Have you ever wondered how metal lathes work? These machines can create amazing projects, from simple tools to intricate designs. Setting up a metal lathe with a power feed can make your work faster and more precise. But where do you begin? With the right setup guide, you can take your skills to the next level.

Imagine transforming a raw piece of metal into a crafted masterpiece. It sounds exciting, right? But using a metal lathe can be tricky without proper guidance. Many beginners feel overwhelmed when starting. A good setup guide can help ease those worries.

In this article, we’ll walk you through the steps to set up a metal lathe with a power feed. You will learn essential tips and tricks that make the process smooth. So grab your tools, and let’s get started on this rewarding journey!

Setup Guide For Metal Lathe Power Feed: Step-By-Step Instructions

Setup Guide for Metal Lathe Power Feed

Setting up a metal lathe power feed is a rewarding project. First, ensure you have all needed parts. Pay attention to assembly. Reading the manual helps avoid mistakes. Did you know that power feeds can improve precision? This means less manual effort and more creativity. A fun fact is that most users report faster work. Check slippage often for safety. With the right steps, you can make your metal lathe work like a pro!Understanding Metal Lathe Power Feed

Definition and purpose of a power feed. Benefits of using a power feed on metal lathes.A power feed is a tool that moves the metal work automatically. This allows you to focus on cutting without using your hands. It makes work faster and smoother. Using a power feed has big benefits:

- Less fatigue: Your hands don’t get tired.

- Precise cuts: It helps create even and accurate shapes.

- Time-saving: You finish tasks quicker.

A power feed is a great addition to metal lathes. It makes crafting easier and helps you enjoy your projects more!

What are the benefits of using a power feed on metal lathes?

The benefits include greater efficiency, improved accuracy, and reduced strain on the operator, making metalworking tasks easier and more enjoyable.

Tools and Equipment Required

List of necessary tools for setup. Recommended accessories for optimal performance.To set up your metal lathe power feed, you’ll need some essential tools and accessories. Here’s what you should gather:

- Wrenches

- Screwdrivers

- Calipers

- Drills

- Measuring tape

- Lubricants

- Safety goggles

For the best performance, consider these recommended accessories:

- Extra cutting tools

- Tool holders

- Power feed motor

- Digital readout

Having the right tools makes setup easier and safer!

What tools do I need for a metal lathe power feed setup?

You will need wrenches, screwdrivers, calipers, and measuring tape. These tools help you properly install and adjust your lathe. Don’t forget safety goggles!

Choosing the Right Power Feed for Your Lathe

Factors to consider when selecting a power feed. Compatibility with different types of metal lathes.Picking the perfect power feed for your lathe can feel like choosing between pizza toppings. There are a few key factors to keep in mind. First, check if it fits your specific lathe model; not all feeds are created equal. Compatibility is crucial—if it doesn’t fit, it’s as useful as a chocolate teapot! Also, consider your work style. Do you want speed or precision? Balance your choice like walking a tightrope—too much of one could topple you over!

| Factor | Description |

|---|---|

| Compatibility | Ensure it matches your lathe type. |

| Speed vs. Precision | Choose what important for your projects. |

| Ease of Use | Look for intuitive controls. |

Preparing Your Metal Lathe for Power Feed Installation

Safety precautions before starting the installation. Steps for cleaning and checking the lathe.Before diving into the exciting world of power feed installation, let’s make sure you’re safe and sound. First, wear your protective gear because safety is no joke. Check your lathe for any dirt or debris, as a clean workspace is a happy workspace. As the wise say, “Cleanliness is next to gear-ness!” Here’s a quick table to guide your cleaning steps:

| Step | Action |

|---|---|

| 1 | Disconnect power to the lathe. |

| 2 | Wipe down surfaces with a soft cloth. |

| 3 | Inspect for any loose parts or wear. |

| 4 | Ensure all moving parts are greased properly. |

By following these steps, your lathe will be ready for some power feed fun. Remember, a well-prepared lathe is like a puppy with a full belly—full of energy and ready to work!

