Have you ever wondered how metal lathes work? They are fascinating machines that help create all sorts of metal parts. One important feature of these lathes is the spindle speed. But how do you control it? That’s where a spindle speed metal lathe wiring diagram comes in.

Imagine you want to build something cool. Maybe it’s a robot or a model car. You need precise cuts and shapes. Without the right wiring, your metal lathe won’t run smoothly. So, understanding that wiring diagram is a key step.

Did you know many hobbyists start with basic lathes? They often find that learning about spindle speed can change their projects. It’s true! The right speed can make cutting metal easy and fun.

This article will help you understand spindle speed and how to read a wiring diagram. You’ll see how it affects your lathe’s performance. Ready to dive into the world of metal lathes? Let’s get started!

Spindle Speed Metal Lathe Wiring Diagram: A Complete Guide

Spindle Speed Metal Lathe Wiring Diagram

Understanding spindle speed on metal lathes is vital for effective machining. A wiring diagram shows how to connect essential components. This helps ensure safety and optimal performance. Did you know the spindle speed affects the type of material you can work with? A clear wiring diagram simplifies troubleshooting and adjustments. It keeps your lathe safe while running smoothly. With the right setup, you can achieve amazing results in your projects. Curious how your lathe can perform better?What is a Spindle Speed Metal Lathe?

Definition and purpose of metal lathes. Importance of spindle speed in machining.A metal lathe is a special machine used to shape metal into different forms. It spins metal pieces while cutting tools carve them. This tool is powerful for making parts for cars, machines, and even toys. Spindle speed is very important in this process. It decides how fast the metal spins. Faster speeds can help make smooth surfaces, while slower speeds can give better control. In short, the right spindle speed is key to getting great results.

What is the importance of spindle speed?

Spindle speed affects the quality and efficiency of machining. Here are some key points about its importance:

- It influences cutting precision.

- Higher speeds can reduce machining time.

- It helps prevent tool wear.

- It allows options for different materials.

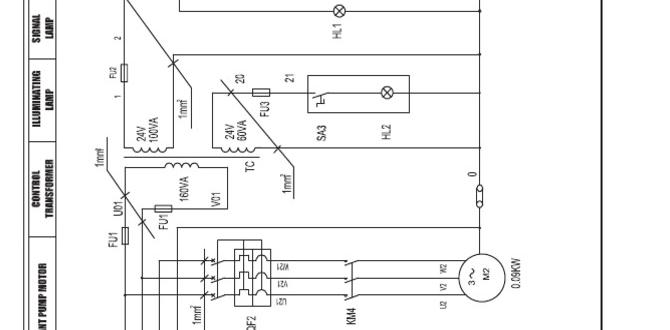

Components of a Metal Lathe Wiring Diagram

Key parts illustrated in the diagram. Explanation of electrical components and their functions.Understanding the wiring diagram for a metal lathe is easier when we break it down. Key components to look for include the motor, switches, and control panel. Each part plays a special role, like the motor that makes things spin, and switches that help you start or stop your machine. It’s like the metal lathe’s way of saying “let’s get to work” or “time for a coffee break!” Here’s a quick look at these essential parts:

| Component | Function |

|---|---|

| Motor | Powers the lathe and spins the spindle. |

| Switches | Control when the lathe turns on or off. |

| Control Panel | Displays settings and helps with adjustments. |

Each part must be connected properly to avoid any “oops” moments. The wiring may look complicated, but with a good diagram and some practice, you’ll be a wiring wizard in no time!

Understanding Spindle Speed Control

Types of spindle speed control mechanisms. Benefits of variable speed control in metal lathes.Spindle speed control is key for any metal lathe. There are a few types of mechanisms that do the job. One is a gearbox, which gives fixed speeds. Another is electronic speed control, allowing for smooth adjustments. This is super handy for different materials. Variable speed control is a big win! It improves accuracy and can even save your tools from wear. So, less breakage equals more fun in the shop!

| Type | Benefits |

|---|---|

| Gearbox | Fixed speeds, sturdy performance |

| Electronic Control | Flexible speeds, better precision |

Having control over speed means you can spin like a pro! So next time, remember: happy lathing equals happy tools!

