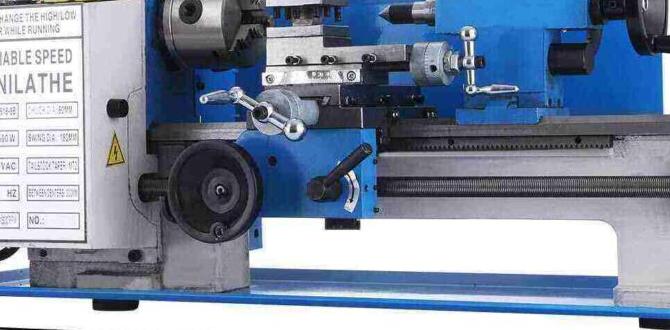

Have you ever wondered how metal lathes get their precision? Many people use a tool holder metal lathe controller board to enhance their projects. It’s amazing how one small piece of technology can make such a big difference.

Imagine you’re in a workshop, surrounded by metal and tools. You need to cut a perfect shape. A controller board can help you do just that! It guides the lathe, giving you control over speed and accuracy.

Did you know that the right controller board can speed up your work? It can help you create beautiful parts with less effort! If you enjoy working with metal, this is a game-changer.

In this article, we’ll explore the benefits and features of a tool holder metal lathe controller board. We’ll also share tips to choose the best one for your needs. Get ready to unlock new possibilities in your metalworking journey!

Tool Holder Metal Lathe Controller Board: Essential Insights

Exploring the Tool Holder Metal Lathe Controller Board

Are you curious about how a tool holder metal lathe controller board works? This board is essential for operating a lathe efficiently. It helps control the spindle speed and movement of the tool, ensuring precision in crafting items. A key fact: many hobbyists and professionals use these boards to improve their projects. With the right controller board, you can enhance your lathe experience, making tasks simpler and more enjoyable. What will you create with improved control?What is a Metal Lathe Controller Board?

Definition and purpose of a metal lathe controller board. Key components and their functions.A metal lathe controller board is a device that helps control a lathe machine. It makes sure everything runs correctly and smoothly. This board helps shape and cut materials like metal or wood into desired shapes. It has several key parts that do important jobs.

- Microcontroller: This is the brain of the board. It processes commands and tells the lathe what to do.

- Power Supply: This part gives energy to the board so it can function properly.

- Motor Driver: This controls the motors, helping them move at the right speed.

- Input Interface: This allows users to give instructions, like selecting speeds.

What do you need to know about the controller board?

The metal lathe controller board is essential for accurate machining. Without it, lathes can’t shape materials correctly. It helps in crafting quality parts with precision.

Benefits of Using a Metal Lathe Controller Board

Advantages of precision and efficiency in machining. Impact on production speed and quality.Using a metal lathe controller board can be a game changer! Imagine working with a tool that helps you cut more precisely and quickly. It’s like having an extra pair of hands that never gets tired! Precision means your parts fit just right, while efficiency boosts your production. You can finish jobs faster without losing quality. It’s the secret sauce that makes every project smoother and more enjoyable. Who knew machines could make life so easy?

| Benefit | Impact |

|---|---|

| Precision Cutting | Better part fits |

| Increased Efficiency | Faster production |

| Quality Control | Fewer mistakes |

How to Choose the Right Controller Board for Your Metal Lathe

Criteria to consider (size, compatibility, features). Recommended brands and models.Choosing the right controller board for your metal lathe can seem tough. Here are some simple criteria to think about:

- Size: Make sure it fits your lathe.

- Compatibility: Check if it works with your tools.

- Features: Look for functions like speed control.

Popular brands include Grizzly and CNC Fusion. Their models are known for reliability and ease of use.

What features should I look for in a controller board?

Focus on speed control, user-friendly interface, and programmability. These features help you work better and faster!

