In short: yes, a TiAlN ball nose end mill with a 40-degree helix angle is an excellent choice for deep slotting HDPE. It provides the necessary strength and heat resistance for efficient material removal, ensuring clean, precise deep cuts in High-Density Polyethylene (HDPE).

Cutting deep slots into High-Density Polyethylene (HDPE) can be a real head-scratcher for beginners. You want a clean, accurate cut, but the plastic can sometimes melt or chip, making the job messy and frustrating. It’s a common challenge when working with plastics on milling machines, but don’t worry! With the right tool and a few simple techniques, you can achieve professional-looking results every time.

This guide will walk you through exactly how to use a TiAlN ball nose end mill for deep slotting HDPE. We’ll cover everything from choosing the right tool to setting up your machine and making those precise cuts safely. Get ready to tackle those deep slots with confidence!

Understanding the Challenge: Machining HDPE

High-Density Polyethylene (HDPE) is everywhere, from cutting boards to pipes. It’s tough, chemically resistant, and affordable, making it a popular material for DIY projects and industrial applications. However, machining HDPE isn’t like cutting wood or softer metals. When you mill HDPE, a few things can go wrong:

- Melting: Plastics, including HDPE, have a low melting point. Friction from the cutting tool can quickly generate heat, causing the plastic to melt and gum up the flutes of your end mill. This leads to poor surface finish, tool breakage, and wasted material.

- Chip Evacuation: Sticky, melted plastic can pack into the flutes, preventing them from clearing chips effectively. Inefficient chip evacuation further increases heat build-up.

- Brittleness: While strong, HDPE can sometimes become brittle, especially with rapid cutting or incorrect tool geometry, leading to chipping or breaking instead of a clean cut.

These issues can make deep slotting particularly tricky. As the slot gets deeper, chip evacuation becomes harder, and heat has more time to build up. That’s where the right tool choice becomes crucial.

Why a TiAlN Ball Nose End Mill is Your Best Friend for HDPE Deep Slotting

Let’s break down why a specific type of end mill—the TiAlN ball nose end mill, often with a 40-degree helix angle—is so effective for this task.

What is a Ball Nose End Mill?

A ball nose end mill has a fully radiused tip, shaped like the tip of a ball. This design is perfect for creating:

- Contoured surfaces: Ideal for complex 3D shapes like molds or carvings.

- Rounded slots: When used for slotting, it creates a semi-circular bottom, which can be advantageous for stress distribution or specific design requirements.

- Full-radius slots: For slotting, it can create a perfectly rounded slot if used correctly.

What Does “TiAlN” Mean?

TiAlN stands for Titanium Aluminum Nitride. This is a very hard and heat-resistant multi-layer coating applied to the carbide or steel of the end mill. For machining plastics like HDPE, this coating is a game-changer because:

- Reduces Heat: The coating acts as a barrier, minimizing friction between the tool and the plastic. This drastically reduces heat buildup, preventing that dreaded melting.

- Increases Tool Life: The hardness and heat resistance mean the end mill stays sharp and effective for much longer, even when cutting tougher materials or at higher speeds.

- Improves Surface Finish: Less melting means cleaner cuts and a smoother finish on your workpiece.

The Significance of the 40-Degree Helix Angle

The helix angle refers to the angle of the cutting edges spiraling around the tool. For plastics like HDPE, a 40-degree helix angle is often recommended:

- Efficient Chip Evacuation: A steeper helix angle (like 40 degrees) provides a more aggressive cutting action and helps lift chips out of the flutes and the slot more effectively. This is critical for preventing melting and for deep slotting where chip packing is a major concern.

- Reduced Cutting Forces: This angle can also help reduce the forces required to cut, leading to a smoother operation and less stress on your machine and the workpiece.

Putting It Together for HDPE Deep Slotting

So, a TiAlN ball nose end mill with a 40-degree helix angle offers:

- Sharpness: The ball nose provides a clean cutting edge.

- Heat Resistance: TiAlN coating fights melting.

- Chip Removal: The 40-degree helix angle helps get chips out.

