Use this simple checklist to troubleshoot:

| Problem | Symptom | Solution |

|---|---|---|

| Blown fuse | Machine won’t start | Replace the fuse |

| Faulty switch | Buzzing noise | Check and replace the switch |

| Damaged wires | Strange sparks | Inspect and repair wires |

Follow these steps, and you might just outsmart your lathe. Remember, a little patience goes a long way—unless it’s with your wiring, then speed matters!

Upgrading Wiring for Enhanced Lathe Performance

Benefits of upgrading existing wiring systems. Tips for selecting higherquality components.Upgrading the wiring in your lathe can make a big difference. It helps your machine run better and last longer. New wiring can reduce problems like shorts or overheating. Plus, it can give you more power and precision. Selecting higher-quality parts is key. Look for durable wires and strong connectors. These choices can boost performance and safety.

- Check for heat resistance.

- Choose thicker wires for better efficiency.

- Use connectors that fit securely.

What are the benefits of upgrading wiring?

Upgrading the wiring improves safety, enhances performance, and prolongs the life of your lathe. Quality wiring can lead to smoother operations and fewer breakdowns.

FAQs about Precision Metal Lathe Wiring

Answers to frequently asked questions regarding wiring diagrams and setups. Common misconceptions and facts about lathe wiring.Wiring diagrams for precision metal lathes often lead to questions. You might wonder, “Can I use a regular extension cord?” The answer is no. Lathes need strong wires to handle power. Another common myth is that all lathe wiring is the same. It’s not! Different models require unique setups. Some folks fear it’s rocket science, but it’s more like baking a cake—follow the recipe, and you’ll be fine. Grab a good manual, and don’t be afraid to ask for help!

| Question | Answer |

|---|---|

| Can I use a regular extension cord? | No, use specific power cords for lathes. |

| Is all lathe wiring the same? | No, wiring varies by model. |

| Is wiring difficult? | No, follow instructions and ask questions! |

Conclusion

In conclusion, a precision metal lathe wiring diagram is essential for understanding your lathe’s electrical system. It helps you connect wires correctly, ensuring safety and efficiency. We encourage you to find a reliable diagram for your specific model. By understanding this wiring, you can confidently troubleshoot issues and enhance your projects. Keep exploring and learning about lathe maintenance!FAQs

Sure! Here Are Five Related Questions On The Topic Of Precision Metal Lathe Wiring Diagrams:Sure! When we look at precision metal lathe wiring diagrams, we can find out how to connect wires. These diagrams show where each wire goes. You can use them to fix or build machines. They help you understand how everything works together. It’s like following a treasure map to find the hidden treasure!

Sure! I can do that. Just give me the question you want answered, and I’ll write a short response for you.

What Are The Key Components That Need To Be Included In A Precision Metal Lathe Wiring Diagram?In a precision metal lathe wiring diagram, you need to include the power supply, like a plug. It also shows the main switch that turns the lathe on and off. You should add the motor connections that help the lathe spin. Don’t forget the emergency stop button for safety! Finally, label all the wires clearly so you know where they go.

How Do You Interpret The Electrical Symbols Used In A Precision Metal Lathe Wiring Diagram?To understand the electrical symbols on a metal lathe wiring diagram, start by looking at each symbol. Each one stands for a part, like a switch or a motor. You can find a key or legend that explains what each symbol means. If you remember these meanings, it will be easier to figure out how everything connects. You can even draw your own little notes next to the symbols to help you remember!

What Safety Precautions Should Be Taken When Wiring A Precision Metal Lathe?When wiring a precision metal lathe, you should always unplug it first. Wear safety glasses to protect your eyes. Make sure your hands are dry to avoid shocks. Check for any loose wires before turning it on. Lastly, ask an adult for help if you’re unsure.

How Can Troubleshooting Be Approached If The Lathe Does Not Operate Correctly After Wiring It According To The Diagram?If the lathe doesn’t work right after wiring it, we can start by checking the connections. Make sure all the wires are connected like the diagram shows. Next, look for any loose or broken wires that might cause problems. We can also check the power source to see if it’s working. If everything looks good, we might need to test the parts to see if they are broken.

Are There Specific Wiring Diagrams For Different Models Of Precision Metal Lathes, And Where Can They Typically Be Found?Yes, different models of precision metal lathes have their own wiring diagrams. You can often find these diagrams in the machine’s manual. If you don’t have the manual, look online on the manufacturer’s website. Some websites also have forums where other users share helpful information.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Precision Metal Lathe Wiring Diagrams:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When we look at precision metal lathe wiring diagrams, we can find out how to connect wires. These diagrams show where each wire goes. You can use them to fix or build machines. They help you understand how everything works together. It’s like following a treasure map to find the hidden treasure!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! I can do that. Just give me the question you want answered, and I’ll write a short response for you.”}},{“@type”: “Question”,”name”: “What Are The Key Components That Need To Be Included In A Precision Metal Lathe Wiring Diagram?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In a precision metal lathe wiring diagram, you need to include the power supply, like a plug. It also shows the main switch that turns the lathe on and off. You should add the motor connections that help the lathe spin. Don’t forget the emergency stop button for safety! Finally, label all the wires clearly so you know where they go.”}},{“@type”: “Question”,”name”: “How Do You Interpret The Electrical Symbols Used In A Precision Metal Lathe Wiring Diagram?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To understand the electrical symbols on a metal lathe wiring diagram, start by looking at each symbol. Each one stands for a part, like a switch or a motor. You can find a key or legend that explains what each symbol means. If you remember these meanings, it will be easier to figure out how everything connects. You can even draw your own little notes next to the symbols to help you remember!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Wiring A Precision Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When wiring a precision metal lathe, you should always unplug it first. Wear safety glasses to protect your eyes. Make sure your hands are dry to avoid shocks. Check for any loose wires before turning it on. Lastly, ask an adult for help if you’re unsure.”}},{“@type”: “Question”,”name”: “How Can Troubleshooting Be Approached If The Lathe Does Not Operate Correctly After Wiring It According To The Diagram?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the lathe doesn’t work right after wiring it, we can start by checking the connections. Make sure all the wires are connected like the diagram shows. Next, look for any loose or broken wires that might cause problems. We can also check the power source to see if it’s working. If everything looks good, we might need to test the parts to see if they are broken.”}},{“@type”: “Question”,”name”: “Are There Specific Wiring Diagrams For Different Models Of Precision Metal Lathes, And Where Can They Typically Be Found?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, different models of precision metal lathes have their own wiring diagrams. You can often find these diagrams in the machine’s manual. If you don’t have the manual, look online on the manufacturer’s website. Some websites also have forums where other users share helpful information.”}}]}