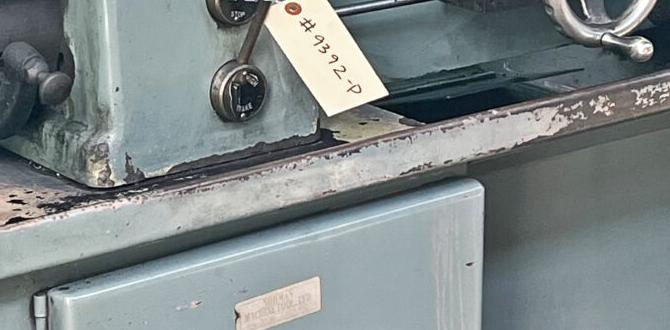

Have you ever watched a metal lathe in action? It’s fascinating! This machine shapes metal into precise forms. But what holds those metal pieces securely while the lathe works? The answer lies in a tool holder.

A tool holder for a metal lathe is important. It keeps tools steady and in place. Without a good holder, the process can go wrong. That’s where CAD design comes in. CAD stands for computer-aided design. It’s a powerful tool that helps create clear designs for tool holders.

Using CAD, designers can make tool holders that fit perfectly. They can test ideas and change them quickly. Imagine designing your own tool holder! What would it look like? Would it have cool shapes or bright colors? The possibilities are endless!

In this article, we will explore how to make the best tool holder for a metal lathe using CAD design. You will learn tips and tricks to create your own. Whether you’re a beginner or an expert, there’s something for everyone. So, let’s dive into the world of CAD and metal lathes!

Tool Holder Metal Lathe Cad Design: A Comprehensive Guide

Tool Holder Metal Lathe CAD Design

Imagine making complex metal parts with ease! The tool holder for a metal lathe plays a key role in this process. With CAD design, you can create precise models that enhance your machining experience. Knowing how to design these holders helps in organizing tools efficiently. This not only improves accuracy but also saves time. Did you know that a well-designed tool holder can drastically reduce setup time? Embrace CAD design to revolutionize your metalworking projects!Understanding Tool Holders in Metal Lathes

Definition and purpose of tool holders in metal lathes. Types of tool holders commonly used in metalworking.Tool holders are essential parts of metal lathes, acting like the handle of a cool kitchen spatula. They securely hold cutting tools while spinning materials, making it easy to shape metal like play dough! There are different types of tool holders used in metalworking. The most common ones are collet chucks, turning tool holders, and quick change tool holders. Each type serves a unique purpose, helping machinists work efficiently and safely with their lathes. You could say they keep everything *lathe-tastic*!

| Type of Tool Holder | Purpose |

|---|---|

| Collet Chuck | Holds tools tightly using a sleeve |

| Turning Tool Holder | Specifically for holding turning tools |

| Quick Change Tool Holder | Allows for fast tool swaps |

Benefits of CAD Design for Tool Holders

Advantages of using CAD software for designing tool holders. How CAD design improves precision and efficiency.Using CAD software for designing tool holders has many benefits. CAD helps in making precise designs. The software allows you to easily adjust shapes and sizes, which can save time. It boosts efficiency by reducing errors. With careful planning, users can create better tool holders quickly.

- Accuracy: CAD ensures accurate designs every time.

- Speed: Changes can be made in seconds.

- Visualization: 3D models help you see how it will look.

Why is CAD design important for tool holders?

CAD design allows for detailed planning and high accuracy, which leads to a better fit and improved function. Combining technology with creativity helps boost manufacturing quality.

Step-by-Step Process of Designing a Tool Holder in CAD

Detailed workflow from concept to completion. Essential design considerations for tool holders.Designing a tool holder in CAD can feel like building a Lego masterpiece—it’s all about the right pieces! Start with a sketch to visualize your idea. Then, think about essential features like size, shape, and material. Remember, a tool holder should fit your tools snugly like a glove! Next, create your 3D model, making sure it’s both practical and stylish. Finally, simulate its use to spot any issues. Happy designing!

| Step | Description |

|---|---|

| 1 | Sketch your initial idea. |

| 2 | Consider size and material necessary for strength. |

| 3 | Create a 3D model in CAD. |

| 4 | Run simulations to test design limits. |

In essence, take it step by step and you’ll have a tool holder that’s as handy as a Swiss Army knife, but maybe less sharp! Isn’t that cool?

