Have you ever wondered how metal parts are shaped with such precision? It all starts with a tool post metal lathe quill. This amazing device helps craftsmen create everything from tiny gears to huge engine parts. Imagine watching a piece of metal slowly transform into a beautiful shape.

Many people do not realize the power of a lathe. With the right setup, you can make almost anything. A tool post metal lathe quill holds the cutting tool firmly in place. This means the tool can cut smoothly and accurately. Once you understand how it works, you can create different shapes and sizes.

For anyone who loves hands-on projects, using a lathe is like magic. Have you ever seen a perfectly round cylinder come out of a block of metal? This happens because of the clever design of the lathe and quill. It allows makers to bring their ideas to life.

In this article, we will explore the tool post metal lathe quill. We will look at its importance, how it works, and why it is a favorite among hobbyists and professionals alike. The world of metalworking awaits!

Essential Tool Post Metal Lathe Quill: Your Guide To Precision

Understanding the Tool Post Metal Lathe Quill

The tool post metal lathe quill is a key component for metalworking. It helps position tools accurately, ensuring precise cuts and smooth finishes. Ever wonder how professionals make such perfect shapes? The quill plays a vital role. It also allows quick tool changes, saving time and boosting productivity. Did you know that using the right quill can enhance your lathe’s performance? This simple part truly makes a big difference in any metalworking project!What is a Tool Post Metal Lathe Quill?

Definition and function of a quill in metal lathes. Importance of the quill in machining operations.A quill is a vital part of a metal lathe. It holds the cutting tool in place. This ensures the tool stays stable while working on the metal. Without the quill, the machining process would be messy and unsafe. Its function is to allow precise cuts. This precision leads to quality work and saves time. The quill’s role is essential in making sure each part is made correctly.

Why is a quill important in machining?

The quill’s importance in machining can’t be overstated. It keeps the cutting tool steady. This stability helps create accurate shapes and sizes. A well-functioning quill improves every project’s efficiency.

- It allows for easy tool changes.

- It reduces vibration during cutting.

- It enhances overall safety in the workspace.

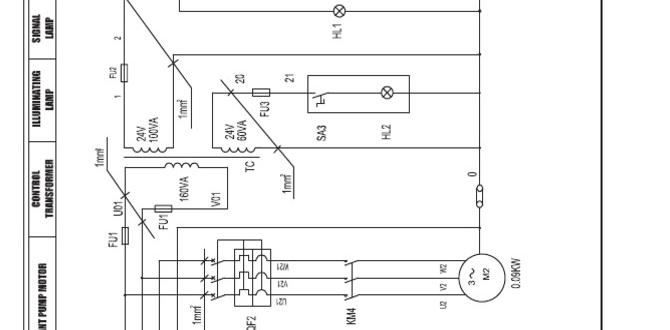

Components of the Tool Post Quill

Key parts that make up a quill. How each component contributes to its functionality.The quill in a tool post is like the heart of a metal lathe. It has several essential parts. First, there’s the quill housing, which holds everything snugly. Next up, we have the lead screw, that moves the quill up and down like a yo-yo. Don’t forget the clamping nut, which keeps the quill steady during operation. Each component works together to make sure cuts are smooth. Like a perfect dance team, they move in harmony!

| Component | Function |

|---|---|

| Quill Housing | Holds all parts together |

| Lead Screw | Moves quill up and down |

| Clamping Nut | Stabilizes the quill |

Choosing the Right Quill for Your Lathe

Factors to consider when selecting a quill. Compatibility with different lathe models.Choosing a quill for your lathe is important. You need to think about compatibility and smoothness of operation. First, check if the quill fits your lathe model. Too big or too small won’t work. Next, look for one that helps with precision. Quills also vary in length, so find one that meets your needs. A good quill can make your work easier and more accurate.

What should I consider when selecting a quill?

Look for compatibility and ease of use.Important Factors:

- Size and fit

- Material used

- Ease of installation

- Adjustment features

Each factor helps you work better with your lathe. Choosing wisely means better projects!

Installation and Adjustment of the Quill

Stepbystep guide to installing a tool post quill. Tips for proper adjustment to ensure precision.Installing a tool post quill is simple. Follow these steps for a great fit:

- First, clean the lathe area.

- Next, align the quill with the tool post.

- Tighten the screws gently.

- Finally, check its stability.

To adjust for precision:

- Keep it straight and level.

- Test with small cuts.

- Make small tweaks for perfect results.

A well-installed quill can improve your work quality!

How do I ensure the quill is precise?

To ensure precision, regularly check alignment and make minor adjustments as needed. Small changes can lead to big improvements in your work!

Common Issues with Tool Post Quills

Identification of typical problems and their causes. Solutions and maintenance practices to prevent issues.Tool post quills can face issues affecting performance. Common problems include wear and tear from use, misalignment, and debris accumulation. These lead to poor accuracy and can even damage the lathe. Regular checks and good cleaning can prevent these troubles. Simple solutions involve:

- Inspecting and aligning regularly.

- Lubricating moving parts frequently.

- Cleaning to remove chips and dust.

Taking care of your equipment keeps it running smoothly and extends its life. Remember, a little maintenance goes a long way!

What are common problems with tool post quills?

Common issues include wear, misalignment, and debris build-up. These problems can lead to reduced accuracy and possible damage.

How can I maintain my tool post quill?

- Check for wear and tear regularly.

- Align and adjust for optimal performance.

- Keep it clean from dust and chips.

Enhancing Precision with Tool Post Quills

Techniques to increase accuracy during machining. Recommended practices for optimal performance.Precision is crucial in machining. Here are some techniques to enhance accuracy with tool post quills:

- Always secure your workpiece tightly.

