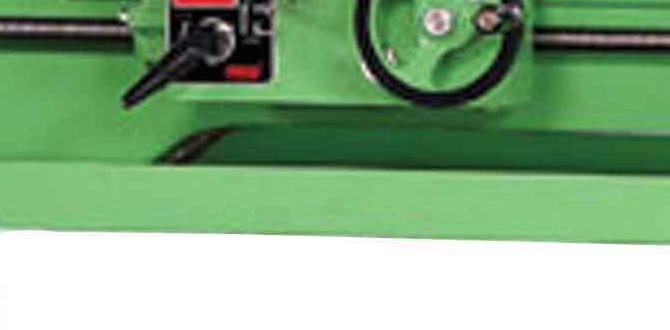

Imagine crafting a small machine part with perfect precision. You turn on your metal lathe, and everything is just right. But wait—what about the tool holder? How do you control it smoothly? That’s where a good control panel comes in!

With a metal lathe, you can make amazing things. But without the right tool holder, your project might fail. A control panel lets you adjust, focus, and make changes quickly. Think about it: every time you twist a knob or push a button, you’re taking charge of your creation.

Did you know that the right setup can make your projects easier and faster? A tool holder metal lathe control panel connects you to your work. It helps you keep track of settings and tools. This simple piece of equipment can change everything!

Join us as we explore the ins and outs of these control panels. You’ll learn how they work and why they matter so much.

Tool Holder Metal Lathe Control Panel: Optimize Your Setup

Tool Holder Metal Lathe Control Panel

The tool holder metal lathe control panel is essential for smooth machining. It allows easy adjustments of speed and feed rates. Have you ever seen a skilled machinist precisely shaping metal? This control panel makes that possible. Users can quickly change tools, enhancing efficiency. Surprising fact: modern lathes can perform complex tasks automatically! Understanding this panel is key to mastering metalworking. Dive in and explore how it can elevate your projects!Key Features of Tool Holder Control Panels

Types of tool holders compatible with control panels. Essential functionalities and interface elements.Tool holder control panels have several important features. They support various types of tool holders, making them flexible for many tasks. Here are some key aspects:

- Types of Tool Holders: Collet chucks, inserts, and screw-on holders.

- Essential Functionalities: Quick tool changes and speed adjustments.

- Interface Elements: Simple dials and buttons for easy operation.

These features help users work faster and smarter. A well-designed control panel makes machine operation fun and efficient!

What types of tool holders are compatible with control panels?

Compatible tool holders include collet chucks, blade holders, and fixed screw-on types. They work with various machines, enhancing flexibility.

Benefits of an Effective Control Panel Design

Enhancing user experience and operational efficiency. Reducing the risk of errors and accidents.An effective control panel design can make life easier for users. Think of it as a friendly guide that helps you drive your metal lathe with ease. Users experience less confusion, which boosts operational efficiency. When everything is labeled clearly, the risk of errors goes down. It’s like having a roadmap that keeps you safe from bumps along the way. A well-designed control panel not only makes work safer but also makes it more fun! Who knew machining could be this exciting?

| Benefits | Details |

|---|---|

| Enhanced User Experience | Clear labels and design help users work faster. |

| Less Chance of Mistakes | Fewer errors mean fewer accidents. Safety first! |

| Increased Fun | A clear design makes the work process enjoyable. |

Common Types of Tool Holder Control Panels

Comparison of manual vs. digital control panels. Pros and cons of each type for various applications.Two popular control panels for tool holders are manual and digital types. Manual panels require hands-on adjustments, perfect for those who like to feel in charge. However, they can be tricky during complex tasks and may lead to mistakes. Digital panels, like that smart friend who always knows the answer, offer precision and ease. Yet, they might feel complicated for some users. Here’s a quick comparison:

| Type | Pros | Cons |

|---|---|---|

| Manual | Simple usage | Can be prone to errors |

| Digital | High accuracy | May confuse some users |

In short, think of manual as a trusty old bicycle and digital as a fancy e-scooter. Both will get you where you want to go, but one might be a little easier for some folks to ride!

Installation and Setup of Tool Holder Control Panels

Stepbystep installation guide. Essential tools and equipment required for installation.Installing a tool holder control panel is both fun and useful. Start by gathering essential tools. You will need:

- Screwdrivers

- Wrenches

- Pliers

- Drill

- Measuring tape

Next, follow these easy steps:

- Turn off the power supply to your machine.

- Carefully remove the old control panel.

- Align the new control panel with the mounting holes.

- Secure it with screws.

- Reconnect any wires as needed.

- Turn the power back on and test the panel.

