Have you ever wanted to create perfect threads on a metal lathe? Setting up a metal lathe threading dial can feel daunting. Yet, it can be a fun adventure! Picture this: you’re crafting a beautiful piece of metal, and suddenly, it all comes together perfectly.

Getting started is easier than you think. Many people struggle with the details, but with the right setup guide, you can excel. Did you know that a simple shift in settings can change everything? Understanding your threading dial is key to success.

In this setup guide, we’ll walk you through each step. Follow along and unleash your creativity. You might just discover that threading is not only simple but also enjoyable!

Setup Guide For Metal Lathe Threading Dial: A Complete Overview

Setup Guide Metal Lathe Threading Dial

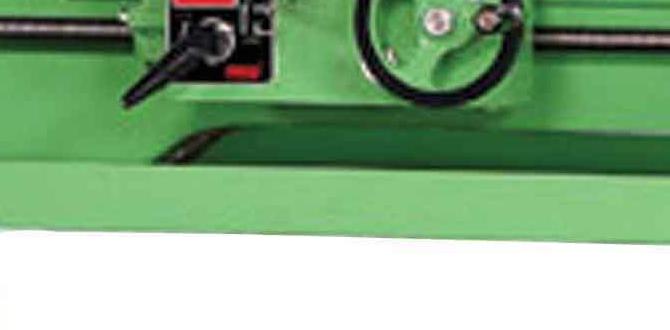

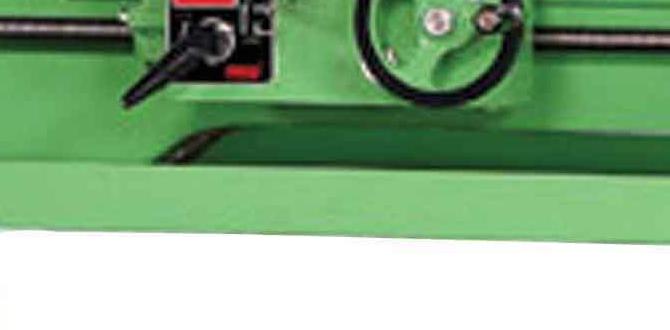

Setting up a metal lathe threading dial can seem tricky. This guide helps you understand its parts and functions. Knowing how to calibrate the dial is crucial for precise threading. Have you ever wondered why small adjustments matter? They can make a big difference in your project’s success! Proper setup ensures smoother operations and better results. With practice, mastering this tool can boost your confidence in your metalworking skills. Let’s explore these tips and unlock the full potential of your lathe!Components of a Metal Lathe Threading Dial

Detailed description of the main parts of a threading dial.. Discussion of materials and manufacturing quality impacting performance..A threading dial has a few important parts. Each part works together to help you cut threads accurately. The main parts include:

- Dial: Shows you where to start.

- Gear: Helps the dial move smoothly.

- Indicator: Shows measurements clearly.

The materials used in making these parts matter a lot. High-quality metal can make the dial last longer. Good quality parts help you work better. Remember, strong materials lead to strong performance!

What is a threading dial used for?

A threading dial is used to help cut threads on a lathe. It lets the user align cuts accurately and efficiently. This tool improves precision and consistency in threading tasks.

Key Benefits:

- Easy measurements

- Better thread quality

- Faster work

Preparing Your Lathe for Threading

Stepbystep instructions for setting up the lathe before threading.. Importance of checking tool alignment and lathe settings for optimal results..Before you start threading on your lathe, make sure it’s ready. Here’s how:

- Check that your lathe is clean.

- Align your tools properly. They need to be set right to ensure a smooth cut.

- Adjust the lathe settings for the material you use.

- Test the threading dial to confirm it works.

These checks help you achieve better results and avoid mistakes. Taking time to set up your lathe correctly can save you from problems later.

Why is Tool Alignment Important?

Tool alignment ensures accuracy. It helps create clean threads without errors. Misalignment can lead to wasted materials and time.

Steps for Optimal Lathe Setting:

- Make sure the tool is level.

- Set the right speed for threading.

- Double-check your measurements.

How to Adjust the Threading Dial

Guidance on calibrating the threading dial for different thread pitches.. Tips for ensuring accuracy and consistency during the adjustment process..To adjust the threading dial, start with the right pitch. Each thread has a specific size. Check your manual for the correct settings. Follow these tips for accuracy:

- Start from zero and turn to your thread pitch.

- Calibrate regularly to keep measurements precise.

- Double-check with a known size to ensure consistency.

Make small adjustments to avoid mistakes. Repeating this process helps maintain accuracy every time you use the lathe.

How do you calibrate a threading dial?

You calibrate by matching the threading dial with your chosen thread pitch and testing with a sample piece.

Safety Precautions When Using a Threading Dial

Essential safety measures to observe while operating a metal lathe.. Discussion of personal protective equipment and workspace organization..Using a metal lathe safely is very important. Always wear personal protective equipment (PPE). This includes safety goggles, gloves, and ear protection. Keep your workspace neat and organized. A clean area helps you avoid accidents. Do not wear loose clothing or jewelry; they can catch in the machine. Always read the machine manual before use to understand its functions. Remember, safety is the first step to learning!

What should I wear for safety while using a metal lathe?

