Quick Summary: The 50-degree TiAlN ball nose end mill is a versatile tool ideal for wood and soft metal roughing. Its specific angle excels at creating smooth contours and efficient material removal, making it a dependable choice for beginners tackling complex shapes. This article guides you through its use, benefits, and when to choose it.

Welcome to the workshop, folks! Daniel Bates here from Lathe Hub. Ever stared at a piece of material, ready to carve out a complex curve or smooth transition, and felt a bit… stuck? You know you need a special kind of tool, something that can handle sweeping arcs without leaving jagged edges, especially when you’re just starting out. That’s where the TiAlN ball nose end mill with a 50-degree angle shines. It might sound a bit technical, but trust me, it’s a game-changer for creating beautiful, flowing shapes in wood and softer metals. We’re going to break down exactly what this tool is, why it’s so useful, and how you can start using it to bring your projects to life. Get ready to unlock some new creative possibilities!

What is a TiAlN Ball Nose End Mill, Anyway?

Let’s break down that name, piece by piece. It’s not as intimidating as it sounds!

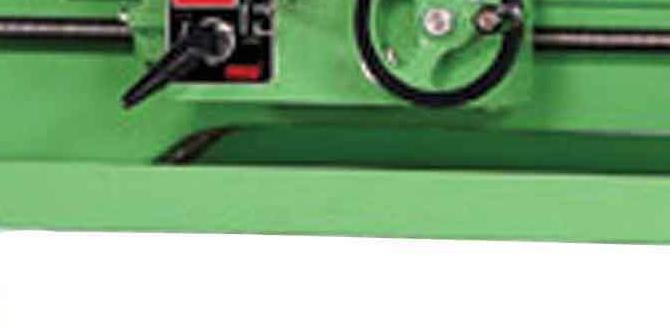

- End Mill: This is a type of milling cutter. Think of it like a drill bit, but instead of just drilling down, it can cut sideways, plunge straight down, and create all sorts of shapes and profiles. They’re designed for use on milling machines.

- Ball Nose: This refers to the shape of the cutting tip. Unlike a flat-ended end mill, a ball nose end mill has a perfectly rounded tip. This shape is fantastic for creating smooth, curved surfaces, fillets, and pockets with rounded bottoms.

- 50 Degree: This is a crucial detail! It refers to the helix angle of the flutes (the spiral grooves on the cutter). A 50-degree helix angle is often considered a good compromise for general-purpose machining, offering a balance between chip evacuation (getting the waste material out of the cut) and surface finish. It’s not as aggressive as a low helix (which might chatter), nor as shallow as a high helix (which might be too delicate for roughing).

- TiAlN (Titanium Aluminum Nitride): This is a coating applied to the end mill. This special coating makes the tool incredibly hard and resistant to heat. This means it can cut tougher materials, run faster, and last much longer than uncoated tools. For materials like aluminum, plastics, and even some steels, this coating is a real workhorse.

So, put it all together: a TiAlN ball nose end mill with a 50-degree helix angle is a coated milling cutter with a rounded tip and a specific spiral flute design, making it tough, heat-resistant, and excellent for creating smooth, curved cuts, especially in materials that aren’t excessively hard.

Why is the 50-Degree Helix Angle So “Proven Essential”?

You might be asking, “Why 50 degrees specifically?” It’s all about balance and performance, especially when we’re talking about applications like roughing or working with materials that are a step up from pure softwoods but not hardened steel.

In milling, the helix angle affects how the tool engages the material. A steeper helix (higher degree) has more of an “up-cut” action, which can be good for chip evacuation but might lead to chatter on harder materials or under heavy loads. A shallower helix (lower degree, closer to flat) has a more shearing cut but can be more prone to chipping or overheating and may not clear chips as effectively.

The 50-degree angle hits a sweet spot. It provides:

- Good Chip Evacuation: It’s efficient at clearing away chips, which is vital for preventing overheating and tool breakage, especially when you’re removing a lot of material (roughing).

- Reduced Chatter: The moderate helix angle helps to smooth out the cutting action. This means less vibration and a more stable cut, leading to a better surface finish straight off the machine and less work for you later.

- Versatility: This angle performs well across a range of materials and cutting strategies. It’s forgiving enough for beginners to learn with, yet capable enough for more experienced users. It’s particularly well-suited for materials where you want efficient material removal without sacrificing finish too much.

This balance makes the 50-degree ball nose end mill a go-to choice for many machining tasks, including those where you need to quickly remove material and create organic shapes. For woodworkers and those working with softer metals, this angle offers a fantastic blend of performance and ease of use.

When Should You Reach for Your 50-Degree TiAlN Ball Nose End Mill?

