Tialn ball nose end mills are excellent for precise brass contouring. They offer smooth finishes and reduce chatter, making them ideal for intricate details and curved surfaces on brass. Follow these steps for successful cutting.

Hey there, fellow makers! Daniel Bates here from Lathe Hub. Ever stared at a piece of brass, excited about the shape you want to create, but worried about getting that perfect smooth, curved finish? Precision cutting on brass can be tricky. It’s a soft metal, which is great, but it can also gum up tools quickly, leading to rough cuts and frustration. If you’ve ever battled with a shy workpiece or been disappointed by a less-than-perfect contour, you’re not alone! But don’t worry, there’s a fantastic solution that can make a world of difference: using a TiAlN (Titanium Aluminum Nitride) coated ball nose end mill. In this guide, we’ll walk through how to use these specialized tools for crisp, clean cuts on brass, transforming your projects from good to gorgeous. Get ready to achieve those beautiful, flowing shapes with confidence!

Why TiAlN Ball Nose End Mills for Brass?

Brass is a wonderfully workable material, but when it comes to machining, it can present unique challenges. It’s relatively soft and ductile, meaning it tends to deform rather than chip cleanly. This can lead to:

- Galling: The brass can stick to the cutting edge of your tool, causing it to build up and create rough surfaces.

- Chip Welding: Small chips of brass can weld themselves onto the cutting tool, further degrading the finish and potentially damaging the tool.

- Chatter: Vibrations during cutting can lead to an uneven, wavy surface.

This is where a TiAlN ball nose end mill shines. Let’s break down why:

The Power of TiAlN Coating

The TiAlN coating is a game-changer for machining various materials, including brass. It’s a thin, hard layer applied to the cutting tool. Here’s what it does:

- Increased Hardness: The coating adds significant hardness to the end mill, allowing it to maintain its sharp edge for longer.

- Reduced Friction: TiAlN is slicker than uncoated carbide. This means less material sticks to the tool, drastically reducing galling and chip welding.

- Heat Resistance: Machining generates heat. This coating helps dissipate heat away from the cutting edge, keeping the tool cooler and prolonging its life.

- Oxidation Resistance: At higher temperatures, TiAlN forms a protective aluminum oxide layer, further enhancing its performance.

For brass, the reduced friction and increased heat resistance are key. They prevent the soft metal from building up on the tool, leading to a cleaner cut and a much smoother surface finish.

The Ball Nose Advantage

A ball nose end mill has a hemispherical tip. This shape is perfect for creating:

- Contoured Surfaces: Ideal for creating curved surfaces, fillets, and organic shapes.

- 3D Machining: Essential for multi-axis machining and creating complex geometries.

- Smooth Transitions: The rounded tip allows for seamless transitions between different cutting paths, preventing sharp corners where they aren’t wanted.

When combined with the benefits of a TiAlN coating, a ball nose end mill becomes a powerful tool for achieving intricate and perfectly smooth details on brass workpieces. A common and effective choice is the tialn ball nose end mill 45 degree for brass for contouring, designed to optimize cutting angles for this specific application.

Essential Tools and Materials

Before we dive into the step-by-step process, let’s make sure you have everything you need for a successful and safe machining session.

