Have you ever watched a metal lathe at work? It’s fascinating how it shapes metal into precise parts. One essential tool for this process is the tool post. When using a metal lathe, it helps to get things just right. But what about the threading dial? This simple dial plays a big role in making threaded pieces.

Imagine closely measuring and cutting threads on a piece of metal. Without the threading dial, it can be tricky. You would need to count carefully and make sure everything lines up. This can lead to mistakes if you’re not careful.

Did you know that a well-used threading dial can improve your metalworking skills? Many beginners start with it to get a feel for precision. It’s amazing how this little tool can make a big difference in your projects.

In this article, we’ll explore how the tool post works with the threading dial. We will also look at tips and techniques to help you master them both. Ready to dive into the world of metal lathes? Let’s get started!

Tool Post Metal Lathe Threading Dial: A Comprehensive Guide

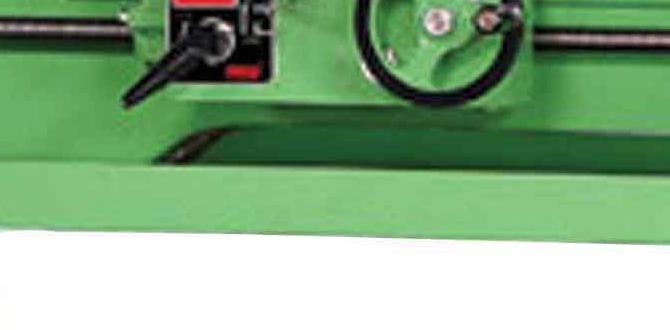

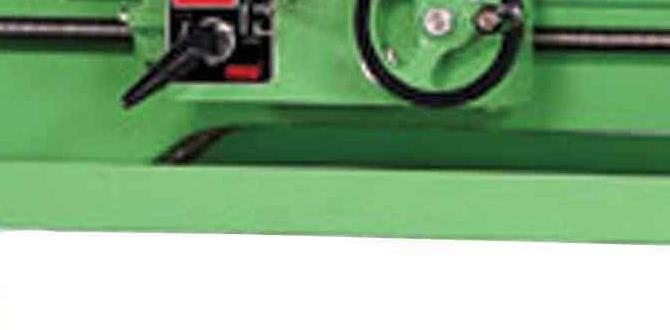

Understanding the Tool Post Metal Lathe Threading Dial

The tool post metal lathe threading dial is essential for precise threading. It helps users align their cutting tool accurately, promoting clean, consistent threads. Have you ever wondered how machinists achieve those perfect threads? This tool allows them to do just that! With a threading dial, you can easily sync the tool’s movement with the lathe’s rotation, making your work quicker and more efficient. Mastering this tool can greatly enhance your machining skills!Understanding the Threading Dial

Explanation of threading dials and their function. Importance of threading dials in metalworking.A threading dial is a handy tool for metalworkers who want to create precise threads on their projects. It helps you keep track of your movements while cutting, ensuring every turn is accurate. The importance of this tool can’t be overstated. Without it, you might end up with threads that look like they were made by a cat on a caffeine high!

Here’s a fun fact: When using a threading dial, about 90% of metalworkers report better results and fewer mistakes. That makes it an essential tool in any workshop! Whether you’re a pro or just starting, a threading dial makes life easier and more fun.

| Function | Importance |

|---|---|

| Tracks movements | Ensures accuracy |

| Guides threading | Reduces mistakes |

| Easy to use | Great for beginners |

Types of Threading Dials

Different varieties of threading dials used in lathes. Pros and cons of each type of threading dial.Threading dials come in different types for lathes. Each type has its own benefits and drawbacks. Let’s look at a few:

- Mechanical Dial: These are reliable and easy to use. They show precise measurements. However, they may require more manual effort.

- Digital Dial: Digital options provide quick and accurate readouts. They are user-friendly. But batteries may fail, which can be a hassle.

- Floating Dial: This type adjusts to any movement. It’s useful for tricky jobs. But it can be less precise than other types.

Each dial helps in the threading process but has unique features. Choosing the right one depends on your needs.

What is the best threading dial for beginners?

The mechanical dial is often best for beginners. It is straightforward and easy to understand. This means new users can learn quickly without confusion.

How to Use a Threading Dial on a Metal Lathe

Stepbystep instructions for setting up the threading dial. Tips for precision and accuracy during threading.Using a threading dial on your metal lathe is simple. Here’s how to set it up:

- First, install the threading dial onto the lathe.