By following this guide, you’ll have the panel set up quickly!

What tools do you need for installation?

You will need screwdrivers, wrenches, pliers, a drill, and a measuring tape.

Maintenance Tips for Longevity and Performance

Regular checks and calibrations to ensure optimal operation. Troubleshooting common issues.Keeping your tool holder metal lathe control panel running well is important. Regular checks help avoid problems. Check all connections, switches, and knobs often. Make sure they are clean and working perfectly. If something goes wrong, troubleshooting can save time. Look for simple fixes first. Here are some tips:

- Inspect wiring for wear.

- Calibrate settings monthly.

- Replace faulty parts quickly.

Good maintenance means better performance and longer life for your machine.

What are common issues with lathe control panels?

Typical problems include unresponsive buttons or error messages. Check these areas first to fix issues quickly!

Upgrading Your Metal Lathe Control Panel

Signs that indicate it’s time for an upgrade. The benefits of modern control panel technologies.Have you noticed strange noises or slow responses from your lathe? Those are signs it’s time for a control panel upgrade! Modern technology can make your work much easier. Improved control panels are often user-friendly and equipped with better safety features. They can also increase your machine’s accuracy. Think of it as giving your lathe a much-needed coffee boost!

| Signs for Upgrade | Benefits of Modern Control Panels |

|---|---|

| Strange noises | Enhanced accuracy |

| Slow responses | User-friendly interface |

| Frequent errors | Better safety features |

With an upgrade, you’ll work smarter, not harder. After all, who wants to wrestle with machinery? A shiny new control panel might just be the boost your metal lathe needs!

Choosing the Right Tool Holder Control Panel for Your Needs

Factors to consider when selecting a control panel. Recommended brands and models in the market.Finding the right control panel for a tool holder can make a big difference in your work. Here are some important factors to think about:

- Compatibility: Make sure it fits your lathe.

- Ease of Use: Look for simple controls and displays.

- Durability: Choose a strong and long-lasting model.

Some popular brands to consider are:

- Mazak – Known for quality.

- Haas – Offers user-friendly options.

- Fanuc – Reliable and well-regarded.

These brands provide powerful features that can improve your setup and workflow.

What should I look for in a control panel?

Look for compatibility, ease of use, and durability to ensure the best choice for your needs.

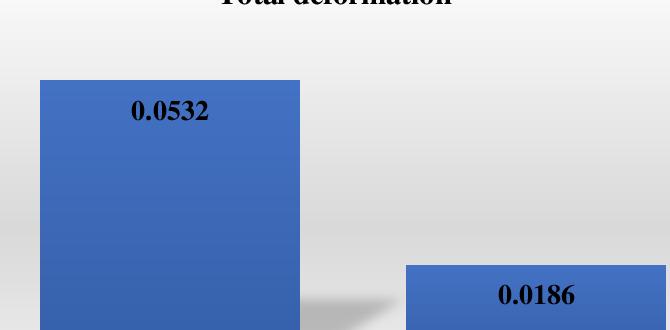

Case Studies: Successful Implementations of Tool Holder Control Panels

Examples of industries that have enhanced productivity. Key takeaways from each case study.Many industries have seen great success using tool holder control panels. For example, a car manufacturing plant increased its production speed by 25% after upgrading its lathe systems. This allowed them to create more cars in less time. Another case is a metalworking shop that saved $5,000 per month in labor costs by using smarter panels that automated their processes. In both cases, efficiency and cost savings were huge winners!

| Industry | Productivity Increase | Key Takeaway |

|---|---|---|

| Automotive | 25% | Faster manufacturing equals more cars! |

| Metalworking | $5,000 saved monthly | Automate to save money! |

Future Trends in Metal Lathe Control Panel Technology

Innovations on the horizon in control panel design and functionality. Predictions for the future of metalworking technology.Imagine a world where using a metal lathe feels like playing a video game! That’s where future control panels are heading. They might come with touch screens, making it super easy to adjust settings with a flick of a finger. Innovations like smart sensors could warn us if something is going wrong before it becomes a disaster. In fact, some experts predict these panels will offer AI support, so your lathe might just give you advice—like a wise old sage, but without the long beard!

| Innovation | Benefit |

|---|---|

| Touch Screen Interface | Easy adjustments |

| Smart Sensors | Proactive alerts |

| AI Assistance | Helpful tips & tricks |

Conclusion

In summary, the tool holder on a metal lathe is essential for accuracy and safety. The control panel lets you manage speed and settings easily. Understanding these features helps you work better and create quality projects. To improve your skills, practice regularly and explore tutorials online. Let’s keep learning and making amazing things together!FAQs

Sure! Here Are Five Questions Related To The Tool Holder Metal Lathe Control Panel:Sure! A tool holder metal lathe control panel helps you control a machine that shapes metal. You can start and stop the machine. You can also change the speed and direction of the tool. It’s important to be careful when using it. Always follow the safety rules!

