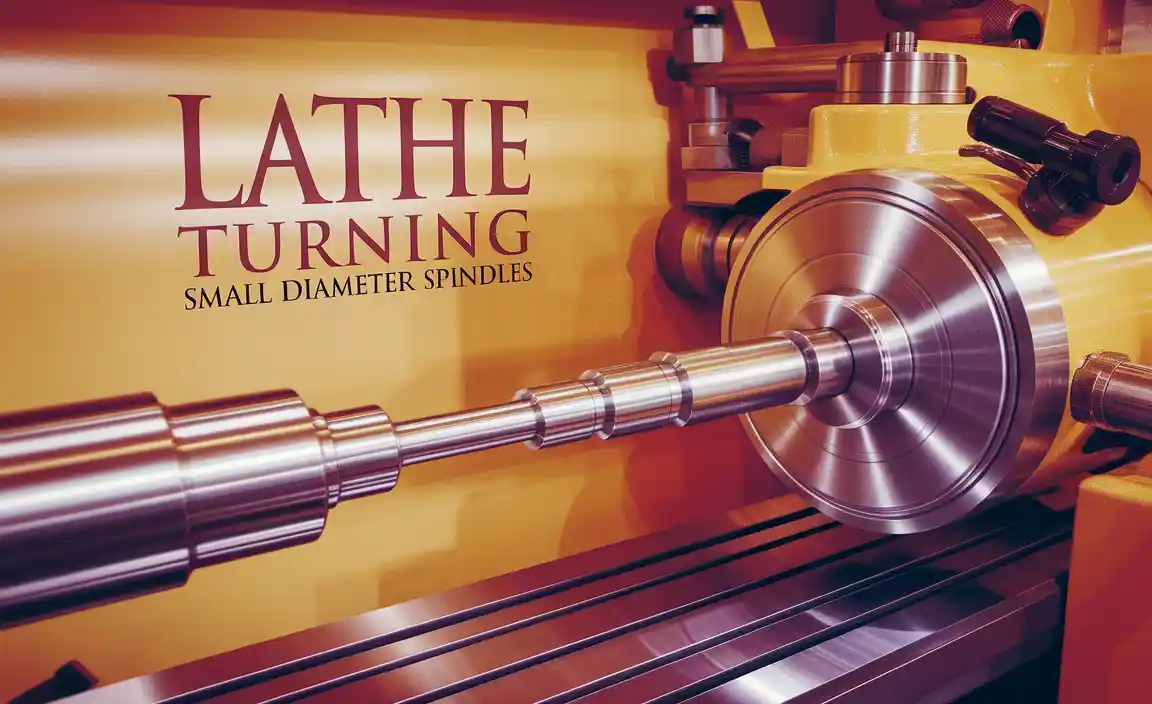

Have you ever watched someone create a metal piece on a lathe? It’s fascinating! A metal lathe can do amazing things, and the spindle speed is vital. It determines how fast the machine turns. This affects how smooth and precise your cuts will be.

Now, imagine you are working on a project. You want to make everything just right. The compound rest helps you adjust your tools accurately. But, did you know that the right spindle speed plays a big role in what your finished piece will look like?

Learning about spindle speed, metal lathes, and compound rests can unlock a world of possibilities. You can create everything from small parts to large designs. Understanding how these parts work makes you a better craftsman. Are you ready to dive into the world of metal turning?

Understanding Spindle Speed On Metal Lathe Compound Rest

Understanding Spindle Speed on Metal Lathes and the Compound Rest

Spindle speed on a metal lathe is essential for smooth machining. It helps control the cutting process, leading to better finish and accuracy. Did you know that adjusting the spindle speed can dramatically change your project’s outcome? The compound rest is a key part of the lathe that allows for precise angle adjustments. Mastering these elements can make you a better machinist. Imagine crafting perfect pieces simply by tweaking your settings!What is Spindle Speed?

Definition of spindle speed in machining.. Importance of spindle speed in metal lathe operations..Spindle speed is how fast a lathe rotates the tool. It is important in machining. If the speed is too low, work takes longer. If it is too high, the tool can break. Finding the right speed helps make clean cuts. This is also important for the type of metal being used.

- High spindle speed produces a smooth finish.

- Low spindle speed is good for tougher materials.

- Correct speed saves time and energy.

What affects spindle speed?

Several factors affect spindle speed, such as material type, tool size, and desired finish. Knowing these helps increase efficiency. Stronger tools can handle higher speeds.

