Have you ever wondered how metal workers create precise parts with a lathe? A tool holder metal lathe drive system is at the heart of this amazing process. It helps attach tools securely and allows them to spin rapidly. This means craftsmen can shape metal into incredible designs.

Imagine a sculptor, but instead of stone, they are working with shiny metal. Each turn of the lathe creates smooth curves and perfect angles. It’s like magic! Using the right tool holder can make a big difference in how a metal piece turns out.

Did you know that the drive system in a lathe works like the engine in a car? It powers the entire machine. With the right setup, even beginners can make impressive projects. What kind of objects do you think a metal lathe can create? From simple parts to complex shapes, the possibilities are endless!

In this article, we will explore the key components of a tool holder metal lathe drive system. You’ll learn how it all works together and why it’s important. Get ready to dive into the world of metalworking!

Tool Holder Metal Lathe Drive System: A Comprehensive Guide

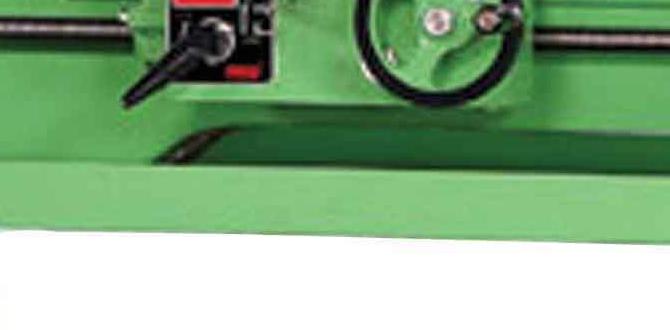

Tool Holder Metal Lathe Drive System

A tool holder metal lathe drive system is crucial for shaping metal accurately. This system holds cutting tools firmly in place, allowing for precise machining. Did you know that the right tool holder can significantly reduce cutting time? Using a quality drive system also decreases wear and tear on tools. It’s like giving your lathe a superpower! Proper maintenance and selection help ensure smooth operation, making your projects easier and more efficient.Understanding Metal Lathe Basics

Definition and purpose of a metal lathe. Key components and their functions.A metal lathe is a machine that shapes metal. It spins the metal to help cut, drill, or shape it. It is used in many places, like factories and schools. Key parts of a metal lathe include:

- Bed: The heavy base that supports the machine.

- Headstock: Holds the spindle and motor.

- Tailstock: Supports long pieces of metal.

- Carriage: Moves the cutting tool.

- Tool holder: Holds the cutting tool securely.

Each part plays an important role in making precise shapes.

What is the purpose of a metal lathe?

The main purpose of a metal lathe is to create different shapes from metal. It helps in making everything from small parts to large pieces for machines.

Why is it important?

A metal lathe is important because it allows us to create exact shapes. This makes parts fit together correctly, which is very crucial in many industries.

Importance of a Tool Holder in Metal Lathes

Role of a tool holder in machining operations. Benefits of using highquality tool holders.A tool holder is crucial in machining. It securely holds the cutting tool in place. This stability leads to better accuracy and smoother finishes in metalworking. High-quality tool holders have many benefits:

- They reduce vibration, improving tool life.

- They ensure better precision, leading to higher-quality parts.

- They are more durable and reliable, reducing downtime.

Using the right tool holder can make a significant difference in metal lathe operations. It helps to create parts that fit perfectly in their intended place.

Why is a tool holder important?

A tool holder keeps the cutting tool secure and allows for precise machining. Without it, machines cannot cut materials effectively.

Choosing the Right Drive System

Explanation of drive systems used in metal lathes. Factors to consider (power, torque, speed).Drive systems play a key role in how metal lathes work. These systems help control the speed and power of the machine. When choosing a drive system, keep these factors in mind:

- Power: This shows how strong the machine is.

- Torque: This tells us how much work the machine can do.

- Speed: This affects how fast the machine spins.

Matching the right drive system to your needs makes your work easier and better!

