Have you ever wondered how metal lathes create precise shapes and parts? Understanding how to set up a metal lathe gear train can make all the difference. It’s like setting the gears in a bike to get the perfect speed. Every part needs to work together smoothly.

Imagine the excitement of taking raw metal and turning it into something useful. That’s the magic of a metal lathe. The gear train is key to this process. It powers the machine and helps it spin at just the right speed.

You might think that setting up a metal lathe gear train is too complex. But fear not! With the right guide, it can be as easy as pie. In this article, we will break it down step by step. You will be amazed at how simple it can be!

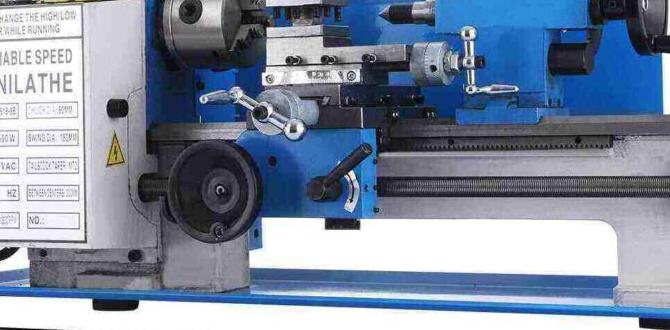

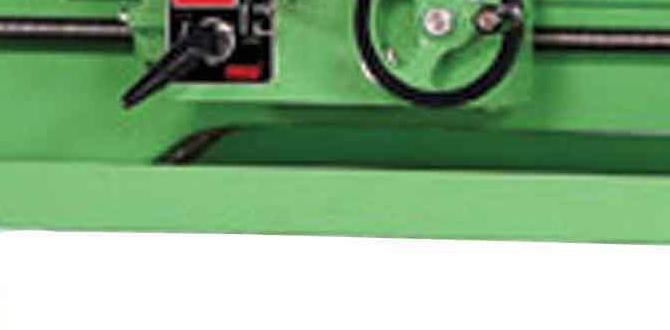

Complete Setup Guide For Metal Lathe Gear Train Adjustments When It Comes To Metalworking, A Gear Train In A Lathe Is An Essential Component That Can Significantly Affect The Machine’S Performance. Understanding How To Set It Up Correctly Is Crucial For Achieving Precision In Your Milling And Turning Tasks. This Setup Guide Will Walk You Through The Necessary Steps And Tips For Successfully Configuring The Gear Train In Your Metal Lathe. What Is A Gear Train In A Metal Lathe? A Gear Train In A Metal Lathe Refers To A Series Of Gears That Work Together To Transmit Power And Adjust The Spindle Speed And Feed Rate. They Allow The Operator To Adapt The Lathe’S Operation For Different Materials And Types Of Cuts. Proper Setup And Adjustment Of The Gear Train Can Lead To Improved Efficiency And Better-Quality Finished Products. Tools You Will Need Before Starting Your Setup, Gather The Necessary Tools Including: – Wrenches (Various Sizes) – Screwdrivers (Flat And Phillips) – Lubricants – Measuring Tools (Calipers, Ruler) – Safety Equipment (Gloves, Goggles) Step-By-Step Setup Guide 1. **Safety First**: Make Sure To Wear The Appropriate Safety Gear And Ensure That The Lathe Is Turned Off And Unplugged Before Starting Any Setup Procedures. 2. **Identify The Gear Train Components**: Familiarize Yourself With The Various Gears, Levers, And Adjustment Points On Your Lathe. Refer To The Machine’S Manual For A Detailed Diagram. 3. **Check And Clean Gears**: Inspect The Gears For Wear And Debris. Clean Them Thoroughly Before Continuing, As Dirt Can Affect Their Performance. 4. **Adjust Gear Ratios**: Set The Desired Gear Ratios According To Your Project Requirements. This Step Will Typically Involve Switching Gears Or Adjusting Settings On The Lathe Itself. 5. **Lubricate Moving Parts**: Apply A Suitable Lubricant To The Gear Train To Minimize Friction And Wear. Follow The Manufacturer’S Recommendations On The Type Of Lubricant To Use. 6. **Test The Setup**: Once Adjustments Are Made, Do A Test Run On Scrap Material. Monitor The Lathe’S Noise And Vibration For Any Signs Of Misalignment. 7. **Fine-Tune As Necessary**: If The Lathe Is Still Not Performing To Expectations, Revisit The Adjustments And Tweak The Gear Ratios Until Optimal Performance Is Reached. Common Issues And Troubleshooting Some Common Issues You Might Encounter Include: – **Incorrect Speed**: This Can Often Be Resolved By Adjusting The Gear Selection. – **Unusual Noises**: Check For Loose Parts Or Misaligned Gears. – **Inconsistent Feeding**: Ensure That The Feed Rate Adjustment Is Correctly Set. Maintenance Tips Regular Maintenance Will Ensure Longevity And Reliability Of Your Gear Train: – Regularly Clean And Inspect Gears. – Replace Worn-Out Or Damaged Gears Immediately. – Keep Lubrication Levels Checked And Adequate. Conclusion Setting Up The Gear Train On Your Metal Lathe Is A Crucial Skill That Can Greatly Enhance Your Machining Capabilities. By Following This Setup Guide, You’Ll Be Able To Configure Your Lathe For Optimal Performance, Whether You’Re A Hobbyist Or A Professional Machinist. Always Remember To Prioritize Safety And Maintenance For A Smooth And Effective Operation.

