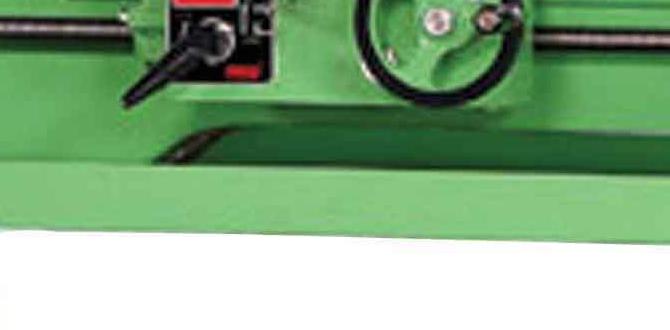

Have you ever wondered how to make your metal lathe work better? A simple setup guide can help you get the most from your machine. It’s all about understanding the parts that make it run smoothly.

Think about the last time you used a tool and it didn’t work right. Frustrating, right? This is where the metal lathe pulley comes in! The pulley system plays an important role in managing speed and power.

Did you know that the correct pulley setup can improve your lathe’s performance? It truly can! A well-set pulley allows for smoother operations.

In this guide, we will explore how to set up your metal lathe pulley properly. You’ll learn how to adjust it step by step. Before you know it, your metal lathe will be ready to tackle any project you have in mind!

Complete Setup Guide For Metal Lathe Pulley Systems

Metal Lathe Pulley Setup Guide

Setting up a metal lathe pulley can be simple and rewarding. First, ensure you have the right tools. Understanding pulley alignment is crucial for smooth operation. Check the belt tension; a loose belt can cause slippages. Did you know that a well-setup pulley can improve cutting precision? Proper adjustments save time and enhance your projects. Always remember to consult the manual for specific settings. Happy machining!Choosing the Right Metal Lathe Pulley System

Factors to consider when selecting pulleys for your lathe. Recommended pulley types for various lathe models.Selecting a metal lathe pulley system involves several important factors. First, think about size. Your pulley must fit your lathe correctly. Also, consider the material. Strong materials last longer. Check the weight capacity too; it needs to handle your tasks. Each lathe model may need different pulley types. Here are some recommended choices:

- For small lathes: Lighter plastic pulleys work well.

- For medium lathes: Consider steel pulleys for strength.

- For heavy lathes: Cast iron pulleys provide excellent durability.

What should I look for in a metal lathe pulley?

Key points include size, material, and weight capacity. Always choose what fits your lathe best.

Tools Required for Setting Up Metal Lathe Pulleys

List of essential tools for pulley installation. Safety equipment necessary during the setup process.To install metal lathe pulleys, you need some important tools and safety gear. Here’s a quick list to help you. Make sure you have:

- A wrench set

- A screwdriver set

- A level

- A hammer

- Measuring tape

Don’t forget your safety gear! Use:

- Safety goggles

- Gloves

- A dust mask

These tools and equipment keep you safe and help you work efficiently!

What tools are essential for pulley installation?

Essential tools include a wrench set, screwdriver set, level, hammer, and measuring tape. Safety gear like goggles and gloves is also very important. Always be careful when working with machinery!

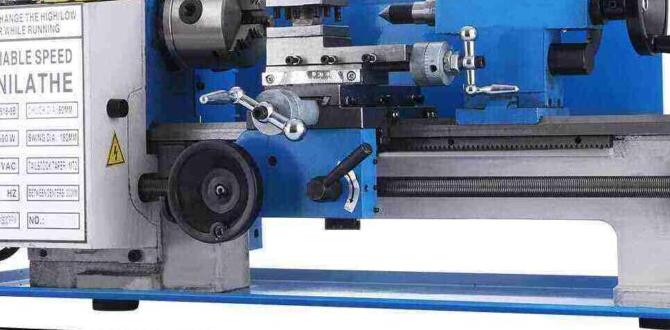

Step-by-Step Setup Process for Metal Lathe Pulleys

Detailed instructions for removing old pulleys. Stepbystep guidance on installing new pulleys.Changing metal lathe pulleys is important for smooth operation. Start by removing the old pulleys. Turn off the power and unplug the machine. Use a screwdriver to take off any covers. Then, loosen the screws holding the pulleys and gently pull them off. Next, install the new pulleys. Slide them onto the shaft and make sure they fit snugly. Tighten the screws but don’t overdo it. Finally, replace the covers and plug the machine back in. You’re all set!

How do you remove a metal lathe pulley?

To remove a metal lathe pulley, first, unplug the machine. Next, unscrew covers and loosen the screws holding the pulley in place. Then, gently pull it off the shaft.

What steps do I follow to install a new pulley?

To install a new pulley, follow these steps:

- Slide the new pulley onto the shaft.

- Ensure it fits tightly.

- Tighten the screws securely.

- Replace any covers you removed.

Common Mistakes to Avoid During Pulley Setup

List of frequent errors made during installation. Tips for troubleshooting and correcting setup issues.Setting up a metal lathe pulley can be tricky. Many people make mistakes along the way. Here are some common errors:

- Not aligning the pulley correctly

- Ignoring the manufacturer’s instructions

- Forgetting to check for wear and tear

- Using the wrong belt size

If you run into issues, try these tips:

- Recheck alignment with a level

- Read your manual step-by-step

- Replace any damaged parts

- Measure the belt before buying

A careful setup can save time and effort later!

