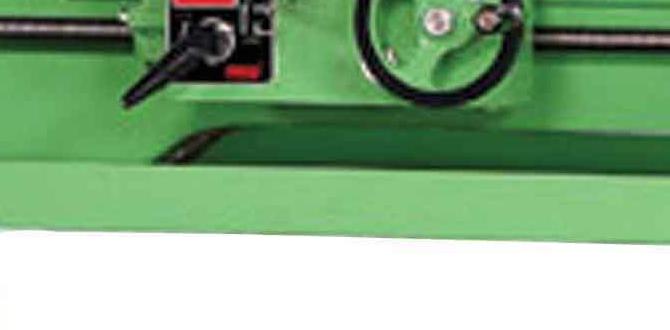

Have you ever looked at a metal lathe and wondered how it works? These machines can create amazing things from solid metal. But to get the best results, you need to set it up correctly. The compound rest is a key part of a metal lathe. It helps in making precise cuts. Getting it right can feel like magic!

Imagine starting your first project with a metal lathe. You may think it’s complicated, but setting up the compound rest is easier than you think. Once it’s in place, you’ll feel like a true craftsman. Did you know that some of the best engineers started with small lathe projects? It’s true! With the right setup guide, you can join them.

This article is here to help you. We will walk you through a simple setup guide for the metal lathe compound rest. With each step, you’ll gain confidence and skill. Ready to bring your metalworking dreams to life? Let’s get started!

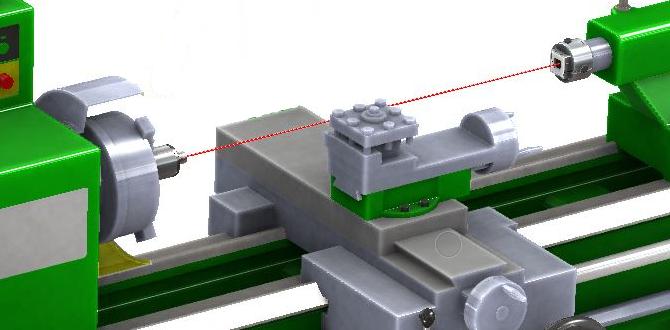

Setup Guide: Metal Lathe Compound Rest Installation Tips

Setup Guide for Metal Lathe Compound Rest

Setting up a metal lathe’s compound rest may seem tricky. However, with some basic steps, it can be done easily. Learn how to align the rest for precision cuts and improve your projects. Did you know that a well-aligned compound rest can enhance accuracy in metalwork? This guide helps you understand angles and adjustments to make your lathe experience smoother and more enjoyable. With patience and practice, you’ll master this important tool in no time!Understanding the Metal Lathe Compound Rest

Definition and purpose of a compound rest in metal lathes. Importance in precision machining and turning operations.A compound rest is a fancy part of a metal lathe. Think of it as a “super-duper” holder for tools. Its job is to help position the cutting tools at different angles. This makes it easier to create precise shapes on metal. When you need accuracy in machining, this part is a must-have. Without it, your projects might end up more wobbly than your neighbor’s home-built treehouse! So, having a trusty compound rest means your turning operations can be smooth and spot-on.

| Function | Importance |

|---|---|

| Holds cutting tools | Ensures precision |

| Adjusts angles | Facilitates complex shapes |

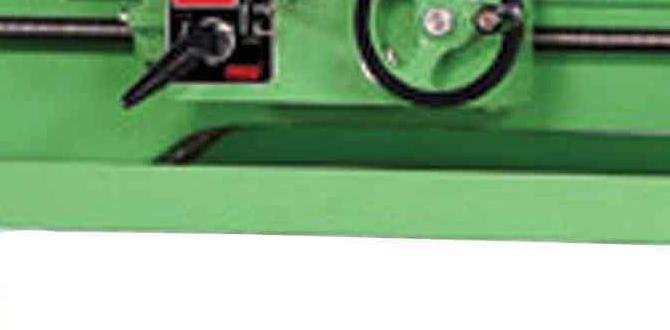

Components of the Metal Lathe Compound Rest

Description of major components: cross slide, top slide, handwheel. How each component contributes to functionality and accuracy.The metal lathe compound rest is like a superhero in your workshop. It has three main parts: the cross slide, the top slide, and the handwheel. The cross slide moves left and right, making sure you cut just where you want. The top slide tilts and angles, adding extra tricks to your shaping game. Finally, the handwheel provides smooth, controlled movements. Together, they keep your work precise. Think of them as the dynamic trio—like the Three Musketeers, but with more metal and fewer swords!

| Component | Function |

|---|---|

| Cross Slide | Moves side to side for precise cuts |

| Top Slide | Tilts for angled work |

| Handwheel | Controls movement efficiently |

Preparation Before Setup

Necessary tools and equipment for setup. Safety precautions to follow before operating the lathe.Before you start, gather your necessary tools. A wrench, a screwdriver, and a level are essential. These items help everything fit together nicely. Without them, you might have more trouble than a cat in a dog park!

