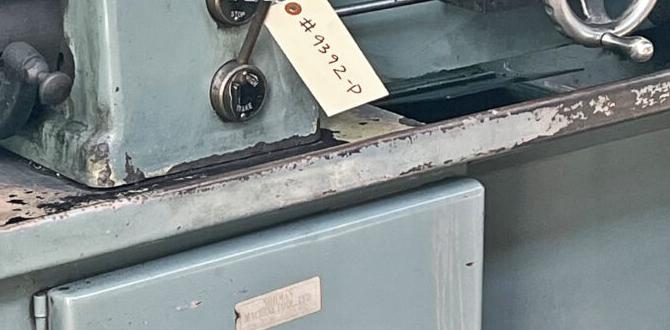

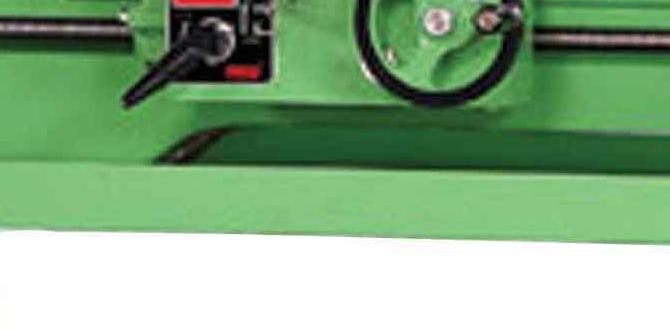

Have you ever watched a metal lathe at work? It’s fascinating to see how it shapes metal pieces. The magic behind this process often starts with the spindle speed. But what does that really mean?

Imagine a small bench in your garage. You place a metal piece on the lathe. The spindle spins it around quickly. This spinning is important. It helps cut and shape the metal into useful tools or parts.

Different projects need different spindle speeds. A higher speed works well for soft metals. But harder metals require slower speeds. Knowing how to adjust the spindle speed makes you a better machinist.

Here’s a fun fact: The right spindle speed can make your work easier and smoother. It can even help you finish projects faster. How cool is that?

In the world of metalworking, the spindle speed on a lathe bench is key. Let’s dive deeper into how this small detail can change everything in your workshop.

Understanding Spindle Speed For Metal Lathe Bench Operations

Understanding Spindle Speed on a Metal Lathe Bench

Spindle speed plays a big role in metal lathe work. It affects how fast the tool cuts through metal. Higher speeds can create smoother finishes, but may also risk overheating. Did you know that different materials need different speeds? For example, aluminum cuts well at high speeds, while steel needs slower speeds. Choosing the right spindle speed can make your projects easier and more successful. Understanding this helps you become a better machinist!What is Spindle Speed?

Definition of spindle speed in metal lathes. Importance of spindle speed in machining processes.Spindle speed is how fast the spindle of a metal lathe turns. It’s a key part when shaping metal. Think of it as the heartbeat of your machine! If the spindle spins too slow, it can’t cut well. If it spins too fast, it might break your tools or burn the metal. Finding the right speed is crucial for making precise cuts and smooth finishes. Remember, it’s all about balance—your lathe doesn’t want to dance too fast or too slow!

| Spindle Speed | Effect |

|---|---|

| Too Slow | Poor cutting, rough surface |

| Just Right | Clean cuts, nice finish! |

| Too Fast | Tool wear, burning metal |

Factors Affecting Spindle Speed

Material type and its impact on speed settings. Tooling considerations and compatibility.Different materials can change how fast your lathe spins. For soft metals like aluminum, you can go faster. Harder materials, like steel, need a slower speed to protect your tools. Using the right speed can save wear and tear on your tools! Compatibility matters too. The tooling must match your material. A poorly matched tool can ruin your work and make it less fun—nobody wants to break a tool mid-project! Check the table below for quick reference:

| Material Type | Recommended Spindle Speed (RPM) |

|---|---|

| Aluminum | 1200-3000 |

| Brass | 800-2000 |

| Steel | 200-600 |

| Cast Iron | 300-800 |

Calculating Optimal Spindle Speed

Formulas for determining ideal spindle speed. Example calculations for different materials.Finding the right spindle speed can feel tricky, but it doesn’t have to be rocket science! You can use a simple formula: Spindle Speed (RPM) = (Cutting Speed × 12) / (π × Diameter). Different materials need different speeds. For instance, soft materials like aluminum can spin faster, while harder metals slow it down. Here’s a quick table to help:

| Material | Cutting Speed (SFPM) | Ideal Spindle Speed (RPM) |

|---|---|---|

| Aluminum | 600 | 2250 |

| Steel | 100 | 300 |

| Brass | 250 | 900 |

Think of it this way: spinning at the right speed is like finding the perfect dance partner—you don’t want to go too fast unless you want to twist an ankle! Keep your material in mind for the best results.

