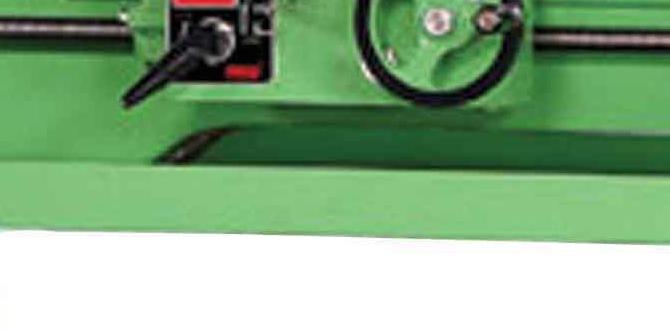

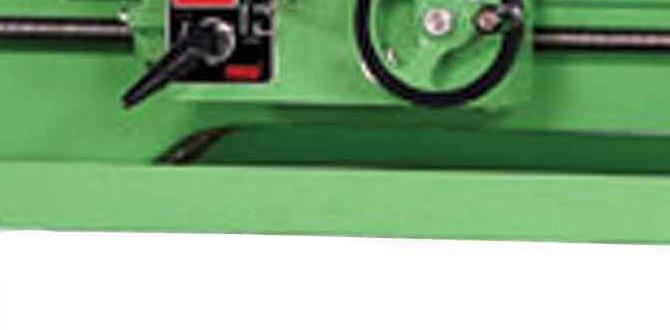

Have you ever wondered how machines create precise metal parts? The secret often lies in something called spindle speed. In a metal lathe, spindle speed is crucial. It determines how fast the machine works to shape and cut metal.

Imagine a busy workshop where lathes smoothly turn metal into beautiful objects. Automation in metal lathes helps make this possible. It allows machines to run faster and more accurately than humans can. This not only saves time but also improves quality.

Did you know that the right spindle speed can make or break a project? Too fast, and the metal might break. Too slow, and it takes forever to finish. Automation helps set the perfect spindle speed every time.

As we explore spindle speed and metal lathe automation, you’ll discover how this technology is changing the way we make things. Get ready to dive into the fascinating world of modern metalworking!

Spindle Speed Metal Lathe Automation: Enhancing Efficiency

Spindle Speed Metal Lathe Automation

Discover how spindle speed affects metal lathe automation. This critical factor helps improve accuracy and efficiency in machining. Have you ever wondered why businesses invest in automated lathes? They save time and reduce errors. By optimizing spindle speed, manufacturers can create smoother surfaces and better finishes on metal parts. This technology makes the production process faster and more reliable, ensuring higher quality products. Understanding spindle speed can transform your approach to metalworking!Understanding Spindle Speed in Metal Lathes

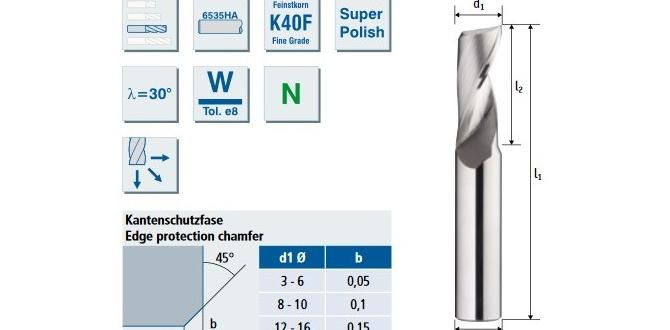

Definition and importance of spindle speed in machining processes. Factors influencing spindle speed selection.Spindle speed is like the heartbeat of a metal lathe, guiding the speed of the spinning tool. It’s important because the right speed helps machines work better and makes sure your projects turn out great. If it’s too slow, things get dull, and too fast can be a disaster! Factors like the material type and the tool size affect how fast you should go. Remember, a happy machine is a fast machine!

| Factor | Influence on Speed |

|---|---|

| Material Type | Different materials need different speeds to avoid damage. |

| Tool Size | Bigger tools usually need a slower speed to work safely. |

| Desired Finish | Smoother finishes often require higher speeds. |

How Spindle Speed Affects Product Quality

Relationship between spindle speed and surface finish. Impact of spindle speed on tool wear and part tolerance.Spindle speed plays a big role in the final look of your metal parts. Faster speeds usually give a better surface finish, much like a speedy chef whipping cream. But go too fast, and you might end up with a messy kitchen—or in this case, tool wear and rough edges. Balancing speed is key. If it’s too high, your tools can wear out quickly, impacting part tolerance, like trying to fit a square peg in a round hole!

