Have you ever wondered how metal parts are made with such precision? One secret lies in a special tool called the tool holder for a metal lathe. This tool holder plays a crucial role in shaping and cutting metal. Without it, metalworking would be much more challenging.

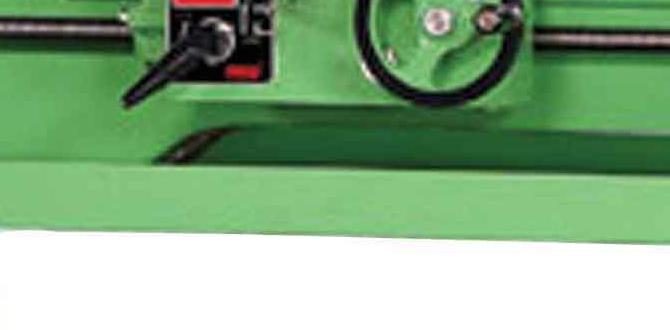

Imagine watching a metal lathe in action. The machine spins, and the tool is held steady. The tool holder metal lathe compound rest keeps everything in place. It allows the operator to make exact cuts and turns. This makes it perfect for creating anything from tiny screws to large engine parts.

Here’s a fun fact: many inventors and craftsmen use these tool holders to create amazing projects. Wouldn’t it be cool to see how this simple tool leads to big creations? In this article, we will dive deeper into the importance of the tool holder metal lathe compound rest and how it works. Get ready to discover the wonders of metalworking!

Tool Holder Metal Lathe Compound Rest: Essential Guide

A tool holder for a metal lathe compound rest helps keep tools organized and easy to access. Imagine trying to make a perfect cut, only to fumble around for your tools! This handy holder securely fastens your cutting tools, boosting accuracy and efficiency. Many professionals use metal tool holders because they are durable and last for years. Did you know that a tidy workspace can actually improve your work quality? Investing in a reliable tool holder can transform your lathe experience!

Understanding the Metal Lathe Compound Rest

Definition and purpose of a compound rest in metal lathes.. Importance of a welldesigned compound rest for precision machining..

A compound rest is a part of a metal lathe. It helps move the cutting tool in different directions. This movement allows for precise shaping of materials. A well-designed compound rest is key for accuracy. If it’s not sturdy, mistakes can happen.

- Allows for smooth movement: It helps adjust the tool easily.

- Enhances precision: This part ensures exact cuts every time.

- Supports creativity: It helps in making unique designs.

Think of a compound rest like a loyal friend. It supports your work and helps you achieve your goals in machining.

What is a compound rest?

A compound rest allows the tool to move and make precise cuts on a metal lathe.

Why is a strong compound rest important?

A strong compound rest prevents mistakes, ensuring accurate machining and better work quality.

Features of an Ideal Tool Holder

Key attributes that enhance performance (e.g., material, adjustability).. How to assess the quality of a tool holder for metal lathes..

An ideal tool holder has important features that boost performance. First, the material matters. Strong metals like steel help the holder last longer. Next, adjustability is key. It allows users to change angles easily. You can assess quality by checking:

- Durability: Does it withstand heavy use?

- Fit: Is it snug on the lathe?

- Ease of use: Is it simple to adjust?

These attributes help ensure your tool holder works well for your projects.

How do I know if my tool holder is good?

Look for strong materials, like steel, and check if it’s easy to adjust. A good holder should fit snugly and last through tough jobs. Quality is about strength and usability.

Benefits of Upgrading Your Compound Rest

Improved accuracy and efficiency in machining operations.. Longer tool life and reduced operating costs..

Upgrading your compound rest can work magic on your machining tasks! First, it boosts accuracy, making that tricky cut feel like a walk in the park. This means fewer mistakes. Fewer mistakes equal happier machinists! Second, efficient operations save time and energy, leaving more moments for coffee breaks. Plus, with an upgraded tool holder, your tools last longer. This cuts down on both operating costs and the need to buy new ones. Who doesn’t love saving money while machining?

| Benefit | Description |

|---|---|

| Improved Accuracy | Less guesswork leads to precise cuts. |

| Efficiency | Faster operations mean more time for snacks! |

| Longer Tool Life | Tools wear slower with upgrades. |

| Reduced Costs | Save money, buy more snacks! |

How to Install and Set Up Your Tool Holder

Stepbystep guide on installation procedures.. Tips for proper alignment and setup to ensure optimal performance..