Now, let’s talk safety. Always wear goggles to protect your eyes from flying chips. Keep your hair tied back. You don’t want it getting caught in the machine. Ensure your workspace is neat. A clean area is a happy area!

| Tools/Equipment | Purpose |

|---|---|

| Wrench | Loosens or tightens bolts |

| Screwdriver | Assembles parts securely |

| Level | Ensures everything is straight |

Remember, safety first, fun second! Following these steps will help you start smoothly.

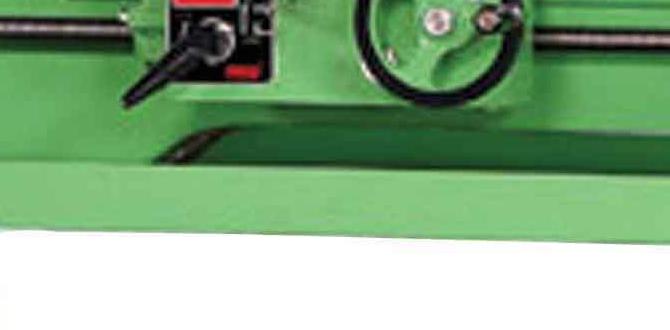

Step-by-Step Setup Process

Detailed steps for assembling the compound rest. Adjustment techniques to ensure proper alignment and function.Setting up a compound rest can be easy with clear steps. First, gather all parts. Then, follow these steps:

- Attach the base to the lathe bed.

- Fix the slide to the base.

- Attach the tool holder to the slide.

After assembly, check the alignment. Adjust by using a square to ensure that the tool holder is level. This helps with precision. Small changes can improve accuracy. Proper setup makes your work smooth and enjoyable!

What is the best way to align the compound rest?

Use a square tool to check for levelness. Adjust the height by turning screws until it’s perfect.

Common Issues and Troubleshooting

Identifying common problems during setup. Effective solutions and adjustments to improve performance.Setting up a metal lathe can be tricky. You may face some common problems early on. For example, if the tool isn’t cutting well, check the angle of the compound rest. A wrong angle can lead to poor cuts. Another issue might be vibration during use. This can result from loose parts or an uneven surface. Ensure everything is secure. Here are some tips:

- Check alignment regularly.

- Adjust the speed for better performance.

- Tighten loose screws to reduce vibrations.

These small adjustments can greatly improve your lathe’s performance.

What should I do if my metal lathe is not cutting properly?

Ensure the tool angle is correct, check for dull blades, and adjust the speed if needed.

How do I reduce vibration on my metal lathe?

To minimize vibration, tighten any loose parts and set the lathe on a sturdy, level surface.

Maintenance Tips for Longevity

Recommended maintenance practices for the compound rest. Importance of lubrication and regular inspections.Keeping your compound rest in tip-top shape is like giving your lathe a mini spa day! Regular maintenance is key. Check for wear and tear, and remember: a little lubrication goes a long way. This helps parts move smoothly and prevents problems down the road. Check out the table below for quick tips on care:

| Task | Frequency |

|---|---|

| Lubricate Moving Parts | Every use |

| Inspect for Damage | Weekly |

| Clean Residue | After Each Project |

Don’t let dirt and grime crash the party! Regularly check and clean your lathe to ensure a long life. Remember: if your compound rest is happy, you’ll be happy, too!

Advanced Techniques Utilizing the Compound Rest

Techniques to enhance precision and efficiency in machining. Tips for skilled operators on maximizing the compound rest’s potential.When using the compound rest, there are advanced techniques to improve both precision and efficiency. Skilled operators can increase their machining skills by following these tips:

- Keep the compound rest clean. Dust affects accuracy.

- Regularly check the alignment to ensure proper cuts.

- Use the right cutting tools for different materials.

- Practice feed rates to achieve smooth finishes.

By mastering these techniques, operators can unlock the full potential of the compound rest. This will lead to better results and more enjoyable machining.

How can you improve machining precision with the compound rest?

Regular maintenance and proper tool selection are key. Proper care allows for smooth operation and precise cuts. Focusing on these aspects can greatly impact your results.

Comparing Compound Rests on Different Metal Lathes

Variation between different brands and models. Key features to look for when choosing a compound rest.Different brands and models of metal lathes have unique compound rests. These variations affect how you can use your lathe. When choosing a compound rest, consider these key features:

- Adjustment ease: Can it be easily adjusted for different angles?

- Material quality: Is it strong and durable?

- Size compatibility: Will it fit your lathe model?

- Grip strength: Does it hold securely in place?

Finding the right compound rest will make your work smoother and more precise.

What should I look for in a compound rest?

Look for ease of adjustment, strong materials, and proper fit with your lathe. These features make working easier and more efficient.

