Quick Summary:

The TiAlN ball nose end mill with a 50-degree helix angle is your go-to tool for effortless contouring, especially in challenging materials like PEEK. Its specialized geometry cuts smoothly, reduces chatter, and leaves a superior surface finish on complex shapes.

Hey everyone, Daniel Bates here from Lathe Hub. Today, we’re diving into a tool that can truly transform the way you approach contouring operations, especially when you’re working with some of those trickier materials out there. Ever found yourself battling chatter, struggling for a decent surface finish, or just feeling like your contoured parts aren’t coming out as cleanly as you’d hoped? You’re not alone. Many beginners find contour machining can be a bit daunting, but the right tool can make all the difference. Get ready, because we’re going to break down how a TiAlN ball nose end mill with a specific 50-degree helix can be your new best friend for achieving smooth, precise curves and shapes with greater ease than you ever thought possible.

We’ll cover why this particular end mill shines, what makes its design so effective, and how you can put it to work in your shop for outstanding results, even on materials notorious for giving machinists a run for their money.

Understanding the TiAlN Ball Nose End Mill 50 Degree

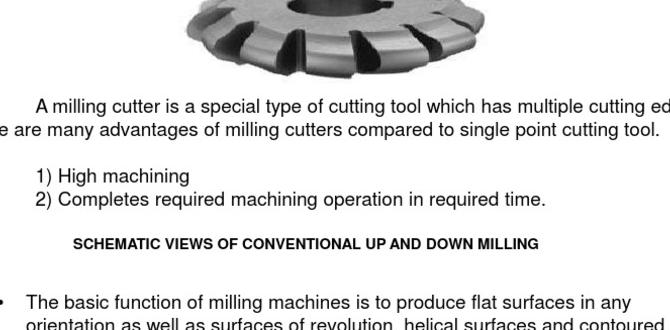

Let’s start by unpacking what exactly a “TiAlN ball nose end mill 50 degree” is and why it’s special. When we talk about end mills, we’re referring to cutting tools used in milling machines to create slots, profiles, and pockets in materials. The “ball nose” part means the cutting tip is perfectly rounded, like a ball. This is crucial for creating smooth, curved surfaces and fillets, which is exactly what contouring is all about.

Now, the “TiAlN” coating is a thin layer of Titanium Aluminum Nitride applied to the surface of the end mill. This coating is a game-changer. It’s incredibly hard, which means it resists wear and abrasion much better than uncoated tools. It also offers excellent thermal stability, meaning it can handle the heat generated during cutting without losing its sharp edge or structural integrity. This is especially important when machining harder materials or when running at higher speeds.

The “50-degree” refers to the helix angle of the flutes. The helix angle is the angle at which the cutting edges spiral around the tool’s body. A higher helix angle, like 50 degrees, generally leads to a more shear cutting action. Think of it like a sharp knife slicing through material rather than scraping it. This results in:

- Smoother cutting action

- Reduced vibration and chatter

- Better surface finish

- Improved chip evacuation

- Increased tool life

Putting it all together, a TiAlN ball nose end mill with a 50-degree helix angle is an advanced cutting tool designed for precise, high-quality contouring and surface finishing, particularly in demanding materials.

Why Choose This Specific End Mill for Contouring?

Contouring is the process of creating curved or complex shapes on a workpiece. It’s a common operation in manufacturing, whether you’re making intricate custom parts, molds, dies, or even decorative elements. Traditional end mills can sometimes leave noticeable tool marks, require multiple passes, or struggle to maintain accuracy on sharp curves. This is where our specialized ball nose end mill comes in.

The rounded tip of the ball nose end mill is perfect for seamlessly blending surfaces and creating smooth transitions. When combined with a 50-degree helix, the cutting action becomes more efficient and less aggressive. This means less force is put on the workpiece and the tool, leading to:

- Reduced Chatter: A common problem in contouring is vibration, or chatter, which ruins surface finish and can damage the tool. The 50-degree helix angle helps to break up the cutting forces, making the cut much smoother and quieter.

- Superior Surface Finish: The shear-like cutting action inherently produces a finer surface finish compared to tools with lower helix angles. This means less post-machining work, like sanding or polishing, is needed.

- Improved Accuracy: A more stable cut means the tool is less likely to deflect, leading to more accurate dimensions on your contoured parts.

- Faster Material Removal (in some cases): While always prioritizing finish, the efficient cutting action can sometimes allow for slightly more aggressive feeds and speeds, speeding up the process without sacrificing quality.

- Longevity: The TiAlN coating and the design of the 50-degree helix end mill work together to prolong the tool’s lifespan, saving you money in the long run and reducing the frequency of tool changes.

Great for PEEK and Other Advanced Materials

One of the key advantages often overlooked by beginners is how well this type of end mill performs on advanced plastics like PEEK (Polyether Ether Ketone). PEEK is a high-performance thermoplastic known for its exceptional mechanical strength, thermal resistance, and chemical inertness. However, these properties also make it notoriously difficult to machine. It can melt easily, gum up tools, and create stringy chips that wrap around the cutter.