Common Mistakes in Spindle Speed Management

Identifying frequent errors and their consequences. Tips to avoid these mistakes during lathe operation.Spindle speed management can be tricky. Many folks make the same mistakes while using a metal lathe bench. Common errors include setting the speed too high or too low. This can result in poor cuts or damage to the tool. To avoid these blunders, always check the material type first. Adjust the speed accordingly so your lathe works smoothly. Remember, slow and steady often wins the race, especially when you don’t want a flying piece of metal!

| Common Mistakes | Consequences | Tips to Avoid |

|---|---|---|

| Wrong speed setting | Poor cuts | Check material type |

| Ignoring tool wear | Tool damage | Regularly inspect tools |

| Not adjusting speed | Reduced performance | Change speeds as needed |

Effects of Incorrect Spindle Speed on Machining

Impact on workpiece quality and surface finish. Potential damage to tools and machinery.Using the wrong spindle speed can ruin your shiny project faster than a cat on a hot tin roof! If the speed is too high or low, the workpiece can end up with scratches and a bumpy surface. This makes it look like a disco ball instead of a smooth finish. Not only that, but the tools could get worn out or even broken. It’s like asking your favorite toy to run a marathon—we all know that won’t end well!

| Spindle Speed Type | Effects |

|---|---|

| Too High | Damaged surface, burnt tools |

| Too Low | Poor finish, excess wear |

Keeping the right spindle speed matters to get the best quality while saving your tools. Remember, a happy lathe means a happy you!

Best Practices for Spindle Speed Optimization

Recommended procedures for achieving optimal speed. Utilizing technology and tools for better speed management.Finding the right spindle speed is key for a smooth metal lathe operation. Here are some recommended steps:

- Check your material’s requirements for speed.

- Use a tachometer to measure current speed.

- Adjust your lathe settings based on cutting needs.

- Embrace digital tools for real-time speed monitoring.

Smart tools help make speed adjustments easier. They provide reports and suggestions too. This ensures you get the best performance from your lathe. Follow these practices, and enjoy better results!

What is the best way to manage spindle speed?

Using digital tools and understanding material needs greatly helps manage spindle speed. This leads to effective cuts and less wear on tools.

Real-World Applications of Proper Spindle Speed

Case studies demonstrating the importance of accurate spindle speed. Industries that benefit from precise spindle speed settings.Using the right spindle speed in a metal lathe is crucial. For example, a car parts manufacturer reduced defects by 30% after adjusting its spindle speed. This simple change saved time and materials. Many industries depend on precise spindle speed settings, such as:

- Aerospace

- Automotive

- Manufacturing

Each of these fields needs accurate speeds to ensure quality and safety. Without it, mistakes happen that can cost time and money.

What happens if spindle speed is incorrect?

If spindle speed is set wrong, it can lead to poor quality parts or even machine damage. Proper settings ensure the best results and a smoother process.

Future Trends in Spindle Speed Technology

Innovations in spindle speed control systems. Emerging technologies that influence metal lathe performance.Exciting changes are happening in spindle speed technology! New control systems are making it easier for metal lathes to work faster and smarter. Think of these systems as brain upgrades for machines—no question they are getting cleverer! Some innovations include sensors and software that adapt to different materials, so you can always get the best results.

Emerging tech like automation and AI is also shaking things up. Machines can now adjust themselves while working, just like a magician pulling a rabbit out of a hat! This means less downtime and more productivity. Here’s a fun fact: studies show that smarter spindle control can increase performance by up to 30%!

| Technology | Impact |

|---|---|

| Sensors | Real-time adjustments |

| Automation | Less downtime |

| AI | Smart performance boosts |

So, next time you use a lathe, just remember: it’s smarter than it looks! Who knew metal work could be so advanced and fun?