Sure! Please provide the question you want me to answer.

What Are The Key Components Of A Metal Lathe Control Panel, And How Do They Interact To Manage The Lathe’S Operations?A metal lathe control panel has several important parts. You have a power switch to turn the lathe on and off. There are buttons that control the speed and direction of the spinning metal. You can also find a feed control to adjust how fast the cutting tool moves. All these parts work together so you can shape the metal safely and accurately.

How Can Operators Customize The Settings On The Control Panel Of A Metal Lathe To Optimize Tool Holder Performance?To make the tool holder work better on a metal lathe, you can change some settings. First, adjust the speed to fit the metal you are using. Next, set the feed rate, which controls how fast the metal moves. Lastly, make sure to choose the right cutting tool for the job. Checking these settings helps your tool holder do its best work!

What Safety Features Are Typically Included In The Control Panel Of A Metal Lathe To Protect Operators During Machining Processes?The control panel of a metal lathe has important safety features. There is an emergency stop button, so you can quickly turn off the machine if something goes wrong. Some lathes have safety shields to protect you from flying metal pieces. There are also warning lights or beeps that let you know when the machine is running. All these features help keep you safe while you work.

How Do Modern Digital Control Panels For Metal Lathes Compare To Traditional Manual Controls In Terms Of User Experience And Precision?Modern digital control panels for metal lathes are easier to use than traditional manual controls. With buttons and screens, you can see information clearly. This helps you make better choices while working. Digital panels also let you make precise adjustments quickly. Overall, they make metalworking simpler and more accurate.

What Troubleshooting Steps Can Be Taken If A Metal Lathe Control Panel Malfunctions Or Displays Error Messages Related To The Tool Holder?If the control panel on the metal lathe isn’t working right, here are some steps you can take. First, check the power connection to make sure it’s plugged in. Then, look for loose wires or connections. Next, restart the machine to see if that helps. If it still shows error messages, read the manual for guidance and call a technician if needed.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To The Tool Holder Metal Lathe Control Panel:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A tool holder metal lathe control panel helps you control a machine that shapes metal. You can start and stop the machine. You can also change the speed and direction of the tool. It’s important to be careful when using it. Always follow the safety rules!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Components Of A Metal Lathe Control Panel, And How Do They Interact To Manage The Lathe’S Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe control panel has several important parts. You have a power switch to turn the lathe on and off. There are buttons that control the speed and direction of the spinning metal. You can also find a feed control to adjust how fast the cutting tool moves. All these parts work together so you can shape the metal safely and accurately.”}},{“@type”: “Question”,”name”: “How Can Operators Customize The Settings On The Control Panel Of A Metal Lathe To Optimize Tool Holder Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make the tool holder work better on a metal lathe, you can change some settings. First, adjust the speed to fit the metal you are using. Next, set the feed rate, which controls how fast the metal moves. Lastly, make sure to choose the right cutting tool for the job. Checking these settings helps your tool holder do its best work!”}},{“@type”: “Question”,”name”: “What Safety Features Are Typically Included In The Control Panel Of A Metal Lathe To Protect Operators During Machining Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The control panel of a metal lathe has important safety features. There is an emergency stop button, so you can quickly turn off the machine if something goes wrong. Some lathes have safety shields to protect you from flying metal pieces. There are also warning lights or beeps that let you know when the machine is running. All these features help keep you safe while you work.”}},{“@type”: “Question”,”name”: “How Do Modern Digital Control Panels For Metal Lathes Compare To Traditional Manual Controls In Terms Of User Experience And Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Modern digital control panels for metal lathes are easier to use than traditional manual controls. With buttons and screens, you can see information clearly. This helps you make better choices while working. Digital panels also let you make precise adjustments quickly. Overall, they make metalworking simpler and more accurate.”}},{“@type”: “Question”,”name”: “What Troubleshooting Steps Can Be Taken If A Metal Lathe Control Panel Malfunctions Or Displays Error Messages Related To The Tool Holder?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the control panel on the metal lathe isn’t working right, here are some steps you can take. First, check the power connection to make sure it’s plugged in. Then, look for loose wires or connections. Next, restart the machine to see if that helps. If it still shows error messages, read the manual for guidance and call a technician if needed.”}}]}