Imagine watching a skilled craftsman create something amazing on a metal lathe. Have you ever wondered how they manage to shape metal so precisely? A big part of that is the tool holder metal lathe gear train. This clever system helps to control the movement of the lathe.

Did you know that even small gear trains can make a huge difference in metalworking? They provide power and accuracy. Without them, creating intricate designs would be much harder.

In this article, we’ll explore how the tool holder metal lathe gear train works. You’ll discover tips on how to choose the right one for your needs. Get ready to dive into the fascinating world of metal lathes!

Tool Holder Metal Lathe Gear Train: Enhance Precision And Efficiency

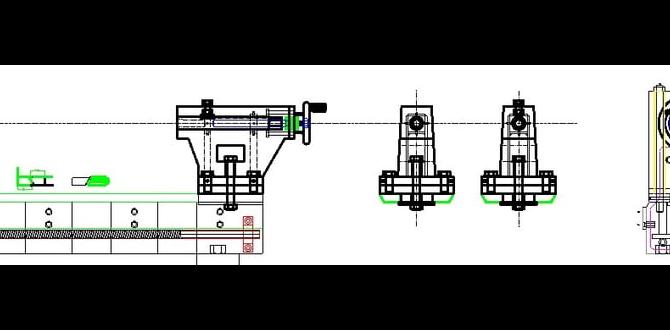

Exploring Tool Holder Metal Lathe Gear Train

A tool holder metal lathe gear train is essential for precision. It connects the motor to the cutting tool. Did you know that gear trains can change speed and torque? This helps create smooth, detailed parts. With the right setup, you can improve your projects and save time. Using a metal lathe not only enhances craftsmanship but also sparks creativity. How will you use this tool to shape your ideas?What is a Tool Holder?

Definition and function of tool holders. Types of tool holders used in metal lathes.A tool holder is a device that securely holds tools for machines, like lathes. It ensures tools stay in the right place during work. These holders come in various types. Some common ones used in metal lathes include:

- **Collet Holders:** Grip tools tightly. Good for small tools.

- **Chuck Holders:** Adjustable. Great for different sizes.

- **Quick-Change Holders:** Allow quick tool changes for better efficiency.

Using the right tool holder helps make work easier and more precise.

What types of tool holders are used in metal lathes?

The main types of tool holders include collet holders, chuck holders, and quick-change holders. Each has unique benefits.

Components of a Gear Train

Description of gear types (spur, helical, bevel). How gears interact within a gear train.Gears are key parts of a gear train. They come in different types. Each type helps machines work smoothly. Here are the main types:

- Spur gears: These are flat and round. They turn easily when they touch each other.

- Helical gears: These have slanted teeth. They make less noise and can handle heavy loads.

- Bevel gears: These change the direction of motion. They are usually found in corners of machines.

In a gear train, gears work together. They transfer motion from one gear to another. Each gear spins and helps the machine perform tasks.

What are the types of gear teeth?

The types of gear teeth include

- Straight teeth: Typical in spur gears.

- Angled teeth: Found in helical gears.

- Cone-shaped teeth: Used in bevel gears.

Understanding these gears can make using a tool holder metal lathe gear train easier and more efficient.

Benefits of Upgrading Tool Holder Gear Trains

Enhanced precision and accuracy in machining. Improved efficiency and productivity.Upgrading the tool holder gear trains can bring big smiles to machinists! First, you’ll see enhanced precision and accuracy in machining. Less wobble means better parts. No more guessing games! Next, improved efficiency and productivity are a bonus. You can whip out those projects much faster. Imagine making toys or parts on a hot summer day without breaking a sweat. Who wouldn’t want that?

| Benefit | Description |

|---|---|

| Precision | Less wobble leads to spot-on cuts. |

| Efficiency | Complete tasks quicker so you can enjoy more playtime! |

Key Features to Consider in Tool Holder Gear Trains

Material durability and wear resistance. Compatibility with existing lathe models.Choosing the right features for tool holder gear trains is crucial. First, material durability matters. You need something that lasts and resists wear. Look for high-quality metals that won’t break easily. Second, check compatibility with your lathe model. Some tools only fit specific lathes. Make sure the tool holder matches yours to avoid issues.

What factors should I consider when choosing a gear train?

Material durability and compatibility are key factors. Choose tough materials and confirm they fit your lathe model well.

- Durable materials resist wear.

- Compatibility avoids fitting problems.

Installation and Maintenance of Tool Holder Gear Trains

Stepbystep installation guide. Maintenance tips for longevity.Installing a tool holder gear train is like a fun puzzle! Start by gathering your tools—this means wrenches, screws, and maybe a snack for energy! First, align the gear train with the lathe, making sure everything fits snugly. Tighten the screws but don’t go Hulk on them; a firm grip is enough.

For long-lasting performance, treat your gear train with care. Clean it regularly to keep it free from dust bunnies, and apply a little oil to keep it spinning smoothly. Remember, joyful tools last longer! A happy lathe means happy gears!

| Maintenance Tips | Frequency |

|---|---|

| Clean surfaces | Weekly |

| Lubricate moving parts | Every month |

| Inspect for wear | Quarterly |

Just like our friends, gears need love too!