What are the different types of drive systems in metal lathes?

There are mainly three types of drive systems: belt drive, direct drive, and geared drive. Each type has its own benefits, like power efficiency or speed control.

Installation and Maintenance of Tool Holders

Stepbystep guide for installation. Best practices for maintenance and longevity.First, grab your tools and set a workspace. For installing your tool holder, start with the main body of the lathe. Securely attach the tool holder to the spindle. Make sure everything is snug; loose parts are like trying to ride a bike with flat tires—no fun and a bit dangerous!

For maintenance, keep it clean and check for wear. Regular inspections can extend the life of your lathe by up to 30%. A few drops of oil now and then can work wonders. Think of it like a spa day for your tools—they deserve it!

| Task | Frequency |

|---|---|

| Cleaning | After each use |

| Oil Check | Weekly |

| Inspection | Monthly |

Follow these steps, and your tool holder will thank you—maybe not with a voice, but it will last longer!

Enhancing Efficiency with Tool Holders

Techniques for optimizing tool holder performance. Impact on production speed and quality.Tool holders can greatly increase work speed and quality. To make them better, use these simple tips:

- Keep tool holders clean. Dirt can slow things down.

- Check for tightness. A secure fit helps your tools work well.

- Choose the right tool holder for each task. Different jobs need different holders.

These techniques can lead to faster production. They also improve the final product. When tool holders work well, you save time and make better items!

How does a tool holder affect production speed?

The right tool holder can speed up production by reducing setup time and maintaining tool stability. This means less waiting and more making!

What is the impact of tool holders on quality?

Good tool holders help make consistent shapes and sizes in products. This leads to higher quality and less waste!

Common Problems and Solutions

Identification of typical issues with tool holders and drive systems. Troubleshooting tips and preventive measures.Many users face issues with tool holder metal lathe drive systems. Common problems include poor fitting, wear and tear, or misalignment. These can lead to inaccurate cuts and wasted materials. Here are some tips to troubleshoot:

- Check for tight connections.

- Inspect for visible damage.

- Make sure the drive belt is not too loose or too tight.

Simple preventive measures, like regular maintenance, can help. Always clean your tools after use. This keeps everything in good shape. By being proactive, you can save time and improve your work quality.

What are common issues with tool holders and drive systems?

Common issues include wear, misalignment, and loose connections. These can affect tool performance and quality of cuts. Regular checks can help find problems early.

Future Trends in Tool Holder Technology

Innovations and advancements in tool holder design. Predictions for the future of metal lathe tool holders.Innovation is speeding up in tool holder design! New materials are popping up like popcorn at a movie. Think stronger, lighter, and even smarter tool holders that can adapt to different lathes. In the near future, we might see auto-adjusting holders that change size as needed. Imagine tool holders that communicate with the lathe—like best friends! These changes will help make our work easier and more fun. Who knew tool holders could be so exciting?

| Feature | Current Technology | Future Predictions |

|---|---|---|

| Material | Steel | Composite materials |

| Weight | Heavier | Lighter design |

| Adaptability | Fixed sizes | Smart size adjustment |

Conclusion

In summary, a tool holder for a metal lathe drive system is essential for precision and efficiency. It keeps tools secure while you work, ensuring smooth cuts. By using the right tool holder, you can improve your projects significantly. Explore different types available and consider which suits your needs best. Happy turning, and enjoy your metalworking journey!FAQs

Sure! Here Are Five Related Questions About Tool Holder Metal Lathe Drive Systems:Sure! A tool holder on a metal lathe helps keep tools in place. This lets us shape or cut metal smoothly. The drive system makes the lathe spin. When it spins, it helps us make things like toys or parts for machines. It’s really useful for many projects!

Sure! Please provide the question you’d like me to answer.

What Are The Main Components Of A Drive System In A Metal Lathe, And How Do They Interact To Facilitate Machining?A metal lathe has a few main parts in its drive system. First, there’s the motor, which gives power. Then, there are belts and pulleys that help move the parts. The spindle turns the piece of metal so we can shape it. All these parts work together to help us make metal items smoothly and accurately.

