Have you ever wished to upgrade your workshop? Imagine turning your metal lathe into a modern CNC machine. It sounds exciting, doesn’t it? The process is more accessible than you might think. Many hobbyists have transformed their traditional lathes into powerful CNC tools.

In this setup guide for metal lathe CNC retrofit, we’ll explore how you can do this too. You don’t need to be an expert. With the right steps, you can enjoy the benefits of CNC control. Just think about all the projects you can create with precision and ease!

Did you know that many machines can be converted with just a few parts? This can save you money and give new life to old equipment. Let’s dive in and discover how to turn your metal lathe into a CNC powerhouse!

Comprehensive Setup Guide For Metal Lathe Cnc Retrofit

Setup Guide for Metal Lathe CNC Retrofit

Retrofitting a metal lathe to CNC can seem daunting. Yet, with the right setup guide, it becomes simpler. You’ll learn essential steps like choosing the right components and tools. Discover how to properly install the CNC kit for smooth operation. There’s a surprising fact: retrofitting can boost productivity significantly. Imagine turning your manual lathe into a high-tech machine! Embrace the challenge and watch your projects come to life with precision.Understanding CNC Retrofit Kits

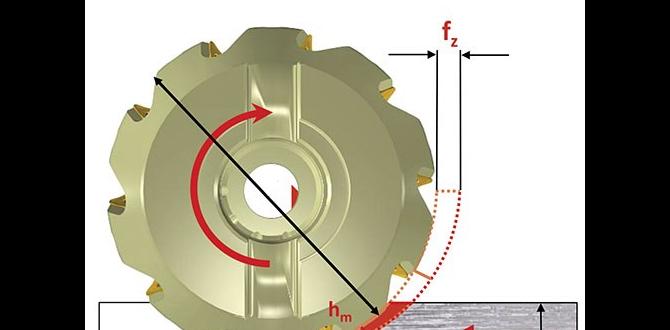

Types of CNC retrofit kits available for metal lathes. Benefits of retrofitting a metal lathe with CNC technology.CNC retrofit kits come in different types for metal lathes. They can help transform old machines into tech-savvy tools. These kits usually include motors, control units, and software. The benefits of retrofitting include:

- Increased precision: CNC lathes are more accurate than manual ones.

- Higher efficiency: Work gets done faster with less effort required.

- Cost savings: Revamping an existing lathe is cheaper than buying new machinery.

Many hobbyists and small businesses see big improvements with CNC retrofits!

What are the benefits of using CNC retrofit kits?

Retrofitting a metal lathe boosts productivity and precision.Selecting the Right Metal Lathe for Retrofit

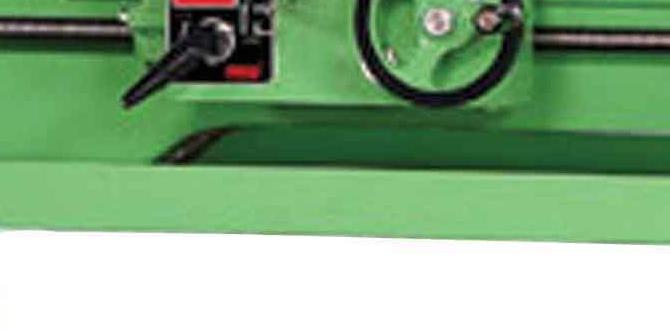

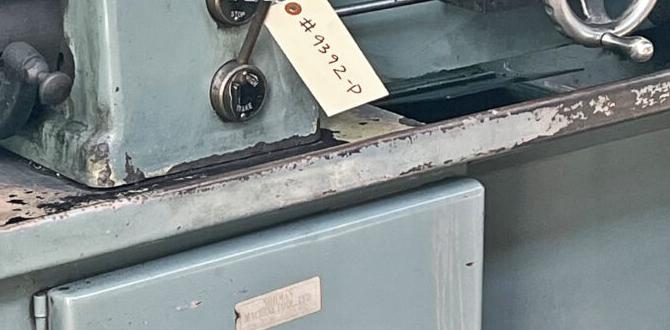

Criteria for choosing a suitable metal lathe for CNC conversion. Popular metal lathe models for retrofitting.Choosing a metal lathe for CNC conversion isn’t just about picking the shiniest one in the shop. Start by looking at its size and weight. A good lathe should be sturdy enough to handle the rigors of CNC work. Popular models for retrofitting include the Grizzly G0602 and the Jet JWL-1442. Both are user-friendly and have great upgrade potential. Think of it like choosing a trusty sidekick for your adventures in machining.

| Lathe Model | Features | Pros |

|---|---|---|

| Grizzly G0602 | Heavy-duty, 10″ swing | Stable, easy to modify |

| Jet JWL-1442 | Variable speed, versatile | User-friendly, reliable |

Make sure your chosen lathe matches your project needs. After all, you want it to spin, not to spin out of control!