Your Machining Setup

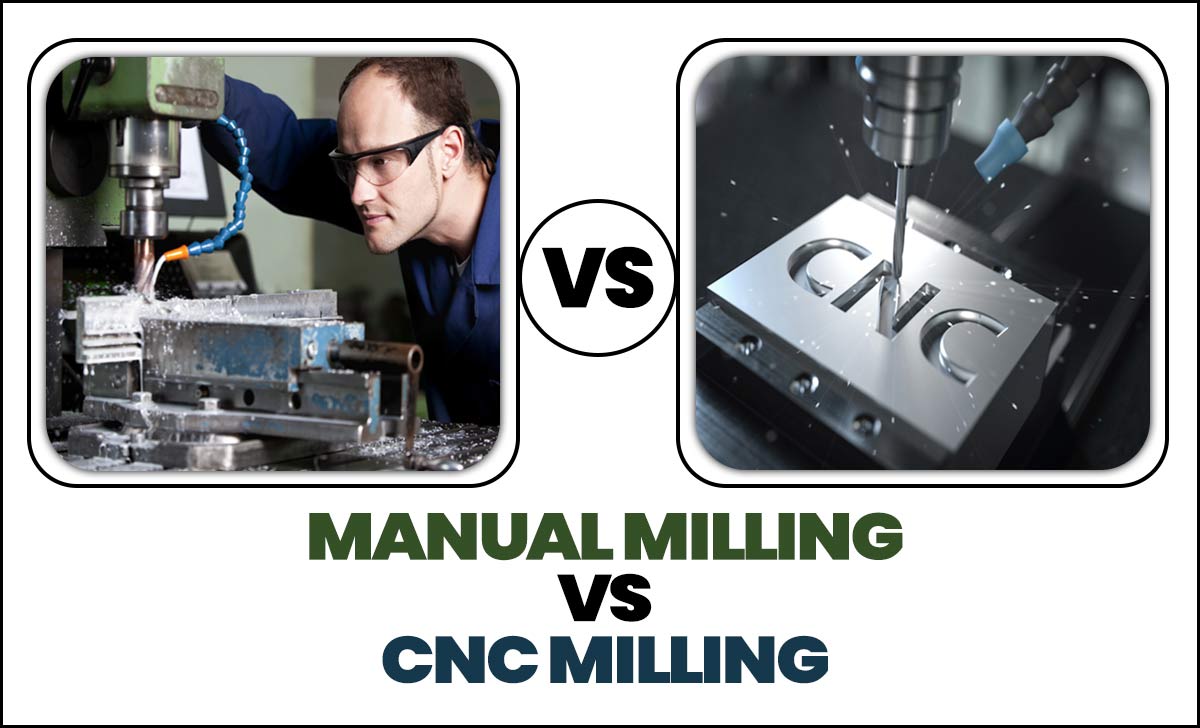

- CNC Mill or Manual Milling Machine: A stable machine is crucial for precision work.

- Workholding Device: This could be a vise, clamps, or fixture to securely hold your brass workpiece. Ensure it won’t mar the surface if it’s visible.

- End Mill Holder/Collet Chuck: To firmly grip your ball nose end mill in the machine spindle.

- Coolant or Lubricant: While TiAlN helps, a light application of a suitable cutting fluid for brass will further improve performance and finish.

The Cutting Tool

- TiAlN Coated Ball Nose End Mill: Ensure it’s the right size and geometry for your project. A 45-degree helix angle is often a good general-purpose choice for brass contouring.

- Diameter Selection: Smaller diameters (e.g., 1/8″, 1/4″) are great for fine details, while larger ones can cover more area.

Measuring and Inspection Tools

- Calipers and/or Micrometers: For accurate measurements of your workpiece and tool.

- Depth Gauge: To set your cutting depth precisely.

- Magnifying Glass or Microscope: Useful for inspecting tool condition and surface finish.

Safety Gear (Non-Negotiable!)

- Safety Glasses or Face Shield: Always protect your eyes from flying chips.

- Gloves: To protect your hands from sharp edges and coolants, though be mindful of entanglement hazards around rotating machinery.

- Hearing Protection: If your machine is particularly loud.

- Dust Mask or Respirator: Especially when dealing with fine brass dust.

Having the right tools and prioritizing safety will make the entire process smoother and more enjoyable. For a deeper dive into essential machine shop safety, the Occupational Safety and Health Administration (OSHA) provides comprehensive guidelines on machine safeguarding.

Preparing Your Brass Workpiece

Proper preparation is key to achieving a clean, precise cut and protecting your tools. Even with brass, a little prep goes a long way.

1. Material Selection and Quality

Start with good quality brass. Different brass alloys have slightly different machining characteristics. Naval brass (like UNS C46400) and free-machining brass (like UNS C36000) are common choices and generally machine well. Ensure your stock is clean and free from significant surface imperfections.