Step-by-Step Guide to Wiring a Metal Lathe

Tools required for wiring installation. Detailed wiring steps to connect spindle motor and controls.Wiring a metal lathe might sound tricky, but it’s easier than tying your shoelaces! First, gather your tools: a screwdriver, wire cutter, electrical tape, and a multimeter—your new best friends for this task. Now, follow these steps to connect the spindle motor and controls:

| Step | Description |

|---|---|

| 1 | Turn off the power! Safety first. |

| 2 | Connect wires from the spindle motor to the control panel. |

| 3 | Use tape to secure connections. No loose ends allowed! |

| 4 | Check everything with your multimeter. |

| 5 | Power it up and watch it spin! |

Following these steps will make your lathe sing! Do it right, and you’ll have all the spindle speed you need. Happy wiring!

Troubleshooting Wiring Issues

Common electrical issues in metal lathe wiring. Tips for diagnosing and fixing problems.Wiring problems in metal lathes can be tricky. Common issues include loose connections and damaged wires. Check your power supply first. Ensure switches and fuses work well. If you notice strange noises, it may signal trouble. Always unplug before checking. Here are some quick tips:

- Look for frayed wires.

- Tighten all connections.

- Test switches with a multimeter.

Being safe is crucial. Don’t hesitate to seek help if needed!

What should I do if my metal lathe won’t turn on?

Check the power supply and fuses first. Ensure the machine is plugged in and the switch is on. If it still doesn’t work, inspect the wiring for any visible damage.

Safety Precautions When Working with Metal Lathe Wiring

Essential safety measures to take prior to beginning work. Importance of following electrical codes and standards.Before starting work with a metal lathe, safety comes first. Always wear proper gear like goggles and gloves. This keeps you safe from flying metal bits—ouch! Next, make sure your wiring follows electrical codes. These codes protect you from dangerous shocks. Remember, a little caution can save a lot of shock! Never skip checking connections to ensure they’re tight. Trust me, loose wires can throw a party you don’t want to attend!

| Safety Precautions | Importance |

|---|---|

| Wear safety gear | Protects from injuries |

| Check wiring connections | Prevents electrical hazards |

| Follow electrical codes | Ensures safety compliance |

Resources for Further Learning

Recommended manuals and guides for metal lathe wiring. Online forums and communities for metalworking enthusiasts.Learning about metal lathe wiring can be fun! Start with helpful manuals and guides. They provide clear instructions and tips for success. You can also dive into online forums. There, metalworking fans share experiences and advice. Need a laugh? Someone might even share a tale of their lathe mishap. Remember, even experts had to learn sometime!

| Resource Type | Recommendations |

|---|---|

| Manuals | “The Complete Guide to Metalworking” |

| Forums | Metalworking Nation, Practical Machinist |

These resources are treasure troves of info! So grab a cup of coffee and dive in.

Conclusion

In conclusion, understanding spindle speed metal lathe wiring diagrams helps you work safely and efficiently. Knowing the wiring connections ensures your lathe runs smoothly. We encourage you to study these diagrams and practice wiring with a real machine. Explore more resources and tutorials to deepen your knowledge and skills. This way, you can become a better metalworking enthusiast!FAQs

What Is The Purpose Of The Spindle Speed Control In A Metal Lathe Wiring Diagram?The spindle speed control in a metal lathe helps you change how fast the machine spins. This lets you work with different materials better. If you go too fast, you might break something. If you go too slow, it takes longer to finish. So, speed control helps you do a good job!

How Can I Interpret The Wiring Connections For The Spindle Motor In A Metal Lathe?To understand the wiring connections for the spindle motor in a metal lathe, look at the wires closely. Usually, there are three main wires: one for power, one for control, and one for ground. You can use a manual or diagram to see where each wire connects. Make sure to follow the colors or labels to avoid mistakes. If you’re not sure, ask someone for help!

What Are The Common Electrical Components Involved In Controlling Spindle Speed On A Metal Lathe?To control spindle speed on a metal lathe, we use several important parts. First, there’s a motor that spins the spindle. Then, we need a speed controller to change how fast the motor runs. We also use a power supply to give energy to the motor. Finally, switches let us turn everything on and off.

How Do I Troubleshoot Spindle Speed Issues Based On A Wiring Diagram For My Metal Lathe?To troubleshoot spindle speed issues, first, check the wiring diagram. Look for loose or damaged wires connecting to the spindle motor. Make sure all the connections are tight and secure. Then, check the settings on your lathe. If everything looks good, test the motor; it might need to be replaced.

Are There Specific Wiring Diagram Variations For Different Types Or Models Of Metal Lathes Regarding Spindle Speed Control?Yes, different metal lathes have unique wiring diagrams. These diagrams help control how fast the spindle spins. Each model may use a different setup, like different buttons or switches. It’s important to follow the right diagram for your lathe. This keeps it working safely and correctly.