Step-by-Step Installation Process

Detailed instructions for installing the power feed. Common pitfalls and how to avoid them.Installing a power feed on your metal lathe can be simple! First, gather your tools: a screwdriver, wrench, and maybe a snack for energy. Start by carefully removing the old manual feed handle. Don’t drop it—your foot won’t appreciate it! Next, attach the power feed unit to the lathe. Ensure the motor is aligned properly to avoid problems. Common pitfalls include loose connections that can ruin your work. Check everything twice before powering up. If it doesn’t sound right, it’s probably not! Follow these steps, and you’ll be turning metal like a pro in no time.

| Step | Action | Tip |

|---|---|---|

| 1 | Remove old feed handle | Watch your toes! |

| 2 | Attach power feed unit | Keep it straight! |

| 3 | Check connections | Double-check to avoid headaches! |

Adjusting the Power Feed Settings

How to set speed and torque for different materials. Troubleshooting common issues with settings.Setting the correct speed and torque is key for smooth work. Different materials need different settings. For soft metals like aluminum, use a faster speed but lower torque. For harder metals, choose a slower speed and higher torque. If you notice the tool stalling or cutting poorly, check your settings. Adjusting them can help fix issues like uneven cuts or vibrations.

How to set speed and torque for different materials?

For aluminum: Fast speed, low torque.

For steel: Slower speed, high torque.

For plastic: Moderate speed, low torque.

Troubleshooting common issues with settings:

- Check if the machine stalls.

- Fix uneven cuts by recalibrating settings.

- Reduce vibrations by adjusting speed.

Maintenance Tips for Longevity of Power Feed

Routine maintenance procedures. Signs that indicate the need for servicing.Regular care helps your power feed last longer. Always check for signs of wear and tear. Clean parts often to remove dust and debris. Lubricate moving parts to ensure smooth operation. Here are some signs you may need servicing:

- Strange noises.

- Unusual vibrations.

- Difficulty in movement.

- Oil leaks.

What are some quick maintenance tips?

Keep it clean, check for damage, and lubricate moving parts regularly! Routine checks will help avoid major problems later.

Frequently Asked Questions

Common queries regarding installation and usage. Expert answers and tips for best practices.Many people wonder how to set up their metal lathe’s power feed. Some common questions pop up, like how to install it and make it run smoothly. A good tip is to read the manual first; it’s like following a treasure map. Do you need special tools? Often no, just what you have at home! Practice makes perfect, so don’t rush it. Ask for help if you feel stuck, and remember, even experts had to start somewhere! Below is a simple FAQ table to guide you.