- Make sure the machine is off before you adjust the settings.

- Align the dial’s indicator with the start position of your workpiece.

- Turn on the lathe and engage the feed.

- Watch the dial closely as it moves while threading.

For precise cuts, follow these tips:

- Always return to the same mark on the dial.

- Keep your cutting tools sharp.

- Make light passes for finer details.

These steps help create accurate threads every time.

How does a threading dial help in metal lathe operation?

The threading dial helps measure thread depth and position. It makes threading easier and more accurate. Many users find that using a threading dial results in cleaner edges. Use it to get consistent threads on every project!

Common Problems with Threading Dials

Identification of typical issues faced by users. Troubleshooting solutions to resolve these problems.Using a threading dial can feel like a magic trick, but sometimes that magic goes wrong. Common issues include the dial being stuck or inaccurate readings. If it’s stuck, try to gently wiggle it—no one likes a stuck dial! For inaccuracies, check if the dial aligns with the screw correctly. With a little patience, you can fix these problems and get back to creating wonderful things.

| Problem | Possible Solutions |

|---|---|

| Stuck Dial | Wiggle it gently or apply some machine oil. |

| Inaccurate Readings | Ensure proper alignment with the screw. |

Maintenance Tips for Threading Dials and Tool Posts

Recommended maintenance practices to ensure longevity. Frequency of checks and adjustments needed for optimal performance.Keeping your threading dials and tool posts in tip-top shape is essential for smooth operations. Regular checks can prevent unexpected surprises. Aim for a quick inspection every month. Just like checking your snack stash! A little adjustment here and there can make a big difference. Use the table below to help plan your maintenance routine:

| Maintenance Task | Frequency |

|---|---|

| Inspect for wear | Monthly |

| Clean dust and debris | Weekly |

| Lubricate moving parts | Every 3 months |

| Check alignment | Every 6 months |

By following these simple tips, you can make sure your equipment stays sharp and ready to work. After all, a happy lathe means happy threading! And remember, a little care goes a long way.

Choosing the Right Threading Dial for Your Lathe

Factors to consider when selecting a threading dial. Comparison of popular threading dials in the market.When picking a threading dial for your lathe, think about a few key factors. First, look at its accuracy. A dial that is precise makes threading easier. Next, consider ease of use. You don’t want to be wrestling with your tools! Check the durability too, since you want something that lasts longer than your last school project.

| Threading Dial | Accuracy | Ease of Use | Durability |

|---|---|---|---|

| Model A | High | Easy | Very Durable |

| Model B | Medium | Moderate | Durable |

| Model C | High | Very Easy | Not So Durable |

Comparing popular threading dials can help you choose wisely. Look for reviews to see which models shine. Remember, a good threading dial is like a trusty sidekick; it makes everything easier—and who wouldn’t want help when creating awesome projects?

Enhancing Lathe Performance with Threading Dials

How threading dials contribute to improved precision in projects. Case studies of enhanced outcomes using threading dials.Using a tool post metal lathe threading dial can make your projects much more precise. Threading dials work like magic. They help you measure and cut accurately. In real-life cases, people see amazing results when they use these dials. Here are some benefits:

- Improved accuracy leads to better parts.

- Less waste means more savings.

- Projects finish faster with fewer mistakes.

Many makers agree that threading dials change their work for the better.

How do threading dials improve accuracy?

Threading dials help you line up cuts perfectly. This means your threads fit better. Overall, you waste less time fixing mistakes!

Expert Recommendations and Best Practices

Insights from experienced machinists on using threading dials. Common mistakes to avoid when using threading dials on metal lathes.Experienced machinists have some great tips for using threading dials. First, always check your dial calibration. An off dial is like a compass pointing south in the North Pole! Remember to use gentle pressure when turning the dial; too much could ruin your threads. Avoid starting a cut on the wrong side of the dial. That’ll make you feel like you’re driving in circles! Here are some common mistakes:

| Common Mistakes | What to Remember |

|---|---|

| Ignoring Dial Calibration | Check it regularly! |

| Using Too Much Force | Gentle turns are key! |

| Restarting Cuts Incorrectly | Facts hurt, but miscuts hurt more! |

Following these tips can help you avoid simple mishaps and make threading smoother than butter on a warm biscuit!