This is where the magic happens – understanding when this specific tool is your best friend. The 50-degree TiAlN ball nose end mill is a versatile workhorse, but it truly excels in certain situations. Consider it your go-to for:

1. Roughing Out Complex Shapes

When you’re milling a complex 3D shape, whether it’s a flowing sculpture in wood or an intricate mold in soft aluminum, you often need to remove a lot of excess material quickly. The ball nose shape allows you to do this efficiently while the 50-degree helix angle helps in clearing those chips effectively. This means you’re not spending excessive time on the initial material removal, letting you get to the finer details sooner.

Think of carving out a bowl or a contoured part for a project. This tool can quickly hog out the bulk material, leaving a surface that’s ready for a finishing pass or further refinement.

2. Creating Smooth Contours and Radii

The rounded tip of a ball nose end mill is naturally suited for creating concave (inward) curves or convex (outward) radii. The 50-degree helix is efficient for cutting these curves without that jarring, stepped effect you might get with a less suitable tool. It helps to blend surfaces smoothly, which is critical for aesthetics and functionality in many projects.

This is perfect for adding smooth transitions between surfaces, rounding edges, or creating fillets in corners—essential for both appearance and structural integrity in many designs.

3. Working with Wood and Softer Metals

The “TiAlN” coating is a big clue here. While it’s a tough coating, it truly shines when paired with materials like:

- Woods: Hardwoods, softwoods, and even some composite wood materials. The ability to clear chips efficiently prevents burning and helps achieve a cleaner cut.

- Plastics: Acrylics, ABS, HDPE, and other common plastics.

- Aluminum and its Alloys: This is a sweet spot for many TiAlN coated tools, allowing for good speeds and feeds.

- Brass and Copper: These softer non-ferrous metals machine well with this type of tool.

It’s generally not the first choice for very hard steels or hardened materials, where specialized coatings or geometries might be preferred. But for the “wood for roughing” use case and softer metals, it’s a champion.

4. Achieving a Good Balance of Speed and Finish

For beginners, tools can sometimes feel like an either/or situation: fast but rough, or slow and pretty. The 50-degree helix angle on a ball nose end mill offers a great compromise. It allows for reasonably aggressive material removal rates (getting the job done faster) while still producing a surface finish that requires minimal cleanup. This is invaluable when you’re learning and trying to get a feel for your machine and cutting parameters.

5. Performing General-Purpose 3D Machining

In CNC machining, especially for 3D contouring, a tool like this is indispensable. It can handle a variety of toolpath strategies, from rastering (back-and-forth) to contouring, and its geometry is well-suited for getting into those tricky, curved areas that flat-bottomed tools can’t reach without leaving awkward walls.

For anyone looking to get into multi-axis machining or detailed 3D carving, this tool is a fundamental part of the toolkit. You can find more about CNC machining basics on resources like this helpful NIST page on Advanced Manufacturing Technology.

Understanding the Benefits: Why It’s a Smart Investment

Choosing the right tool isn’t just about getting the job done; it’s about making your life easier, improving your results, and saving money in the long run. The TiAlN ball nose end mill with a 50-degree helix angle offers several compelling benefits for us home machinists and hobbyists.

Durability and Longevity

The number one benefit of the TiAlN coating is its incredible hardness and heat resistance. This means the cutting edges stay sharp for much longer, even when working with materials that generate a lot of friction. For you, this translates to:

- Fewer tool changes mid-project.

- Consistent cutting performance over time.

- A reduced risk of tool failure due to overheating.

This is especially important for beginners, as it provides a more forgiving cutting experience and reduces the frustration of prematurely worn-out tooling. A durable tool is a reliable tool!

Enhanced Cutting Performance

Beyond just lasting longer, the coating and the 50-degree helix angle work together to improve the cutting process:

- Smoother Cuts: The ball nose geometry is designed for curves, and the 50-degree helix angle ensures a relatively smooth engagement with the material, minimizing chatter and vibration. This results in a better surface finish right off the machine.

- Efficient Material Removal: The helix angle helps clear chips effectively. This is critical for preventing the tool from getting clogged, which can lead to overheating, poor surface finish, and tool breakage.

- Faster Cutting Speeds: Because the tool is harder and more heat-resistant, you can often push it a bit faster (higher spindle speed or feed rate) than an uncoated tool. This means you can get through your projects more quickly.

Versatility Across Materials

As we touched on, this tool isn’t a one-trick pony. While it’s perfect for wood and softer metals, the robust TiAlN coating gives it some capability to handle slightly tougher materials than an uncoated tool might. This means one end mill can potentially serve multiple purposes in your workshop, saving you money and space.

It’s perfect for:

- 3D contouring in wood.

- Creating rounded fillets and pockets in aluminum.

- Machining plastics with good surface finishes.

Always remember to consult manufacturer recommendations for specific material-tool compatibility.

Improved Surface Finish

The combination of the rounded tip and the optimized helix angle directly contributes to a superior surface finish compared to less specialized tools. For tasks involving curved surfaces or when you need to avoid sharp corners, this end mill leaves a much cleaner, smoother result. This often means less time spent on secondary operations like sanding or polishing, which is a huge win for any hobbyist.