| Question | Answer |

|---|---|

| What tools do I need? | Usually hand tools and a wrench will do! |

| Can I run it without a manual? | It’s risky! Manuals are like cheat codes. |

| Is maintenance necessary? | Yes! A little care goes a long way. |

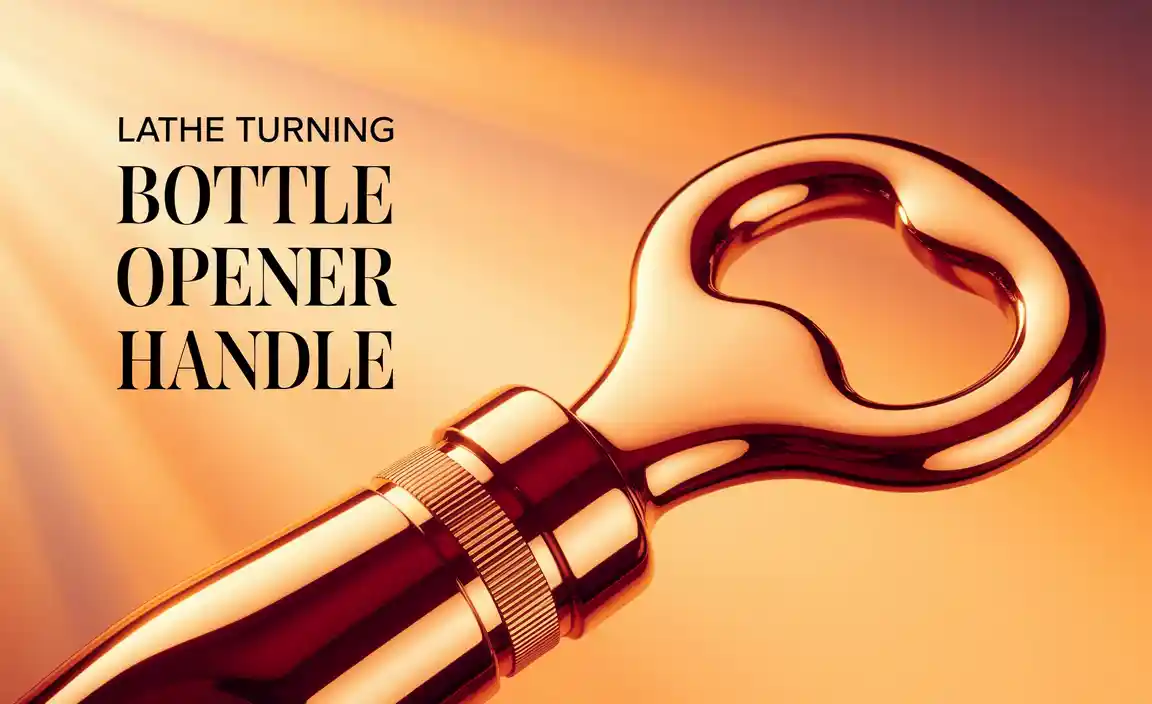

Real-World Applications of Metal Lathe Power Feed

Examples of projects that benefit from power feed. Case studies showcasing improvements in efficiency.Many projects benefit from a metal lathe’s power feed. For example, it speeds up making parts for machines. Also, it helps when crafting furniture or toys. With this tool, users can enjoy a smoother finish. Here are some benefits:

- Improved accuracy: The power feed allows for precise cuts.

- Time saving: It reduces manual effort and speeds up production.

- Consistency: Parts come out uniform and neat.

One case study showed that a local shop improved its output by 30% after using a power feed. This example shows how useful this tool can be in real life.

What projects can use a metal lathe power feed?

Projects such as making gears, automotive parts, or custom tool handles can benefit greatly.

Conclusion

In conclusion, a setup guide for a metal lathe power feed is essential for smooth operation. Start by carefully following instructions for proper installation. Check alignment and settings to ensure accuracy. Remember, practice makes perfect! You can improve your skills over time. Keep reading more guides to expand your knowledge and enhance your metalworking projects.FAQs

Sure! Here Are Five Related Questions On The Topic Of Setting Up A Metal Lathe Power Feed:Sure! Here are five questions you might ask about setting up a metal lathe power feed: 1. What is a metal lathe? A metal lathe is a machine that shapes metal. It spins the metal, and you can cut it into the right shape. 2. Why use a power feed? A power feed helps move the tool automatically. This makes it easier to make smooth cuts without getting tired. 3. How do you set up the power feed? First, read the manual for your lathe. Then, connect the power feed to the machine. Finally, test it to see if it works. 4. What safety tips should I remember? Always wear safety glasses. Keep your hands away from moving parts. And never rush when using the lathe. 5. Can I use a power feed for all metal types? You can use it for most metals, like aluminum and steel. Just be sure the lathe is set up for the type you’re using.

Sure! Please provide the question you would like me to answer.

What Are The Essential Components Required For Setting Up A Power Feed On A Metal Lathe?To set up a power feed on a metal lathe, you need a few important parts. First, you need a motor to provide power. Next, you need a control switch to turn the motor on and off. You’ll also need gears or belts to connect the motor to the lathe. Lastly, make sure you have a way to adjust the feed speed for different jobs.

How Do I Properly Align The Power Feed Mechanism With The Lathe’S Carriage?To align the power feed mechanism with the lathe’s carriage, start by turning off the lathe. Then, find the adjustment screws on the power feed. Next, gently move the carriage until it lines up with the mechanism. Tighten the screws to hold everything in place. Finally, check that everything moves smoothly when you turn the lathe back on.

What Safety Precautions Should I Observe While Installing A Power Feed On My Metal Lathe?When you install a power feed on your metal lathe, always wear safety glasses to protect your eyes. Make sure to turn off the machine and unplug it before you start. Keep your hands away from moving parts to avoid getting hurt. Use the right tools and follow the instructions carefully. Lastly, ask an adult for help if you’re unsure about anything.

Can I Retrofit An Existing Manual Lathe With A Power Feed System, And What Modifications Are Needed?Yes, you can add a power feed system to a manual lathe. You’ll need to buy a power feed kit. This kit usually has a small motor and some gears. You may also need to make room for the motor and connect it to the lathe’s controls. With some tools and help, you can do this!

How Do I Troubleshoot Common Issues With Metal Lathe Power Feeds During Operation?To fix problems with a metal lathe’s power feeds, start by checking the power source. Make sure it’s plugged in and switched on. Then, look for any stuck parts and clean them if needed. If it still won’t work, check the settings to ensure they are correct. Lastly, if you’re unsure, ask someone more experienced for help.