This is where the TiAlN 50-degree ball nose end mill truly shines. The TiAlN coating helps to resist the heat generated from friction, preventing the plastic from melting and sticking to the tool. The 50-degree helix provides a cleaner, more shearing cut, which is vital for managing the plastic’s tendency to deform and create swarf. This combination allows for:

- Melt-Free Machining: The coating’s heat resistance minimizes thermal build-up.

- Reduced Stickiness: A cleaner cut prevents gummy material from adhering to the flutes.

- Controlled Chip Evacuation: The helix angle helps manage the often stringy chips produced by plastics like PEEK.

- Smooth Contours on Plastic: Achieve the same quality of curved surfaces on PEEK as you would on many metals.

For anyone working with PEEK or similar demanding engineering plastics, this end mill is almost a necessity for achieving clean, precise contours without constant tool clogging or melted mess.

How to Use Your TiAlN Ball Nose End Mill for Effortless Contouring

Using any cutting tool effectively involves understanding its capabilities and setting up your machine correctly. For a TiAlN ball nose end mill with a 50-degree helix, the principles are straightforward, but attention to detail is key.

Step 1: Tool Selection and Inspection

Before you even touch your machine, grab the correct end mill. Ensure it’s the right diameter for your part and that the tip radius is suitable for the smallest curve you plan to machine. Always inspect the tool for any damage, chips, or signs of wear. A damaged tool is a recipe for disaster.

Step 2: Secure Your Workpiece

This is paramount for safety and accuracy. Your workpiece must be held firmly and securely in your milling machine. Use appropriate workholding methods like vises, clamps, or fixtures. For PEEK and other plastics, it’s often advisable to use soft jaws or clamping elements that won’t mar the surface. A loose workpiece can lead to catastrophic failure.

Step 3: Setting Up Your Machine

Spindle Speed (RPM): The optimal spindle speed depends on the material you’re cutting, the diameter of the end mill, and the cutting parameters recommended by the manufacturer. For PEEK, generally, slower speeds are preferred to avoid melting. However, the 50-degree helix can sometimes allow for slightly faster speeds than a lower helix due to better chip evacuation. Always consult your material and tool manufacturer’s guidelines. A good starting point for plastics might be between 5,000 and 15,000 RPM, while for metals, it can be much higher, but heat and chip load are critical.

Feed Rate: This is how fast the tool moves into the material. The feed rate needs to be balanced with the spindle speed to achieve a proper “chip load” – the thickness of the chip being removed by each cutting tooth. Too low a chip load and the tool will rub and overheat; too high, and you risk breaking the tool or overloading the spindle. For contouring, especially on curves, the feed rate often needs to be adjusted dynamically by your CNC controller. A good starting chip load for a ball nose end mill might be around 0.001″ to 0.005″ per tooth, varying by material and tool diameter.

Depth of Cut (DOC): This is how deep the tool cuts into the material with each pass. For contouring, you’ll typically use a shallow depth of cut, especially on the final finishing passes, to achieve a better surface finish. For roughing passes, you can take a deeper cut, but this also depends on the tool’s rigidity and the material’s properties. A radial depth of cut (how much of the tool’s diameter is engaged sideways) is also critical in contouring, especially when using a ball nose end mill. For finishing passes, a small radial depth of cut (e.g., 0.010″ to 0.050″) is common to get a smooth surface.

Coolant/Lubrication: For metals, a suitable coolant is essential to reduce heat and flush away chips. For PEEK and plastics, air blast or specific plastic-friendly coolants are often used. Sometimes, machining dry is preferred if the material is prone to becoming sticky with liquid coolants. Always verify the best practice for your specific material.

Step 4: Toolpath Generation (CNC Machining)

This is where the “effortless” part truly happens with CNC machines. Your CAM (Computer-Aided Manufacturing) software is what generates the precise path the end mill will follow. For contouring, you’ll typically use:

- 2D Contour Toolpaths: For outlining shapes.

- 3D Contour Toolpaths: Essential for complex, sculpted surfaces.

- Ball Nose Milling Strategy: This tells the software to use the rounded tip effectively, often creating parallel passes across the surface or along a boundary.

When setting up your toolpath, make sure to:

- Select the correct tool (your TiAlN 50-degree ball nose).

- Specify accurate material properties.

- Set appropriate stepover (radial engagement) and stepdown (axial engagement) values for roughing and finishing passes. A small stepover is crucial for a smooth contoured surface finish.

- Ensure the toolpath accounts for the radius of the ball nose end mill to avoid gouging or leaving unwanted material.

You can find excellent resources on generating toolpaths for contouring from sources like the National Institute of Standards and Technology (NIST), which discusses advancements in CAM and manufacturing technologies.

Step 5: Executing the Cut

Once everything is set up and verified, you can start the machining process. Always stay aware of the machine’s operation. Listen for unusual noises that might indicate chatter or tool overload. Watch chip formation – they should be consistent and relatively small, not long, stringy, or dusty. Be ready to hit the emergency stop if anything seems off.