This combination makes it exceptionally well-suited for cutting deep, clean slots in HDPE without the common problems of melting and poor chip evacuation. You’re essentially choosing a tool engineered to overcome the specific challenges of machining this type of plastic.

Essential Tools and Setup for Deep Slotting HDPE

Before you even think about hitting the “go” button, make sure you have everything ready. Proper setup is half the battle, especially when working with plastics.

1. Your CNC Mill or Milling Machine

Any standard milling machine (manual or CNC) can handle this. Ensure it’s clean, well-maintained, and all axes move smoothly. For CNC machines, make sure your controller is set up correctly.

2. The Right TiAlN Ball Nose End Mill

As discussed, look for a tool with:

- Material: Carbide is generally preferred for its rigidity and sharpness.

- Coating: TiAlN (Titanium Aluminum Nitride) is key.

- Geometry: Ball nose tip.

- Helix Angle: Around 40 degrees is ideal for plastics.

- Number of Flutes: For plastics, 2-flute end mills are often recommended. They have larger flute capacity for better chip evacuation, which is crucial to prevent melting.

- Diameter: Size depends on your slot width and depth requirements.

Always check the manufacturer’s recommendations for machining plastics if available. Reputable brands often provide specific advice.

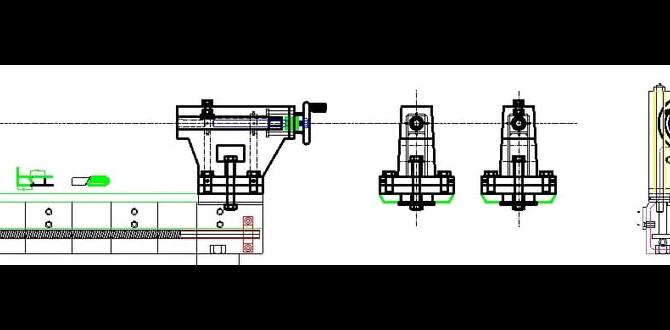

3. Workholding System

Securely holding your HDPE is paramount. Loose material will move, leading to inaccurate cuts and potential tool breakage. Options include:

- Vise: A sturdy milling vise with soft jaws (if you want to protect the surface) or standard jaws if clamping on a non-critical edge.

- Clamps: Edge clamps or toe clamps can work if your machine bed or fixture plate allows.

- Fixtures: For production runs or specific shapes, a custom fixture ensures repeatable accuracy.

Ensure the HDPE is clamped firmly, but avoid crushing it, which can deform the material.

4. Measuring Tools

- Calipers or a precise ruler to mark out your slot locations.

- A surface gauge or dial indicator for setting Z-height (depth).

5. Safety Gear (Absolutely Non-Negotiable!)

Even though you’re cutting plastic, safety always comes first. Ensure you have:

- Safety Glasses: Always wear them. Small chips can fly.

- Hearing Protection: Milling can be loud.

- Dust Mask: While HDPE dust isn’t as hazardous as some metals, it’s good practice to avoid inhaling plastic particles.

- Gloves: Consider lightweight, snug-fitting gloves for handling material, but avoid loose gloves around rotating machinery.

Always follow recommended Occupational Safety and Health Administration (OSHA) guidelines for machining operations, even in a home workshop.

6. Lubricant/Coolant (Optional but Recommended)

While some machinists prefer dry machining for plastics to avoid mess, a light mist of coolant or a specialized plastic cutting fluid can significantly help with heat reduction and chip evacuation. For HDPE, something like a water-based coolant works well, applied as a fine mist. Compressed air blowing across the cut can also be very effective for chip clearing and cooling.

Step-by-Step Guide to Deep Slotting HDPE

Now, let’s get down to the actual machining! Follow these steps carefully for the best results.

Step 1: Prepare Your HDPE Workpiece

Ensure your HDPE sheet or block is clean and free of any dirt or debris. If necessary, use a deburring tool or fine-grit sandpaper to clean up any rough edges.

