Have you ever watched a milling machine at work? It’s fascinating, right? These machines cut, shape, and form materials like metal and wood. But did you know that there’s a secret to making them run better? That secret is called tool length offset for milling tools.

Imagine a carpenter trying to build a treehouse. If their tools are not the right length, it could lead to problems. The same goes for milling machines. They need to know the exact tool length to create perfect cuts every time.

Tool length offsets help machines accurately measure cutting tools. This allows for precise cuts and reduces waste. Isn’t it amazing how such a simple calculation can make a big difference? In this article, we will explore how tool length offsets work and why they are crucial for successful milling.

Tool Length Offset For Milling Tools: Understanding Its Importance

Understanding Tool Length Offset for Milling Tools

Tool length offset in milling tools is crucial for precise machining. It helps adjust the tool’s position, ensuring accurate depth cuts. When you use different tools, each may have varying lengths. This offset helps compensate for that difference. Have you ever wondered how machines create perfect shapes? Understanding offsets makes it possible! By using the right tool length, you’ll save time and reduce errors. It’s like having a magic ruler for your machine!What is Tool Length Offset?

Definition and explanation of tool length offset. Importance in CNC milling processes.Tool length offset is a setting in CNC milling that helps machines know how long their cutting tools are. This is important because each tool may be different in length. By using tool length offset, the machine can make perfect cuts without mistakes. It adjusts the height of the tool automatically, ensuring accuracy. This saves time and material, making the process smoother.

Why is tool length offset important?

Using tool length offset helps in many ways:

- Improves precision of cuts.

- Reduces the risk of damaging tools.

- Saves time and costs by avoiding errors.

How Tool Length Offset Works

Detailed mechanics of tool length offset calculations. Explanation of Gcode commands related to tool length.Tool length offset is like giving your milling tool a trusty measuring tape! It helps in knowing how deep the tool goes into the material. When you set the tool length offset, the machine can adjust itself perfectly. It’s all about using the right G-code commands. For example, G54 sets the work coordinate system, while G43 adds the tool length offset. Keep this chart handy for quick reference:

| G-code | Function |

|---|---|

| G54 | Sets work coordinate system |

| G43 | Activates tool length offset |

Remember, accurate offsets lead to great results. So, it’s like putting on your favorite pair of shoes before heading out—make sure they fit just right!

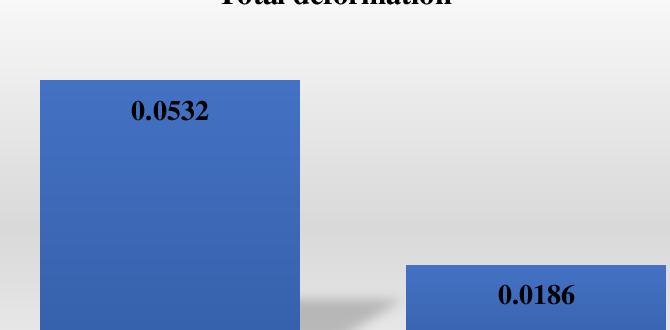

Why Tool Length Offset is Crucial for Precision Machining

Impact on part accuracy and repeatability. Consequences of incorrect offset settings.Precision in machining is like a chef measuring ingredients. If the tool length offset isn’t set right, the results can turn into a mess! It affects part accuracy and repeatability. If your offset is off by even a tiny bit, the part may not fit right. This could lead to wasted materials or long fixes. Remember, a small mistake can feel like a big hiccup in a smooth operation!

| Offset Setting | Impact |

|---|---|

| Correct | High accuracy and repeatability |

| Incorrect | Wasted time and materials |

So, always double-check those settings! It might save your project and some hair-pulling moments!

Setting Up Tool Length Offset in CNC Machines

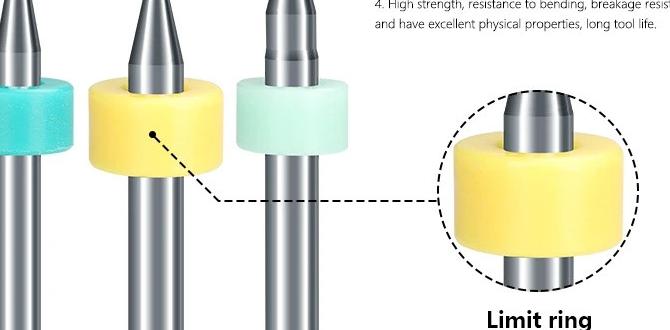

Stepbystep guide to setting tool length offset. Common tools and methods used for measuring offsets.Setting tool length offset in CNC machines is like teaching your robot to measure its pencils! First, you need to gather common tools like a caliper or a tool setter for accuracy. Then, follow these easy steps:

| Step | Description |

|---|---|

| 1 | Turn on the CNC machine. |

| 2 | Insert your milling tool. |

| 3 | Use a measuring tool to find the length. |

| 4 | Input this value into your CNC. |

Now you’ve got the perfect length! Remember, too much offset can lead to clumsy cuts, and nobody wants a clumsy robot. Keep it precise to avoid those “oops” moments!

Common Challenges and Troubleshooting Tool Length Offsets

Frequent issues encountered when setting offsets. Tips for resolving offsetrelated problems.Setting tool length offsets can be tricky. Common issues include incorrect measurements and tool wear. These problems lead to poor cuts and wastage. To resolve them, double-check your measurements. Use a reliable gauge to measure tool length. Make sure to regularly inspect your tools for wear. Keeping your workspace clean also helps maintain accuracy.

What are common challenges when setting offsets?

Frequent issues include miscalculations in measurements and tool damage. Always confirm your readings to avoid mistakes.

Tips for resolving offset-related problems:

- Double-check measurements using a caliper.

- Inspect tools for wear and tear.

- Clean the workspace regularly.

- Use clear labels for each tool.

Best Practices for Managing Tool Length Offsets

Recommended practices for effective offset management. Importance of regular calibration and maintenance.Managing tool length offsets can be as tricky as juggling water balloons. To keep things flowing smoothly, it’s best to regularly check and adjust offsets. This means measuring the tool lengths when you swap them out, like making sure your shoelaces are tied before a race! Calibration should happen often—think of it as a tune-up for your tools. Maintain your equipment with care; a well-oiled machine is a happy machine! Regular checks can save you from big messes later.

| Practice | Importance |

|---|---|

| Regular Calibration | Ensures accuracy and consistent results. |

| Timely Maintenance | Prevents unexpected failures. |

| Document Changes | Helps track performance over time. |

Tool Length Offset in Different Milling Applications

Variations in offset requirements for different materials. Specific considerations for milling operations and workpiece geometries.Different materials need different settings for tool length offset during milling. Soft metals like aluminum require a smaller offset, while harder materials like steel need a larger one. A rounded workpiece shape also demands careful adjustment to avoid errors.

- Soft materials: Less offset, smoother cuts.

- Hard materials: More offset, prevents tool wear.

- Complex shapes: Precise offset ensures accuracy.

By adjusting the offsets, you can improve your milling results and create better parts!

What factors affect tool length offset?

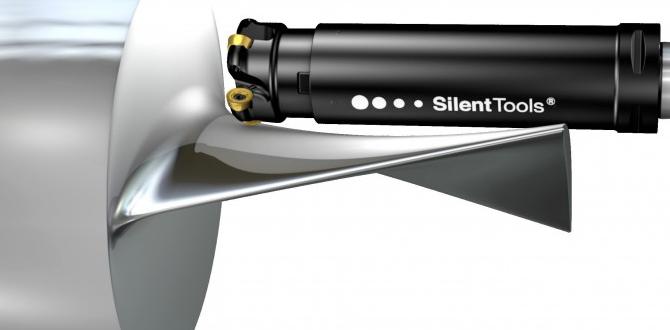

Material hardness, geometry of the workpiece, and specific machine settings all play a big role in determining the right tool length offset.Future Trends in Tool Length Offset Technology

Innovations and advancements in tooling technology. Predictions for the future of tool length management in CNC machining.New ideas and cool gadgets are popping up in tooling technology. These innovations will make managing tool lengths easier and faster. Imagine a tool that can measure itself! That’s the future. With CNC machines getting smarter, we predict less time spent adjusting and more time making things. Tools will soon talk to their machines, saving everyone headaches. It’s like your favorite robot butler! Keeping an eye on these upgrades could bring sharper tools and brighter jobs.

| Trend | Description |

|---|---|

| Self-measuring Tools | Tools that automatically check and adjust their length. |

| Smart CNC Integration | CNC machines that sync with tools for better accuracy. |

Conclusion

In summary, tool length offsets are crucial for milling tools to ensure accuracy. They help you measure how long your tools are. This guarantees precise cuts and better results in your projects. Make sure to check and set your offsets properly. For more tips and tricks, explore guides or ask experienced friends. Happy milling!FAQs

What Is The Purpose Of Tool Length Offset In Cnc Milling Operations, And How Does It Affect Machining Accuracy?Tool length offset helps a CNC mill know how long each cutting tool is. When we set this, the machine can use the right length for the job. This means it cuts at the right depth and avoids mistakes. If the tool length is wrong, it can make parts too big or small. So, using a tool length offset helps us make better and more precise parts.

How Can You Measure And Set Tool Length Offsets For Milling Tools Effectively?To measure and set tool length offsets for milling tools, you can use a tool setter or caliper. First, place the tool in the machine. Next, move the tool down until it touches the work surface. Record this distance. Use this measurement to set the tool offset in the machine’s controls. This helps the machine know how deep to cut.

What Are The Common Methods For Calibrating Tool Length Offsets In A Cnc Milling Machine?To calibrate tool length offsets in a CNC milling machine, you can use a few methods. First, you can use a special tool called a tool setter or touch plate. You place the tool on it and the machine measures the length. Another way is to use a known reference point on the workpiece to check and adjust the tool. Lastly, you can also manually measure the tool length with a ruler and enter it into the machine.

How Do Variations In Tool Wear Impact The Required Tool Length Offsets During Machining?When a tool wears down, it becomes shorter. This means we need to adjust the tool length to make it work properly. If we don’t fix this, the tool might not cut the material correctly. So, we check the tool’s wear and change the length offset to keep everything accurate.

What Are The Potential Consequences Of Incorrect Tool Length Offsets In Milling Setups?If you set the tool length wrong in milling, you might cut too deep or too shallow. This can ruin the piece you’re working on. It can also damage the tool or machine. Fixing mistakes takes time and may waste materials. So, getting the tool length right is very important!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Is The Purpose Of Tool Length Offset In Cnc Milling Operations, And How Does It Affect Machining Accuracy? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Tool length offset helps a CNC mill know how long each cutting tool is. When we set this, the machine can use the right length for the job. This means it cuts at the right depth and avoids mistakes. If the tool length is wrong, it can make parts too big or small. So, using a tool length offset helps us make better and more precise parts.”}},{“@type”: “Question”,”name”: “How Can You Measure And Set Tool Length Offsets For Milling Tools Effectively? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To measure and set tool length offsets for milling tools, you can use a tool setter or caliper. First, place the tool in the machine. Next, move the tool down until it touches the work surface. Record this distance. Use this measurement to set the tool offset in the machine’s controls. This helps the machine know how deep to cut.”}},{“@type”: “Question”,”name”: “What Are The Common Methods For Calibrating Tool Length Offsets In A Cnc Milling Machine? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calibrate tool length offsets in a CNC milling machine, you can use a few methods. First, you can use a special tool called a tool setter or touch plate. You place the tool on it and the machine measures the length. Another way is to use a known reference point on the workpiece to check and adjust the tool. Lastly, you can also manually measure the tool length with a ruler and enter it into the machine.”}},{“@type”: “Question”,”name”: “How Do Variations In Tool Wear Impact The Required Tool Length Offsets During Machining? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When a tool wears down, it becomes shorter. This means we need to adjust the tool length to make it work properly. If we don’t fix this, the tool might not cut the material correctly. So, we check the tool’s wear and change the length offset to keep everything accurate.”}},{“@type”: “Question”,”name”: “What Are The Potential Consequences Of Incorrect Tool Length Offsets In Milling Setups? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you set the tool length wrong in milling, you might cut too deep or too shallow. This can ruin the piece you’re working on. It can also damage the tool or machine. Fixing mistakes takes time and may waste materials. So, getting the tool length right is very important!”}}]}