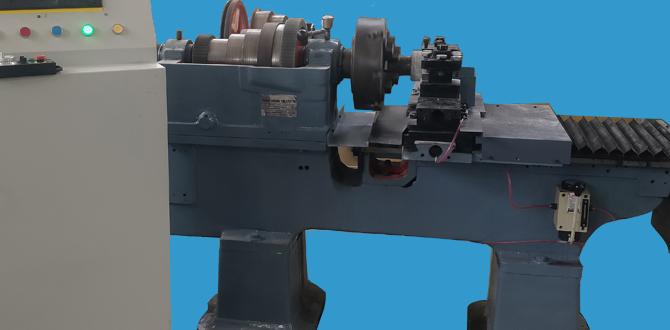

Have you ever thought about turning your old metal lathe into something special? Imagine transforming a simple machine into a powerful CNC tool. Many hobbyists and professionals are doing just that with metal lathe CNC retrofits.

These upgrades can make machining easier and more precise. But how do you know if a retrofit is right for you? With so many options available, finding trustworthy reviews can help you make the best decision.

Did you know that some users saw improved accuracy right away? Upgrading can be like giving your lathe a new life. It’s fascinating to think how a bit of tech can change the game! Let’s dive into what makes these retrofits so popular and why the right review can guide your choice.

Reviews Of Metal Lathe Cnc Retrofit: Upgrading Your Machine

Reviews of Metal Lathe CNC Retrofit

Want to upgrade your metal lathe? Reviews of metal lathe CNC retrofit kits can help. They share real user experiences with different retrofitting options. Many users find that CNC retrofits make lathes more accurate and easier to use. Plus, with several options available, you can choose one that fits your needs. Did you know that a simple retrofit can transform an old lathe into a modern machine? Exploring these reviews might inspire your next project!Understanding CNC Retrofit for Metal Lathes

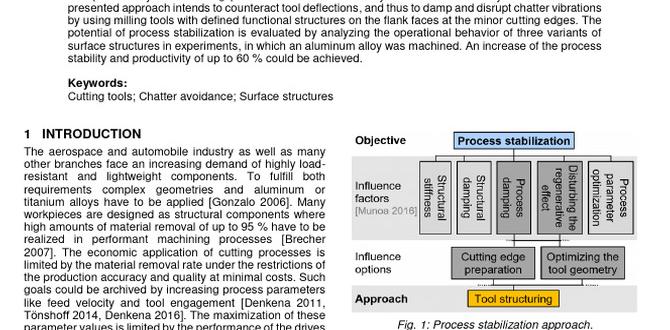

Definition of CNC retrofit and its significance in machining. Common components involved in a metal lathe CNC retrofit.CNC retrofit means upgrading a machine to use computer controls. This change makes metal lathes more efficient and accurate. Many old machines can finally meet modern needs. It’s like giving an old bike a new engine! Here are some key parts for a metal lathe CNC retrofit:

- Stepper motors – They move the machine precisely.

- CNC controller – This is the brain of the machine.

- Lead screws – They help in moving parts smoothly.

- Power supply – Provides the needed energy for operation.

Retrofitting can save money and time. It’s great for businesses that want to upgrade older machines.

What is the importance of CNC retrofit in machining?

CNC retrofit increases efficiency and precision in machining. It allows older machines to handle modern tasks effectively. This upgrade is essential for staying competitive in the industry.

Benefits of Retrofitting a Metal Lathe with CNC

Increased precision and efficiency in machining processes. Costeffectiveness compared to purchasing new CNC machines.Upgrading your metal lathe to CNC brings fantastic benefits. First, it boosts precision and makes machining your desired shapes as easy as pie. Don’t forget about efficiency! This change lets you work faster and smarter. Plus, buying new CNC machines can hurt your wallet. A retrofit saves cash while achieving the same results. Why spend more when you can upgrade what you already own? It’s like turning your trusty bicycle into a speedy e-bike without breaking the bank!

| Benefit | Details |

|---|---|

| Increased Precision | Achieve accurate cuts and shapes. |

| Efficiency | Work faster with less effort. |

| Cost-Effectiveness | Save money by retrofitting, not buying new. |

Top Metal Lathe CNC Retrofit Kits in 2023

Detailed reviews of the most popular CNC retrofit kits available. Key features, specifications, and pricing of each kit.Looking to upgrade your metal lathe? Let’s check out 2023’s top CNC retrofit kits! These kits promise to make your old lathe feel brand new, like a makeover for machines! Here are some popular options:

| Kit Name | Key Features | Price |

|---|---|---|

| Xylotex CNC Retrofit Kit | Easy installation, sturdy design | $399 |

| Dyno CNC Package | Supports multiple lathe sizes, great software | $750 |

| ClearPath Servo System | Quiet operation, high precision | $1,200 |

Each of these kits boasts unique features, making it easy to find one that fits your needs. Whether you want whisper-quiet motors or simple setups, there’s something for everyone! So, get ready for some serious turning action!