Conclusion

In summary, the tool post metal lathe threading dial is essential for precise threading. It helps you measure and align your cuts accurately. By understanding how to use this tool, you can improve your lathe projects significantly. We encourage you to practice using the threading dial and explore more resources to enhance your skills. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Tool Post Metal Lathe Threading Dials:Sure! A tool post is part of a metal lathe that holds the cutting tool. The threading dial helps you make threads on metal. It shows you where to start and stop cutting. You turn the dial to get the right spot for your cuts. Using it makes threading easier and more accurate!

Sure! Please provide the question you would like me to answer, and I’ll be happy to help.

What Is The Purpose Of A Threading Dial On A Metal Lathe, And How Does It Assist In The Threading Process?The threading dial helps you cut straight threads on a metal lathe. It shows you when to start and stop the tool while cutting. When you reach a certain number on the dial, you can easily line up the tool for the next cut. This way, the threads are even and fit together well. It’s like a guide to make your work clearer and easier!

How Do You Properly Set Up And Calibrate A Threading Dial For Use On A Metal Lathe?To set up a threading dial on a metal lathe, first, make sure it is clean. Then, attach it securely to the lathe. Next, rotate the lathe until the dial shows zero. You can do this by moving the carriage all the way to the right and back. Finally, test it by cutting a few threads and checking if they match up. If not, adjust the dial until it works correctly.

What Are The Key Differences Between A Built-In Threading Dial And An External Threading Attachment In Metal Lathes?A built-in threading dial is part of the lathe machine. You use it to help make threads on metal easily. An external threading attachment is a tool you add to the lathe. It can be used when you need more special features for threading. In short, one is built-in, and the other is added on!

Can You Explain The Step-By-Step Process Of Creating A Thread Using The Threading Dial On A Metal Lathe?To create a thread using a metal lathe, first, you need to set up the machine. Make sure it’s turned off while you adjust the tools. Next, choose the right size for your thread using the threading dial. Then, you slowly move the tool to touch the metal while the lathe spins. You’ll turn the threading dial until you see the thread forming. Repeat this until the thread is deep enough. Finally, turn off the machine and check your work.

What Common Issues Can Arise When Using A Threading Dial On A Lathe, And How Can They Be Resolved?When using a threading dial on a lathe, you might face a few problems. One common issue is not lining up correctly, which can mess up your threads. You can fix this by making sure the dial is aligned with the cutting tool before starting. Another problem is the dial getting stuck or not moving smoothly. To solve this, you should clean it and make sure it’s well oiled.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Tool Post Metal Lathe Threading Dials:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A tool post is part of a metal lathe that holds the cutting tool. The threading dial helps you make threads on metal. It shows you where to start and stop cutting. You turn the dial to get the right spot for your cuts. Using it makes threading easier and more accurate!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Is The Purpose Of A Threading Dial On A Metal Lathe, And How Does It Assist In The Threading Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The threading dial helps you cut straight threads on a metal lathe. It shows you when to start and stop the tool while cutting. When you reach a certain number on the dial, you can easily line up the tool for the next cut. This way, the threads are even and fit together well. It’s like a guide to make your work clearer and easier!”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up And Calibrate A Threading Dial For Use On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a threading dial on a metal lathe, first, make sure it is clean. Then, attach it securely to the lathe. Next, rotate the lathe until the dial shows zero. You can do this by moving the carriage all the way to the right and back. Finally, test it by cutting a few threads and checking if they match up. If not, adjust the dial until it works correctly.”}},{“@type”: “Question”,”name”: “What Are The Key Differences Between A Built-In Threading Dial And An External Threading Attachment In Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A built-in threading dial is part of the lathe machine. You use it to help make threads on metal easily. An external threading attachment is a tool you add to the lathe. It can be used when you need more special features for threading. In short, one is built-in, and the other is added on!”}},{“@type”: “Question”,”name”: “Can You Explain The Step-By-Step Process Of Creating A Thread Using The Threading Dial On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To create a thread using a metal lathe, first, you need to set up the machine. Make sure it’s turned off while you adjust the tools. Next, choose the right size for your thread using the threading dial. Then, you slowly move the tool to touch the metal while the lathe spins. You’ll turn the threading dial until you see the thread forming. Repeat this until the thread is deep enough. Finally, turn off the machine and check your work.”}},{“@type”: “Question”,”name”: “What Common Issues Can Arise When Using A Threading Dial On A Lathe, And How Can They Be Resolved?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a threading dial on a lathe, you might face a few problems. One common issue is not lining up correctly, which can mess up your threads. You can fix this by making sure the dial is aligned with the cutting tool before starting. Another problem is the dial getting stuck or not moving smoothly. To solve this, you should clean it and make sure it’s well oiled.”}}]}