Tips for Designing a High-Performance Tool Holder

Best practices for optimizing tool holder design. Common mistakes to avoid in CAD design.Designing a tool holder for a metal lathe can be a fun adventure, kind of like building a spaceship out of Legos! Start by focusing on strong materials to ensure it can handle the job without losing its cool. Avoid the common pitfall of making it too complex; simplicity is key! Remember, not all heroes wear capes, but they definitely use easy-to-read designs in CAD. Check out the table below for a quick guide to best practices and mistakes to avoid:

| Best Practices | Common Mistakes |

|---|---|

| Use quality materials | Overcomplicating designs |

| Optimize for stability | Ignoring tool weight |

| Keen on measurements | Skipping prototypes |

With these tips, your tool holder will shine like a pro! Remember, design smart and play safe!

Real-World Applications of Tool Holders in Metal Lathing

Examples of tool holders in various metalworking industries. Case studies demonstrating successful tool holder designs.Tool holders play a big role in many metalworking industries. They help machines cut and shape metal parts. Here are some examples:

- Aerospace Industry: Tool holders are used to make precise components for airplanes.

- Automotive Industry: They help create engine parts that fit perfectly.

- Medical Device Manufacturing: Tool holders are vital for crafting tools used in surgeries.

Success stories show how clever designs improve efficiency. For example, a custom tool holder reduced waste by 30% in a factory. These tools are essential for quality production in metal lathing.

What are common applications of tool holders?

Tool holders are used widely in aviation, automotive, and medical equipment industries.Why are tool holders important?

- They improve accuracy.

- They lessen waste.

- They speed up production.

Future Trends in Tool Holder Design and CAD Technology

Emerging technologies affecting tool holder design. Predictions for the future of tool holder CAD innovations.Exciting changes are coming in tool holder design! New technologies like 3D printing and smart sensors are making tool holders more efficient and precise. Imagine a lathe tool holder that knows exactly when to adjust itself. Future CAD innovations might include super cool features like artificial intelligence that learns from past designs. This could save time and reduce errors. Imagine telling your tool holder a joke, and it gives a perfect response – now that’s a smart tool!

| Emerging Technologies | Predictions for the Future |

|---|---|

| 3D Printing | More customizable designs will become available. |

| Smart Sensors | Tool holders that adjust themselves automatically. |

| Artificial Intelligence | Learning from past tool holder performances. |

Conclusion

In summary, a tool holder for metal lathe CAD design is essential for precision work. You can create custom designs to fit your needs. Using CAD software helps make your projects easier and more efficient. So, explore different designs and experiment with tools. You’ll improve your skills and understand lathe operations better. Keep learning and have fun with your creations!FAQs

Sure! Here Are Five Related Questions On The Topic Of Tool Holder Metal Lathe Cad Design:Sure! Here are five questions about tool holder metal lathe CAD design you can explore: 1. What is a metal lathe? A metal lathe is a machine that helps shape metal into different forms. 2. How does CAD help with designing tool holders? CAD, which stands for Computer-Aided Design, makes it easier to create and change designs. 3. Why do we need tool holders? Tool holders keep the tools in place while the lathe is working. 4. What materials can we use for tool holders? We can use strong metals like steel and aluminum for making tool holders. 5. Can you show me a simple design for a tool holder? Yes! A simple design can have a base, an arm, and a slot for the tool.

Sure! Please provide the question you’d like me to answer.

What Are The Key Design Considerations When Creating A Cad Model For A Tool Holder Used In A Metal Lathe?When you create a CAD model for a tool holder, think about a few important things. First, it should fit the metal lathe perfectly. We need to make sure it’s strong enough to hold tools without breaking. You should also design it to be easy to change the tools quickly. Finally, check that it won’t get in the way while you work.