Installation Process for Metal Lathe CNC Retrofit Kits

Stepbystep guide on the installation procedure. Common challenges faced during installation and how to overcome them.Installing a CNC retrofit kit for a metal lathe can be exciting. Follow these steps:

- Prepare your workspace. Keep tools handy and clear any clutter.

- Disconnect the lathe from power.

- Remove old parts carefully.

- Attach the new CNC components.

- Connect the wiring as per the instructions.

- Test everything before using the lathe.

You might face some challenges, like misaligned parts or confusing wires. To fix these:

- Double-check all connections.

- Consult the manual for any unclear steps.

- Ask for help if needed.

With patience, you’ll have a working CNC retrofitted lathe!

What are common challenges during installation?

Many face misalignment of parts or incorrect wiring. These can slow you down. It’s best to follow instructions closely to avoid mistakes.

What can I do if parts don’t fit?

If you notice parts don’t fit, check for:

- Right size of the kit

- Proper alignment before connecting

- Any missing components in the package

Real User Experiences and Case Studies

Testimonials from users who have retrofitted their metal lathes. Analysis of productivity improvements after retrofitting.Many users share positive stories about retrofitting their metal lathes. These upgrades can boost performance and efficiency. For example:

- Mark reported a 30% increase in speed after retrofitting his lathe.

- Lisa enjoyed greater precision, cutting errors by half.

- James found he could complete projects faster, doubling his output.

Retrofits help users work smarter. They make tasks easier and improve quality. Enthusiastic testimonials show real benefits of taking this step.

What are some benefits of retrofitting a metal lathe?

Improved speed, enhanced accuracy, and increased productivity are just a few benefits that users experience after retrofitting their metal lathes.

Comparative Analysis of DIY vs. Professional Retrofits

Pros and cons of DIY installations versus hiring a professional. Cost implications and time commitments for both options.Choosing between DIY installations and hiring a professional can feel like picking between a pizza and a taco. Both are tasty but serve different needs! DIY might save you cash, but it takes *time* and a bit of bravery. On the other hand, hiring a pro can cost more, yet you gain expert skills and speedy results—like superheros swooping in to save the day!

| Option | Pros | Cons |

|---|---|---|

| DIY | Cost-effective, fun, skill-building | Time-consuming, potential errors |

| Professional | Fast, expert quality, stress-free | Higher cost, less hands-on |

Statistically, many DIYers admit their projects can double in time and expenses. Remember, it’s all about your comfort zone and how much you value time. Choose wisely, and don’t forget to have fun in the process!

Maintenance Tips for CNC Retrofit Lathes

Best practices for maintaining retrofitted metal lathes. Common issues and troubleshooting tips.Keeping your retrofitted metal lathe in top shape is important. Here are some best practices:

- Clean the machine regularly to remove dust and debris.

- Check for loose wires and connections often.

- Lubricate moving parts to ensure smooth operation.

- Inspect the motor and belts for wear and tear.

- Update software and control systems when needed.

If problems arise, consider these troubleshooting tips:

- Stuck parts? Ensure all components are well-lubricated.

- Uneven cuts? Check alignment and tool sharpness.

- Strange noises? Examine belts and bearings for damage.

By following these tips, you can keep your CNC retrofit lathe running smoothly and efficiently.

What are common issues with CNC retrofit lathes?

Common issues include alignment problems and software glitches. Regular checks can help catch these early.

How often should maintenance be done?

Maintenance should ideally be done weekly. This keeps everything running like new.

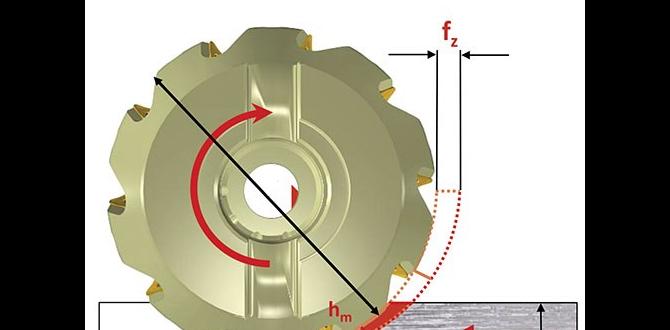

Future Trends in CNC Technology for Metal Lathes

Emerging technologies and innovations in CNC retrofitting. Predictions for the future of metal lathe automation and efficiency.Exciting changes are brewing in the world of CNC technology for metal lathes! New innovations, like smart sensors, are popping up to make retrofitting easier than opening a soda can. These sensors can help machines communicate better, increasing efficiency and boosting productivity. Imagine robots and lathes working together like a well-rehearsed dance team! In the future, we might see an even greater focus on automation, making tasks quicker and more precise.

