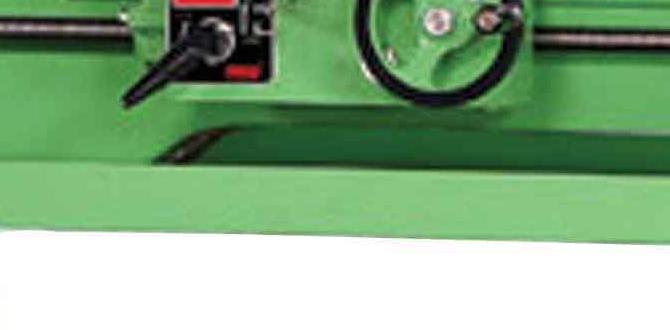

Have you ever wondered how metal shapes into sleek objects? A tool post metal lathe pulley is a key part of that magic. It helps turn raw metal into parts for machines, toys, or even jewelry.

Imagine a giant machine in a workshop, spinning and cutting with precision. That’s what a tool post metal lathe does. It uses pulleys to make everything smooth and easy. Without these pulleys, your favorite gadgets might look very different!

Did you know that ancient craftsmen used simple tools to create amazing things? Today, we still rely on clever inventions like the tool post metal lathe pulley. These small parts play a big role in making the world around us!

By the end of this article, you’ll see just how important these pulleys really are. So, are you ready to dive into the fascinating world of metalworking?

Tool Post Metal Lathe Pulley: Essential Features And Benefits

Tool Post Metal Lathe Pulley Summary

A tool post metal lathe pulley plays a vital role in metalworking. It helps control the spindle speed effectively. Understanding how it functions can boost efficiency during your projects. Did you know that a proper pulley can double your turning speed? This device connects the motor to the lathe, ensuring smooth operation. By mastering this component, you can enhance your skills and create precise parts. Isn’t it exciting to think how a simple tool can change your work?What is a Tool Post Metal Lathe Pulley?

Definition and function of a tool post metal lathe pulley. Importance in the operation of a metal lathe.A tool post metal lathe pulley is a key part that helps control the movement of tools on a lathe. Think of it as the orchestra conductor for your metal shaping. It makes sure everything works smoothly and precisely. Without it, things could get messy! The pulley transfers power and speeds up or slows down the tool. If your lathe is a dance floor, the pulley is the DJ, keeping the beat just right. Learning about this part can help you master the art of metalworking.

| Function | Importance |

|---|---|

| Controls Tool Movement | Ensures Precision in Machining |

| Transfers Power | Affects Speed and Efficiency |

Material Selection for Tool Post Pulley

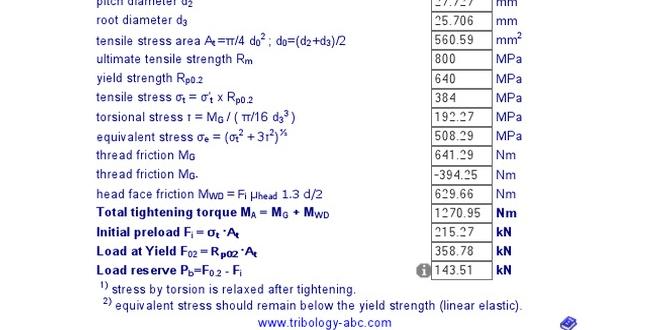

Common materials used in pulleys and their properties. Pros and cons of different materials.Choosing the right material for a tool post pulley can feel like picking a favorite ice cream flavor—it’s important! Most pulleys are made from steel, aluminum, or plastic. Steel is super strong but can be heavy. Aluminum is light and resistant to rust, but it can get bent more easily. Plastic is light and cheap, but it might not last long if it has to work hard.

| Material | Pros | Cons |

|---|---|---|

| Steel | Very strong | Heavy |

| Aluminum | Light and rustproof | Can bend easily |

| Plastic | Cheap and lightweight | Less durable |

So, pick wisely, and don’t be surprised if your pulley starts to feel like a superstar depending on what material you choose. Remember: Stronger isn’t always better—sometimes, you need a little finesse too!

