Quick Summary:

To stop chatter on a wood lathe, achieve a balanced setup. This involves ensuring your lathe bed is stable, the workpiece is securely mounted and balanced, your tools are sharp, and your cutting technique is smooth and consistent. Proper setup is key to a vibration-free turning experience.

Hey there, fellow wood turners! Daniel Bates here from Lathe Hub. If you’ve spent any time at the wood lathe, you’ve probably met a common, frustrating foe: chatter. That’s the annoying vibration that makes your beautiful wood turn into a bumpy, uneven mess. It can ruin a project and make your lathe sound like it’s about to take flight. But don’t worry, it’s a very common issue for beginners, and thankfully, it has simple, effective solutions. We’re going to walk through exactly how to chase it away, step-by-step, so you can get back to creating smooth, satisfying finishes.

Understanding Wood Lathe Chatter

Chatter, also known as vibration or chattering, is that tell-tale buzzing or shaking you feel and hear when turning wood on a lathe. It happens when the cutting tool and the workpiece aren’t in consistent contact. Think of it like hitting a speed bump repeatedly – it jolts the tool and tears at the wood. This can happen for a variety of reasons, from a wobbly lathe to a poorly mounted blank or even a dull tool. The good news is, by systematically checking a few key areas, you can eliminate this problem and enjoy smooth, clean cuts.

Why is Chatter a Problem?

Beyond the unpleasant noise and vibration, chatter actively degrades the quality of your work. It:

- Creates rough surfaces that require extensive sanding.

- Can cause tools to dig in uncontrollably, leading to gouges.

- Makes it difficult to achieve precise shapes and diameters.

- Puts unnecessary stress on your lathe and tools.

- Can be a safety hazard if it causes the tool to jump.

Essential Steps to Elimate Wood Lathe Chatter

Stopping chatter is all about creating a stable, balanced system. We’ll break this down into manageable steps, starting with the foundation – your lathe itself. Each step builds on the last, so let’s dive in!

Step 1: Ensure a Stable Lathe Base

Your lathe needs to be as solid as a rock. Any movement in the lathe itself will translate directly to the workpiece, inviting chatter. Check these points:

- Level Surface: Is your lathe sitting on a perfectly level floor? Even a slight tilt can cause issues. Use a spirit level to check. If it’s not level, use shims under the lathe legs to correct it.

- Tighten All Fasteners: Go around your lathe and ensure every bolt, screw, and locknut is snug. This includes the legs to the bed, the headstock to the bed, the tailstock to the bed, and any other accessible fasteners.

- Weight and Stability: Heavier lathes are generally more stable. If you have a lighter benchtop model, consider bolting it down to a sturdy workbench or adding weight to its base. Adding sandbags or specialized weights can make a big difference.

- Check the Bed: Ensure the lathe bed itself is free from damage, warps, or debris. A damaged bed can prevent the tailstock and tool rest from moving smoothly and securely.

Step 2: Proper Tool Rest Setup

The tool rest is where your cutting tool rests, and its position is crucial. Incorrect placement is a major culprit for chatter.

- Proximity to the Workpiece: The tool rest should be as close as possible to the wood without actually touching it during rotation. Aim for a gap of no more than 1/8th of an inch (about 3mm). This minimizes the leverage the wood has to vibrate the tool.

- Height Adjustment: For most basic cuts with a gouge or skew, the top of the tool rest should be roughly level with the center of the workpiece. For scraping or specialized tools, this might vary, but the principle of minimal leverage remains.

- Securely Locked: Ensure the tool rest is locked down firmly. If it can pivot or slide easily while you’re cutting, it will introduce massive vibrations and chatter.

Step 3: Secure and Balanced Workpiece Mounting

The wood you’re turning must be held firmly and, ideally, balanced from the start. An unbalanced blank will wobble significantly, leading to chatter.

- Faceplate or Chuck: If mounting to a faceplate, ensure the screws are evenly spaced and secure the blank tightly. Use a backing block if needed. If using a chuck, make sure the jaws are gripping the wood evenly and are tightened sufficiently.

- Centering: For faceplate work, it’s vital to mount the blank as close to the center of the faceplate as possible. Off-center mounting is a guaranteed recipe for wobble and chatter.

- Rough Balancing (for larger pieces): If you’re starting with a large, irregular piece of wood, you can often rough-balance it by taking off the most obvious high spots with a bandsaw or grinder before mounting it. This reduces the initial wobble.