Setup Guide Metal Lathe Gear Train

Understanding the metal lathe gear train is crucial for any aspiring machinist. This setup guide covers the basic components and functions of the gear train, offering clear steps to arrange them for optimal performance. Did you know that a well-organized gear train can enhance your lathe’s efficiency and precision? By learning how to correctly position each gear, you can significantly improve your project outcomes. Dive into the world of metalworking and unlock the secrets of smooth machining!Understanding the Basics of Gear Trains

Definition and purpose of gear trains in metal lathes. Types of gear configurations commonly used in metal lathe setups.Gear trains in metal lathes are like the superheroes of machining. They help transfer power from the motor to the spindle, making sure everything runs smoothly. Think of them as a team of gears working together to change speed and torque. Common types include simple, which link together easily, and compound, where gears are stacked for extra awesomeness. Here’s a look at a few popular configurations:

| Type of Gear Configuration | Purpose |

|---|---|

| Simple | Used for basic, straightforward tasks. |

| Compound | Ideal for complex operations requiring multiple speeds. |

| Reversing | Allows for forward and backward movement. |

Understanding these basics is key, and who knows—you might even make gears your new best friends!

Components of a Metal Lathe Gear Train

Detailed description of key components (gears, pulleys, belts). Importance of each component in achieving desired machining results.The metal lathe gear train includes important parts like gears, pulleys, and belts. Each part works together to help shape metal accurately. Here’s how they contribute:

- Gears: They change the direction and speed of the lathe. The right gear helps create smooth cuts.

- Pulleys: Pulled by belts, they transfer motion from the motor to the spindle. Proper pulley size affects speed control.

- Belts: They connect the motor to the pulleys. Good condition is key for efficient movement.

These components work in harmony to achieve the desired machining results. When parts are well-maintained, it leads to better performance and longer life for the lathe.

What is the importance of gears in a metal lathe?

Gears are crucial because they determine how fast or slow the lathe turns. They help adjust cutting speeds to match different materials. This ensures precise shaping of metal.

Why are pulleys needed in a metal lathe setup?

Pulleys are essential for changing the direction of the drive belt. They enable smooth transitions for power from the motor to the lathe. This allows for consistent operation and control.

What role do belts play in a lathe’s function?

Belts play a vital role by connecting the motor and pulleys. They transfer power effectively. If a belt wears out, it can cause problems in the lathe’s operation.

Step-by-Step Setup Process

Initial preparations before setting up the gear train. Detailed walkthrough of assembling the gear train components.Before setting up the gear train, you need to make some initial preparations. First, gather all your tools and gear parts. Check for any missing pieces. You don’t want to start your masterpiece only to realize you’re missing that one tiny screw! Once you’re ready, follow these steps:

| Step | Description |

|---|---|

| 1 | Align the base securely and level it, like a skateboarder finding the perfect ramp. |

| 2 | Attach the main gears carefully, ensuring they mesh smoothly—like two best friends in sync! |

| 3 | Connect the drive gears and check the tension. Not too loose, not too tight—like a good hug. |

| 4 | Finally, double-check everything. If it shakes, it might just want to dance, but we want it to work! |

Follow these steps for a successful setup, and you’ll be ready to craft those amazing gears. Happy turning!

Adjusting Gear Ratios for Optimal Performance

How to calculate and select the appropriate gear ratios. Effects of different gear ratios on cutting speed and feed rate.Finding the right gear ratio is like choosing the perfect pizza toppings—get it wrong, and you end up with a messy situation! To calculate the right ratio, divide the number of teeth on the driven gear by the number of teeth on the drive gear. Gear ratios affect cutting speed and feed rate. A high gear ratio means faster cutting but might lead to a rough finish. A low ratio gives a smoother cut but is slower. Balance is key!

| Gear Ratio | Cutting Speed | Feed Rate |

|---|---|---|

| High (e.g., 4:1) | Fast | Slow |

| Low (e.g., 1:4) | Slow | Fast |

In summary, selecting the right gear ratio is all about finding your sweet spot. A little math can make your lathe work wonders!

Troubleshooting Common Gear Train Issues

Identifying and resolving common issues during setup. Maintenance tips to prevent gear train problems.Setting up your metal lathe gear train can sometimes lead to problems. Look out for some common issues. A loose fitting can cause noise. Gears might not mesh well, leading to grinding sounds. Regular cleaning helps, too. Dirt can cause friction and wear. Check gear lubrication often. Proper oil keeps everything running smoothly. Always refer to your manual for specific guidance.

How do you troubleshoot gear train issues?

To troubleshoot gear train issues, first check for loose parts. Then, ensure proper lubrication. Clean the gears to avoid friction. If the problem persists, refer to the user manual for further help.