Installing your tool holder can feel like woodworking magic. First, ensure you have all parts nearby, or you might find yourself in a treasure hunt! Place the holder on the compound rest and align the base correctly. Using a level will ensure everything is straight—like your mom’s best advice! Tighten the screws gently. Too tight and you might break something, too loose and things will wiggle. Your lathe will thank you for a secure fit, and remember, measure twice, tighten once!

| Step | Action |

|---|---|

| 1 | Gather all parts |

| 2 | Align base level |

| 3 | Tighten screws |

Maintenance Tips for Longevity

Routine maintenance practices to keep the compound rest in top shape.. Common issues and troubleshooting tips for tool holder problems..

Keeping your tool holder metal lathe compound rest in good shape is important. Regular checks and upkeep can make it last longer. Here are some simple maintenance tips:

- Clean the area often to remove dust and shavings. This helps prevent jams.

- Check for loose screws and tighten them if needed.

- Lubricate moving parts to keep everything running smoothly.

- Look for wear and tear, and replace worn-out parts.

Common problems may include tools not holding correctly. If this happens, make sure the holder is clean and free of debris. You can also check the tension to ensure it’s set right.

What are the signs of a tool holder problem?

Signs of a tool holder problem include: tools slipping or not being secure. A noisy or rough movement can also indicate something is wrong.

Best Practices for Using a Tool Holder on a Metal Lathe

Techniques for maximizing tool performance.. Safety considerations when operating a lathe with various tool holders..

Using a tool holder on a metal lathe can feel like being a wizard, turning raw metal into magic! First, maximize your tool’s performance by ensuring it’s sharp and securely fastened. A wobbly tool can lead to disaster—like a dancing giraffe! Safety matters too. Always wear goggles and use guards to keep sharp bits away from your fingers. Remember—no one wants a trip to the ER for a silly mistake!

| Tip | Explanation |

|---|---|

| Check Tool Tightness | Make sure your tool is snug in the holder. |

| Wear Protection | Goggles keep eyes safe from flying debris. |

| Use Guards | Guards help cover sharp parts of the lathe. |

Comparative Analysis of Popular Tool Holders on the Market

Review of toprated tool holders for metal lathe compound rests.. Price vs. performance evaluation for informed purchasing decisions..

Many brands offer tool holders for metal lathe compound rests. Some stand out for their quality and performance. Consider key factors like durability, usability, and price. Here are some popular choices:

- Brand A: Known for sturdy designs, priced around $50.

- Brand B: Offers high precision at about $70, but worth it for serious projects.

- Brand C: Affordable at $30, suitable for beginners.

When choosing, think about your needs. Remember, a higher price often means better materials and features.

What should I look for in a tool holder for a metal lathe?

Look for durability, ease of use, and price. A good tool holder will not only work well but also last long.

Conclusion

In summary, a tool holder for a metal lathe compound rest keeps tools organized and secure. It helps you work efficiently and safely. Remember to choose one that fits your lathe well. For better results, practice using it with different tools. Explore more about metal lathes and tool holders to enhance your skills further. Happy machining!

FAQs

What Are The Primary Functions Of The Compound Rest In A Metal Lathe?

The compound rest on a metal lathe helps you move the cutting tool. You can turn it at different angles. This makes it easier to shape metal pieces. We can also slide it back and forth for more precise cuts. It helps us create smooth and accurate designs.

How Do You Properly Set Up And Adjust The Tool Holder On A Compound Rest For Different Machining Operations?

To set up the tool holder on the compound rest, first, make sure it is clean. You can then attach the tool holder firmly. Next, adjust the angle of the tool holder for the job you want to do. Use the knobs to change the height and angle until it feels right. Finally, double-check everything is tight before you start working.

What Materials Are Commonly Used For Manufacturing Tool Holders In Lathe Compound Rests, And How Do They Affect Performance?

Tool holders in lathe compound rests are often made from steel, aluminum, or plastic. Steel is strong and lasts a long time, helping you make better cuts. Aluminum is lighter, making it easier to move but may wear out faster. Plastic is lightweight and cheap, but it’s not as strong. The material you choose affects how well your tools work.

What Are The Advantages Of Using An Advanced Tool Holder System Over A Standard Tool Holder On A Metal Lathe’S Compound Rest?

Using an advanced tool holder system on a metal lathe makes your work easier. It holds tools more securely, so they don’t slip. This helps you make better cuts and shapes. Also, you can change tools quickly without much hassle. Overall, it helps you do your work faster and with better results.

How Can Regular Maintenance Of The Compound Rest And Tool Holder Improve The Accuracy And Lifespan Of A Metal Lathe?

Taking care of the compound rest and tool holder on a metal lathe helps it work better. When we regularly clean and tighten these parts, they can hold tools more securely. This means our cuts will be more precise. A well-maintained lathe will also last longer because we prevent wear and tear. In short, good care makes our projects better and our tools last.