2. Securing the Workpiece

- Stable Mounting: Your brass must be held absolutely rock-solid. Any movement will result in poor surface finish and potential tool breakage.

- Vise Jaw Protection: If using a vise, consider using soft jaws (made of aluminum, brass, or plastic) to prevent marring the visible surfaces of your workpiece.

- Alignment: Ensure the workpiece is perfectly square or aligned to your machine’s axes as required by your cutting path.

3. Cleaning the Surface

Before machining, clean the surface of the brass you’ll be cutting. Remove any oil, dirt, or oxidation. A degreaser or a light abrasion with fine-grit sandpaper or Scotch-Brite can be effective. A clean surface ensures your cutting tool interacts directly with the brass, not contaminants.

4. Setting the Datum (Origin Point)

This is critical for CNC machining. You need to tell the machine where your workpiece is relative to its programmed path. This is often done using an edge finder or probe to locate a specific corner, edge, or center point. For manual machining, you’ll be setting your X, Y, and Z zero points directly on the workpiece.

A common practice is to set your X and Y zeros at a corner of the workpiece and your Z zero at the top surface of the brass. Always double-check your datum setup!

Understanding Cutting Parameters for Brass

Setting the right cutting parameters is vital for good results. Brass is relatively soft, so you don’t need aggressive speeds and feeds. The TiAlN coating also allows for slightly higher parameters than uncoated tools due to its heat dissipation properties.

Here’s a general guideline for brass, but always consult the end mill manufacturer’s recommendations for their specific tool. These parameters are a starting point:

| Parameter | Typical Value for Brass (with TiAlN Ball Nose) | Notes |

|---|---|---|

| Surface Speed (SFM) | 200 – 400 SFM (60 – 120 m/min) | Higher end for good coolant and rigid setups. |

| Feed Per Tooth (IPT) | 0.0005″ – 0.002″ (0.012 – 0.05 mm) | Depends heavily on tool diameter and flute count. Smaller tools need lower IPT. |

| Spindle Speed (RPM) | RPM = (SFM 3.82) / Diameter (inches) OR (SFM 1000) / Diameter (mm) | Calculated from Surface Speed and tool diameter. |

| Axial Depth of Cut (DOC) | 0.010″ – 0.050″ (0.25 – 1.27 mm) | For finishing passes, use very shallow DOC. For roughing, can be deeper. |

| Radial Depth of Cut (Stepover) | 10% – 50% of tool diameter | Larger stepover speeds up machining but can affect finish. 20-30% is common for contouring. |

Important Considerations:

- Tool Diameter: Smaller diameter tools require higher RPMs and potentially lower feed rates.

- Flute Count: For brass, 2 or 4-flute end mills are common. More flutes can allow for higher feed rates if chip evacuation is managed well.

- Machine Rigidity: A more rigid machine can handle slightly higher parameters.

- Actual Brass Alloy: Some brass alloys are harder or leaded more, affecting machining rates.

- Coolant/Lubrication: Using a suitable cutting fluid is highly recommended. It keeps the tool cool, lubricates the cut, and helps clear chips.

Example Calculation:

Let’s say you have a 1/4″ diameter TiAlN ball nose end mill and you want to run at 300 SFM.

RPM = (300 SFM 3.82) / 0.25 inches = 4584 RPM.

If your feed rate is 0.001″ per tooth and you have a 4-flute end mill:

Feed Rate (IPM) = 4584 RPM 0.001 IPT * 4 flutes = 18.3 IPM.

Always start on the conservative side and increase parameters if the cut is smooth and the chip looks good. Listen to your machine—unusual noises often indicate a problem.

Step-by-Step Precision Cutting with TiAlN Ball Nose End Mills

Now that we’re prepared, let’s get to the exciting part: making chips!

1. Tool Installation

Carefully insert the TiAlN ball nose end mill into the collet chuck or end mill holder. Ensure it is seated properly and tightened securely. A runout of the tool can lead to poor surface finish and premature wear.