Maintenance Tips

- Keep gears clean and free of dirt.

- Regularly check for loose bolts.

- Lubricate the gears often.

- Inspect for wear and tear.

Accessories to Enhance Gear Train Functionality

Recommended accessories to boost gear train efficiency. Benefits of using advanced tools and gadgets with the gear train.Having fun with your metal lathe gear train is easier with some handy accessories! Special tools can really boost efficiency, making your projects smoother. For instance, including precision gears can help with accuracy, while dampers can keep vibrations down, making your machine shine. Plus, cool gadgets like digital readouts ensure you get exact measurements, saving time and materials. Why mess up when you can gear up?

| Accessory | Benefit |

|---|---|

| Precision Gears | Improved accuracy |

| Dampers | Reduced vibrations |

| Digital Readouts | Exact measurements |

Safety Tips When Working with Metal Lathes

Essential safety precautions during gear train setup. Best practices for safe operation of metal lathes.Safety comes first in the metal lathe world! Always wear protective goggles to keep those pesky metal shavings out of your eyes. Don’t forget gloves—they’re not just for cooking. Make sure your workspace is clean and organized; nobody wants to trip over that snack wrapper from last week! Check the gear train before starting. A loose gear is like a cat on a hot tin roof—it’s bound to cause chaos!

| Precaution | Description |

|---|---|

| Wear Protective Gear | Use goggles and gloves to protect yourself. |

| Keep Area Tidy | Clear away clutter to prevent accidents. |

| Check Equipment | Inspect gears and tools for safety before use. |

By following these simple tips, you’ll keep yourself and others safe while having fun with your metal lathe. Always remember, it’s better to be safe than sorry—unless you’re a chicken, then it’s just a lifestyle!

Maintenance and Upkeep for Longevity

Routine maintenance procedures for gear train components. Signs of wear to watch out for and when to replace parts.Keeping your gear train in good shape is important for long-lasting performance. Here are some routines to follow:

- Check for loose screws and tight connections regularly.

- Grease moving parts to reduce friction.

- Inspect gears for chips or cracks.

- Clean dust and grime with a soft cloth.

Look for these signs of wear:

- Noisy operation might mean something is wrong.

- Worn gears can lead to slipping.

- Feeling too much vibration is a warning.

If you notice these issues, it may be time to replace the worn parts. Regular checks and quick fixes help keep your gear train running smoothly.

What are the best practices for gear train maintenance?

Best practices include regular cleaning, lubrication, and thorough inspections for signs of wear. Follow these steps for longevity!

Conclusion

In summary, a setup guide for a metal lathe gear train helps you understand how to configure and use it effectively. We learned about gear arrangements, adjustments, and maintenance tips. Now, you can confidently get started on your projects. For more detailed information, explore additional resources or tutorials to deepen your knowledge and skills. Happy turning!FAQs

Here Are Five Related Questions On The Topic Of Setting Up A Metal Lathe Gear Train:To set up a metal lathe gear train, you first need to choose the right gears. Make sure they fit well together. Then, you should align them properly so they can turn easily. Check that everything is tight and secure. Finally, test the lathe to make sure it works smoothly.

Sure! Just ask your question, and I will provide a short, simple answer for you.

What Are The Key Components Of A Metal Lathe Gear Train, And How Do They Work Together To Facilitate Turning Operations?A metal lathe gear train has a few important parts. These include gears, pulleys, and belts. Gears help change the speed and direction of the lathe’s movement. When you turn the handle, the gears work together to spin the piece of metal. This makes it easier for us to shape and cut the metal smoothly.

How Do You Determine The Appropriate Gear Ratios Needed For Different Cutting Speeds And Feed Rates On A Metal Lathe?To determine the right gear ratios for a metal lathe, you start by knowing the cutting speed you want. Cutting speed is how fast the tool moves against the metal. Next, check the feed rate, which is how quickly the tool goes into the metal. Then, use the lathe’s manual to find the correct gears that match these speeds. Adjust the gears until you get the best combination for your project.

What Are The Common Troubleshooting Steps For Issues That Arise During The Setup Of A Metal Lathe Gear Train?If you have problems setting up a metal lathe gear train, here are some steps to try. First, check that all the gears are lined up properly. Next, make sure the gears are tight and not loose. You should also look for any damage on the gears. Finally, test the lathe to see if it works correctly after making changes.

How Do You Correctly Align And Secure The Gears To Ensure Smooth Operation And Minimize Wear And Tear On A Metal Lathe?To align the gears on a metal lathe, first check that they fit together well. Make sure they are not too tight or too loose. You can use a ruler or a special tool to help see if they are straight. Once they’re lined up, secure them tightly with screws. Always check them again after some use to ensure they stay in place. This way, you help the lathe run smoothly and last longer!

What Are The Safety Precautions To Take When Adjusting Or Operating The Gear Train On A Metal Lathe?When using a metal lathe, always wear safety glasses to protect your eyes. Make sure your hair and clothes are tucked away so they don’t get caught. Before you start, check that all tools are clean and in good shape. Keep your hands away from moving parts while the lathe is on. Lastly, always follow the instructions from your teacher or guide.