Essential Tools and Materials Needed

List of tools required for the retrofit process. Materials and components to consider.To start your retrofitting project, you need some important tools and materials. Here’s a quick list:

- Wrenches and screwdrivers

- Measuring tape

- Power supply

- Cables and connectors

- Stepper motors

- Control board

Also, consider these components for your setup:

- Computer with CNC software

- Metal lathe

- Mounting brackets

These tools will help you make your metal lathe shine!

What tools do you need for retrofitting?

You need basic tools like wrenches and screwdrivers. A good measuring tape is also key. Don’t forget the power supply and steppers! Each item helps your project go smoothly.

Step-by-Step CNC Retrofit Process

Disassembling the metal lathe and preparing for retrofit. Installing CNC components, including motors and controllers.Start by carefully taking apart the metal lathe. Keep track of all the pieces. This helps later when putting everything back together. Next, prepare the machine for new tools. Install CNC components like motors and controllers. These parts will help the lathe run automatically. Follow the steps closely for a successful retrofit.

- Disassemble metal lathe.

- Organize all parts.

- Install CNC motors.

- Connect controllers.

What is the CNC retrofit process?

The CNC retrofit process upgrades older machines to use modern technology. This makes them faster and more precise. Many schools and workshops find this helpful.

Calibration and Testing

Techniques for calibrating the retrofitted metal lathe. Test runs and troubleshooting common issues.Calibrating your retrofitted metal lathe is like tuning a guitar—get it right, and it sings! Start by adjusting the axes. A simple ruler can help measure distance accurately. Run a few test cuts on scrap metal to see how it performs. If something feels off, check the drive belts; they might just be having a lazy day! Here’s a little table to help you troubleshoot:

| Issue | Solution |

|---|---|

| Wobbly Cuts | Check for loose joints or uneven surfaces. |

| Unusual Noises | Inspect bearings and lubrication levels. |

| Poor Surface Finish | Adjust cutting speed and tool sharpness. |

Remember, even the best machines need a little love and attention! Happy machining!

Safety Considerations

Important safety guidelines for operating a retrofitted CNC lathe. Safety gear and precautions during the conversion process.Working with a CNC lathe can be fun, but safety is important. Always wear the proper safety gear. This helps protect you from accidents. Here are some key safety tips:

- Wear goggles to protect your eyes.

- Use gloves to avoid cuts.

- Keep long hair tied back.

- Ensure the area is clean to avoid slips.

- Read the manual carefully before starting.

Remember, a safe workspace keeps everyone safe!

What safety gear do I need when retrofitting a CNC lathe?

You will need goggles, gloves, and ear protection. These items keep you safe from flying debris and loud noise.

Maintaining Your CNC Retrofit Metal Lathe

Longterm maintenance tips to ensure longevity and performance. Common repairs and troubleshooting techniques postretrofit.Keeping your CNC retrofit metal lathe in top shape is important. Regular checks can help it last longer and work better. Here are some simple but effective maintenance tips:

- Clean the machine after each use.

- Check for loose screws and tighten them.

- Lubricate moving parts regularly.

- Test the software often for updates.

If something goes wrong, don’t worry. Many issues are easy to solve. For example, if the machine stops, check the power supply. If it makes strange noises, look for debris inside. Regular care keeps your lathe running smoothly and extends its life.

What are common repairs for CNC lathes?

Common repairs include fixing wiring issues, replacing worn-out bearings, and adjusting alignment. These fixes can often be done at home with the right tools.

Conclusion

In conclusion, a CNC retrofit for your metal lathe can enhance its capabilities and efficiency. You gain precision, speed, and automation. Start by researching compatible kits and tools. Gather resources, like online guides and forums, for support. Don’t hesitate to ask for help if needed. Get ready to transform your lathe and take your projects to the next level!FAQs

Sure! Here Are Five Related Questions On The Topic Of Setting Up A Metal Lathe Cnc Retrofit:Sure! Here are some questions about setting up a metal lathe CNC retrofit: 1. What is a CNC retrofit? It means changing a regular lathe to be controlled by a computer. 2. Why would you want to do a CNC retrofit? It helps you make things more accurately and quickly. 3. What tools do you need for this project? You will need a CNC kit, basic tools, and safety gear. 4. How long does it take to set up? It can take a few hours to a few days, depending on your skills. 5. Do you need to practice first? Yes, it’s a good idea to practice on a smaller project before starting.

