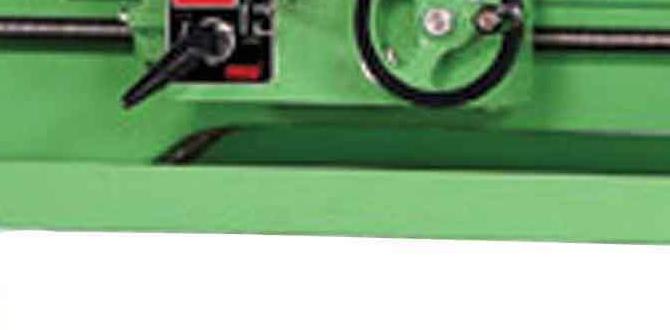

Have you ever wondered how a metal lathe works? It’s a fascinating machine that can shape metal into amazing forms. But to use it well, you need to know a few things, especially about the quill. This part can seem tricky, but setting up a metal lathe quill doesn’t have to be hard.

Imagine crafting a perfectly shaped piece after hours of hard work. Sounds exciting, right? That’s the magic of a well-adjusted quill. It helps you make precise cuts and shapes. In this setup guide for a metal lathe quill, we’ll break down the steps. You’ll learn tips that make the process easier and fun.

Did you know that even small adjustments to the quill can change the entire outcome? That’s why knowing how to set it up is crucial for success. Get ready to dive into this guide! You’ll be amazed at what you can create.

Complete Setup Guide For Metal Lathe Quill Operation

Setup Guide for Metal Lathe Quill

Setting up a metal lathe quill can feel tricky, but it doesn’t have to be. This guide helps you understand the essential steps. First, check the alignment to ensure accurate cutting. You’ll also learn how to adjust the quill for different projects, ensuring versatile usage. A well-set quill can increase your lathe’s performance and create better finishes. Did you know that a tiny adjustment can lead to a smoother operation? Dive in and start mastering your lathe!Understanding the Metal Lathe Quill

Definition and function of the quill in a metal lathe. Types of quills and their applications.The quill in a metal lathe is a clever little part. It holds cutting tools tightly while they spin and slice metal. Think of it as the lathe’s best buddy! There are different types of quills, each with its own job. Some are adjustable for deep cuts, while others are fixed for standard jobs. Essentially, the quill makes sure your projects don’t turn into a modern art nightmare!

| Type of Quill | Application |

|---|---|

| Fixed Quill | Ideal for basic turning tasks |

| Adjustable Quill | Perfect for deep cuts and detailed work |

With the right quill, your metal lathe can become a magic machine. Always pick the right one for the task, because nobody likes a messy project!

Pre-Setup Considerations

Key factors to assess before starting the setup process. Safety precautions to take when handling a lathe.Before you set up your metal lathe, think about a few important things. Assess your workspace. Is it clean and organized? Next, ensure you have adequate lighting. You don’t want to miss any small details. Safety is crucial. Always wear safety glasses and avoid loose clothing. Here are some key precautions:

- Wear gloves and a dust mask.

- Check all tools for damage.

- Keep hands away from moving parts.

Being aware of these factors keeps you safe and helps your setup go smoothly!

What should I do before using a lathe?

Before using a lathe, make sure to assess your workspace, ensure proper lighting, and wear safety gear.

Step-by-Step Setup Process

Detailed instructions on preparing the quill for use. Adjustments for alignment and calibration.Start by carefully unpacking the quill. Check all parts to ensure they’re there; you wouldn’t want to chase after a missing piece like it’s a game of hide-and-seek! Next, attach the quill to the lathe while aligning it correctly. Just like lining up for a photo, everyone wants to look their best! Then, calibrate for precision. Use a dial gauge for fine adjustments – it’s like making tiny, tiny tweaks until it’s perfect. Finally, double-check everything, so you won’t have surprise surprises in your project!

| Step | Action |

|---|---|

| 1 | Unpack the quill and check all parts. |

| 2 | Attach the quill, ensuring proper alignment. |

| 3 | Calibrate using a dial gauge for accuracy. |

| 4 | Double-check everything before use. |

Troubleshooting Common Quill Issues

Identifying and resolving common problems with quill setup. Maintenance tips to prevent future issues.Quills can act up sometimes. Knowing the common problems helps keep things running smoothly. First, check for tightness; a loose quill can cause uneven cuts. If you hear strange noises, it may mean lubrication is needed. Regularly clean and oil the parts to avoid jams or breaks.

- Inspect for debris. Dust can block movement.

- Check alignment. Misalignment can lead to inaccuracy.

- Lubricate often. A well-lubed quill works best.

What are signs of quill problems?

Look for inconsistent performance, unusual noise, or sticky movement. If you notice any of these, it’s time to check your quill.

Keeping up with maintenance prevents future troubles. Regular checks and cleaning will help your metal lathe quill work better and last longer.

Optimizing Performance of Your Metal Lathe Quill

Techniques for enhancing precision and efficiency. Recommended accessories and tools for better operation.Improving your metal lathe quill can make a big difference. Here are some useful techniques:

- Keep your lathe clean. Dust can cause problems in precision.

- Use high-quality cutting tools. They help in getting better results.

- Adjust the speed according to the material. This boosts efficiency.

Also, consider these recommended accessories:

- Centering tools for accuracy.

- Tool holders for easy changes.

- Digital readouts for precise measurements.

These steps can help you work smarter and make great creations!

How can I ensure accuracy with my metal lathe quill?

To ensure accuracy, keep your tools sharp and well-maintained. Use digital readouts for precise measurements. This reduces errors and improves results.

Expert Tips and Best Practices

Insights from seasoned metalworkers for effective quill usage. Common mistakes to avoid during setup and operation.Using a metal lathe’s quill correctly can make a world of difference. Seasoned metalworkers say to always check your alignment before starting. A tiny mistake can lead to big headaches! Some common missteps include ignoring safety measures or skipping the warm-up phase. Remember, “Measure twice, cut once,” or in this case, “Check twice, quill once!” To help you avoid trouble, here’s a quick reference table:

| Common Mistakes | Expert Tips |

|---|---|

| Skipping calibration | Always calibrate before use. |

| Forgetting safety gear | Wear goggles and gloves. |

| Improper speed settings | Adjust speed for material type. |

These little tweaks can help you operate the quill like a pro! Have fun and keep it safe.

Resources for Further Learning

Suggested books, websites, and forums for metal lathe enthusiasts. Training courses and workshops available for handson experience.Learning about metal lathes can be fun and exciting! There are fantastic resources available to help you dive deeper. Check out classic books like “The Metal Lathe” by David J. Gingery. Websites like the Metalworking Reddit and Practical Machinist are also great for tips and tricks. Join a workshop for hands-on experience. Remember, practice makes perfect, and soon you’ll be turning metal like a pro!

| Resource Type | Name | Link |

|---|---|---|

| Book | The Metal Lathe | Amazon |

| Website | Metalworking Reddit | Check it out! |

| Forum | Practical Machinist | Visit now! |

Conclusion

In summary, a setup guide for a metal lathe quill helps you understand its parts and functions. Knowing how to adjust the quill enhances your projects. Start by practicing with your lathe and following a guide. For more tips, check out additional resources or tutorials. This way, you become more skilled and confident in your metalworking journey!FAQs

Here Are Five Related Questions On The Topic Of Setting Up A Metal Lathe Quill:To set up a metal lathe quill, first make sure the machine is turned off. Next, check that the quill is clean and free from any dust. You can then carefully slide the quill into place. Tighten any screws to keep it secure. Finally, double-check everything to ensure it’s right before you start working!

Sure! Please provide the question you would like me to answer.

What Are The Key Components Of A Metal Lathe Quill That Need To Be Inspected Before Setup?Before we set up a metal lathe quill, we need to check a few important parts. First, look at the quill itself to see if it moves smoothly. Next, check the bearings to make sure they aren’t worn out. We should also inspect the motor connection to ensure it fits snugly. Lastly, we need to examine the drive belt for any cracks or damage. These steps help keep everything safe and working well.

How Do You Properly Align The Quill To Ensure Accurate Machining Results?To align the quill, first, make sure your machine is turned off. Then, check if the quill is straight by looking at it from the front. You can use a level tool to see if it’s even. Adjust it gently until it looks straight and level. Finally, tighten all the screws to keep it in place, and you’re ready to start machining!

What Are The Common Adjustments To Make On The Quill For Different Types Of Cutting Operations?When you use a quill in cutting, you can change a few things. First, you can adjust the depth, which is how deep the cutting tool goes. Then, you can change the speed, deciding how fast the tool moves. Lastly, you might switch the tool itself for different cuts. These adjustments help you cut better for different tasks.

How Can You Troubleshoot Issues Related To Quill Movement Or Accuracy During Metal Lathe Operations?To fix problems with quill movement on a metal lathe, you can start by checking the machine for stuck parts. Make sure everything is clean and well-oiled. If the quill doesn’t move smoothly, it might need adjustment. You can also measure the accuracy by checking your cuts with a ruler. If it’s not right, double-check your settings and tools.

What Safety Precautions Should Be Taken When Setting Up And Operating A Metal Lathe Quill?When you set up and use a metal lathe quill, always wear safety goggles to protect your eyes. Keep long hair tied back and avoid wearing loose clothing. Make sure the work area is clean and free of clutter. Always check that tools and parts are secure before starting the machine. Finally, never touch moving parts while the lathe is running.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Setting Up A Metal Lathe Quill:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe quill, first make sure the machine is turned off. Next, check that the quill is clean and free from any dust. You can then carefully slide the quill into place. Tighten any screws to keep it secure. Finally, double-check everything to ensure it’s right before you start working!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Components Of A Metal Lathe Quill That Need To Be Inspected Before Setup?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Before we set up a metal lathe quill, we need to check a few important parts. First, look at the quill itself to see if it moves smoothly. Next, check the bearings to make sure they aren’t worn out. We should also inspect the motor connection to ensure it fits snugly. Lastly, we need to examine the drive belt for any cracks or damage. These steps help keep everything safe and working well.”}},{“@type”: “Question”,”name”: “How Do You Properly Align The Quill To Ensure Accurate Machining Results?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the quill, first, make sure your machine is turned off. Then, check if the quill is straight by looking at it from the front. You can use a level tool to see if it’s even. Adjust it gently until it looks straight and level. Finally, tighten all the screws to keep it in place, and you’re ready to start machining!”}},{“@type”: “Question”,”name”: “What Are The Common Adjustments To Make On The Quill For Different Types Of Cutting Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a quill in cutting, you can change a few things. First, you can adjust the depth, which is how deep the cutting tool goes. Then, you can change the speed, deciding how fast the tool moves. Lastly, you might switch the tool itself for different cuts. These adjustments help you cut better for different tasks.”}},{“@type”: “Question”,”name”: “How Can You Troubleshoot Issues Related To Quill Movement Or Accuracy During Metal Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix problems with quill movement on a metal lathe, you can start by checking the machine for stuck parts. Make sure everything is clean and well-oiled. If the quill doesn’t move smoothly, it might need adjustment. You can also measure the accuracy by checking your cuts with a ruler. If it’s not right, double-check your settings and tools.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Setting Up And Operating A Metal Lathe Quill?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you set up and use a metal lathe quill, always wear safety goggles to protect your eyes. Keep long hair tied back and avoid wearing loose clothing. Make sure the work area is clean and free of clutter. Always check that tools and parts are secure before starting the machine. Finally, never touch moving parts while the lathe is running.”}}]}