Cost-Effectiveness (When Used Appropriately)

While specialized end mills can be an investment, a good quality 50-degree TiAlN ball nose end mill is surprisingly cost-effective when you consider its lifespan and performance. By investing in a tool that lasts longer and performs better, you reduce the frequency of replacements and benefit from more efficient machining times. This makes it a smart choice for anyone serious about improving their machining capabilities without breaking the bank.

A Table of Applications: Where This Tool Shines

To give you a clearer picture, here’s a look at typical applications where this end mill is a fantastic choice:

| Project Type | Material Example | Why the 50-Degree TiAlN Ball Nose Excels | Key Benefits |

|---|---|---|---|

| 3D Carving & Sculpting | Wood (Walnut, Maple), Foam | Efficiently removes bulk material while creating smooth, flowing surfaces. Ball nose allows for undercuts and complex contours. | Faster roughing, smoother finish, reduced manual cleanup. |

| Mold Making (Soft Materials) | Aluminum Alloys, Plastics (ABS, Acrylic) | Can create rounded cavities and features with good surface finish. TiAlN coating handles aluminum well. | Good chip evacuation prevents clogging, extended tool life, reliable results. |

| Creating Radii and Fillets | Wood, Aluminum, Plastics | The naturally rounded tip is perfect for creating consistent inside and outside radii and smooth corner transitions. | Achieves desired aesthetics and structural integrity, less post-processing. |

| Pocketing with Rounded Bottoms | Aluminum, Plastics | When a pocket needs a radiused bottom to avoid stress risers or for specific functional reasons. | Precise feature creation that flat-bottomed tools can’t achieve, cleaner operation. |

| Prototyping Complex Parts | Aluminum, Plastics | For rapid iteration of designs that feature complex curves and surfaces. | Speed of material removal combined with acceptable finish for early prototypes. |

Getting Started: Basic Usage and Safety

Alright, you’ve got your 50-degree TiAlN ball nose end mill. Now what? Using it effectively and safely is key to great results. Don’t worry, it’s straightforward!

Choosing Your Mill

End mills come in various diameters. For beginners, starting with a common size like 1/4 inch (6mm) or 1/2 inch (12mm) is a good idea. Larger diameters remove material faster but require more machine power and rigidity. Smaller diameters are good for finer detail but are more delicate.

Setting Up in Your Milling Machine

- Secure the Workpiece: Make absolutely sure your workpiece is clamped down firmly. A loose workpiece is a recipe for disaster. Use vises, clamps, or fixtures as appropriate for your machine and project.

- Install the End Mill: Place the end mill securely in your machine’s collet or tool holder. Ensure it’s seated properly and the collet nut is tightened to prevent slippage. This is critical for accuracy and safety.

- Set the Spindle Speed (RPM): This is SUPER important. The right RPM depends on your machine, the material you’re cutting, and the diameter of the end mill. A good starting point for aluminum with a 1/2 inch end mill might be 4,000-6,000 RPM, but for wood, you might run slower. Too fast can melt plastic or burn wood; too slow can lead to chatter and poor finish. Always check recommended speeds and feeds for your specific material and tool. A great resource for common speeds and feeds can be found on many tooling manufacturer websites or online calculators. For general guidance, this article from Machinery Magazine provides excellent foundational knowledge.

- Set the Feed Rate: This is how fast the cutter moves through the material. For roughing, you can use a relatively aggressive feed rate, but always listen to your machine. If it sounds strained or starts chattering, back off. For finishing passes, you’ll use a much slower feed rate to get a super smooth surface.

Cutting Strategies

For roughing with a ball nose end mill, you’ll often use toolpaths that step down progressively. Your milling software will help you define these:

- 2D/3D Contour Toolpaths: These follow the outline of your design.

- Pocketing Toolpaths: For clearing out areas to a specific depth.

- Stepped Roughing: Where the tool takes multiple shallow passes to remove material, rather than one deep cut.

For wood, you might run a slightly lower RPM and a slightly higher feed rate than for aluminum. The TiAlN coating helps prevent burning by reducing friction.

Chip Evacuation

Keep an eye on those chips! Good chip evacuation is key. This is where the 50-degree helix helps immensely. If you’re working with metal, a little bit of coolant or cutting fluid can go a long way to keep things cool and clear chips. For wood, a good dust collection system is essential, and sometimes a blast of compressed air can help clear chips from the cutting zone.

Safety First!

- Eye Protection: Always wear safety glasses. Flying chips or tool fragments demand it.

- Hearing Protection: Milling machines can be loud.

- No Loose Clothing or Jewelry: These can get caught in rotating machinery.

- Be Aware of Your Machine: Know where all the controls are and how to stop the