Sure! Please ask your question, and I’ll give you a clear and simple answer.

What Are The Essential Components Needed For A Successful Cnc Retrofit Of A Metal Lathe?To make a metal lathe work with a CNC system, you need a few important parts. First, you will need a good computer or controller to send commands. Next, you should get motors that move the lathe parts smoothly. You will also need sensors to help the system know where it is. Lastly, don’t forget the software that lets you design and control your projects.

How Do You Determine The Appropriate Stepper Or Servo Motors For Your Specific Lathe Model During The Retrofit Process?To choose the right stepper or servo motors for your lathe, first, check how much power your lathe needs. Then, look at the size of the motors. You can find this information in the lathe’s manual or online. After that, think about how fast and accurate you want it to move. Finally, compare different motors and pick the ones that match your lathe’s needs best.

What Software Options Are Available For Controlling A Retrofitted Cnc Metal Lathe, And How Do You Choose The Right One?You can use different software to control a CNC metal lathe that you have changed. Some popular options are Mach3, LinuxCNC, and GRBL. To pick the right one, think about what you want to do. Check if it works with your computer and if it is easy to use. Look for tutorials and community help, too!

What Are The Common Challenges Faced During A Metal Lathe Cnc Retrofit, And How Can They Be Overcome?When we change a metal lathe to use a Computer Numerical Control (CNC), we face several problems. First, fitting new parts can be tricky because they might not match exactly. We can solve this by measuring carefully and sometimes changing the part size. Second, learning to use new software can be hard. To help with this, we should take our time and practice. Finally, getting everything to work together smoothly can be tough. We can fix this by testing each part step by step.

How Can You Ensure Accuracy And Repeatability After Completing The Retrofitting Process On A Metal Lathe?To ensure accuracy and repeatability after retrofitting a metal lathe, you should first check all the parts. Make sure everything is tightly connected and properly aligned. Next, run a test piece and measure it carefully. If it meets your measurements, you can trust your lathe. Always adjust and test again if needed.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Setting Up A Metal Lathe Cnc Retrofit:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some questions about setting up a metal lathe CNC retrofit: 1. What is a CNC retrofit? It means changing a regular lathe to be controlled by a computer. 2. Why would you want to do a CNC retrofit? It helps you make things more accurately and quickly. 3. What tools do you need for this project? You will need a CNC kit, basic tools, and safety gear. 4. How long does it take to set up? It can take a few hours to a few days, depending on your skills. 5. Do you need to practice first? Yes, it’s a good idea to practice on a smaller project before starting.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll give you a clear and simple answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Components Needed For A Successful Cnc Retrofit Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a metal lathe work with a CNC system, you need a few important parts. First, you will need a good computer or controller to send commands. Next, you should get motors that move the lathe parts smoothly. You will also need sensors to help the system know where it is. Lastly, don’t forget the software that lets you design and control your projects.”}},{“@type”: “Question”,”name”: “How Do You Determine The Appropriate Stepper Or Servo Motors For Your Specific Lathe Model During The Retrofit Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right stepper or servo motors for your lathe, first, check how much power your lathe needs. Then, look at the size of the motors. You can find this information in the lathe’s manual or online. After that, think about how fast and accurate you want it to move. Finally, compare different motors and pick the ones that match your lathe’s needs best.”}},{“@type”: “Question”,”name”: “What Software Options Are Available For Controlling A Retrofitted Cnc Metal Lathe, And How Do You Choose The Right One?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use different software to control a CNC metal lathe that you have changed. Some popular options are Mach3, LinuxCNC, and GRBL. To pick the right one, think about what you want to do. Check if it works with your computer and if it is easy to use. Look for tutorials and community help, too!”}},{“@type”: “Question”,”name”: “What Are The Common Challenges Faced During A Metal Lathe Cnc Retrofit, And How Can They Be Overcome?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we change a metal lathe to use a Computer Numerical Control (CNC), we face several problems. First, fitting new parts can be tricky because they might not match exactly. We can solve this by measuring carefully and sometimes changing the part size. Second, learning to use new software can be hard. To help with this, we should take our time and practice. Finally, getting everything to work together smoothly can be tough. We can fix this by testing each part step by step.”}},{“@type”: “Question”,”name”: “How Can You Ensure Accuracy And Repeatability After Completing The Retrofitting Process On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To ensure accuracy and repeatability after retrofitting a metal lathe, you should first check all the parts. Make sure everything is tightly connected and properly aligned. Next, run a test piece and measure it carefully. If it meets your measurements, you can trust your lathe. Always adjust and test again if needed.”}}]}