How Does The Choice Of Motor Type (Ac Vs. Dc) Affect The Performance Of A Metal Lathe Drive System?The type of motor you choose for a metal lathe affects how it works. An AC motor (Alternating Current) can run for a long time without getting hot. It also needs less maintenance. A DC motor (Direct Current) is great for speed control, which lets you change how fast the lathe spins. So, if you want speed changes, you might pick a DC motor, but if you want something more reliable, an AC motor is a good choice.

What Role Does Gear Reduction Play In The Torque Output And Operational Speed Of A Metal Lathe?Gear reduction helps a metal lathe turn objects more easily. It makes the motor’s power stronger, giving more torque. Torque is like the twisting force that makes things turn. So, while it slows down the overall speed, it helps you work with tougher materials. This way, you can shape hard metal better.

How Can Advancements In Drive System Technology Improve The Precision And Efficiency Of Metal Lathes?Advancements in drive system technology can make metal lathes work better and faster. With better motors, lathes can move more smoothly and accurately. This means you’ll get cleaner cuts and shapes in metal. It also helps save time, so you can finish projects quickly. Overall, these improvements make lathes easier to use and more productive!

What Are The Common Maintenance Practices For Ensuring The Longevity And Reliability Of A Metal Lathe Drive System?To keep a metal lathe drive system working well, we need to do a few important things. First, we should regularly clean it to remove dust and dirt. Next, check the oil levels and add more if needed. We also need to tighten any loose parts so they don’t break. Lastly, it helps to inspect the belts and gears for any signs of wear.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions About Tool Holder Metal Lathe Drive Systems:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A tool holder on a metal lathe helps keep tools in place. This lets us shape or cut metal smoothly. The drive system makes the lathe spin. When it spins, it helps us make things like toys or parts for machines. It’s really useful for many projects!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Main Components Of A Drive System In A Metal Lathe, And How Do They Interact To Facilitate Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe has a few main parts in its drive system. First, there’s the motor, which gives power. Then, there are belts and pulleys that help move the parts. The spindle turns the piece of metal so we can shape it. All these parts work together to help us make metal items smoothly and accurately.”}},{“@type”: “Question”,”name”: “How Does The Choice Of Motor Type (Ac Vs. Dc) Affect The Performance Of A Metal Lathe Drive System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The type of motor you choose for a metal lathe affects how it works. An AC motor (Alternating Current) can run for a long time without getting hot. It also needs less maintenance. A DC motor (Direct Current) is great for speed control, which lets you change how fast the lathe spins. So, if you want speed changes, you might pick a DC motor, but if you want something more reliable, an AC motor is a good choice.”}},{“@type”: “Question”,”name”: “What Role Does Gear Reduction Play In The Torque Output And Operational Speed Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Gear reduction helps a metal lathe turn objects more easily. It makes the motor’s power stronger, giving more torque. Torque is like the twisting force that makes things turn. So, while it slows down the overall speed, it helps you work with tougher materials. This way, you can shape hard metal better.”}},{“@type”: “Question”,”name”: “How Can Advancements In Drive System Technology Improve The Precision And Efficiency Of Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Advancements in drive system technology can make metal lathes work better and faster. With better motors, lathes can move more smoothly and accurately. This means you’ll get cleaner cuts and shapes in metal. It also helps save time, so you can finish projects quickly. Overall, these improvements make lathes easier to use and more productive!”}},{“@type”: “Question”,”name”: “What Are The Common Maintenance Practices For Ensuring The Longevity And Reliability Of A Metal Lathe Drive System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe drive system working well, we need to do a few important things. First, we should regularly clean it to remove dust and dirt. Next, check the oil levels and add more if needed. We also need to tighten any loose parts so they don’t break. Lastly, it helps to inspect the belts and gears for any signs of wear.”}}]}