Finishing Passes: For the highest quality surfaces, it’s common practice to use a dedicated finishing pass with a very small stepover (e.g., 0.005″ to 0.015″) and a shallow depth of cut. This pass is all about surface finish, not material removal.

Step 6: Inspection and Post-Processing

After the machining is complete, carefully inspect your part. Check for dimensional accuracy, surface finish quality, and any signs of machining defects like marks or chatter. The TiAlN 50-degree ball nose end mill should leave you with a cleanly contoured surface that requires minimal post-processing.

Key Features and Benefits Table

To summarize the advantages of using this specific type of end mill, let’s break them down into a table for easy reference.

| Feature | Benefit for Contouring | Best Suited For |

|---|---|---|

| Ball Nose Tip | Creates smooth, seamless curved surfaces and fillets. Ideal for blending surfaces. | 3D contouring, mold making, artistic designs, fillet creation. |

| 50-Degree Helix Angle | Shear cutting action reduces chatter, improves surface finish, and enhances chip evacuation. | Demanding materials, high-quality finish requirements, reducing vibration. |

| TiAlN Coating | High hardness and thermal resistance. Prevents tool wear, overheating, and material buildup (especially important for plastics). | Hard metals, abrasive materials, high-temperature alloys, advanced plastics like PEEK. |

| Combined Effect | Effortless, precise, and high-quality contouring with superior surface finishes, even in difficult-to-machine materials. | Complex parts, prototypes, production runs requiring excellent finish and accuracy. |

When to Consider Alternatives

While the TiAlN 50-degree ball nose end mill is incredibly versatile, especially with PEEK, it’s good to know when other tools might be a better fit. For very aggressive roughing operations where surface finish is secondary, a square-shoulder or corner-radius end mill might clear material faster. For very soft plastics that melt easily and don’t require high precision, a simpler uncoated end mill might suffice.

However, for achieving that clean, smooth contour, especially in intermediate to hard materials and advanced plastics, this tool is hard to beat. The balance it strikes between speed, finish, and tool life is exceptional. If you’re struggling with surface finish or tool wear on your contoured parts, switching to this type of end mill is often the most effective solution.

Maintenance and Care

To get the most out of your TiAlN 50-degree ball nose end mill, proper care is essential:

- Cleaning: After each use, clean the flutes and coating thoroughly. For metals, remove any metal chips. For plastics like PEEK, ensure no gummy residue is left. Use appropriate solvents or cleaners if necessary, being careful not to damage the coating.

- Inspection: Regularly check the cutting edges for wear, chipping, or signs of dullness. A dull tool will lead to poor surface finish and increased heat.

- Storage: Store end mills in a protective case or holder to prevent accidental damage to the cutting edges. Keep them in a dry environment to prevent corrosion, although the TiAlN coating offers good protection.

- Re-sharpening: While TiAlN coated tools are very durable, they can eventually be re-sharpened by specialized services. However, it’s often more cost-effective for high-performance coatings to replace the tool once it reaches its end of life, especially for hobbyists.

Proper maintenance ensures your tool performs optimally and lasts as long as possible, giving you reliable results job after job.

Frequently Asked Questions (FAQ)

Q1: What is the main advantage of a ball nose end mill for contouring?

A1: The rounded tip of a ball nose end mill allows it to create perfectly smooth, continuous curved surfaces and fillets without sharp corners, which is exactly what contouring requires. It blends surfaces seamlessly.

Q2: Why is the 50-degree helix angle important?

A2: A 50-degree helix angle provides a more aggressive, shearing cut. This reduces vibration and chatter, leading to a better surface finish and improved chip evacuation, making it ideal for achieving smooth contours and working with challenging materials.

Q3: How does the TiAlN coating help when machining PEEK?

A3: TiAlN (Titanium Aluminum Nitride) coating is very hard and resistant to heat. When machining PEEK, it helps prevent the material from melting and sticking to the tool (galling) and reduces the wear on the end mill, allowing for cleaner cuts and longer tool life.

Q4: Can I use this end mill for roughing or only finishing?

A4: You can use it for both. For roughing, you might use slightly larger depths of cut and stepovers to remove material efficiently. For finishing, you’ll use shallower cuts and smaller stepovers to achieve the highest surface quality. The tool is versatile enough for both stages of contour machining.

Q5: What are common machining issues this end mill helps to solve?

A5: It excels at solving issues like tool chatter and vibration, poor surface finish (tool marks), material buildup on the cutter (especially plastics), and premature tool wear when contouring in harder materials or plastics like PEEK.

Q6: Where can I find reliable information on cutting parameters?

A6: Always start with the recommendations from your end mill manufacturer. You can also consult reliable machining resources like university manufacturing departments, such as <a href="https://www.egr.msu.edu/academics/departments/mechanical-engineering/research/advanced-manufacturing" target="_blank