Role of the Compound Rest in Metal Lathes

Explanation of the compound rest function and components.. How the compound rest enhances machining precision..The compound rest in a metal lathe is an important tool. It holds the cutting tool and lets it move easily. This part helps create precise shapes. The compound rest includes several components: a base, a swivel, and a slide. Each piece works together to improve accuracy in machining. This means better parts for projects!

Here’s how the compound rest enhances machining precision:

- Control: It provides better control over cutting angles.

- Movement: The sliding action allows for exact adjustments.

- Stability: It keeps the tool steady during operation.

What is the function of a compound rest in a lathe?

The compound rest allows for precise movement of the cutting tool, making it easy to create detailed shapes and designs. It improves accuracy by allowing fine adjustments.

Calculating Optimal Spindle Speed

Formula for calculating spindle speed based on material type.. Factors influencing spindle speed choices, such as workpiece diameter and tooling material..Want to find the perfect spindle speed? It’s all about knowing the type of material you’re working with. To calculate it, use the formula: Spindle Speed (RPM) = (Cutting Speed x 12) / (π x Diameter). Factors like the workpiece diameter and tooling material also play a major role. For example, larger diameters often mean slower speeds. And remember, you wouldn’t want to spin a pizza too fast, or it might fly off the plate!

| Material Type | Recommended Cutting Speed (SFM) |

|---|---|

| Aluminum | 100-200 |

| Steel | 80-120 |

| Brass | 150-250 |

Adjusting Spindle Speed for Compound Rest Operations

Stepbystep guide to adjusting spindle speed while using a compound rest.. Tips for maintaining stability and precision during speed adjustments..To adjust spindle speed during compound rest operations, follow these simple steps: First, turn off the lathe to ensure safety. Then, locate the speed control. Next, slowly adjust the spindle speed dial. Always watch the indicator closely as you change speeds. For stability and precision:

- Keep both hands steady on the lathe.

- Check all tools are secure in the compound rest.

- Make small adjustments to avoid overshooting.

Remember, taking your time helps make better cuts!

How do you maintain precision during speed adjustments?

Stay calm and use slow, gentle movements. This minimizes vibrations and keeps everything aligned for perfect cuts.

Impact of Spindle Speed on Tool Life and Workpiece Quality

How spindle speed affects tool wear and longevity.. Relationship between spindle speed and the surface finish of machined parts..The spindle speed plays a big role in how long your tools last. Too high a speed makes the tool wear faster, while a lower speed can help it stick around for a while longer. Think of it like riding a bike; go too fast, and you might skid! For surface finish, the right speed gives a shiny, smooth finish. However, too slow might lead to bumps and grooves. It’s all about balance, a bit like walking a tightrope!

| Spindle Speed | Tool Life | Surface Finish Quality |

|---|---|---|

| High | Shorter | Poor |

| Optimal | Longer | Better |

| Low | Varies | Variable |

Always remember: a happy spindle means a happy tool! Adjust it wisely to keep everything in tip-top shape.

Case Studies and Practical Applications

Realworld examples of effective spindle speed adjustments in metal lathe projects.. Analysis of outcomes when optimal spindle speeds and compound rest techniques are employed..In real-life metal lathe projects, adjusting spindle speed can make a big difference. For example, a woodworker changed the spindle speed and created a smoother finish on a project. This simple adjustment helped reduce vibrations and improved the final look of the work.

With the right spindle speed and using the compound rest well, results can be outstanding. Here are some key outcomes:

- Better Surface Quality: Smoother finishes are easier to achieve.

- Increased Tool Life: Proper speeds can make tools last longer.

- Enhanced Accuracy: Precision in cuts is improved.

Many users report these benefits when they make the right adjustments. A skilled craftsman stated, “Finding the right speed is like unlocking a secret.” This shows how important these choices are for success in metalworking.

What are the outcomes of using optimal spindle speeds?

Using optimal spindle speeds leads to higher quality finishes and longer tool life. Many metalworkers see a big change in their projects after adjusting speeds.

Benefits of Proper Spindle Speed:

- Improved cut quality

- Reduced wear on tools

- Less waste material

Conclusion

In conclusion, spindle speed is crucial for metal lathes. It affects how quickly and smoothly you can work. The compound rest lets you change angles easily, improving your cuts. Understanding these tools helps you improve your skills. Explore more about metal lathes and practice regularly. You’ll become a better machinist in no time! Keep learning and experimenting!FAQs

Sure! Here Are Five Questions Related To Spindle Speed, Metal Lathes, And The Compound Rest:Sure! Spindle speed is how fast the machine turns a part. We need the right speed for different materials. A metal lathe is a tool that shapes metal by spinning it. The compound rest helps us tilt and move the tool for better cuts. It makes our work more precise and easier!

