Is a TiAlN ball nose end mill essential for facing cast iron? Yes, a TiAlN ball nose end mill is ideal for efficiently and smoothly facing cast iron, providing excellent heat resistance and tool life for this common machining task.

Machining cast iron can sometimes feel like a puzzle, especially when you’re aiming for that perfectly flat, smooth surface. One common challenge is getting a clean, consistent finish when facing the material. If you’ve ever struggled with chatter, poor surface finish, or tools that wear out too quickly when facing cast iron, you’re not alone! It might seem daunting, but the right tool and technique can make all the difference. We’ll walk you through how to use a TiAlN ball nose end mill for facing cast iron, turning a potentially frustrating job into a straightforward success. Get ready to achieve those smooth, professional finishes you’ve been working towards!

Why Facing Cast Iron Can Be Tricky

Cast iron, while a fantastic material for many projects, presents its own set of challenges when it comes to machining, especially surfacing. It’s harder and more brittle than many steels, which can lead to issues like:

- Tool Wear: The abrasive nature of cast iron can quickly dull standard cutting edges.

- Surface Finish: Achieving a smooth, mirror-like finish can be tough without the right strategy.

- Chip Evacuation: Cast iron tends to produce powdery chips that can build up, causing heat and re-cutting.

- Chatter: Vibrations can easily occur, leading to a rough, unacceptable surface.

This is where specialized tooling, like a TiAlN ball nose end mill, becomes a real game-changer for facing operations.

Introducing the TiAlN Ball Nose End Mill

Let’s break down what makes this particular tool so effective for cast iron:

The Ball Nose Design

A ball nose end mill has a semicircular cutting tip. This means it doesn’t have a sharp corner like a flat-bottomed end mill. For facing operations, especially on contoured surfaces or when you want to avoid leaving a sharp corner at the periphery of your cut, the ball nose is excellent. It creates a smooth, radiused transition. While we often think of ball nose end mills for 3D profiling, their smooth cutting action and ability to handle varying depths make them surprisingly useful for planar facing too. They distribute the cutting load more evenly.

What is TiAlN Coating?

TiAlN stands for Titanium Aluminum Nitride. This is a very popular and effective coating for machining materials at higher speeds and temperatures. Here’s why it’s so good for cast iron:

- High Hardness: It’s extremely hard, which helps resist wear and abrasion from the cast iron.

- Heat Resistance: It forms a protective aluminum oxide layer at high temperatures, acting as a thermal barrier. This keeps the cutting edge cooler, allowing for faster cutting speeds and extending tool life significantly.

- Reduced Friction: The coating helps reduce friction between the tool and the workpiece, leading to cleaner cuts and better chip flow.

When you combine the gentle, non-chipping cutting action of a ball nose with the extreme durability and heat resistance of a TiAlN coating, you get a powerful tool for tackling cast iron.

Why is a 35-Degree Helix Angle Often Recommended?

While end mills come in various helix angles (the angle of the flutes), a 35-degree helix angle is often favored for cast iron. Here’s why it’s a sweet spot:

- Smooth Cutting Action: A moderate helix angle like 35 degrees offers a good balance. It provides a smoother engagement with the material compared to a very steep helix (e.g., 45 degrees), which can reduce chatter.

- Good Chip Evacuation: It’s aggressive enough to help lift and evacuate the powdery chips produced by cast iron effectively, preventing them from re-cutting or clogging flutes.

- Strength: It provides sufficient flute space for strength while still allowing for effective material removal.

For facing cast iron, you might also encounter end mills with a shallower helix (e.g., 15-30 degrees) or even a straight flute design. However, the 35-degree helix often represents a reliable all-around choice for balancing smoothness, chip evacuation, and tool life.

When to Choose a TiAlN Ball Nose End Mill for Facing Cast Iron

While you can face cast iron with other tools, a TiAlN ball nose end mill shines in several scenarios:

- Achieving Superior Surface Finish: If your goal is a very smooth, aesthetically pleasing surface, the ball nose geometry is inherently better at providing a continuous, sweeping cut than a flat end mill taking a shallow depth of cut.

- When Tool Life is a Priority: The TiAlN coating significantly extends the life of the end mill, making it more cost-effective for repetitive or production-oriented tasks.

- Dealing with Heat Buildup: If you find your tools are overheating and losing their edge quickly, the heat resistance of TiAlN is invaluable.

- Machining Contoured Surfaces: Although we’re talking about facing, many parts have slight radii or complex geometries that a ball nose can handle more gracefully than a flat end mill.

- Reducing Chatter: The geometry of a ball nose, combined with the smooth engagement of a moderate helix, can help dampen vibrations.

Essential Tools and Setup for Facing Cast Iron

Before you start facing, ensure you have the right setup. This is crucial for safety and success.

