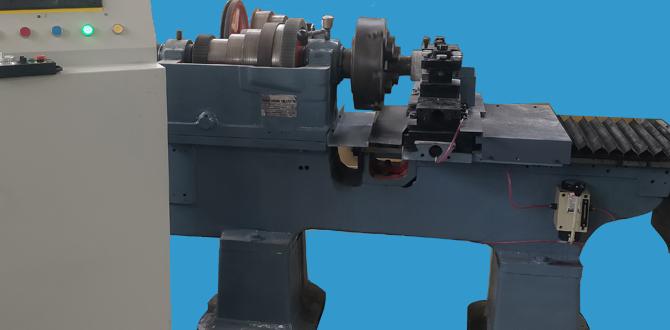

Have you ever wondered how machines can create precise parts? Imagine turning a piece of metal into something special with your own hands. That’s where a tool post metal lathe comes in. This amazing machine can shape metal with incredible accuracy. But what if you could make it even better?

Now, many people are retrofitting their lathes with CNC technology. CNC stands for Computer Numerical Control. This upgrade means your metal lathe can follow complex commands from a computer. It’s like turning your simple machine into a smart robot!

Think about it. Instead of relying only on your hands, you can program the machine to do the hard work. This is a game-changer for hobbyists and professionals alike. You can now make intricate designs that seemed impossible before.

In this article, we will explore the world of tool post metal lathe CNC retrofit. You will discover how to transform your lathe and make it work like a dream. Are you ready to unlock new possibilities? Let’s dive in!

Tool Post Metal Lathe Cnc Retrofit: Enhance Your Machining Efficiency

Tool Post Metal Lathe CNC Retrofit

Upgrading your metal lathe with a CNC retrofit can transform your workshop. Imagine the precision and efficiency you can gain! A tool post CNC retrofit allows for automatic control of the lathe, enhancing your projects. You’ll learn how this upgrade improves speed and accuracy. Plus, it can save time on repetitive tasks. Curious about how to make the switch? Retrofits can open doors to a new level of creativity in metalworking.Benefits of Retrofitting Your Metal Lathe

Improved precision and accuracy compared to manual operation.. Increased productivity and reduced cycle times..Retrofitting your metal lathe with CNC technology brings a treasure chest of benefits. First, you’ll enjoy improved precision and accuracy that leaves manual operations in the dust. No more guessing; it’s like having a laser-guided squirrel helping you! Increased productivity is another perk. You can cut cycle times significantly, which means more time for coffee breaks and less time stressing. Who wouldn’t want that?

| Benefit | Description |

|---|---|

| Precision | Enhances accuracy, making your cuts spot-on. |

| Productivity | Speeds up production, so you can finish projects faster. |

Components Required for a CNC Retrofit

Essential hardware components: stepper motors, drivers, and control systems.. Necessary software for programming and operation..To update your metal lathe to CNC, you’ll need some important parts. Key components include stepper motors, which move the tools. You’ll also need drivers to control those motors. A control system helps everything work together. Besides hardware, special software is essential for programming and operation. This software tells your lathe what to do. Without these items, retrofitting will not go smoothly.

What hardware do I need for a CNC retrofit?

- Stepper Motors: These move the lathe tools precisely.

- Drivers: They control the speed and direction of motors.

- Control Systems: They connect everything to work as one.

Adding these elements will make your lathe smarter. It can produce more accurate parts faster. This upgrade can boost your workshop’s capability! Isn’t it exciting to think about what you can create?

Selecting the Right Tool Post for Your CNC Retrofit

Types of tool posts suitable for CNC lathes.. Criteria for choosing the best tool post for your application..Choosing a tool post for your CNC retrofit can feel like picking the right ice cream flavor—everyone has their favorite! There are various types to consider, like dropping tool posts and lazy susan tool posts. Each type works differently depending on your needs. To select the best one, think about factors like the size of your lathe and the materials you’ll use. Remember, using the wrong tool is like trying to fix a flat tire with a spoon—it’s just not going to work!

| Tool Post Type | Best For |

|---|---|

| Dropping Tool Post | Quick changes and versatility |

| Lazy Susan Tool Post | Stable cuts on larger pieces |

| Square Tool Post | Basic operations and rigidity |

Keep these tips in mind to select the right tool post and make your CNC projects run smoothly, just like a well-oiled machine (or a well-oiled chef in the kitchen)!

Step-by-Step Guide to Retrofitting Your Metal Lathe

Detailed instructions on disassembling the existing setup.. Instructions on integrating CNC components and software installation..To retrofit your metal lathe, start by carefully disassembling the existing setup. Follow these steps:

- Unplug the lathe to ensure safety.

- Remove the drive belt and motor cover.

- Take off the old control box and wiring.

- Keep all parts organized for easier reassembly.

Next, integrate the new CNC components. Connect the motors and install the software. Make sure to:

- Calibrate the motors correctly.

- Test the software with simple commands.

- Verify the connections for safety.

This step-by-step guide will help you transform your lathe into a CNC machine.

How does CNC retrofitting improve lathe performance?

CNC retrofitting makes lathes more precise and efficient. It allows for better control, faster production, and improved accuracy. Many users notice a significant boost in their work quality.

Common Challenges and Solutions in CNC Retrofitting

Typical issues faced during retrofitting and how to troubleshoot them.. Effective strategies for ensuring a smooth retrofit process..Retrofitting a CNC machine can feel like solving a giant puzzle, sometimes with missing pieces! Common issues include electrical glitches, software bugs, and mechanical mismatches. Each can make you want to pull your hair out, but don’t despair. To troubleshoot, start by checking connections and ensuring your software is up to date. If all else fails, consulting experts is a smart move. Follow these steps for a smoother retrofit:

| Challenge | Solution |

|---|---|

| Electrical Issues | Check wiring and connections. |

| Software Bugs | Update to the latest version. |

| Mechanical Mismatches | Ensure parts are compatible with your setup. |

Remember, patience is key. Every problem has a solution, sometimes buried under too many cables or above a toolbox filled with mystery parts! Keep your humor handy—it helps the troubleshooting process.

Maintenance Tips for CNC-Retrofit Metal Lathes

Routine maintenance practices to ensure longevity and performance.. Common signs that indicate the need for service or adjustment..Keeping your CNC retrofitted metal lathe in tip-top shape is like watering a plant. A little care goes a long way! Regular checks on belts, oil levels, and tools help keep things running smoothly. Watch for sounds like squeaks or clunks—these are like alarm bells for repairs. Remember to look for uneven cuts or excessive vibrations; they’re signs your lathe might need some TLC. Treat it well, and it will treat you well right back!

| Maintenance Task | Signs It’s Time for Service |

|---|---|

| Check oil levels | Low or dirty oil |

| Inspect belts | Squealing noises |

| Clean the machine | Dust and debris buildup |

| Calibrate settings | Uneven cuts |

Lastly, remember: if your lathe starts acting like a drama queen, it’s time for a check-up! A little effort can save a big headache later.

Real-World Examples of Successful CNC Retrofits

Case studies from various industries showcasing successful retrofitting.. Lessons learned and insights gained from these retrofits..CNC retrofits can improve factories and workshops. Many businesses have shared how they did it. Here are some interesting case studies:

- Automotive Industry: A car manufacturer upgraded their CNC machines. They saved time and increased precision.

- Aerospace Sector: An aerospace company fitted their lathes with new controls. They produced lighter, stronger parts quicker than before.

- Tool Maker: A small tool shop retrofitted two lathes. They noticed better product quality and less waste.

Lessons from these examples include the importance of staff training and choosing the right technology. Each successful retrofit taught valuable insights and boosted business performance.

What are some benefits of CNC retrofitting?

CNC retrofitting improves efficiency, accuracy, and reduces production costs. It lets older machines work better, saving money instead of buying new ones.

Cost Considerations for a CNC Retrofit Project

Breakdown of costs associated with different components and labor.. ROI analysis: is retrofitting worth the investment?.Cost can be a big part of a CNC retrofit project. First, consider the costs of different parts like motors, drives, and software. Each of these adds up. You also need to think about labor costs. Skilled labor can be expensive but is important for a good job.

- Motors: $200 – $1,000

- Drives: $150 – $800

- Software: $300 – $1,500

- Labor: $50 – $100 per hour

Now, is this investment worth it? Many users say retrofitting can boost speed and accuracy. In fact, some reports claim returns of over 30% within the first year. This makes it a smart choice if you plan well.

What are typical costs of upgrading a CNC machine?

The cost of a CNC upgrade varies widely. Typically, you will spend around $1,000 to $5,000 for a complete retrofit, depending on the machine and features.

Future Trends in CNC Retrofitting for Metal Lathes

Emerging technologies and innovations in CNC retrofitting.. Predictions on how CNC retrofitting will evolve in the coming years..New technologies are changing CNC retrofitting for metal lathes. Many companies are now using smart automation and AI to improve efficiency. These innovations help machines work faster and more accurately. In the future, we can expect:

- Increased customizability to meet different needs.

- Better software for easier operation.

- More affordable options for small businesses.

These changes will likely make retrofitting more popular, helping older machines stay useful and effective.

How will CNC retrofitting evolve?

CNC retrofitting will likely become easier and more affordable. As technology improves, more businesses will upgrade their older machines to stay competitive.

Conclusion

In conclusion, a tool post metal lathe CNC retrofit helps you upgrade your lathe for better precision. This upgrade improves your machining capabilities and efficiency. You can customize it for specific projects and save time. Consider researching retrofit kits or tutorials to get started. With the right tools, you can enhance your metalworking skills and tackle exciting new projects!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Tool Post Metal Lathe Cnc Retrofit:Sure! A tool post metal lathe CNC retrofit is when we upgrade a regular lathe machine. This means we can make it work like a computer-controlled machine. We do this to make precise parts faster and easier. It’s like turning a regular bike into an electric bike! Retrofitting helps us create more accurate shapes and saves time.

Sure! Please provide the question you’d like me to answer.

What Are The Primary Benefits Of Retrofitting A Traditional Metal Lathe With Cnc Capabilities?Retrofitting a traditional metal lathe with CNC (Computer Numerical Control) makes it better and easier to use. You can make more complicated shapes and designs quickly. It also means you can create many parts that are the same, which saves time. Plus, using CNC helps reduce mistakes, so your work looks great every time!

What Components Are Necessary For A Successful Cnc Retrofit Of A Tool Post Lathe?To successfully add computer control to a tool post lathe, you need a few key parts. First, get a good CNC controller to tell the machine what to do. Next, add motors that can move the lathe’s parts smoothly. You also need sensors to help the machine know where it is. Finally, don’t forget the software to program your tasks on the computer.

How Can I Determine If My Existing Metal Lathe Is Suitable For A Cnc Retrofit?To see if your metal lathe can change to CNC (Computer Numerical Control), check its size and condition. Look for a strong, working motor and a solid body. You also need enough space to add new parts. Finally, think about how much you’re ready to spend on the upgrade.

What Software Options Are Available For Controlling Cnc Retrofitted Lathes, And How Do They Differ?There are several software options to control CNC retrofitted lathes. Some popular ones are Mach3, LinuxCNC, and Fusion 360. Mach3 is easy to use and great for hobbyists. LinuxCNC is free and works well for more advanced users. Fusion 360 combines design and control but needs a subscription. Each one has different tools and features to help you with your projects.

What Common Challenges Might I Face During The Retrofit Process, And How Can They Be Addressed?During the retrofit process, you might face challenges like finding the right materials or workers. Sometimes, the new parts don’t fit well with the old ones. You can deal with these problems by planning ahead and measuring carefully. It’s also helpful to ask for help from experts who know what to do. Being patient and flexible will make the process easier!