2. Setting Z-Axis Zero

This is critical for accurate depth control. Use your preferred method (edge finder, probe, or touch-off block) to set the Z-axis zero point precisely at the top surface of your brass workpiece. You want the machine to know exactly where the material begins.

3. Loading Your Machining Program (CNC) or Setting Setups (Manual)

- CNC: Load your CAM-generated G-code file into the machine controller. Perform a “dry run” or air cut at a safe height to verify the toolpath and ensure no crashes will occur.

- Manual: Set your X and Y zero points using your DRO (Digital Readout) or carefully align your tool to the desired starting points. For contouring, you’ll be feeding the machine along the desired path.

4. Applying Coolant/Lubricant

Before the tool engages the material, turn on your coolant or apply a light mist of cutting fluid. For brass, a general-purpose cutting fluid or even a bit of WD-40 can help reduce friction and assist chip evacuation. Ensure the coolant is directed at the cutting zone.

5. Initiating the Cut

CNC Machining: Start the program. Monitor the cutting process closely. Listen for any unusual sounds. Watch for chip formation—they should be a clean, small size, not long stringy curls that might indicate too slow a spindle speed or too fast a feed rate, or hot, fused chips suggesting overheating or poor lubrication.

Manual Machining:

- Plunge (if necessary): If you’re starting a cut in the middle of the material, slowly plunge the ball nose end mill to the desired depth. Once at depth, begin to move sideways.

- Contouring: Move the tool along the programmed or intended path. For ball nose end mills, you’ll typically be moving the tool sideways to create curved surfaces or profiles.

- Feed Rate Control: Maintain a consistent and steady feed rate. Avoid jerky movements.

6. The Importance of Stepover and Stepdown in Contouring

When creating a contoured surface, especially in 3D, the ball nose end mill isn’t just cutting a simple line. It’s often used in a raster pattern (like mowing a lawn) or a spiral path.

- Stepdown (Axial DOC): This is the depth the tool cuts into the material on each pass. For a fine finish, use small stepdowns, perhaps 0.020″ to 0.050″ (0.5mm to 1.2mm) or even less, depending on your tool diameter and machine capability.

- Stepover (Radial DOC): This is how far the tool moves sideways between passes. A smaller stepover results in a smoother surface finish because the scallops left by the tool are closer together. For detailed contouring on brass, a stepover of 10-25% of the tool diameter is often ideal. A 45-degree helix angle on the end mill helps with chip evacuation and finish in these angled cuts.

This combination of precise stepdown and a small stepover is how you achieve that beautifully smooth, almost polished surface on your brass contours.

7. Finishing Passes

For the absolute best surface finish, consider a dedicated “finishing pass.” This pass uses:

- A very shallow axial depth of cut (e.g., 0.005″ – 0.010″).

- A small radial stepover (e.g., 5-15% of the tool diameter).

- Potentially a slightly reduced feed rate to enhance the finish.

- Ensure optimal coolant flow.

This final pass will “clean up” any remaining tooling marks and leave your brass surface looking spectacular.

8. Tool Wear and Inspection

Periodically pause your machining to inspect the end mill. Look for signs of wear, chipping, or material buildup on the cutting edges. The TiAlN coating is durable, but it’s not indestructible. If you notice a degradation in the surface finish or hear the tool struggling, it might be time to replace it. A worn tool will always produce a poor finish and can eventually lead to tool breakage.

9. Post-Processing

Once machining is complete, carefully remove the workpiece. Clean away any residual coolant and chips. Inspect your work. You might find that a light polish with a fine-grit sandpaper, a buffing wheel, or even artistic metal polish can enhance the already great finish achieved by the TiAlN ball nose end mill.

Troubleshooting Common Issues

Even with the best tools, you might run into a hiccup. Here are some common problems and how to fix them:

<td rowspan="3| Problem | Possible Cause | Solution |

|---|---|---|

| Rough Surface Finish | Tool wear or damage | Inspect and replace the end mill. |

| Excessive stepover | Reduce the radial stepover (percentage of tool diameter). | |

| Insufficient coolant/lubrication | Increase coolant flow or use a better lubricant. | |