A Tialn ball nose end mill with a 45-degree helix angle is an excellent choice for efficiently clearing acrylic. Its specific geometry helps manage heat and chip evacuation, leading to cleaner cuts and prolonging tool life when used correctly.

Working with acrylic can sometimes feel like a bit of a dance. That smooth, shiny material can quickly turn into a gummy mess if you don’t have the right tool or technique. It’s a common frustration for many in the workshop – getting clean cuts without melting or chipping the acrylic. But don’t worry, it doesn’t have to be that way! With the right tools and a few key settings, you can achieve fantastic results. We’re going to walk through how a specific type of cutter, the Tialn ball nose end mill with a 45-degree helix, can be your secret weapon for clearing acrylic like a pro. Stick around, and we’ll show you exactly how to make it work for you!

Understanding Your Tialn Ball Nose End Mill (45 Degree) for Acrylic

So, what makes a Tialn ball nose end mill with a 45-degree helix angle so good for acrylic? It all comes down to its design and how that design interacts with this tricky material. Acrylic can be prone to melting due to friction, and it can also chip if the cutting forces are too high or if chips aren’t removed effectively.

A standard end mill might have issues. The geometry of a ball nose end mill means it has a rounded tip, which is great for creating curved surfaces. The 45-degree helix angle is a bit of a sweet spot. It’s not as aggressive as a higher helix angle, which can sometimes chatter in softer materials like acrylic, nor is it as shallow as a low helix, which might not provide enough cutting action. The Tialn coating adds another layer of benefit. Tialn (Titanium Aluminum Nitride) is a hard coating that increases surface hardness and offers excellent thermal resistance. This means it can handle the heat generated when cutting acrylic better than uncoated tools, which helps prevent melting and sticking.

This combination makes it ideal for “adaptive clearing” operations. Adaptive clearing is a high-efficiency machining strategy that uses a fixed radial stepover and a large axial depth. The tool path constantly adjusts to remain engaged with the material in the most efficient way possible, removing material quickly while minimizing tool pressure and heat buildup. The 45-degree helix ball nose Tialn end mill is perfectly suited for this kind of task in acrylic.

Key Features and Benefits

Let’s break down why this specific tool is a game-changer for your acrylic projects:

- Ball Nose Geometry: Essential for 3D contouring and creating smooth, finished surfaces. It also helps in reducing stress concentration at the cutting edge compared to a sharp square end.

- 45-Degree Helix Angle: This angle provides a good balance of shear and cutting action. It helps to efficiently evacuate chips and reduce the cutting forces that can lead to melting or breaking brittle acrylic.

- Tialn Coating: This advanced coating offers superior hardness and excellent heat resistance. It acts as a barrier, preventing the acrylic from melting onto the cutter and significantly extending tool life.

- Chip Evacuation: The flute design, combined with the helix angle, is optimized to move chips away from the cutting zone quickly. This is crucial for acrylic to prevent recutting chips, which causes melting.

- Reduced Vibration: The moderate helix angle can help to dampen vibrations, leading to a smoother cut and a better surface finish.

- Adaptive Clearing Compatibility: This tool’s geometry and performance characteristics make it a perfect partner for advanced CAM strategies like adaptive clearing, allowing for faster material removal.

Preparing for the Cut: What You’ll Need

Before you even think about hitting the “run” button, a little preparation goes a long way. Having the right setup ensures your machining process is smooth, safe, and yields the best results. Think of it as setting the stage for a successful performance!

Essential Tools and Materials

Here’s a checklist of what you should have ready:

- Tialn Ball Nose End Mill (45 Degree): Make sure you have the correct diameter for your project.

- CNC Machine: A stable and well-maintained CNC (Computer Numerical Control) machine is essential.

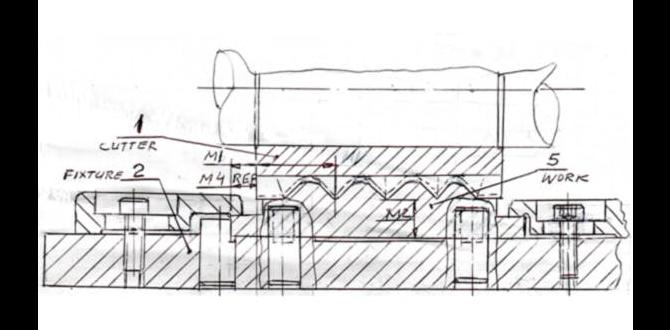

- Workholding: This is critical! You need a way to securely hold your acrylic sheet so it doesn’t move during machining. Options include:

- Vacuum table

- Clamps (ensure they don’t interfere with the tool path)

- Double-sided tape (for smaller or less demanding jobs)

- Material: Your acrylic sheet. Ensure it’s clean and free from debris.

- CAM Software: To generate your toolpaths.