Conclusion

In conclusion, spindle speed on a metal lathe bench is crucial for your work. Faster speeds cut quickly but can be risky. Slower speeds are safer and better for precise tasks. Always choose the right speed for the material you work with. Explore more about spindle speeds to improve your skills and achieve better results in your projects!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Spindle Speed For Metal Lathe Benches:Sure! Spindle speed is how fast a lathe spins the metal. You need the right speed for your project. If it’s too fast, the metal can get too hot. If it’s too slow, you won’t cut well. Always check your machine’s guide for safe speeds!

Sure! Please provide the question you’d like me to answer.

What Factors Influence The Optimal Spindle Speed For Machining Different Metals On A Lathe Bench?The best spindle speed on a lathe depends on the metal you are using. Softer metals like aluminum need a faster speed, while harder metals like steel need a slower speed. We also consider the size of the tool and the type of cut we want to make. Speed helps us get a smooth finish and keeps our tools working well.

How Can You Calculate The Correct Spindle Speed For A Specific Workpiece Diameter And Tool Material?To find the right spindle speed, you first need the diameter of the workpiece. Then, we can use a simple formula that involves that diameter. If your workpiece is small, you’ll spin it faster. If it’s big, spin it slower. You also need to consider the tool material; some tools work better at different speeds.

What Are The Potential Consequences Of Operating A Metal Lathe At Incorrect Spindle Speeds?If you use the wrong spindle speed on a metal lathe, it can cause problems. The metal might get too hot and burn. Your workpiece could break or get damaged, making it unusable. Plus, it might make your tools wear out faster. This can lead to accidents, which is dangerous for you and others around you.

How Do Variable Speed Drives Enhance The Spindle Speed Control Of A Metal Lathe?Variable speed drives help control how fast the spindle of a metal lathe spins. This means we can easily change the speed for different jobs. If a part needs to be cut slowly, we can make it go slow. If we need it to go fast, we can do that too. This makes our work easier and gives us better results!

What Is The Relationship Between Spindle Speed, Feed Rate, And Cutting Tool Wear In Lathe Operations?When you use a lathe, spindle speed is how fast the tool spins. If the spindle speed is too high, it can wear the cutting tool out quickly. The feed rate is how fast the tool moves across the material. If the feed rate is too high, it also makes the tool wear faster. So, we must find a good balance to make tools last longer.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Spindle Speed For Metal Lathe Benches:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Spindle speed is how fast a lathe spins the metal. You need the right speed for your project. If it’s too fast, the metal can get too hot. If it’s too slow, you won’t cut well. Always check your machine’s guide for safe speeds!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Factors Influence The Optimal Spindle Speed For Machining Different Metals On A Lathe Bench?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The best spindle speed on a lathe depends on the metal you are using. Softer metals like aluminum need a faster speed, while harder metals like steel need a slower speed. We also consider the size of the tool and the type of cut we want to make. Speed helps us get a smooth finish and keeps our tools working well.”}},{“@type”: “Question”,”name”: “How Can You Calculate The Correct Spindle Speed For A Specific Workpiece Diameter And Tool Material?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right spindle speed, you first need the diameter of the workpiece. Then, we can use a simple formula that involves that diameter. If your workpiece is small, you’ll spin it faster. If it’s big, spin it slower. You also need to consider the tool material; some tools work better at different speeds.”}},{“@type”: “Question”,”name”: “What Are The Potential Consequences Of Operating A Metal Lathe At Incorrect Spindle Speeds?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you use the wrong spindle speed on a metal lathe, it can cause problems. The metal might get too hot and burn. Your workpiece could break or get damaged, making it unusable. Plus, it might make your tools wear out faster. This can lead to accidents, which is dangerous for you and others around you.”}},{“@type”: “Question”,”name”: “How Do Variable Speed Drives Enhance The Spindle Speed Control Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Variable speed drives help control how fast the spindle of a metal lathe spins. This means we can easily change the speed for different jobs. If a part needs to be cut slowly, we can make it go slow. If we need it to go fast, we can do that too. This makes our work easier and gives us better results!”}},{“@type”: “Question”,”name”: “What Is The Relationship Between Spindle Speed, Feed Rate, And Cutting Tool Wear In Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a lathe, spindle speed is how fast the tool spins. If the spindle speed is too high, it can wear the cutting tool out quickly. The feed rate is how fast the tool moves across the material. If the feed rate is too high, it also makes the tool wear faster. So, we must find a good balance to make tools last longer.”}}]}