Common Issues with Tool Holder Gear Trains

Identifying wear and tear signs. Troubleshooting common gear train problems.Finding problems in a gear train is important for keeping it in good shape. Look for signs of wear and tear. This includes unusual sounds, loose parts, or a rough feel. If you notice these things, take action quickly. Here are some common issues to troubleshoot:

- Worn gears: Check for chips or scratches.

- Misalignment: Ensure gears line up correctly.

- Lubrication: Keep parts well-oiled to avoid friction.

- Broken parts: Replace any damaged components.

Being aware of these signs will help you fix problems before they get worse.

What are common signs of wear in gear trains?

Common signs include strange noises and parts that don’t fit well. Check regularly for any cracks or deformation.

Future Trends in Tool Holder Gear Train Technology

Innovations in material and design. Predictions for the future of lathe technology.Imagine a world filled with super strong and lightweight materials for tool holders. That’s where we are headed! The future of lathe technology promises exciting innovations in design and materials. We might soon see tool holders made of carbon fiber or titanium alloys instead of traditional metals. These changes can improve performance and reduce wear. Experts predict that smart technology will help automakers avoid errors, making lathes as reliable as your grandma’s secret cookie recipe. Get ready for some amazing crafting ahead!

| Innovative Materials | Predicted Features |

|---|---|

| Carbon Fiber | Lightweight and strong |

| Titanium Alloys | Durable and versatile |

| Smart Technology | Error reduction and efficiency |

Conclusion

In conclusion, a tool holder for a metal lathe gear train is essential for precision work. It keeps tools secure and improves accuracy. Understanding how it works helps you create better projects. We encourage you to explore more about lathes and tool holders online. Practicing with these tools will boost your skills and confidence in metalworking!FAQs

What Are The Primary Functions Of A Gear Train In A Metal Lathe Tool Holder System?A gear train in a metal lathe helps us control the speed and direction of the tool. It connects different gears to make turning easier. When we change gears, we can create different shapes or cut materials better. This system helps us work faster and more accurately when using the lathe.

How Do Different Gear Ratios In The Gear Train Affect The Speed And Torque Output Of A Metal Lathe?Different gear ratios help change how fast or strong the lathe works. A low gear ratio gives you more torque, which means it can work harder. This is good for tough jobs. A high gear ratio makes the lathe spin faster, which is useful for lighter jobs. So, the gear ratio helps you choose between speed and strength.

What Materials Are Commonly Used For The Gears In A Metal Lathe Gear Train, And How Do They Impact Durability And Performance?Metal lathes often use gears made from steel or plastic. Steel gears are very strong and last a long time. They help the lathe work better and handle tough tasks. Plastic gears are lighter and can be quieter, but they can wear out faster. Choosing the right material helps the lathe run smoothly and last longer.

How Can Gear Train Configuration Be Optimized For Specific Machining Tasks In A Metal Lathe?To optimize a gear train in a metal lathe, you can change the gears to match your task. For fast cutting, use smaller gears for more speed. If you need to cut hard metal, use bigger gears for more power. Always pick the right gear setup to get the best results for your project!

What Are The Common Maintenance Practices For Ensuring The Proper Functioning Of A Gear Train In A Metal Lathe Tool Holder?To take care of a gear train in a metal lathe tool holder, you should regularly clean it. Dust and dirt can make it work poorly. Use a soft cloth to wipe down the parts. You should also check for any loose screws or parts and fix them. Lubricate (put oil on) the gears to keep them moving smoothly. This way, your lathe will work better and last longer!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Primary Functions Of A Gear Train In A Metal Lathe Tool Holder System? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A gear train in a metal lathe helps us control the speed and direction of the tool. It connects different gears to make turning easier. When we change gears, we can create different shapes or cut materials better. This system helps us work faster and more accurately when using the lathe.”}},{“@type”: “Question”,”name”: “How Do Different Gear Ratios In The Gear Train Affect The Speed And Torque Output Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different gear ratios help change how fast or strong the lathe works. A low gear ratio gives you more torque, which means it can work harder. This is good for tough jobs. A high gear ratio makes the lathe spin faster, which is useful for lighter jobs. So, the gear ratio helps you choose between speed and strength.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used For The Gears In A Metal Lathe Gear Train, And How Do They Impact Durability And Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes often use gears made from steel or plastic. Steel gears are very strong and last a long time. They help the lathe work better and handle tough tasks. Plastic gears are lighter and can be quieter, but they can wear out faster. Choosing the right material helps the lathe run smoothly and last longer.”}},{“@type”: “Question”,”name”: “How Can Gear Train Configuration Be Optimized For Specific Machining Tasks In A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To optimize a gear train in a metal lathe, you can change the gears to match your task. For fast cutting, use smaller gears for more speed. If you need to cut hard metal, use bigger gears for more power. Always pick the right gear setup to get the best results for your project!”}},{“@type”: “Question”,”name”: “What Are The Common Maintenance Practices For Ensuring The Proper Functioning Of A Gear Train In A Metal Lathe Tool Holder? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To take care of a gear train in a metal lathe tool holder, you should regularly clean it. Dust and dirt can make it work poorly. Use a soft cloth to wipe down the parts. You should also check for any loose screws or parts and fix them. Lubricate (put oil on) the gears to keep them moving smoothly. This way, your lathe will work better and last longer!”}}]}