- Use sharp cutting tools to prevent vibration.

- Keep your machine clean for smooth operations.

For optimal performance, check your settings regularly. Make small adjustments as needed. This way, you can avoid mistakes and achieve great results. Remember, accuracy leads to quality!

What is the importance of using a tool post quill?

Using a tool post quill improves support and stability when cutting. It allows for precise movements that lead to better accuracy during machining.

Comparative Analysis: Manual vs. Powered Quills

Pros and cons of manual versus powered quill systems. Situations where one may be favored over the other.Both manual and powered quills have their pros and cons. Manual quills are simple and easy to use, making them good for small jobs. They are also less expensive. However, they can take more effort to control. Powered quills do the hard work for you. They are faster and can handle bigger tasks. But they are often pricier and need electricity. Choose manual when you want precision and cost-effectiveness. Go for powered when speed and muscle are key.

What are the advantages of each quill type?

Manual quills offer simplicity, while powered quills provide speed and ease of use.Here are some quick pros and cons:

- Manual Quills: Less expensive, easy to fix.

- Powered Quills: Faster work, reduces physical strain.

Future Trends in Tool Post Quill Technology

Innovations and advancements in quill design. Predictions for the future of lathe quills in machining industries.The world of tool post quills is changing fast. New designs are making them better and easier to use. Engineers are focusing on lightweight materials. This helps improve the efficiency of machining tasks. Also, smart technology is on the rise. It can help control the quill better during work. More automation may also reduce human error in the future. Here are some key trends:

- Advanced materials for strength and weight.

- Smart sensors for precise control.

- Improved designs for easier handling.

These innovations show a bright future for lathe quills in the machining industry.

What are the current advancements in lathe quills?

Recent advancements include the use of lightweight materials and smart sensors for precision.

Conclusion

In summary, a tool post metal lathe quill is essential for precise machining. It helps hold and adjust tools easily. Understanding its function improves your lathe skills. You can create better projects with practice. Explore more about lathe operations or find tutorials online to enhance your knowledge. Happy machining, and keep experimenting with your tools!FAQs

What Is The Primary Function Of A Quill In A Tool Post On A Metal Lathe?The quill is a part of the tool post on a metal lathe. Its main job is to hold and move the cutting tool. You can make the tool go up and down to cut metal. This helps us shape the metal pieces we are working on. It makes cutting easier and more precise.

How Does The Design Of A Quill Impact The Precision And Accuracy Of Machining Operations On A Lathe?The design of a quill helps keep the cutting tool steady. When the quill is strong, it reduces wiggling. This makes the cuts more precise, meaning they are cleaner and closer to what we want. A good quill design also helps with accuracy, so the machine works just like we expect it to. This helps us make better parts on the lathe.

What Materials Are Commonly Used To Manufacture Quills For Tool Posts In Metal Lathes, And Why?Quills for tool posts in metal lathes are usually made from steel or aluminum. Steel is strong and can handle heavy work. Aluminum is lighter and easier to move. We use these materials because they help make precise and safe cuts in metal.

How Can Users Maintain And Adjust The Quill In Their Metal Lathe To Ensure Optimal Performance?To keep the quill working well on your metal lathe, you should regularly clean it. Check for any dirt or chips and wipe them away. You can also check the settings to make sure they are right for your work. If the quill feels loose or tight, you might need to adjust some screws to fix it. Always remember to follow safety rules when working with the lathe!

What Are The Advantages Of Using A Hydraulic Quill Versus A Manual Quill In A Tool Post Setup?Using a hydraulic quill is easier than a manual quill. With a hydraulic quill, you just press a button, and it moves smoothly. You don’t have to twist or turn anything, which saves you time and effort. It lets you control the tool better, making your work more precise. Overall, a hydraulic quill makes it simpler and faster for you to get the job done!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Is The Primary Function Of A Quill In A Tool Post On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The quill is a part of the tool post on a metal lathe. Its main job is to hold and move the cutting tool. You can make the tool go up and down to cut metal. This helps us shape the metal pieces we are working on. It makes cutting easier and more precise.”}},{“@type”: “Question”,”name”: “How Does The Design Of A Quill Impact The Precision And Accuracy Of Machining Operations On A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The design of a quill helps keep the cutting tool steady. When the quill is strong, it reduces wiggling. This makes the cuts more precise, meaning they are cleaner and closer to what we want. A good quill design also helps with accuracy, so the machine works just like we expect it to. This helps us make better parts on the lathe.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used To Manufacture Quills For Tool Posts In Metal Lathes, And Why? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Quills for tool posts in metal lathes are usually made from steel or aluminum. Steel is strong and can handle heavy work. Aluminum is lighter and easier to move. We use these materials because they help make precise and safe cuts in metal.”}},{“@type”: “Question”,”name”: “How Can Users Maintain And Adjust The Quill In Their Metal Lathe To Ensure Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the quill working well on your metal lathe, you should regularly clean it. Check for any dirt or chips and wipe them away. You can also check the settings to make sure they are right for your work. If the quill feels loose or tight, you might need to adjust some screws to fix it. Always remember to follow safety rules when working with the lathe!”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Hydraulic Quill Versus A Manual Quill In A Tool Post Setup? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a hydraulic quill is easier than a manual quill. With a hydraulic quill, you just press a button, and it moves smoothly. You don’t have to twist or turn anything, which saves you time and effort. It lets you control the tool better, making your work more precise. Overall, a hydraulic quill makes it simpler and faster for you to get the job done!”}}]}