Installation and Setup of Tool Post Metal Lathe Pulley

Stepbystep guide on how to install a pulley. Tips for proper alignment and adjustment.Installing a pulley on your tool post lathe can be a breeze. Start by gathering your tools: a wrench, screwdriver, and maybe a snack for energy. First, firmly attach the pulley to the spindle and secure it tightly. Next, ensure everything is aligned. A crooked pulley can cause chaos! Slowly adjust the pulley until it spins freely. Remember, a little wiggle room is good—just not too much! Always double-check your work before using it to avoid any funny accidents.

| Step | Action |

|---|---|

| 1 | Gather your tools. |

| 2 | Attach the pulley to the spindle. |

| 3 | Check for alignment. |

| 4 | Adjust as needed. |

| 5 | Double-check before use. |

Maintenance of Tool Post Metal Lathe Pulleys

Routine maintenance practices to ensure optimal performance. Signs of wear and when to replace your pulley.Keeping your tool post metal lathe pulleys in tip-top shape is super important! Regular checks keep everything running smoothly. Look for any strange noises or wobbly movements. These could mean your pulley is wearing out quicker than your favorite pair of shoes!

Replace the pulley if you spot cracks, frays, or if it starts to slip like a banana peel! Here’s a little table to help you know what to look for:

| Sign of Wear | Action |

|---|---|

| Cracks | Replace immediately |

| Wobbling | Check alignment |

| Slipping | Consider replacing |

Stay on top of your maintenance, and your lathe will thank you! A happy lathe means smooth sailing for your projects.

Common Issues and Troubleshooting

List of common problems encountered with tool post pulleys. Effective solutions and preventive measures.Many people face issues with tool post metal lathe pulleys. Common problems include slipping belts, misalignment, and noise. These problems can slow down work and frustrate users. Here are some effective solutions:

- Check the belt tension regularly.

- Align pulleys properly for smooth movement.

- Lubricate moving parts to reduce noise.

Preventive tips can also help. Always keep the lathe clean and inspect parts often. This can save time and keep your projects running smoothly!

What are the common problems with tool post pulleys?

Common problems include slipping belts and misalignment. These can happen due to wear or improper setup. Regular checks can catch issues early.

What are effective solutions for pulleys?

Effective solutions include adjusting tension and aligning components. Make sure to lubricate often too. Regular maintenance keeps everything in top shape.

Performance Enhancements for Metal Lathe Pulleys

Modifications and aftermarket options to improve efficiency. Advantages of upgrading your pulley system.Upgrading the pulley system in your metal lathe can lead to better performance and efficiency. Simple modifications or aftermarket parts can enhance your system significantly. Here are some advantages of upgrading:

- Improved speed control

- Less vibration

- Longer lifespan of components

- Higher precision in cuts

These changes can help you work faster and with greater accuracy, making your projects easier and more enjoyable. Don’t underestimate the power of a good pulley system!

What are aftermarket options to improve lathe pulleys?

Aftermarket options include upgraded belts, tensioners, and pulleys that boost efficiency. These parts can offer better durability and performance for your lathe.

Safety Considerations when Using Tool Post Pulleys

Essential safety guidelines to follow while operating a metal lathe. Personal protective equipment (PPE) recommended for users.Using a metal lathe can be fun, but safety comes first. Follow these essential guidelines to stay safe:

- Always wear gloves to protect your hands.

- Wear safety glasses to shield your eyes from flying debris.

- Keep hair tied back to avoid getting caught in moving parts.

- Ensure your clothing is tight-fitting.

- Check the machine for any loose parts before use.

By following these rules, you can enjoy your work and keep safe. Always remember, safety is cool!

What personal protective equipment should I use?