- Tailstock Support: For longer spindles or when starting to turn a less than perfectly round blank, use the tailstock for initial support. This keeps the workpiece from flexing as much. Don’t tighten it excessively, as it can cause splitting in green wood.

Step 4: Sharp Tools Are Your Best Friend

Dull tools don’t cut; they tear. This tearing action is a primary cause of chatter and rough surfaces.

- Regular Sharpening: Make tool sharpening a part of your routine. A sharp tool slices through wood cleanly, requiring less force and producing less vibration.

- Correct Grinding Angle: Ensure your tools are ground to the correct bevel angle specified for their type and the wood you’re working with. An incorrect angle can also lead to poor cutting and chatter.

- Honing: After grinding, honing the edge with a fine abrasive stone or leather strop will give you a razor-sharp, smooth cutting surface.

A good rule of thumb is to sharpen your tools every 15-20 minutes of continuous turning, or whenever you notice a change in the sound or feel of the cut. For more on sharpening, check out resources like this guide on chainsaw sharpening for the principle of maintaining a keen edge, which applies directly to lathe tools.

Step 5: Proper Cutting Technique

How you approach the wood with your tool significantly impacts chatter.

- Smooth, Consistent Cuts: Avoid jerky or hesitant movements. Use smooth, sweeping motions. Let the tool do the work.

- Tool Angle: Experiment with the angle at which you present your tool to the wood. A slight lifting or lowering of the tool can sometimes change the cutting action and eliminate chatter. For most gouges, you’ll be cutting slightly on the bevel.

- Depth of Cut: Don’t try to remove too much material at once. Shallow, consistent cuts are much less prone to chatter than aggressive ones. Take multiple passes if needed.

- Support the Tool: Grip your tool firmly and rest it securely on the tool rest. Your body should also be stable, acting as a dampener for any residual vibrations.

- Cutting Direction: Generally, cutting downhill (from the tailstock towards the headstock for spindle work) can be smoother. For faceplate work, cutting from the outside inward is common.

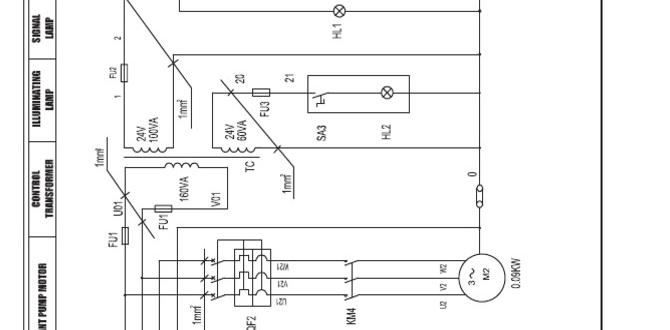

Step 6: Inspect the Lathe Drive System

The parts that make your lathe spin can also be sources of vibration.

- Drive Belt Tension: On belt-driven lathes, check the belt tension. If it’s too loose, it can slip and cause inconsistent rotation (jerking), which leads to chatter. If it’s too tight, it can put undue stress on the motor and spindle bearings. Refer to your lathe’s manual for the correct tension.

- Motor Mounts: Ensure the motor is securely mounted to the lathe and that any rubber grommets or dampeners are in good condition.

- Spindle and Bearings: Listen for any grinding or rumbling sounds from the headstock and tailstock. Worn bearings can cause play and vibration.

Step 7: Workpiece Moisture Content

The condition of the wood itself can play a role.

- Green Wood Issues: Very wet or “green” wood is more prone to flexing and deforming under the stress of turning, which can lead to chatter.

- Drying Out: Ensure your wood is adequately dried for the project. Wood that is too dry can also be brittle and prone to tearing.

- Avoid Warping: If you’re turning a blank that has been stored improperly, it might be warped. This can cause an uneven diameter rotation, initiating chatter.

Troubleshooting Common Chatter Scenarios

Let’s look at some specific situations and how to tackle them.

Scenario: Chatter on the initial roughing out of a log

Cause: Unbalanced blank, tool rest too far away, dull tool.

Solution: Rough balance the log on a bandsaw first. Bring the tool rest as close as possible. Use a sharp roughing gouge and take steady, sweeping cuts. Ensure the lathe base is stable.

Scenario: Chatter on end grain platters

Cause: Workpiece flex, tool digging into changing grain patterns, tool rest too far.

Solution: Ensure ample jaw grip on chuck or secure screw mounting. Minimize tool rest distance. Use a scraper or a bowl gouge with a shallow cut. For face grain, sometimes a slower RPM can help.

