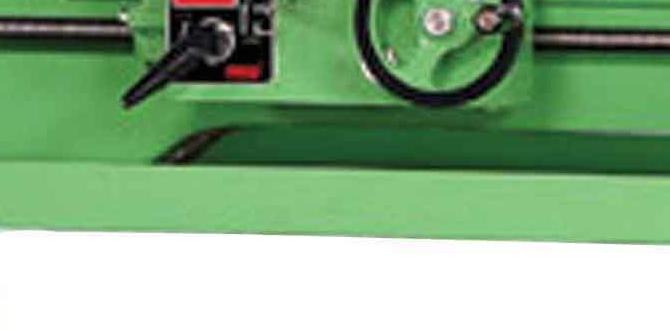

Have you ever wondered how to make your metal lathe work better? A tool holder metal lathe quill can be the answer. This handy device helps hold your tools firmly in place. It makes turning metal pieces much easier and more accurate.

Imagine trying to carve a piece of wood with a tool that keeps slipping. Frustrating, right? Now, think about how a good holder can keep your tools steady. You can create amazing projects without worrying about accidents.

Did you know that many metalworkers believe a solid quill is the secret to their success? It helps them achieve precise cuts and smooth finishes. So, if you’re looking to improve your metalworking game, learning more about a tool holder metal lathe quill could be the perfect first step.

Tool Holder Metal Lathe Quill: Essential For Precision Work

Understanding Tool Holder Metal Lathe Quill

A tool holder metal lathe quill is essential in metalworking. It securely holds cutting tools and helps ensure accuracy. Do you wonder how lathes create perfectly shaped metal pieces? The quill allows precise adjustments, making it easier for users to achieve their desired dimensions. With a well-maintained quill, your metal projects can turn out polished and professional. Knowing how to use a quill can elevate your metalworking skills, making your creations truly shine.Understanding Metal Lathe Quills

Definition and purpose of a quill in metal lathes. Types of quills available in the market.A quill in a metal lathe is a tool holder that holds cutting tools securely. It helps shape materials like metal and wood. Quills make it easier to change tools quickly and keep everything tight. There are different types of quills available:

- Standard quills: Basic design for everyday tasks.

- Extended quills: Longer for deeper cutting.

- Precision quills: Designed for accuracy in detail work.

Choosing the right quill makes your work easier and improves your projects!

What are the types of quills in metal lathes?

There are three main types: standard, extended, and precision. Each type suits different tasks, helping you complete your work better.

Benefits of Using Tool Holder Metal Lathe Quills

Improved precision and accuracy in machining. Enhanced tooling versatility and efficiency.Using tool holder metal lathe quills comes with many advantages. First, they help improve precision and accuracy in machining. This means your projects will fit together better than a jigsaw puzzle, with less chance of frustration! Enhanced tooling versatility means you can switch out tools quickly, saving time. Who doesn’t love more time, especially when it means fewer trips to the toolbox? Plus, with these quills, your efficiency will soar like a rocket. Every machinist will appreciate that!

| Benefit | Description |

|---|---|

| Precision | Improved fit and finish in projects |

| Versatility | Quick tool changes for various tasks |

| Efficiency | More work done in less time |

Choosing the Right Tool Holder Quill for Your Metal Lathe

Factors to consider: size, material, and compatibility. Recommended quill specifications for various applications.Picking the right tool holder quill for your metal lathe is like finding the perfect pair of shoes—size matters! You must check the size to ensure a snug fit. Next, think about the material; metal quills are sturdy, while others can be lightweight. Lastly, make sure it’s compatible with your lathe. For various projects, look for these specs:

| Application | Quill Size | Material |

|---|---|---|

| Precision Turning | 1 inch | Steel |

| Heavy Cuts | 1.5 inches | Carbide |

| Light Finishing | 0.75 inches | Aluminum |

Choosing wisely will save you a headache and maybe a few lost screws!

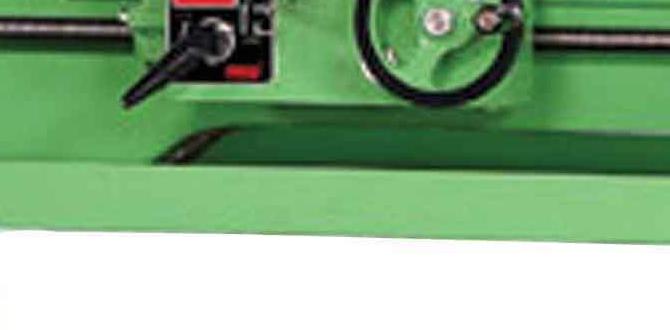

Installation and Setup of Tool Holder Metal Lathe Quills

Stepbystep guide on installing a quill. Tips for ensuring proper alignment and operation.Follow this simple guide to install your quill properly. First, turn off the lathe and disconnect the power. Next, remove the old quill if needed. Then, attach the new quill securely to the lathe. Make sure the quill aligns with the spindle. Check the fit by moving the quill up and down. Finally, tighten all screws. For smooth operation, ensure everything is aligned. This helps avoid problems while using the metal lathe.