Installation Process for Metal Lathe Controller Boards

Stepbystep guide to installation. Common pitfalls to avoid during setup.Getting that metal lathe controller board up and running is easier than finding a cat in a box! Start by turning off all power to your lathe. Next, follow these simple steps:

| Step | Action |

|---|---|

| 1 | Connect the power supply. |

| 2 | Attach the controller board to the lathe. |

| 3 | Wire the motors carefully. |

| 4 | Upload the setup software. |

Remember, avoid mixing up the wires. It’s like choosing between pizza or broccoli—pick wisely! Double-check connections before powering on. Common mistakes include improper wiring or skipping the manual. Just like you wouldn’t teach a fish to climb a tree, don’t overlook those instructions!

Maintenance Tips for Longevity of Metal Lathe Controller Boards

Recommended maintenance practices. Troubleshooting common issues.Keeping your metal lathe controller board in top shape is like giving it a big bear hug! Regular maintenance can prevent unexpected issues. Clean the board gently to remove dust. Check the connections; loose wires can make it grumpy. If you hear strange noises, don’t panic! It might just need a little oiling. Always keep the software updated for smooth sailing.

| Common Issues | Troubleshooting Tips |

|---|---|

| Unresponsive controls | Check the power supply and connections. |

| Strange noises | Lubricate moving parts and check for debris. |

| Slow operation | Make sure your software is updated. |

By following these tips, your controller board will stay happy and healthy. Remember, a little care goes a long way, just like a good pot of chili—nobody likes the burnt bottom!

Upgrading Your Metal Lathe Controller Board

Signs that an upgrade is necessary. Benefits of upgrading and available options.Knowing when to upgrade your controller board can save you time and improve your work. Signs include unexpected shutdowns, slow response times, or difficulty controlling speeds. Upgrading brings many benefits. You can expect better accuracy, faster operations, and improved safety. With better features, your projects become easier. Options vary widely, from simple upgrades to high-tech boards. Choose one that fits your needs and budget. Investing in quality can make a big difference in your metal lathe experience.

Why should I upgrade my metal lathe controller board?

Upgrading helps you get more efficiency, speed, and reliability. New boards can handle more tasks and improve safety, making your work smoother.

Signs to consider upgrading:

- Frequent errors or crashes

- Slow performance

- Poor control of speeds

- Incompatibility with new tools

Future Trends in Metal Lathe Technology

Innovations in controller board technology. Predictions for the future of metal lathe machining.Exciting changes are on the way for metal lathes! New controller board technology is making machines smarter. These boards can learn and adapt, sort of like your pet goldfish, but way more helpful. People predict that future metal lathes will work faster and with better precision. Imagine your lathe doing complex tasks while you snack on popcorn! The future looks bright. Expect shiny new features that make machining easier and more fun!

| Innovation | Benefit |

|---|---|

| Smart Sensors | Automatic adjustments |

| AI Integration | Enhanced efficiency |

| User-Friendly Interfaces | Simplified operation |

Conclusion

In conclusion, a tool holder metal lathe controller board is essential for precision machining. It helps you control your lathe efficiently. By understanding its features and setup, you can improve your projects. We encourage you to explore tutorials and guides online. This will help you master your lathe and enhance your skills. Keep learning and practicing for the best results!FAQs

Sure! Here Are Five Related Questions On The Topic Of Tool Holder Metal Lathe Controller Boards:Sure! Here are some things about tool holder metal lathe controller boards. A controller board helps run the lathe, which is a machine for shaping metal. It tells the lathe how to move and cut. You can use it to make precise parts for different projects. Learning to use a controller board can be fun and useful!

Sure! Please share your question, and I’ll be happy to answer it in simple terms.

What Are The Essential Features To Look For In A Controller Board For A Metal Lathe Tool Holder?When looking for a controller board for a metal lathe tool holder, you should check a few important features. First, make sure it has easy controls. You want to use it without confusion. Second, it should have good power to control the tools effectively. Finally, it’s great if it can connect to a computer for programming. This helps you create more complex shapes easily!