- Coolant/Lubricant (Optional but Recommended): While some machinists get by without it for acrylic, a mist coolant or a specialized acrylic lubricant can make a huge difference in reducing heat and improving surface finish. Compressed air is often used as a primary chip blower.

- Safety Gear: Always wear safety glasses, and consider hearing protection and a dust mask if you’re worried about fine acrylic dust.

Securing Your Acrylic: The Importance of Workholding

I can’t stress this enough: secure workholding is paramount!

When machining, tools exert forces on the material. If your acrylic isn’t held down firmly, it can shift, vibrate, or even lift out of place. This can lead to:

- Inaccurate cuts

- Tool breakage

- Damage to your workpiece and machine

- Serious safety hazards

For acrylic, vacuum tables are often the best choice because they provide even holding pressure across the entire surface. However, if you’re using clamps, make sure they are positioned away from the cutting area and tightened securely. For lighter jobs, high-strength double-sided tape can work, but always test its holding power first.

Setting Up Your CAM Software for Acrylic Clearing

The magic really happens in your CAM software. This is where you tell your CNC machine exactly how to cut your acrylic. Getting these settings right is key to leveraging the strengths of your Tialn ball nose end mill.

Key CAM Strategy: Adaptive Clearing

As mentioned, adaptive clearing is a highly effective strategy for materials like acrylic when using a tool like your Tialn ball nose end mill. It involves:

- Constant Tool Engagement: The tool path keeps the flutes engaged with the material in a way that minimizes high-impact cuts and maximizes material removal.

- Optimized Stepover: A consistent radial stepover (how far the tool moves sideways for each pass) ensures predictable cutting forces.

- Deep Axial Cuts: The tool can take larger bites vertically into the material, which is often more efficient than many shallow passes.

This strategy works brilliantly with the Tialn ball nose end mill’s geometry and coating because it allows for efficient chip removal and manages heat effectively, preventing the acrylic from melting.

Recommended Cutting Parameters (Starting Points)

These are general guidelines. Always perform test cuts on scrap material first and adjust based on your specific machine, acrylic type, and tool brand. It’s always better to be conservative when starting out.

| Parameter | Typical Setting for Acrylic | Why it Matters for Acrylic |

|---|---|---|

| Spindle Speed (RPM) | 12,000 – 18,000 RPM | Higher speeds help manage heat by letting the tool exit the cut faster. |

| Feed Rate (IPM or mm/min) | 20 – 50 IPM (300 – 800 mm/min) | Too fast can cause chipping or melting; too slow can cause excessive heat and gumming. This depends heavily on the tool diameter and depth of cut. |

| Engagement (In/mm) – Axial Depth of Cut | 0.05 – 0.15 inches (1.2 – 3.8 mm) | Taking too deep a bite can overload the tool or cause melting. A controlled depth is crucial. |

| Stepover (Radial) | 20% – 50% of tool diameter (e.g., for 1/4″ tool, 0.05″ – 0.125″) | This is central to adaptive clearing. A wider stepover removes material faster but requires careful chip management. The Tialn coating and 45-degree helix help here. |

| Peck Drilling (for holes) | Use small pecks, e.g., 0.1 x tool diameter | Essential for clearing chips when drilling to prevent binding and overheating. |

| Cooling/Lubrication | Compressed air blast directed at the cutting zone. Mist coolant is also effective. | Critical for preventing melting and improving finish. |

Important Note on Feed Rate: The feed rate is often calculated based on the chip load (how much material each cutting edge removes per revolution). For acrylic, you want a chip load that’s sufficient to create small, manageable chips without being so large that it causes excessive heat or breakage. A good rule of thumb for acrylic might be around 0.001 – 0.003 inches per tooth. To calculate feed rate: Feed Rate = RPM x Number of Flutes x Chip Load per Tooth.

Toolpath Strategy Considerations

When setting up your toolpath, consider these points:

- Lead/Lag Angle: In adaptive clearing, the tool path will have a lead or lag angle. For acrylic, try to keep this as smooth as possible, typically between 5 to 15 degrees, to avoid abrupt changes in cutting force.

- Ramps: Instead of plunging straight down into the material, use a ramp entry. A shallow ramp angle (e.g., 2-5 degrees) is best for acrylic. This allows the tool to enter the material gradually, minimizing stress and heat.

- Smooth Transitions: Ensure your CAM software is set to create smooth, flowing transitions between cutting segments. Sharp corners or abrupt changes in direction can be problematic for acrylic.

For more information on best practices in CNC machining, resources from organizations like the National Institute of Standards and Technology (NIST) provide valuable insights into manufacturing processes. You can often find guides on machining plastics and tool selection on their technical pages or through industry associations.

Performing the Cut: Step-by-Step

With your CAM project set up and your material secured, it’s time to machine. Follow these steps carefully for safe and effective acrylic clearing.