You should wear safety goggles, gloves, and ear protection.Additional Safety Tips:

- Keep your hair tied back.

- Ensure all tools are in good condition.

- Don’t rush your work.

Troubleshooting Threading Dial Issues

Identification of common problems experienced with threading dials.. Solutions and fixes for maintaining optimal performance..Common problems with threading dials can lead to frustration. Users may face issues like inaccurate readings or a stuck dial. To solve these problems, follow these tips:

- Check for dirt: Keep the dial clean and free from debris.

- Lubricate: Use oil on moving parts to ensure smooth operation.

- Inspect alignment: Ensure the dial is properly aligned with the lathe.

- Replace worn parts: Damaged components should be fixed or changed.

By addressing these common problems, you can maintain your threading dial’s performance.

What can cause threading dial problems?

Issues like misalignment, dirt buildup, and lack of lubrication often cause threading dial problems.How to fix a sticking threading dial?

To fix a sticking threading dial, first clean it thoroughly, lubricate it, and check for damage.Maintenance Tips for Longevity of the Threading Dial

Regular maintenance practices to ensure the threading dial operates smoothly.. Importance of lubrication and part inspections for prolonged use..To keep your threading dial in great shape, regular checks are key. Look for dirt or wear often. Also, lubrication is important. A little oil goes a long way. It helps the parts move easily and prevents rust. Here are quick tips:

- Clean the dial regularly.

- Apply oil monthly.

- Inspect screws and parts often.

Doing these simple tasks can help your threading dial last longer and work better.

How can I ensure my threading dial lasts long?

Check it often, clean it regularly, and keep it lubed. This will make it last longer and work better.

Comparing Threading Dials: Manual vs. CNC

Differences in functionality between manual and CNC threading dials.. Benefits and drawbacks of each type for various user needs..Threading dials come in two main types: manual and CNC. Each has its strengths and weaknesses.

- Manual Dials: Simple to use, they require the operator to control movements. They can be great for hobbyists and small projects.

- CNC Dials: Automatic and precise, they require code but are excellent for larger tasks. They save time but may cost more.

Choosing the right type depends on the user’s skill level and project needs. Think about what works best for you!

What are the key differences between manual and CNC threading dials?

Manual threading dials require hands-on control, while CNC dials use computers for precision. Manual dials are simpler, while CNC dials can handle complex tasks.

Conclusion

In summary, a setup guide for your metal lathe’s threading dial is essential. It helps you understand how to adjust the dial accurately. This ensures precise threading for your projects. Always refer to your machine’s manual for specific instructions. Now, grab your tools and start practicing! You can also explore more resources online to enhance your skills further.FAQs

How Do You Install And Calibrate A Threading Dial On A Metal Lathe?To install a threading dial on a metal lathe, you first need to find the right spot for it. You can usually attach it to the front of the lathe. Then, use screws to hold it in place. To calibrate it, turn the dial while carefully moving the lathe tool. Make sure the measurements line up with the cutting tool. Adjust until it matches perfectly for accurate threads.

What Are The Different Types Of Threading Dials Available For Metal Lathes, And How Do They Differ?There are two main types of threading dials for metal lathes: the fractional and the metric dial. The fractional dial measures in inches, using fractions, like 1/4 or 1/8. The metric dial uses millimeters, which is part of the metric system. You choose one based on the type of measurements you prefer or need for your work. They help us make precise threads, but they work with different units.

How Do You Use The Threading Dial To Ensure Accurate Thread Cutting On A Metal Lathe?To use the threading dial on a metal lathe, first, set the machine to threading mode. Then, make sure the dial reads zero at the start. Now, turn the lathe on and move the cutting tool to the metal. When the tool reaches the beginning of the cut, you can turn the dial until it lines up with a specific number. This helps you cut the threads evenly.

What Common Issues Might Arise When Using A Threading Dial, And How Can They Be Resolved?When using a threading dial, you might face some problems. Sometimes, it skips numbers, making it hard to see where you are. If this happens, you can stop and carefully check the dial. Another issue could be that the thread gets stuck. To fix this, you can gently pull the thread while turning the dial. Always take your time to avoid mistakes!

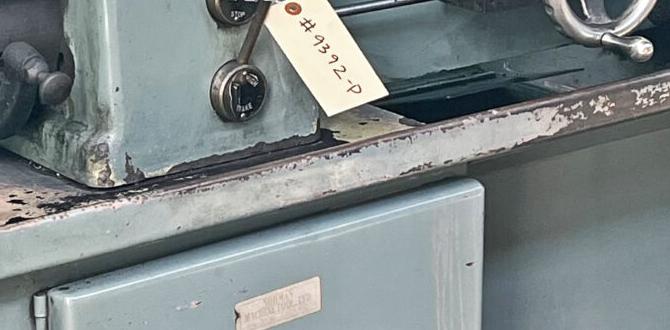

Can A Threading Dial Be Retrofitted To An Older Model Metal Lathe, And If So, What Considerations Should Be Taken Into Account?Yes, you can add a threading dial to an older metal lathe. First, check if your lathe has enough space for it. You’ll also need to make sure it fits well with your machine’s parts. Some lathe models may need extra work or special tools to install the dial. Lastly, ask an expert if you’re unsure about any steps.