| Trend | Description |

|---|---|

| Smart Sensors | Devices that enhance communication between machines. |

| Increased Automation | More robots taking over humdrum tasks, freeing up time for creativity! |

With these advancements, the future looks bright for metal lathe users. As technology improves, we might even see machines that can learn and adapt on their own. How cool is that? Get ready to say goodbye to manual errors and hello to a new era of accuracy!

Frequently Asked Questions About CNC Retrofit Kits

Common queries and concerns regarding CNC retrofitting. Expert answers to enhance reader understanding and confidence.People often wonder about CNC retrofit kits. It’s like trying to turn your trusty old bike into a snazzy electric model! Common questions include how difficult the upgrade is. The answer? It’s easier than teaching a cat to fetch! Many also worry about compatibility with their existing machines. Fear not, most kits fit just fine. Another hot topic is cost. While prices vary, think of it as an investment in your future productivity. Going retro means better results in the workshop!

| Question | Answer |

|---|---|

| How hard is installation? | Not hard, more like a fun puzzle! |

| Will it work with my old lathe? | Most likely, yes! |

| How much will it cost? | Depends, but think of it as a wise investment! |

Conclusion

In conclusion, reviews of metal lathe CNC retrofits show many benefits. They improve accuracy and efficiency in machining. You can find affordable options to upgrade your equipment. We encourage you to read more reviews and compare products. Doing this will help you make the best choice for your needs. Enjoy enhancing your workshop with the right retrofit!FAQs

Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Cnc Retrofit:Sure! Here are some common questions about metal lathe CNC retrofit: 1. What is a CNC retrofit? A CNC retrofit updates an old machine with new technology. It helps improve accuracy and speed. 2. Why would I retrofit my metal lathe? Retrofitting makes your metal lathe work better. It can save you time and money on projects. 3. How much does it cost to retrofit a metal lathe? The cost can vary. It usually depends on the parts you need and the work required. 4. Can I do the retrofit myself? Yes, you can! But you might need help if you’re not familiar with machines. 5. What tools do I need for a retrofit? You’ll need basic hand tools, a computer, and the new parts for the machine.

Sure! Please provide the question you would like me to answer.

What Are The Key Benefits Of Retrofitting A Traditional Metal Lathe With Cnc Capabilities?Retrofitting a traditional metal lathe with CNC (Computer Numerical Control) makes it easier to use. You can create complex shapes quickly and accurately. It saves time because you can set it up to work automatically. You also get better quality because it reduces mistakes. Plus, it can help you make more items in less time!

What Components Are Typically Needed For A Successful Cnc Retrofit Of A Metal Lathe?To turn a metal lathe into a CNC (Computer Numerical Control) machine, you need a few important parts. First, you need stepper motors to move the lathe. Next, you need a controller to manage the motors. Then, we need software to tell the machine what to do. Finally, you might want sensors to help with accuracy.

How Does The Cost Of Retrofitting A Metal Lathe Compare To Purchasing A New Cnc Lathe?Retrofitting a metal lathe means adding new parts to make it work like a CNC lathe, which is a machine that cuts metal automatically. This can cost less than buying a brand-new CNC lathe. However, if your old lathe is very old or needs a lot of fixes, it might be better to buy new. We should think about the total cost and how long we’ll use the machine. Sometimes, new machines come with good support and tools, which can be helpful.

What Challenges Might One Encounter During The Retrofitting Process Of A Metal Lathe?When you retrofit a metal lathe, you might face some challenges. First, finding the right parts can be hard. Sometimes, old parts don’t fit new ones, so you may need to change a lot. You also need to be careful to keep everything safe. Finally, learning how to use the new parts can take time and practice.

Can Retrofitting A Metal Lathe Improve Precision And Repeatability In Machining Operations, And If So, How?Yes, retrofitting a metal lathe can make it more precise and repeatable. When we add new parts, the lathe works better. For example, better tools and controls help it cut shapes more accurately. This means you make the same piece exactly the same way each time. Overall, it helps you create better parts more easily.