How Can Cad Software Help In Optimizing The Geometry And Dimensions Of A Tool Holder For Enhanced Performance And Rigidity?CAD software helps you design tool holders. It lets you draw shapes and check how strong they are. You can change sizes and angles easily. This helps make the tool holder work better and be tougher. With CAD, you can try many ideas quickly and find the best one!

What Materials Are Commonly Used In The Fabrication Of Tool Holders For Metal Lathes, And How Can Cad Design Accommodate For These Material Properties?Tool holders for metal lathes are often made from steel, aluminum, or sometimes plastic. Steel is strong and lasts a long time. Aluminum is lighter and easier to shape. With CAD design, we can create special shapes that fit these materials well, making them work better. CAD helps us see how the material will act before we build it.

How Can Simulation Tools Within Cad Software Aid In Assessing The Durability And Wear Resistance Of A Tool Holder Design Before Physical Production?Simulation tools in CAD (Computer-Aided Design) software help us see how a tool holder will behave before we make it. We can test how strong it is and how it handles wear over time. This lets us find problems and fix them early. By using these tools, we can save time and materials. It helps ensure our design is safe and lasts a long time.

What Techniques Can Be Employed In Cad Design To Ensure Compatibility Of A Tool Holder With Various Tooling Systems And Lathe Configurations?To make sure a tool holder fits different tools and lathes, we can use a few helpful techniques. First, we can create flexible designs that adjust to different shapes. Next, we should use standard sizes so they fit many machines. We can also test the designs with computer programs to see how they work together. This way, we know everything will fit and work well before making them.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Tool Holder Metal Lathe Cad Design:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about tool holder metal lathe CAD design you can explore: 1. What is a metal lathe? A metal lathe is a machine that helps shape metal into different forms. 2. How does CAD help with designing tool holders? CAD, which stands for Computer-Aided Design, makes it easier to create and change designs. 3. Why do we need tool holders? Tool holders keep the tools in place while the lathe is working. 4. What materials can we use for tool holders? We can use strong metals like steel and aluminum for making tool holders. 5. Can you show me a simple design for a tool holder? Yes! A simple design can have a base, an arm, and a slot for the tool.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Design Considerations When Creating A Cad Model For A Tool Holder Used In A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you create a CAD model for a tool holder, think about a few important things. First, it should fit the metal lathe perfectly. We need to make sure it’s strong enough to hold tools without breaking. You should also design it to be easy to change the tools quickly. Finally, check that it won’t get in the way while you work.”}},{“@type”: “Question”,”name”: “How Can Cad Software Help In Optimizing The Geometry And Dimensions Of A Tool Holder For Enhanced Performance And Rigidity?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CAD software helps you design tool holders. It lets you draw shapes and check how strong they are. You can change sizes and angles easily. This helps make the tool holder work better and be tougher. With CAD, you can try many ideas quickly and find the best one!”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used In The Fabrication Of Tool Holders For Metal Lathes, And How Can Cad Design Accommodate For These Material Properties?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Tool holders for metal lathes are often made from steel, aluminum, or sometimes plastic. Steel is strong and lasts a long time. Aluminum is lighter and easier to shape. With CAD design, we can create special shapes that fit these materials well, making them work better. CAD helps us see how the material will act before we build it.”}},{“@type”: “Question”,”name”: “How Can Simulation Tools Within Cad Software Aid In Assessing The Durability And Wear Resistance Of A Tool Holder Design Before Physical Production?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Simulation tools in CAD (Computer-Aided Design) software help us see how a tool holder will behave before we make it. We can test how strong it is and how it handles wear over time. This lets us find problems and fix them early. By using these tools, we can save time and materials. It helps ensure our design is safe and lasts a long time.”}},{“@type”: “Question”,”name”: “What Techniques Can Be Employed In Cad Design To Ensure Compatibility Of A Tool Holder With Various Tooling Systems And Lathe Configurations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make sure a tool holder fits different tools and lathes, we can use a few helpful techniques. First, we can create flexible designs that adjust to different shapes. Next, we should use standard sizes so they fit many machines. We can also test the designs with computer programs to see how they work together. This way, we know everything will fit and work well before making them.”}}]}