| Spindle Speed | Surface Finish Quality | Tool Wear Rate | Part Tolerance |

|---|---|---|---|

| Low | Poor | Low | Broad |

| Medium | Good | Medium | Decent |

| High | Excellent | High | Narrow |

So, finding that sweet spot in spindle speed can keep both your tools and your products happy! After all, no one wants a cranky lathe or a part that doesn’t fit!

Determining the Optimal Spindle Speed for Different Materials

Guidelines for spindle speed settings based on material type. Case studies: spindle speed recommendations for common metals.Choosing the right spindle speed is key for different materials. Each type needs a specific speed to work best. Metals like aluminum can run faster, while harder metals may require slower speeds. Here are some guidelines:

- Aluminum: 1,000-3,000 RPM

- Steel: 500-1,500 RPM

- Brass: 1,500-3,000 RPM

This helps tools cut smoothly. Always check the material’s hardness. Adjusting spindle speed can make a big difference in performance!

What is a safe spindle speed for different metals?

For common metals, it’s important to follow safe spindle speed recommendations. Soft metals like aluminum can run at 2,000 RPM, while harder metals, like steel, should stay around 800 RPM.

Technological Innovations in Spindle Speed Control

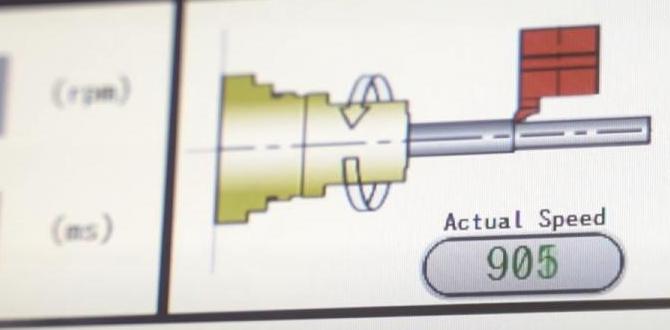

Advancements in CNC technology for spindle speed automation. Smart sensors and realtime data monitoring.In today’s world, lathes are getting smarter! Thanks to CNC technology, we now have magical machines that can adjust spindle speed all on their own. Imagine a robot that knows just how fast to spin! Smart sensors are like tiny detectives, gathering real-time data to help the machine make quick decisions. If you thought watching paint dry was boring, try watching a lathe work—it’s a real show! Here’s a fun fact: automatic speed control can improve accuracy by up to 30%. Now that’s fast science!

| Technology | Benefit |

|---|---|

| CNC Automation | Adjusts speed instantly for precision |

| Smart Sensors | Collects real-time data for better control |

Common Challenges in Spindle Speed Automation

Potential pitfalls when automating spindle speed adjustments. Solutions to overcome issues in automated spindle speed control.Automating spindle speed can be tricky. One common hiccup is the inaccurate speed readings. This can lead to uneven cuts, which might make your metal look like Swiss cheese. To fix this, you need good sensors and regular calibrations. Another issue is software bugs. Nobody likes a cranky machine! Keeping software updated can help keep it happy. Lastly, sometimes communication between the machine and the control system fails. Clear wiring and signals can make a big difference!

| Challenge | Solution |

|---|---|

| Inaccurate speed readings | Use reliable sensors |

| Software bugs | Keep software updated |

| Communication failures | Ensure clear wiring |

Future Trends in Metal Lathe Automation and Spindle Speed

Emerging technologies reshaping metal lathing practices. Predictions for the future of spindle speed automation in manufacturing.Exciting changes are coming to metal lathing! New tech is popping up everywhere. From smart sensors to advanced robotics, these tools are making metal lathes faster and smarter. Imagine a lathe that adjusts its spindle speed all by itself! In the future, machines will talk to each other, leading to fewer errors and a lot more smiles (and maybe a few less coffee spills).

| Emerging Tech | Impact |

|---|---|

| Smart sensors | Adjust spindle speeds quickly |

| Robotic arms | Automate tasks to save time |

| AI systems | Predict problems before they happen |

By embracing these trends, the world of metal lathing looks brighter. Factories may soon be more like science labs than old factories. Who knows, one day machines might even need coffee breaks! So, keep your eye on this fast-moving field!