Step 2: Secure the Workpiece

Mount your HDPE firmly in your vise or using clamps. Double-check that it’s rigid and won’t move during the cutting process. Make sure the surface you’re milling the slot into is accessible and clear.

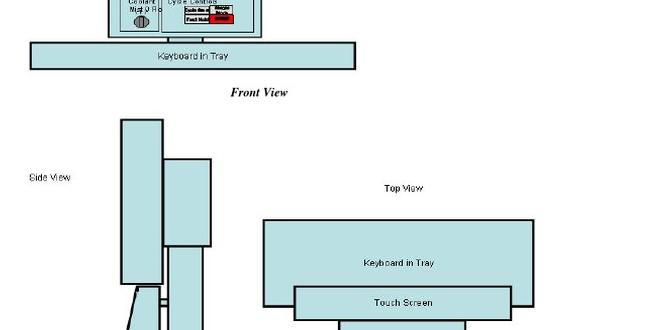

Step 3: Set Up the End Mill and Machine

Tool Installation: Install your TiAlN ball nose end mill into the collet or tool holder. Ensure it’s seated properly and tightened securely.

Zeroing Axes:

- X and Y Axes: Jog the end mill to the desired starting point for your slot. Use spray chalk, a probe, or carefully jog the tool to find the edge of your material and set your X and Y zero points according to your CAM software or manual machining plan.

- Z Axis: This is critical for depth. Carefully bring the tip of the ball nose end mill down until it just touches the top surface of your HDPE. Use a piece of paper (the “paper trick”)—when you can feel just a slight drag on the paper as you slide it between the tool tip and the surface, you’ve found your zero. Set your Z zero reference point here.

Step 4: Determine Cutting Parameters (Speeds and Feeds)

This is where it gets a little technical, but we’ll keep it simple. For HDPE:

- Surface Speed (SFM): HDPE machines best at relatively high surface speeds. A good starting point for many plastics is around 300-600 SFM (Surface Feet per Minute).

- Spindle Speed (RPM): This depends on your tool diameter. The formula is:

RPM = (SFM 12) / (π Tool Diameter)

For example, if you have a 1/4 inch (0.25 inch) diameter end mill and aim for 400 SFM:

RPM = (400 12) / (3.14159 0.25) ≈ 6110 RPM

Start on the lower end of the recommended SFM if you’re unsure, and gradually increase if the cut is clean. - Feed Rate (IPM): This is how fast the tool moves into the material. For plastics, you generally want a relatively aggressive feed rate to help clear chips and avoid melting. Start with around 0.001 to 0.003 inches per tooth (IPT), depending on the chip load your machine can handle and the rigidity of your setup.

Feed Rate (IPM) = RPM Number of Flutes IPT

Using the example above with a 2-flute end mill and 0.002 IPT:

Feed Rate (IPM) = 6110 2 0.002 ≈ 24.4 IPM

This is a very light feed, good for initial testing. You might be able to push this higher. - Depth of Cut (DOC): For deep slotting, you will make multiple passes. Don’t try to cut the full depth in one go, especially with aggressive speeds. A common strategy is to take smaller step-downs. For HDPE, a DOC of 0.1 to 0.25 inches is often a good starting point for each pass, especially in the initial layers.

Important Note: These are starting points. Always listen to your machine and look at the chips. If you hear chattering, see melting, or have poor chip evacuation, adjust your speeds and feeds. A good resource for typical machining parameters for various plastics is found on manufacturer datasheets, such as those provided by Reliance Helicopters, which covers a range of plastics and considerations.