Wear safety glasses, ear protection, and gloves when using tool post pulleys. This gear helps protect you from accidents. Remember, being safe makes work enjoyable!

Buying Guide for Tool Post Metal Lathe Pulleys

Key factors to consider when purchasing a pulley. Recommended manufacturers and brands in the market.Buying the right pulley for your metal lathe is important. Here are some key factors to help you decide:

- Material: Look for strong materials like steel or aluminum.

- Size: Choose a size that fits your lathe perfectly.

- Weight Capacity: Make sure it can handle your projects.

Some top manufacturers include:

- Jet

- Grizzly

- Mitutoyo

These brands are known for their quality and reliability. Picking the right pulley can make your work smoother and more efficient.

What should I look for when buying a pulley?

You should check the material, size, and weight capacity of the pulley.

Conclusion

In summary, a tool post metal lathe pulley is essential for smooth operation. It helps manage the lathe’s speed and controls tool movement. Understanding how it works can improve your projects. If you’re interested, explore more about its setup and maintenance. Hands-on experience will make you a better craftsman. Let’s keep learning and creating!FAQs

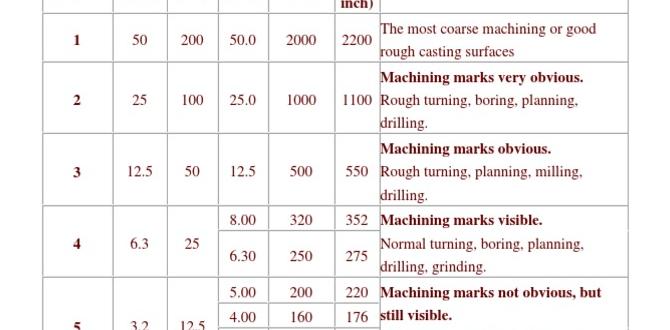

What Are The Different Types Of Pulley Systems Used In Tool Post Metal Lathes, And How Do They Affect Machining Efficiency?In tool post metal lathes, there are a few types of pulley systems. The main types are flat pulleys and V-belt pulleys. Flat pulleys help machines spin smoothly, while V-belt pulleys make it easier to change speeds. These systems help you work faster and make your work more accurate, which means better results when you’re making something.

How Do You Properly Align And Maintain The Pulleys In A Tool Post Metal Lathe To Ensure Optimal Performance?To align the pulleys on a tool post metal lathe, first, turn off the machine. You need to check if the pulleys sit straight. Adjust them if they lean or wobble. Tighten the screws to keep them in place. Regularly clean the pulleys to remove dust and dirt. This helps everything run smoothly.

What Materials Are Commonly Used For Pulleys In Metal Lathes, And What Are The Advantages And Disadvantages Of Each?Pulleys in metal lathes are usually made from metal, plastic, or composite materials. Metal pulleys are strong and last a long time, but they can be heavy and expensive. Plastic pulleys are lighter and cheaper but might wear out faster. Composite materials combine the best of both worlds; they are strong and lighter than metal, but can be costly. Each material has its own benefits and downsides, so it’s good to choose the right one for your needs.

How Can Variations In Pulley Size And Configuration Impact The Torque And Speed Settings On A Tool Post Metal Lathe?The size and setup of pulleys can change how fast a metal lathe works. Bigger pulleys can make the lathe spin faster. Smaller pulleys can give more power, which is called torque. The way we arrange the pulleys also matters. When we change the pulleys, we change how the lathe cuts materials.

What Safety Precautions Should Be Taken When Working With Pulley Systems On Metal Lathes To Prevent Accidents And Injuries?When using pulley systems on metal lathes, always wear safety glasses to protect your eyes. Keep your hands and loose clothing away from moving parts to avoid getting caught. Make sure the area is clean and free of tools or debris. Check the pulleys and belts for any damage before you start. Always follow instructions carefully to stay safe.