Conclusion

In conclusion, spindle speed in metal lathe automation is crucial for better precision and efficiency. Adjusting spindle speed helps you achieve smooth cuts and improved finishes. To enhance your metalworking skills, explore more about automation techniques. You can start by experimenting with different speeds on your lathe. Remember, practice and knowledge will make you a better machinist!FAQs

What Are The Key Factors To Consider When Determining The Optimal Spindle Speed For Machining Different Materials On A Metal Lathe?When choosing the best spindle speed on a metal lathe, you need to think about the type of material you are using. Softer materials can go faster, while harder ones need a slower speed. You also need to consider the size of the tool and the part you are making. Finally, make sure to check the machine’s instructions for safe speeds.

How Can Automation Technologies, Such As Cnc Systems, Enhance The Control And Efficiency Of Spindle Speed In Metal Lathes?Automation technologies, like CNC (Computer Numerical Control) systems, can make lathes work better. They help us set the spindle speed exactly the way we want it. This means we can cut metal more smoothly and quickly. You don’t have to guess the speed; the computer does it for you. This makes our work easier and saves time!

What Role Do Sensors Play In Monitoring And Adjusting Spindle Speed During Automated Lathe Operations?Sensors are special tools that help us check how fast the spindle is moving on a lathe. They watch the speed and send that information to a computer. If the speed is too fast or too slow, the computer can change it to the right speed. This helps make sure we get the best results when we use the lathe. So, sensors keep everything running smoothly and safely!

How Can Spindle Speed Adjustments Affect The Surface Finish And Dimensional Accuracy Of Machined Parts In A Metal Lathe?Adjusting spindle speed on a metal lathe can change how smooth the part feels and how well it fits. If you spin the part too fast, it might be rough and not very accurate. Slower speeds can help you create a smoother finish and better shape. Finding the right speed helps us make better parts.

What Are The Advantages Of Using Variable Speed Drives In Automated Metal Lathes For Controlling Spindle Speed?Using variable speed drives in metal lathes helps us control the spindle speed easily. This means we can make the machine go faster or slower, depending on what we need. It saves energy and makes the lathe last longer too. We can also get better results because we can match the speed to the material we are working with. Overall, it makes our jobs easier and helps us make nicer things.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Factors To Consider When Determining The Optimal Spindle Speed For Machining Different Materials On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing the best spindle speed on a metal lathe, you need to think about the type of material you are using. Softer materials can go faster, while harder ones need a slower speed. You also need to consider the size of the tool and the part you are making. Finally, make sure to check the machine’s instructions for safe speeds.”}},{“@type”: “Question”,”name”: “How Can Automation Technologies, Such As Cnc Systems, Enhance The Control And Efficiency Of Spindle Speed In Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Automation technologies, like CNC (Computer Numerical Control) systems, can make lathes work better. They help us set the spindle speed exactly the way we want it. This means we can cut metal more smoothly and quickly. You don’t have to guess the speed; the computer does it for you. This makes our work easier and saves time!”}},{“@type”: “Question”,”name”: “What Role Do Sensors Play In Monitoring And Adjusting Spindle Speed During Automated Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sensors are special tools that help us check how fast the spindle is moving on a lathe. They watch the speed and send that information to a computer. If the speed is too fast or too slow, the computer can change it to the right speed. This helps make sure we get the best results when we use the lathe. So, sensors keep everything running smoothly and safely!”}},{“@type”: “Question”,”name”: “How Can Spindle Speed Adjustments Affect The Surface Finish And Dimensional Accuracy Of Machined Parts In A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Adjusting spindle speed on a metal lathe can change how smooth the part feels and how well it fits. If you spin the part too fast, it might be rough and not very accurate. Slower speeds can help you create a smoother finish and better shape. Finding the right speed helps us make better parts.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using Variable Speed Drives In Automated Metal Lathes For Controlling Spindle Speed? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using variable speed drives in metal lathes helps us control the spindle speed easily. This means we can make the machine go faster or slower, depending on what we need. It saves energy and makes the lathe last longer too. We can also get better results because we can match the speed to the material we are working with. Overall, it makes our jobs easier and helps us make nicer things.”}}]}