Scenario: Chatter on spindle turning near the end of the cut

Cause: Tool catching at the end, tailstock binding, workpiece flex.

Solution: Finish cuts with a skew chisel or a very sharp scraper. Ensure tailstock is snug but not overtightened. Consider reducing speed and depth of cut as you approach the finishing stage.

Table: Lathe Components and How They Affect Chatter

Understanding how each part of your lathe can contribute to or prevent chatter is key.

| Lathe Component | How it Affects Chatter | Checks and Solutions |

|---|---|---|

| Lathe Bed | Provides the foundation. Any instability or warp leads to vibration. | Ensure level surface. Tighten all bed fasteners. Check for damage. |

| Tool Rest | Supports the cutting tool. Incorrect positioning creates leverage for vibration. | Keep it very close to the workpiece. Lock it down securely. Set at appropriate height. |

| Workpiece Mounting (Chuck/Faceplate) | Holds the wood. An unbalanced or insecure mount will cause wobble. | Ensure all jaws/screws are tight and evenly gripping. Center the blank. |

| Cutting Tools | The point of contact. Dull or improperly shaped tools tear wood. | Sharpen tools regularly. Hone them to a keen edge. Use the correct tool for the job. |

| Drive System (Belts/Motor) | Responsible for smooth rotation. Slipping belts or worn components cause inconsistent speed. | Check belt tension. Listen for bearing noise. Ensure motor mounts are secure. |

Advanced Tips for Chatter-Free Turning

Once you’ve got the basics down, here are a few more things to consider:

- Workpiece Balance on the Go: As you turn, especially with larger pieces, the shape changes. Periodically reassess for balance. You might need to adjust tool rest position or take lighter cuts.

- Experiment with Speeds: There’s often a “sweet spot” for RPMs. Too fast can exacerbate vibrations, while too slow might lead to tearing. Generally, larger diameters require slower speeds than smaller ones. Consult resources like this overview of wood lathe operation for guidance on speed settings.

- Use Vibration-Dampening Mats: Placing a thick rubber mat under your lathe can help absorb some minor vibrations before they become noticeable chatter.

- Embrace Scrapers (Carefully):** For difficult woods or finishing passes, a well-sharpened scraper can sometimes get through chatter-prone areas more smoothly than a gouge, though they require a different touch and technique.

- Read the Wood: Pay attention to the sound and feel of your cut. A sudden change can indicate an impending chatter situation. Be ready to back off the cut pressure or adjust your tool.

Frequently Asked Questions About Stopping Wood Lathe Chatter

What is the most common reason for wood lathe chatter?

The most common reasons are a dull cutting tool, the tool rest being too far from the workpiece, or an unbalanced workpiece causing wobble.

Should I turn faster or slower to stop chatter?

It depends. Sometimes a slightly slower speed can reduce vibration, but often, chatter is more about vibration frequency than speed itself. Focus on tool sharpness and setup first. If you’re experiencing significant wobble, slower speeds are usually better.

Can a poorly mounted blank cause chatter?

Absolutely. An off-center blank or one that isn’t securely gripped will wobble, which is a direct cause of chatter. Ensuring the blank is centered and tightly mounted is critical.

How far should the tool rest be from the wood?

As close as possible without touching. A gap of about 1/8th of an inch (3mm) is usually ideal. This minimizes leverage and vibration transfer.

Does the type of wood affect chatter?

Yes. Softer woods can sometimes tear more easily, while very hard or knotty woods can be more prone to chatter due to inconsistencies. Also, green (wet) wood can flex, contributing to chatter.

Is there a specific tool that helps prevent chatter?

While any sharp tool is better, specialized tools like bowl gouges with a good grind, or even scrapers for certain applications, can sometimes manage chatter more effectively by having a different cutting action. However, proper setup is far more important than the tool itself.

Conclusion

Stopping chatter on your wood lathe might seem like a daunting task at first, but as you can see, it’s a process of meticulous setup and good practice. By systematically addressing the stability of your lathe, the positioning of your tool rest, the secure mounting of your workpiece, and the sharpness of your tools, you’re building a foundation for smooth, effortless turning. Remember, chatter isn’t a sign you’re doing something fundamentally wrong; it’s usually a clear indicator that one or more of these essential elements needs a tweak. Keep practicing, keep your tools sharp, and don’t be afraid to experiment. Each piece you turn, and each chatter-free surface you achieve, will boost your confidence and hone your skills. Happy turning!