How Does A Cnc Controller Board Enhance The Precision And Efficiency Of A Metal Lathe?A CNC controller board helps a metal lathe work better and make perfect shapes. It tells the machine exactly what to do, like cutting or shaping metal. This makes it faster and more accurate. You don’t have to guess where to move, which saves time and reduces mistakes. With a CNC board, you can create lots of pieces that look the same every time!

What Types Of Software Are Compatible With Metal Lathe Controller Boards For Programming And Operation?You can use different types of software with metal lathe controller boards. Some popular ones are Mach3, LinuxCNC, and GRBL. These programs help you write instructions for the lathe to follow. You can also use software like Fusion 360 for designing parts. Each software makes it easier to work with the lathe and create cool projects!

How Can A User Troubleshoot Common Issues Encountered With A Metal Lathe Controller Board?To fix problems with a metal lathe controller board, you can start by checking the wires. Make sure they are all connected tightly. Next, look for any signs of damage, like burns or breaks. You can also restart the machine to see if that helps. If it still doesn’t work, ask a grown-up for help.

What Are The Differences Between Different Types Of Controller Boards (E.G., Arduino, Machand Proprietary Systems) For Metal Lathes?Different controller boards help run metal lathes, which are machines that cut metal. Arduino boards are simple and great for beginners. They are open-source, meaning you can change their code easily. Mach systems are more complex and often have special features built in. Proprietary systems are custom-made for certain machines, so they don’t always work with others. Each type has its own strengths, so choose based on what you need!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Tool Holder Metal Lathe Controller Boards:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some things about tool holder metal lathe controller boards. A controller board helps run the lathe, which is a machine for shaping metal. It tells the lathe how to move and cut. You can use it to make precise parts for different projects. Learning to use a controller board can be fun and useful!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share your question, and I’ll be happy to answer it in simple terms.”}},{“@type”: “Question”,”name”: “What Are The Essential Features To Look For In A Controller Board For A Metal Lathe Tool Holder?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When looking for a controller board for a metal lathe tool holder, you should check a few important features. First, make sure it has easy controls. You want to use it without confusion. Second, it should have good power to control the tools effectively. Finally, it’s great if it can connect to a computer for programming. This helps you create more complex shapes easily!”}},{“@type”: “Question”,”name”: “How Does A Cnc Controller Board Enhance The Precision And Efficiency Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A CNC controller board helps a metal lathe work better and make perfect shapes. It tells the machine exactly what to do, like cutting or shaping metal. This makes it faster and more accurate. You don’t have to guess where to move, which saves time and reduces mistakes. With a CNC board, you can create lots of pieces that look the same every time!”}},{“@type”: “Question”,”name”: “What Types Of Software Are Compatible With Metal Lathe Controller Boards For Programming And Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use different types of software with metal lathe controller boards. Some popular ones are Mach3, LinuxCNC, and GRBL. These programs help you write instructions for the lathe to follow. You can also use software like Fusion 360 for designing parts. Each software makes it easier to work with the lathe and create cool projects!”}},{“@type”: “Question”,”name”: “How Can A User Troubleshoot Common Issues Encountered With A Metal Lathe Controller Board?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix problems with a metal lathe controller board, you can start by checking the wires. Make sure they are all connected tightly. Next, look for any signs of damage, like burns or breaks. You can also restart the machine to see if that helps. If it still doesn’t work, ask a grown-up for help.”}},{“@type”: “Question”,”name”: “What Are The Differences Between Different Types Of Controller Boards (E.G., Arduino, Machand Proprietary Systems) For Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different controller boards help run metal lathes, which are machines that cut metal. Arduino boards are simple and great for beginners. They are open-source, meaning you can change their code easily. Mach systems are more complex and often have special features built in. Proprietary systems are custom-made for certain machines, so they don’t always work with others. Each type has its own strengths, so choose based on what you need!”}}]}