Conclusion

In summary, a setup guide for a metal lathe compound rest helps you position tools accurately. Proper setup improves your projects and makes them easier. Start with clean surfaces and check all adjustments. Don’t hesitate to refer back to the guide as you work. Keep practicing and exploring resources to enhance your skills. You’re on your way to mastering metal lathes!FAQs

Sure! Here Are Five Related Questions On Setting Up A Metal Lathe Compound Rest:Sure! Here are five questions you might ask when setting up a metal lathe compound rest: 1. What is a metal lathe compound rest? It is a part of the lathe that helps you move and cut the metal smoothly. 2. How do I adjust the compound rest? You can loosen the knobs, move the rest to the right spot, and then tighten the knobs again. 3. Why is it important to set it correctly? If it’s not set right, your cuts won’t be straight, and the piece may not fit together well. 4. What tools do I need to set it up? You will need a wrench for the knobs and possibly a ruler for measuring. 5. How can I check if it’s set correctly? Look at your cut. It should be straight and level with the rest of the metal piece.

Sure! Please provide the question you’d like me to answer.

What Are The Essential Tools Required For Setting Up The Compound Rest On A Metal Lathe?To set up the compound rest on a metal lathe, you need a few important tools. First, you’ll need a wrench to tighten the screws. Next, a screwdriver helps you adjust and secure parts. A ruler or caliper measures distances accurately. Finally, a level makes sure everything is straight and balanced. With these tools, you can set up the compound rest easily!

How Do You Align The Compound Rest To Ensure Accurate Machining On A Metal Lathe?To align the compound rest on a metal lathe, you first need to check that the lathe is level. Then, you adjust the compound rest so it is straight and square to the main part of the lathe. You can use a square tool to make sure everything lines up correctly. Finally, tighten the screws so it stays in place. This helps make sure your cuts are accurate.

What Are The Steps To Adjust The Angle Of The Compound Rest For Taper Turning On A Metal Lathe?To adjust the angle of the compound rest for taper turning, first, you need to loosen the locking screws on the rest. Then, you tilt the compound rest to the angle you want. Make sure to check the angle with a protractor if you can. After that, tighten the locking screws back in place. Now, you’re ready to start taper turning!

How Can You Determine The Correct Height For The Compound Rest In Relation To The Workpiece On A Metal Lathe?To find the right height for the compound rest on a metal lathe, we can use a simple method. First, place the workpiece on the lathe. Next, raise or lower the compound rest until its cutting tool is at the same height as the center of the workpiece. This way, we make sure the tool cuts smoothly and evenly. Finally, make any small adjustments if needed.

What Common Mistakes Should Be Avoided When Setting Up The Compound Rest On A Metal Lathe?When you set up the compound rest on a metal lathe, make sure it’s level. If it’s not, your cuts will be uneven. Check the angles carefully; wrong angles can ruin your work. Also, tighten everything securely to avoid movement while you cut. Finally, always measure twice before you start cutting to avoid mistakes.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On Setting Up A Metal Lathe Compound Rest:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions you might ask when setting up a metal lathe compound rest: 1. What is a metal lathe compound rest? It is a part of the lathe that helps you move and cut the metal smoothly. 2. How do I adjust the compound rest? You can loosen the knobs, move the rest to the right spot, and then tighten the knobs again. 3. Why is it important to set it correctly? If it’s not set right, your cuts won’t be straight, and the piece may not fit together well. 4. What tools do I need to set it up? You will need a wrench for the knobs and possibly a ruler for measuring. 5. How can I check if it’s set correctly? Look at your cut. It should be straight and level with the rest of the metal piece.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Tools Required For Setting Up The Compound Rest On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up the compound rest on a metal lathe, you need a few important tools. First, you’ll need a wrench to tighten the screws. Next, a screwdriver helps you adjust and secure parts. A ruler or caliper measures distances accurately. Finally, a level makes sure everything is straight and balanced. With these tools, you can set up the compound rest easily!”}},{“@type”: “Question”,”name”: “How Do You Align The Compound Rest To Ensure Accurate Machining On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the compound rest on a metal lathe, you first need to check that the lathe is level. Then, you adjust the compound rest so it is straight and square to the main part of the lathe. You can use a square tool to make sure everything lines up correctly. Finally, tighten the screws so it stays in place. This helps make sure your cuts are accurate.”}},{“@type”: “Question”,”name”: “What Are The Steps To Adjust The Angle Of The Compound Rest For Taper Turning On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the angle of the compound rest for taper turning, first, you need to loosen the locking screws on the rest. Then, you tilt the compound rest to the angle you want. Make sure to check the angle with a protractor if you can. After that, tighten the locking screws back in place. Now, you’re ready to start taper turning!”}},{“@type”: “Question”,”name”: “How Can You Determine The Correct Height For The Compound Rest In Relation To The Workpiece On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right height for the compound rest on a metal lathe, we can use a simple method. First, place the workpiece on the lathe. Next, raise or lower the compound rest until its cutting tool is at the same height as the center of the workpiece. This way, we make sure the tool cuts smoothly and evenly. Finally, make any small adjustments if needed.”}},{“@type”: “Question”,”name”: “What Common Mistakes Should Be Avoided When Setting Up The Compound Rest On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you set up the compound rest on a metal lathe, make sure it’s level. If it’s not, your cuts will be uneven. Check the angles carefully; wrong angles can ruin your work. Also, tighten everything securely to avoid movement while you cut. Finally, always measure twice before you start cutting to avoid mistakes.”}}]}