What should I check first when I have pulley trouble?

Start by checking the alignment. If it’s off, your pulley may not function well. Use a level to fix it quickly!

Maintenance Tips for Longevity of Metal Lathe Pulleys

Best practices for maintaining pulley systems. Signs of wear and when to replace pulleys.To keep your metal lathe pulleys in great shape, you need proper care. Here are some best maintenance tips:

- Clean the pulleys regularly to remove dust and grime.

- Check the alignment. Misalignment can cause wear.

- Lubricate moving parts to reduce friction.

- Inspect belts for damage and replace them if needed.

Look for signs of wear, such as:

- Cracks or chips on the surface.

- Unusual noises during operation.

- Pulleys slipping or not functioning smoothly.

Replace pulleys as needed. This can help your machine work better and last longer!

What are the signs that pulleys need replacing?

You can listen for unusual noises and check for visible damage. If your lathe is not running smoothly, it may be time for a replacement.

Upgrading Your Metal Lathe Pulley System

Benefits of upgrading to advanced pulley systems. How to assess whether an upgrade is necessary.Upgrading your metal lathe pulley system can make a big difference. Newer pulleys can boost performance, making your machine smoother and faster. Imagine spinning your workpiece like a pro! You might wonder if it’s worth the trouble. First, check for wear and tear on your old pulleys. If they wobble or squeak, it’s time! A better setup means less hassle and more fun in your workspace.

| Benefits of Upgrading | Signs You Need an Upgrade |

|---|---|

| Improved performance | Worn out parts |

| Smoother operation | Unusual noises |

| Higher speed options | Inconsistent results |

Conclusion

In conclusion, a setup guide for a metal lathe pulley is essential for smooth operation. You learn how to choose the right pulley and install it correctly. Remember to check the alignment and tension as you work. For more tips, explore additional resources online or ask experienced machinists in your community. Let’s get creating!FAQs

What Is The Purpose Of The Pulleys In A Metal Lathe Setup?Pulleys in a metal lathe help us control the speed of the machine. They connect different parts and let us change how fast the metal spins. By using pulleys, we can make thin cuts or thick cuts easily. This makes our work more precise and safe.

How Do I Properly Size The Belts For The Pulleys On My Metal Lathe?To size belts for your metal lathe, first measure the distance between the pulleys. Use a tape measure to get the length in inches. Next, check the size of the pulleys. You want the belt to fit snugly around them. Finally, choose a belt that matches the length you measured. Make sure it’s not too loose or too tight!

What Steps Should I Follow To Align The Pulleys On My Metal Lathe For Optimal Performance?To align the pulleys on your metal lathe, first, turn off the machine and unplug it. Then, check if the pulleys are straight and not wobbly. You can adjust the position of each pulley by loosening the screws. Make sure they are lined up next to each other. Finally, tighten the screws and test the lathe to see if it runs smoothly.

How Can I Troubleshoot Common Pulley-Related Issues On A Metal Lathe?To troubleshoot pulley problems on a metal lathe, first check if the belt is loose or worn out. You can tighten or replace the belt if needed. Next, look for any broken parts on the pulleys. If the pulleys are dirty, clean them to make sure they work smoothly. Finally, listen for unusual sounds when the lathe is running; if you hear strange noises, turn it off and inspect it closely.

What Safety Precautions Should I Take While Setting Up Or Adjusting The Pulleys On My Metal Lathe?When you set up or change the pulleys on your metal lathe, always make sure the machine is turned off. Wear safety glasses to protect your eyes. Keep your fingers and tools away from moving parts. Make sure everything is tight and secure before you start the lathe again. Always ask for help if you’re unsure about something.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Is The Purpose Of The Pulleys In A Metal Lathe Setup? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Pulleys in a metal lathe help us control the speed of the machine. They connect different parts and let us change how fast the metal spins. By using pulleys, we can make thin cuts or thick cuts easily. This makes our work more precise and safe.”}},{“@type”: “Question”,”name”: “How Do I Properly Size The Belts For The Pulleys On My Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To size belts for your metal lathe, first measure the distance between the pulleys. Use a tape measure to get the length in inches. Next, check the size of the pulleys. You want the belt to fit snugly around them. Finally, choose a belt that matches the length you measured. Make sure it’s not too loose or too tight!”}},{“@type”: “Question”,”name”: “What Steps Should I Follow To Align The Pulleys On My Metal Lathe For Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the pulleys on your metal lathe, first, turn off the machine and unplug it. Then, check if the pulleys are straight and not wobbly. You can adjust the position of each pulley by loosening the screws. Make sure they are lined up next to each other. Finally, tighten the screws and test the lathe to see if it runs smoothly.”}},{“@type”: “Question”,”name”: “How Can I Troubleshoot Common Pulley-Related Issues On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot pulley problems on a metal lathe, first check if the belt is loose or worn out. You can tighten or replace the belt if needed. Next, look for any broken parts on the pulleys. If the pulleys are dirty, clean them to make sure they work smoothly. Finally, listen for unusual sounds when the lathe is running; if you hear strange noises, turn it off and inspect it closely.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should I Take While Setting Up Or Adjusting The Pulleys On My Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you set up or change the pulleys on your metal lathe, always make sure the machine is turned off. Wear safety glasses to protect your eyes. Keep your fingers and tools away from moving parts. Make sure everything is tight and secure before you start the lathe again. Always ask for help if you’re unsure about something.”}}]}