What You’ll Need:

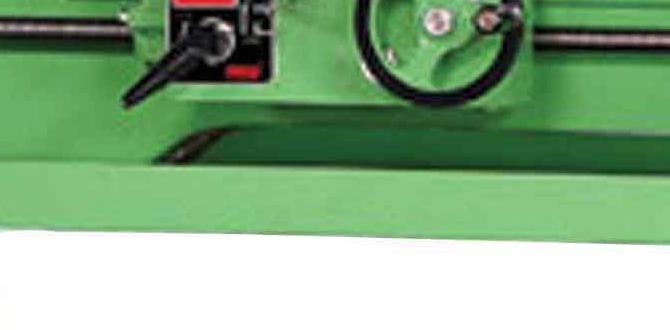

- Your Milling Machine: Whether it’s a small desktop CNC, a manual Bridgeport-style mill, or a larger industrial machine, ensure it’s clean, well-lubricated, and stable.

- The TiAlN Ball Nose End Mill: Appropriate diameter (e.g., 1/2 inch or 12mm for general work) with the desired number of flutes (often 2 or 3 for cast iron). A 35-degree helix is a good starting point.

- Workholding: A sturdy vise or clamps to securely hold your cast iron workpiece. Never attempt to machine unsecured material!

- Coolant/Lubrication: For cast iron, a light flood coolant or a mist coolant system is highly recommended. Dry machining is possible but generates a lot of dust and heat. A good quality cutting fluid designed for ferrous metals will help. For beginner guidance on coolant applications, check out resources from the National Institute of Standards and Technology (NIST) on machining.

- Safety Gear: Safety glasses are non-negotiable. Hearing protection is also advised.

- Measuring Tools: Calipers, a dial indicator, or a height gauge to set your Z-axis and verify dimensions.

- Deburring Tool: For cleaning up edges after machining.

Setting Up Your Machine:

- Secure the Workpiece: Mount your cast iron block or part firmly in your vise. Ensure it’s as flat and stable as possible. Use parallels if needed to get a good grip and ensure the surface you’ll be facing is accessible.

- Install the End Mill: Insert the TiAlN ball nose end mill into your collet or tool holder. Make sure it’s seated properly and tightened securely.

- Indicating (Optional but Recommended): If you need extreme accuracy and a perfectly flat surface relative to your machine’s axes, you can indicate your workpiece. This involves using a dial indicator to ensure the surface you’re about to face is perfectly perpendicular to the spindle. This adds an extra layer of precision.

Step-by-Step: Facing Cast Iron with a TiAlN Ball Nose End Mill

Let’s get down to the actual machining. We’ll assume you’re using a CNC mill, as this is where programming for facing is most common, but the principles apply to manual milling with careful feed and speed control.

Step 1: Determine Your Cutting Parameters

This is critical. The exact parameters will depend on your specific machine, the size of your end mill, the type of cast iron, and your coolant. However, here are some general guidelines for a tough material like cast iron:

- Spindle Speed (RPM): Start conservatively. For a 1/2-inch (12mm) end mill, you might begin in the range of 1500-3000 RPM. You’ll need to adjust based on sound and feel.

- Feed Rate (IPM or mm/min): This is how fast the tool moves through the material. For cast iron, you’ll want a moderate feed rate. A common starting point for a 4-fluted end mill might be around 0.002 to 0.005 inches per tooth (IPT) or 50-125 mm/min per tooth. So, for a 2-flute end mill at 0.004 IPT, your feed rate would be 2 flutes 0.004 IPT calculated RPM = feed rate. It’s better to run a little slower and smoother than too fast and risk chatter.

- Depth of Cut (DOC): For facing, you’ll typically want a shallow depth of cut. Cast iron can be brittle. A DOC of 0.010 to 0.050 inches (0.25 to 1.25 mm) is common. If you’re just skimming to get a perfect finish, you might go even shallower.

- Width of Cut (WOC) / Stepover: This is how much the end mill overlaps from one pass to the next. For a good finish, aim for about 50% to 75% of the end mill diameter. A smaller stepover will result in a smoother, more consistent finish but will take longer. Aiming for 50% of the end mill diameter is a good balance for facing.

Tip: Always check the manufacturer’s recommendations for your specific end mill. Companies like LMT USA or Kennametal often provide detailed charts.

Step 2: Program Your Facing Operation (CNC)

Using your CAM software or by manually programming G-code:

- Define Tool: Input the diameter, number of flutes, and type of your TiAlN ball nose end mill.

- Facing Strategy: Select a “2D Contour,” “Pocket” with a large area, or specifically a “Facing” operation. Most CAM packages have a dedicated “Facing” strategy which is ideal. This tells the machine to start outside the part and sweep across to cover the entire top surface.

- Set Boundaries: Define the area to be machined. Make sure it extends slightly beyond the actual physical boundary of your part to ensure a full clean cut.