Step 1: Double-Check Everything

Before you power up:

- Confirm Workholding: Ensure the acrylic is absolutely stable. Give it a good push to be sure.

- Tool Verification: Make sure the correct Tialn ball nose end mill is firmly seated in the collet or tool holder.

- Zero Axis: Verify that your machine’s zero point (home position) is correctly set on your workpiece.

- Clearance: Check that the tool has adequate clearance in all directions, especially when returning to home or moving between operations.

- Material Inspection: Look for any cracks, flaws, or loose debris on the acrylic sheet.

Step 2: Set Up Your Coolant/Air Blast

If you are using compressed air, position the nozzle so it blows directly at the cutting zone. This is your primary method for chip evacuation and cooling. If using mist coolant, ensure steady, consistent delivery directly to the point of cut.

Step 3: Run a Dry Simulation

Most CNC machines and CAM software allow for a “dry run” or simulation. Activate this feature without the spindle spinning or the tool in the material. Watch the toolpath closely to ensure:

- The tool stays within the bounds of your material.

- It doesn’t collide with any clamps or fixtures.

- The motion appears smooth and logical.

Step 4: Perform a Test Cut

This is vital! Cut a small, non-critical section of your acrylic, or use a scrap piece of the same material. Use the parameters you’ve set in your CAM software. Observe the cutting process:

- Is the acrylic melting or becoming gummy? If so, you might need to increase spindle speed, reduce the feed rate, or improve chip evacuation.

- Are there chips accumulating excessively? This also points to cooling/chip evacuation issues or potentially too high a feed rate.

- Is there excessive noise or vibration? This might mean the feed rate is too high, the depth of cut is too large, or there’s an issue with workholding.

Adjust your settings based on the test cut results. A slightly slower feed rate or reduced depth of cut is often a good starting point if you encounter issues.

Step 5: Execute the Main Cut

Once your test cut is successful and you’re confident in your settings:

- Load Your Program: Load the final G-code program into your CNC controller.

- Initiate Spindle and Air: Start the spindle to your programmed speed and engage the air blast or mist coolant.

- Engage the Cut: Carefully start the cutting program. Keep a close eye on the process, especially in the first few minutes. Listen to the sound of the cut.

- Monitor for Issues: Watch for any signs of melting, excessive chip buildup, unusual noises, or vibration. Be ready to pause or stop the machine if necessary.

- Completion: Allow the program to run to completion without interruption.

Step 6: Post-Machining Inspection

Once the machine has finished:

- Cool Down: Let the workpiece and tool cool down slightly before handling.

- Remove Workpiece: Carefully unclamp and remove your machined acrylic part.

- Inspect the Cut: Examine the edges and surfaces for smoothness, chipping, or signs of melting.

- Inspect the Tool: Check your Tialn ball nose end mill for any signs of excessive wear, chipping, or material buildup. The Tialn coating should help keep it remarkably clean.

Troubleshooting Common Acrylic Machining Issues

Even with the best tools and techniques, you might run into hiccups. Here are some common problems with acrylic and how to address them:

Problem: Melting or Gumming of Acrylic

This is the most common complaint when machining acrylic.

- Cause: Excessive heat generated at the cutting edge. This can be from the tool spinning too slowly, feeding too slowly, taking too deep a cut, or insufficient chip evacuation/cooling.

- Solution:

- Increase spindle speed (RPM): Letting the tool exit the cut faster reduces heat dwell time.

- Increase feed rate: A slightly faster feed can produce a larger chip that carries heat away better. Check your chip load.

- Reduce depth of cut (axial engagement): Take shallower passes.

- Improve chip evacuation: Ensure your air blast or coolant is effectively blowing chips away from the cut. Consider a vacuum system to help pull chips away.

- Use a lubricant: A specialized acrylic lubricant or even mild soap and water can help.

- Check your tool: Ensure the Tialn coating is intact and the flutes are clean.

Problem: Chipping or Cracking of Acrylic

Acrylic can be brittle, especially thinner sheets.

- Cause: Too much force applied suddenly, poor workholding, or dull tooling. Can also be caused by too aggressive a feed rate or a low helix angle tool that “pushes” material rather than cutting it.

- Solution:

- Ensure robust workholding: The acrylic must be firmly supported all around the cut.

- Reduce feed rate: Slower, more deliberate cuts reduce impact.

- Use a finer stepover: For some finishing passes, a smaller percentage of radial stepover can reduce sideways forces.

- Check tool sharpness: A sharp tool cuts cleanly with less force.

- Consider a climb or conventional milling strategy: For some plastics, conventional milling (where the cutter rotates against the feed direction) can sometimes be gentler on the edge, though adaptive clearing typically uses climb mowing.

Problem: Poor Surface Finish

The cut surface isn’t as smooth as you’d like.

- Cause: Tool vibration, chips being recut, taking too large a chip load, or a worn tool.

- Solution: