Quick Summary:

Mastering lathe tools is key for beginners! Discover the essential cutting tools, measuring instruments, and safety gear that unlock precision and creativity on your lathe. This guide breaks down every need-to-know tool for success.

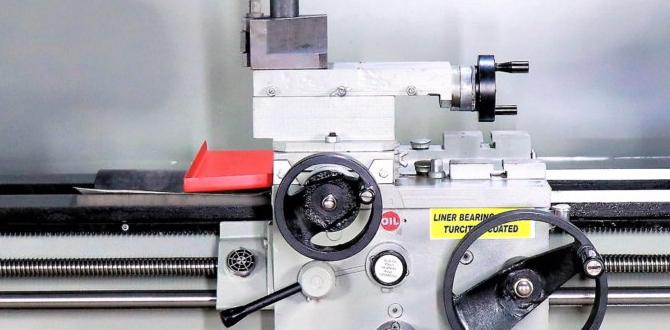

Welcome to Lathe Hub! If you ever look at a lathe and feel a bit overwhelmed by all the different attachments, you’re not alone. It’s like having a toolbox full of potential, but not knowing which wrench to grab first. That’s where understanding your essential tools comes in. Getting the right setup makes a huge difference, turning frustration into fantastic projects. We’re going to break down the must-have tools for your lathe, making sure you feel confident and ready to create.

The Heart of the Matter: Essential Lathe Cutting Tools

The cutting tools are what actually shape your workpiece on the lathe. Think of them as the sculptor’s chisels for metal or wood. For beginners, focusing on a few versatile types is more important than having a huge collection right away.

Turning Tools: Getting the Basic Shape

These are your go-to tools for removing material and creating the basic diameter of your part. They come in various shapes and sizes, but a few will cover most of your early projects.

- Roughing Gouge: This is a hearty tool with a scooped shape, perfect for quickly removing large amounts of material to get your workpiece close to the desired size. It’s great for shaping the initial rough form.

- Spindle Gouge: A more refined version of the gouge, this tool is excellent for creating smooth curves, coves, and beads on spindles (long, thin pieces). It offers more control than a roughing gouge.

- Parting Tool (or Parting Off Tool): This is a thin, narrow blade used to cut completely through a workpiece, separating it from the stock. It’s also handy for creating narrow grooves.

- Scrapers: While often used for finishing, flat scrapers can also be used for heavy-duty material removal on certain shapes. They scrape rather than cut, leaving a slightly rougher finish than a proper cutting tool.

Threading Tools: For Those Perfect Threads

If you need to create screw threads, a specific tool is required. These are designed to cut the precise V-shaped or square profile of a thread.

- Threading Tool (or Threading Chisel): This tool has a specific profile ground to match the desired thread form (e.g., V-thread, Acme thread). It’s used to cut threads in a series of passes. Accurate depth setting is crucial here.

Knurling Tool: Adding Grip

Knurling creates a diamond-shaped pattern on the surface of a workpiece, usually for improved grip or aesthetics. It doesn’t remove material but rather deforms it.

- Knurling Tool: This tool holds two hardened wheels with a raised pattern. As it’s pressed into the workpiece, the pattern is impressed onto the surface.

Measuring and Marking Tools: Precision is Key

You can’t make it right if you don’t measure it right! These tools ensure your dimensions are accurate and your cuts are where you want them.

Calipers: Precise Measurements

Calipers are vital for both measuring the diameter of your workpiece and accurately transferring measurements to it.

- Outside Calipers: Used to measure the outside diameter of a workpiece. You set them by feel or against a measuring scale, then measure the caliper jaws with a ruler or micrometer.

- Inside Calipers: Used to measure the internal diameter of holes. Similar to outside calipers, they are set by feel and then measured.

- Vernier Calipers: These offer a direct reading of measurements and are very versatile for both inside and outside measurements, as well as depth. A digital version is often easier for beginners to read.

Micrometers: Ultimate Accuracy

For the highest level of precision, micrometers are indispensable. They offer finer resolution than calipers.

- Outside Micrometer: Used for highly accurate external diameter measurements. Most home workshop lathes will benefit from a standard range, like 0-1 inch or 0-25mm.

- Inside Micrometer: For precise internal measurements.

Rulers and Tapes: Basic but Essential

Don’t underestimate the simple ruler! It’s your first line of defense for marking out lengths and rough measurements.

- Steel Rule: A sturdy ruler marked in inches, millimeters, or both.

- Tape Measure: Useful for longer stock or setting up larger operations.

Marking Tools: Where to Cut

Before you cut, you need to mark your lines clearly.

- Center Punch: Creates a small indent to guide your drill bit or parting tool, preventing it from wandering.

- Scribe: A sharp-pointed tool used to scratch lines onto the workpiece. Essential for marking cut-off points or diameters.

- Marking Gauge: Useful for marking lines parallel to an edge or face.

Chucks and Faceplates: Holding Your Workpiece Securely

This is how you attach your material to the lathe spindle. A secure hold is crucial for safety and accuracy.

Scroll Chucks: The All-Rounder

These are the most common and versatile chucks for metal and wood lathes. They have jaws that move in and out simultaneously, gripped by a scroll. They can hold both external and internal diameters.

- Three-Jaw (3-Jaw) Scroll Chuck: The workhorse for most beginners. It’s self-centering, meaning all jaws move together to grip the workpiece precisely in the center. Ideal for round stock and common operations.

- Four-Jaw (4-Jaw) Independent Chuck: Each jaw moves independently. This is more complex to center but allows you to grip irregularly shaped objects or off-center work.

Faceplates: For Flat, Large Work

A faceplate is a flat disc that screws onto the lathe spindle. Your workpiece is then bolted or clamped to the faceplate. They are ideal for larger, flatter pieces that might not fit in a chuck.

Collets: Precision for Smaller Stock

Collets are specialized sleeves that grip small diameter stock very accurately within a collet chuck or headstock. They offer excellent concentricity but are typically for specific size ranges.

Lathe Accessories: Enhancing Functionality and Safety

Beyond the core tools, these accessories make your lathe experience safer, more efficient, and more capable.

Centers: Supporting Long Work

For long, slender workpieces, especially in woodturning, support is essential. Centers are mounted in the headstock and tailstock to hold the work.

- Live Center: Rotates with the workpiece, reducing friction. Mounted in the tailstock.

- Dead Center: A stationary hardened point. Often used in the headstock for certain operations, but requires lubrication to prevent the workpiece from spinning against it and damaging it.

- Revolving Live Center: The most popular type for tailstock support, as it spins with the workpiece.

Tool Rests: Stable Support

Crucial for woodturning, tool rests provide a stationary surface for your gouges and chisels to pivot on. Proper positioning is key to safe and effective turning.

- Straight Tool Rest: For general turning.

- Curved Tool Rest: Useful for hollowing out bowls or doing internal work.

Tailstock Accessories: Expanding Capabilities

The tailstock isn’t just for support; it can also hold tools.

- Drill Chuck: Mounts in the tailstock to hold drill bits, reamers, or countersinks. This allows you to drill holes precisely down the center of your workpiece.

- Morse Taper Adapters: Many lathe centers, drill chucks, and tool shanks have Morse tapers (a standard conical fitting). You’ll need matching sleeves to fit them into your headstock or tailstock spindles.

Safety First: Essential Lathe Safety Gear

Machining can be dangerous if proper safety precautions aren’t taken. Never compromise on safety gear!

Eye Protection: Non-Negotiable

Flying chips are a serious hazard. Always wear appropriate eye protection.

- Safety Glasses: Look for glasses that wrap around your face and meet ANSI Z87.1 standards.

- Face Shield: For metalworking, a full face shield worn over safety glasses offers superior protection against flying chips.

Hearing Protection: Save Your Ears

Lathes, especially when working with metal, can be noisy. Prolonged exposure can lead to hearing loss.

- Ear Plugs: Disposable or reusable.

- Ear Muffs: Offer a higher level of protection, especially in very noisy environments.

Respiratory Protection: Dust and Fumes

When working with certain materials, especially MDF, plastics, or during sanding, fine dust or fumes can be an issue.

- Dust Mask: A simple mask for basic dust protection.

- Respirator: For finer dust particles or specific fumes, a respirator with appropriate cartridges offers better protection. Consult the material safety data sheet (MSDS) for your workpiece material if unsure.

Gloves: Use With Caution

This is a point of debate in machining. Never wear loose gloves when operating a lathe, especially with rotating metal. They can get caught and wrap your hand around the workpiece with catastrophic results. However, for handling rough stock or during deburring, sturdy work gloves can be useful.

For woodturning, many pros will wear leather gloves for extra grip and protection of the hands, but understanding the risks and keeping them free of entanglement is paramount. Always prioritize keeping your hands clear of the rotating workpiece.

Apparel: Keep it Tidy

- No Loose Clothing: Roll up sleeves, tuck in shirts, and wear sturdy, closed-toe shoes.

- Tie Back Long Hair: Keep hair away from the machine.

Lathe Tool Sharpening: Maintaining Your Cutting Edge

Dull tools don’t cut well, they tear, and they are more dangerous. Learning to sharpen your tools will save you money and frustration. Every machinist and woodturner needs a sharpening system.

Methods for Sharpening

- Grinding Wheels: Often found on bench grinders. A slow-speed grinder with a specialized grinding wheel for lathe tools is ideal. Always use water or a coolant to prevent overheating and losing the tool’s temper. Many beginners start with a standard bench grinder, but care must be taken not to overheat the steel.

- Sharpening Stones: Water stones, oil stones, or diamond plates. These are excellent for achieving a fine, sharp edge. They require a technique to maintain the correct bevel angle.

- Honing Guides: These devices help you maintain a consistent angle when sharpening on stones, which is crucial for beginners to achieve repeatable results.

For metal cutting tools, especially HSS (High-Speed Steel), a fine-grit grinding wheel and then a honing stone or diamond file is common. For woodturning tools, water stones are very popular for achieving a razor-sharp edge that cuts cleanly without tearing.

A good rule of thumb is to sharpen your tools frequently. A quick touch-up on the stone is much easier than trying to re-establish a decent edge on a severely dulled tool.

Choosing the Right Tools for Your Lathe: A Practical Guide

So, you’ve got the basics. How do you select the right tools for your specific lathe and projects? It depends on what you’re turning (metal or wood) and the size of your machine.

Metal Lathe Essentials for Beginners

For a typical beginner metal lathe (like an 8×12 or 10×20 size), you’ll want a versatile set of HSS (High-Speed Steel) or carbide-tipped lathe bits.

Wood Lathe Essentials for Beginners

Wood lathes often come with a couple of basic chisels. Expanding your collection with a few key woodturning gouges and scrapers is the way to go.

The United States National Tooling & Machining Association (NTMA) provides valuable resources on tooling and machining practices, which can offer insights into industry standards and best practices.

Here’s a general breakdown of what to look for:

| Lathe Type | Essential Cutting Tools | Essential Holding Tools | Essential Measuring Tools |

|---|---|---|---|

| Metal Lathe (Beginner) | Set of HSS or Carbide Turning Tools (e.g., Right/Left Hand Cutoff, Round Nose, Facing), Parting Tool, Threading Tool (if needed) | 3-Jaw Scroll Chuck (usually comes with lathe), Faceplate (optional for larger work) | Vernier Calipers (digital recommended), Outside Micrometer (0-1″), Steel Rule, Center Punch, Scribe |

| Wood Lathe (Beginner) | Roughing Gouge, Spindle Gouge, Scrapers (Round Nose, Flat), Parting Tool (optional) | 3-Jaw Scroll Chuck (highly recommended), Faceplate (essential for bowls) | Tape Measure, Calipers (for joint fitting), Pencil/Marker |

Carbide vs. HSS for Metal Lathes

It’s worth understanding the difference:

- High-Speed Steel (HSS): More forgiving, easier to sharpen, and less prone to chipping if you make a mistake. It’s also more affordable. Ideal for beginners learning the feel of cutting.

- Carbide: Much harder and can cut at higher speeds and depths, leading to a better surface finish. However, it’s brittle and will chip if subjected to shock or used incorrectly. Carbide inserts are common (they fit into tool holders) and are replaced when worn.

For most beginners on smaller metal lathes, a good set of HSS tools is often recommended to start. You can then add carbide inserts as you gain experience.

Frequently Asked Questions (FAQ)

What are the most important tools for a beginner metal lathe?

For a beginner metal lathe, the most important tools are a versatile set of turning tools (like HSS bits for roughing, facing, and parting), a good quality 3-jaw chuck, and accurate measuring tools like digital calipers and a micrometer. Don’t forget essential safety gear: glasses and hearing protection.

Do I need a specific chuck for woodturning?

Yes, while some wood lathes come with a simple faceplate, a 3-jaw scroll chuck is highly recommended for woodturning beginners. It makes holding smaller spindles and doing general turning much easier and more secure than just using a faceplate or basic spur drive.

How often should I sharpen my lathe tools?

Sharpening frequency depends on the material being cut and how much you’re using the tool. For metalworking, touch up with a honing stone after each significant session. For woodturning, sharpen when the tool starts to “grab” or burnish instead of cutting cleanly. It’s always better to slightly over-sharpen than to work with a dull tool.

What is the difference between a live center and a dead center?

A live center rotates with the workpiece, reducing friction and heat, making it ideal for supporting longer pieces on the tailstock. A dead center is stationary; the workpiece spins against it. This requires lubrication to prevent galling and is typically used in the headstock for facing operations or when a chuck isn’t used. For beginners, a revolving live center is usually the best choice.

Why is a center punch so important for metal lathe work?

A center punch creates a small dimple on the workpiece. This dimple acts as a guide for drill bits and parting tools, preventing them from “walking” or drifting off the intended center point when you start cutting or drilling. It ensures accuracy right from the start.

Can I use regular wrenches to tighten chuck jaws?

Most scroll chucks use a specific chuck key. Always use the correct key that fits snugly. Using the wrong tool or a worn-out key can damage the chuck jaws or mechanism, or not tighten it properly, leading to a potentially dangerous situation where the workpiece could slip.

Conclusion: Building Your Lathe Arsenal

Starting out with a lathe can feel like stepping into a world of intricate tools and techniques. But by focusing on the essentials – reliable cutting tools, precise measuring instruments, secure workholding, and paramount safety gear – you build a solid foundation. Each tool serves a purpose, from the roughing gouge that quickly shapes your stock to the fine micrometer that ensures your final dimensions are perfect.

Remember, your lathe is a powerful tool for creativity. It’s about transforming raw material into something functional or beautiful. As you