- Input Parameters: Enter your calculated Spindle Speed, Feed Rate, Depth of Cut, and Stepover.

- Engage Coolant: Ensure your coolant is programmed to turn on before cutting begins.

- Set Z-Axis Zero: This is a critical step. You’ll need to carefully touch off on the surface of your workpiece to establish your zero point for the Z-axis. This tells the machine where the top of your material is. Use a probe, a simple dial indicator, or an edge finder for accuracy.

Step 3: Perform a Dry Run (Highly Recommended!)

Before you engage the high-speed spindle and start cutting metal, run the program with the spindle off (or in cool mist mode only) and the Z-axis “air cutting” slightly above the workpiece. Watch the toolpath on your controller screen or the physical machine to ensure:

- The toolpath covers the entire surface.

- There are no unexpected crashes or movements.

- The Z-depth is correct.

This one step can save you a broken tool or damaged workpiece.

Step 4: Execute the Cut

Once you’re confident from the dry run:

- Ensure coolant is flowing.

- Start the spindle to your programmed RPM.

- Initiate the cutting feed.

- Listen and Watch: Pay close attention to the sound of the cut. A smooth hum is good; a ringing or chattering sound means something is wrong – potentially too high a feed rate, too deep a cut, or insufficient rigidity.

- **Observe Chip Formation: For cast iron, you want fine, powdery chips, not large, stringy ones. The coolant should be washing them away.

Step 5: Inspect and Refine

After the facing operation is complete:

- Turn off the spindle and coolant.

- Retract the tool.

- Carefully remove the workpiece (it might be hot!).

- Inspect the surface finish. Is it smooth? Is it flat?

- Use your calipers or a height gauge to measure the removed material if needed.

If the finish isn’t perfect, you might need to adjust your parameters: a slightly slower feed, a shallower depth of cut, or a smaller stepover could improve things. Ensure your machine gibs are properly adjusted for rigidity.

Alternative Strategies and Considerations

Depth of Cut for Different Finishes

The depth of cut (DOC) significantly impacts results:

- Roughing: If you need to remove a significant amount of material quickly, a deeper DOC is appropriate, but expect a rougher finish. Here, a TiAlN coated flat end mill might be more efficient.

- Semi-Finishing: A moderate DOC removes less material, improving the finish.

- Finishing: A very shallow DOC (e.g., 0.005 – 0.010 inches) is crucial for achieving a highly polished surface. A ball nose end mill excels here because its rounded tip allows for smooth transitions and blending of passes.

The Role of Stepover

The stepover, or the amount of overlap between consecutive passes, critically affects surface finish. A smaller stepover means more passes but a smoother, more uniform surface without visible ” scallops” from the tool path. For aesthetics, a stepover of 25-50% of the end mill diameter is generally recommended. For pure functional facing where finish isn’t paramount, a larger stepover (up to 75%) can speed up the process. A 35-degree helix ball nose helps blend these passes smoothly.

Manual Milling vs. CNC

If you’re using a manual milling machine, the principles are the same, but control is entirely hands-on. You’ll need to:

- Set your RPM manually.

- Use the handwheels to control feed and depth of cut.

- This requires more practice and feel. Start very slow and conservative.

- For consistent depth, “climb milling” can sometimes offer a better finish, but “conventional milling” is often safer for beginners.

For machining cast iron on a manual mill, you can find great general machining advice from organizations like the American Welding Society (AWS) which also covers related fabrication and machining topics.

Feed Rate Optimization

Finding the sweet spot for feed rate is key. Too fast, and you’ll get chatter and tool breakage. Too slow, and you risk rubbing the tool, generating excessive heat, and poor chip formation (leading to a dull finish or tool damage). You’re looking for a steady, consistent chip being produced. Adjust your feed rate (often in conjunction with spindle speed) until the cutting sound is smooth and the chips are forming nicely.

Maintaining Your TiAlN Ball Nose End Mill

Even with a durable coating like TiAlN, proper care ensures longevity:

- Cleanliness: Always clean your end mill after use. Remove any residual chips or coolant to prevent corrosion.

- Inspection: Regularly check the cutting edges for wear, chipping, or signs of overheating. A worn end mill will produce a poor finish.

- Proper Storage: Store end mills in a clean, dry place. A tool holder case protects them from damage.

- Avoid Resharpening (Generally): Most coatings like TiAlN are difficult to resharpen effectively without specialized equipment. For most hobbyist and light-duty users, it’s more economical to replace a worn-out coated end mill than to attempt resharpening.

Troubleshooting Common Issues

Here are some common problems and how to fix them when facing cast iron with a TiAlN ball nose end mill:

| Problem | Possible Cause | Solution |

|---|---|---|

| Rough Surface Finish | Too high feed rate, too large stepover, dull tool, insufficient rigidity, chatter. | Reduce feed rate, reduce stepover

|