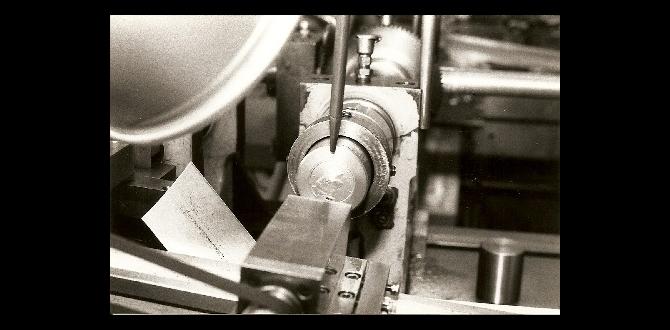

Step 5: Perform the First Slotting Pass

Plunge Move: If you’re cutting a slot from scratch, you’ll need to plunge the end mill into the material. For plastics, a slower, controlled plunge is best. Avoid aggressive plunging as it can generate a lot of heat at the entry point. A feed rate for plunging might be half or even a quarter of your linear feed rate. Alternatively, step-cutting vertically can be better than a direct plunge, especially for very deep slots.

Cutting the Slot: Once at the desired depth, begin the side milling (slotting). Use an appropriate milling strategy:

- Conventional Milling: The tool rotates against the direction of feed. This can sometimes lead to better surface finish in plastics but might require higher feed rates.

- Climb Milling: The tool rotates with the direction of feed. This generally results in lower cutting forces and can improve chip evacuation, making it often preferred for plastics and for creating cleaner cuts.

For HDPE deep slotting, climb milling is often the preferred method to help pull chips out and reduce heat. Ensure your machine has its backlash compensation set correctly for climb milling.

Step 6: Chip Evacuation and Cooling

As you cut, pay close attention to chip evacuation.

- Compressed Air: A blast of compressed air directed into the slot can work wonders. It blows chips away and helps cool the cutting area.

- Lubricant/Coolant: If you’re using a coolant mist, ensure it’s hitting the cutting zone effectively.

- Pause and Clear: For very deep slots or if you notice any signs of melting, pause the machine periodically. Manually blow out chips with compressed air and allow the tool and material to cool slightly before resuming.

Step 7: Make Subsequent Passes for Depth

Once the first pass is complete, increment the Z-axis downwards by your chosen Depth of Cut (DOC) and make another pass. Repeat this process until you reach your desired slot depth.

Important Considerations for Depth:

- Slot Bottom Radius: Remember, a ball nose end mill creates a rounded bottom. If you need a precise flat bottom, you’ll need to use a different tool (like an end mill designed for flat-bottomed slots) or plan for a secondary operation.

- Tool Stick-out: As you cut deeper, ensure your end mill has enough usable length. Excessive tool stick-out (the amount of end mill extending past the collet) can lead to chatter and reduced accuracy. If your slot is very demanding on tool length, consider a longer, more rigid tool or re-fixturing the part to do the slot in stages.

Step 8: Inspect and Finish

Once the slotting is complete, carefully inspect the results. The slot should be clean, the walls smooth, and the bottom correctly radiused by the ball nose. Use a deburring tool to clean up any minor imperfections or burrs at the entrance and exit of the slot.

Troubleshooting Common Issues

Even with the best tools, you might encounter a few hiccups. Here’s how to fix them:

- Melting/Gunking:

- Cause: Too much heat, too slow a feed rate, poor chip evacuation.

- Solution: Increase spindle speed slightly (if within SFM limits), increase feed rate, use more compressed air or coolant, reduce depth of cut per pass, ensure you’re using climb milling.

- Chatter/Vibration:

- Cause: Loose workpiece, dull tool, excessive depth of cut, too much tool stick-out, incorrect speeds/feeds.

- Solution: Secure workpiece more firmly, use a sharper tool, reduce DOC, use a shorter tool if possible, adjust speeds and feeds, check machine rigidity.

- Poor Surface Finish on Slot Walls:

- Cause: Feed rate too low, tool not sharp, material not fully supported.

- Solution: Increase feed rate, try climb milling, ensure workpiece is rigid, check tool for chipping or wear.

- End Mill Breaking:

- Cause: Too aggressive plunge rate, excessive side load, cutting too fast or too deep, running into unexpected material hardness.

- Solution: Slow down plunge feeds, reduce speeds/feeds/DOC, ensure workpiece is secure, use climb milling.

When to Consider Alternatives or Advanced Techniques

While the TiAlN ball nose end mill is excellent