How do I ensure proper alignment?

Check the alignment regularly and adjust if needed. Use a level tool to verify the quill sits straight. Misalignment can lead to uneven cuts. Also, always double-check before starting any project!

Maintenance Tips for Longevity of Tool Holder Quills

Regular maintenance practices for optimal performance. Common issues and troubleshooting techniques.Taking care of your tool holder quill can make it last longer and work better. Keep it clean and lubricated. Regularly check for signs of wear and tear. Pay attention to these common issues:

- Rust buildup

- Worn bearings

- Loose screws

If you notice any of these problems, fix them right away. A little care goes a long way!

How do I keep my tool holder quill clean?

To keep your tool holder quill clean, use a soft cloth and mild soap. Wipe it down regularly to prevent dirt and grime. Lubricate it every month to keep everything moving smoothly.

Expert Recommendations and Reviews

Market analysis of toprated tool holder metal lathe quills. Pros and cons of popular brands and models.Checking out tool holder metal lathe quills? You’re in for a treat! Some brands really shine. For instance, quick setups and solid construction are the stars here. But every rose has its thorn. Some models can be pricey. Others might not hold tools as tightly as you’d like. Here’s a quick look at what popular choices are offering:

| Brand | Pros | Cons |

|---|---|---|

| Brand A | Durable, easy to use | Pricey |

| Brand B | Budget-friendly | Not as sturdy |

| Brand C | Great grip, reliable | Heavy |

On the whole, consider your needs and budget before picking a tool holder. After all, your lathe deserves the best, right?

Applications and Use Cases of Metal Lathe Quills

Industries that benefit from quills in metal lathes. Specific projects that utilize quills effectively.Quills in metal lathes are like superheroes for many industries. They save the day in manufacturing, automotive, and even crafts. These nifty tools make projects easier by holding different attachments. For example, a quill can aid in fabricating precision parts for cars or maybe turning wooden bowls for your grandma. It’s like having a trusty sidekick in your workshop! Plus, they help save time and ensure quality, so your projects turn out great every time.

| Industry | Project |

|---|---|

| Manufacturing | Precision parts |

| Automotive | Engine components |

| Crafts | Wooden bowls |

Conclusion

In summary, a tool holder for a metal lathe quill is essential for precise work. It securely holds tools, making your projects smoother and easier. Remember to choose the right size and type for your lathe. Now that you know more, consider exploring different tool holders or dive deeper into metal lathe techniques. Happy crafting!FAQs

Sure! Here Are Five Related Questions On The Topic Of Tool Holder Metal Lathe Quills:Sure! A metal lathe is a machine that helps shape metal into different forms. The quill is a part of the lathe that holds tools. It can move up and down, allowing you to cut or shape the metal as needed. Tool holders fit into the quill and keep the tools securely in place. This makes it easier for you to work on your projects!

Sure! Please provide the question you’d like me to answer.

What Are The Primary Functions Of A Quill In A Metal Lathe Tool Holder?A quill in a metal lathe tool holder helps to adjust the tool’s position. It moves the cutting tool closer or farther away from the metal you are working on. This makes it easier to cut shapes and sizes you want. The quill also helps you keep the tool steady while you work. Overall, it makes your job simpler and more precise.

How Do Different Quill Designs Impact The Precision And Performance Of The Lathe Operations?Different quill designs can change how accurately and smoothly a lathe works. A quill holds the tool and helps it move. If a quill is straight and strong, it helps you cut better shapes. If it wobbles or is weak, your cuts might not be as good. So, the right quill helps you make better things!

What Materials Are Typically Used For Constructing Quills In Tool Holder Systems, And How Do They Affect Durability?Quills in tool holder systems are usually made from steel, aluminum, or plastic. Steel is strong and lasts a long time, while aluminum is lighter but still durable. Plastic quills are lighter and can be cheaper, but they aren’t as strong as metal ones. The materials you choose can make a big difference in how long the quill lasts.

How Does The Adjustment Mechanism Of A Quill Influence Tooling Setup And Workpiece Alignment In A Metal Lathe?The quill on a metal lathe helps you move tools up and down easily. When you adjust the quill, you can change where the tool touches the metal piece, or workpiece. This helps you align everything correctly so your cuts are smooth. If the tool is set right, your work will be neat and even. So, using the quill properly makes your work more accurate!

What Maintenance Practices Are Recommended To Ensure The Longevity And Accuracy Of A Metal Lathe Quill?To keep your metal lathe quill in good shape, you should clean it regularly. Dust and metal shavings can cause issues, so wipe it down often. You also need to oil the moving parts. This helps them work smoothly and last longer. Lastly, check for any loose screws or parts to keep everything tight and working right.