Sure! Please provide the question you’d like me to answer.

What Is The Effect Of Spindle Speed On The Cutting Performance And Surface Finish When Machining Metal On A Lathe?Spindle speed is how fast the lathe spins the metal. When you increase the speed, the cutting tool removes metal faster. This can help you finish your work quickly. However, if the speed is too high, it can make the surface rough. So, finding the right speed is important for a smooth and clean finish.

How Do You Calculate The Optimal Spindle Speed For Different Materials When Using A Metal Lathe?To find the best spindle speed for a metal lathe, you need to know the material you are using. First, look up its cutting speed in feet per minute (FPM). Then, you can use a simple formula: spindle speed (in RPM, which means revolutions per minute) equals the cutting speed divided by the diameter of the tool. For example, if the cutting speed is 100 FPM and the tool’s diameter is 1 inch, you would set the spindle speed to 100 RPM. Adjust the speed based on how the material feels while cutting.

What Role Does The Compound Rest Play In Conjunction With Spindle Speed Adjustments During Taper Turning Operations?The compound rest helps us tilt the cutting tool for taper turning. Taper turning is when we make one end of a piece smaller or larger than the other. When you change the spindle speed, it can help the tool cut better and smoother. So, you use the compound rest with the right spindle speed to get a nice finish on your work.

How Can Improper Spindle Speed Settings Impact Tool Wear And Overall Machining Accuracy On A Lathe?If you set the spindle speed too fast or too slow, the tool can wear out quickly. A worn tool can make bad cuts, which means your workpiece won’t be shaped correctly. This can lead to mistakes and extra parts that don’t fit. It’s important to choose the right speed to keep everything working well.

What Techniques Can Be Used To Adjust The Spindle Speed Of A Metal Lathe To Achieve The Desired Cutting Conditions For Various Operations?You can adjust the spindle speed of a metal lathe using a few simple methods. First, you can change the settings on the machine’s control panel. Second, you can switch gears if your lathe has that option. Lastly, you can use a variable speed control to make it faster or slower. Each adjustment helps you cut metal more easily.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Spindle Speed, Metal Lathes, And The Compound Rest:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Spindle speed is how fast the machine turns a part. We need the right speed for different materials. A metal lathe is a tool that shapes metal by spinning it. The compound rest helps us tilt and move the tool for better cuts. It makes our work more precise and easier!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Is The Effect Of Spindle Speed On The Cutting Performance And Surface Finish When Machining Metal On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Spindle speed is how fast the lathe spins the metal. When you increase the speed, the cutting tool removes metal faster. This can help you finish your work quickly. However, if the speed is too high, it can make the surface rough. So, finding the right speed is important for a smooth and clean finish.”}},{“@type”: “Question”,”name”: “How Do You Calculate The Optimal Spindle Speed For Different Materials When Using A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the best spindle speed for a metal lathe, you need to know the material you are using. First, look up its cutting speed in feet per minute (FPM). Then, you can use a simple formula: spindle speed (in RPM, which means revolutions per minute) equals the cutting speed divided by the diameter of the tool. For example, if the cutting speed is 100 FPM and the tool’s diameter is 1 inch, you would set the spindle speed to 100 RPM. Adjust the speed based on how the material feels while cutting.”}},{“@type”: “Question”,”name”: “What Role Does The Compound Rest Play In Conjunction With Spindle Speed Adjustments During Taper Turning Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The compound rest helps us tilt the cutting tool for taper turning. Taper turning is when we make one end of a piece smaller or larger than the other. When you change the spindle speed, it can help the tool cut better and smoother. So, you use the compound rest with the right spindle speed to get a nice finish on your work.”}},{“@type”: “Question”,”name”: “How Can Improper Spindle Speed Settings Impact Tool Wear And Overall Machining Accuracy On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you set the spindle speed too fast or too slow, the tool can wear out quickly. A worn tool can make bad cuts, which means your workpiece won’t be shaped correctly. This can lead to mistakes and extra parts that don’t fit. It’s important to choose the right speed to keep everything working well.”}},{“@type”: “Question”,”name”: “What Techniques Can Be Used To Adjust The Spindle Speed Of A Metal Lathe To Achieve The Desired Cutting Conditions For Various Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can adjust the spindle speed of a metal lathe using a few simple methods. First, you can change the settings on the machine’s control panel. Second, you can switch gears if your lathe has that option. Lastly, you can use a variable speed control to make it faster or slower. Each adjustment helps you cut metal more easily.”}}]}