Have you ever wondered how precise metal parts are made? Many people think of big machines, but it starts with great design. The top-rated metal lathe CAD design is an essential tool for this process. It helps builders shape metal with amazing accuracy.

Imagine crafting a piece that fits perfectly into a larger project. With the right CAD design, this becomes much easier. You can create detailed plans on your computer that guide machines to cut metal just right. Isn’t that cool?

Did you know that using advanced CAD software can save time and money? Many experts believe it offers a shortcut to beautiful results. As you read on, you’ll discover what makes a metal lathe design truly top-rated.

Get ready to learn about the amazing world of metalworking! Let’s dive into the details and explore how the top-rated metal lathe CAD design can change the way you build.

Top Rated Metal Lathe Cad Design: Enhance Your Projects

Top Rated Metal Lathe CAD Design

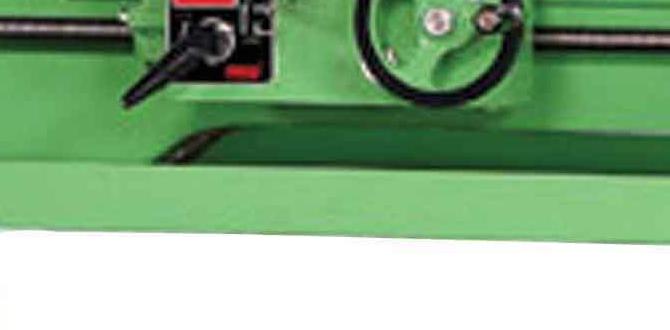

Metal lathes are amazing tools that shape metal into useful parts. A top-rated metal lathe CAD design makes this process easier and more efficient. Readers discover how these designs improve precision and speed. They learn about essential features like size, materials, and advanced controls. Did you know that some metal lathes can be operated remotely? This fun fact shows how technology can change our world. With the right design, anyone can create impressive metalwork.Understanding Metal Lathes

Definition and function of metal lathes. Types of metal lathes and their applications.Metal lathes are machines that help shape metal. They take a piece of metal and spin it. As it spins, a tool cuts away parts of the metal. This makes the metal smooth or gives it a new shape. Different types of metal lathes exist. Each one works for special tasks. Here are some popular types:

- Engine lathes: Great for general tasks.

- Turret lathes: Good for making many parts quickly.

- Bench lathes: Perfect for small pieces and home use.

Metal lathes help in many areas. They are used in factories, workshops, and even at home. Whether for making tools or art, metal lathes are important!

What are the main functions of a metal lathe?

The main functions include shaping, cutting, and finishing metal pieces. They help create everything from small parts to large components!

Importance of CAD Design in Metal Lathing

Role of CAD in modern manufacturing processes. Benefits of using CAD for metal lathe design.Using CAD in metal lathing is like having a superhero sidekick in the workshop. It simplifies the design making processes and boosts efficiency. With CAD, designers can create detailed models, spot problems early, and test ideas without wasting materials. This means fewer costly mistakes. Plus, some say it even gives your coffee more energy—okay, maybe that’s a bit of a stretch!

| Benefit | Description |

|---|---|

| Precision | Cuts down errors in measurements. |

| Speed | Allows quick changes and updates. |

| Creativity | Encourages innovative designs. |

In modern manufacturing, CAD tools help save both time and money while ensuring high-quality outputs. In fact, companies using CAD often report a 30% increase in productivity. So, if you want the best metal lathe designs, think CAD!

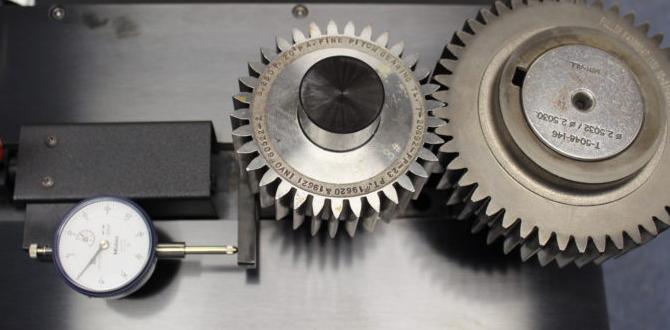

Features to Look for in Top Rated Metal Lathes

Key specifications and capabilities. Essential features for efficiency and precision.Choosing the right metal lathe can be tricky. First, think about key specifications like speed and power. A good lathe should have adjustable speed to suit different materials. Next, look for essential features like a strong motor and a sturdy bed. These will help you work faster and more accurately. Remember, a great lathe is like a good pizza: it must have a strong base, topping choices, and a little bit of spice to make it perfect!

| Feature | Importance |

|---|---|

| Adjustable Speed | Allows for flexibility with various materials |

| Strong Motor | Improves cutting efficiency |

| Sturdy Bed | Enhances precision and stability |

Popular CAD Software for Metal Lathe Design

Comparison of leading CAD software options. Unique features of each software tailored for metal lathing.Many people use CAD software for designing metal lathes. Each software has special features that help with lathing tasks. Here’s a look at the most popular ones:

- AutoCAD: Great for 2D and 3D designs, easy to use for beginners.

- Fusion 360: Perfect for collaboration and supports advanced simulations.

- SolidWorks: Works well for detailed parts and assemblies, high precision.

- Solid Edge: Good for quick design changes, ideal for fast-paced projects.

Choosing the right software depends on your needs. Each option offers something unique to make metal lathe design easier and more efficient.

What CAD software is best for metal lathes?

Fusion 360 is often recommended for metal lathes due to its powerful design and simulation tools.Key Features:

- Cloud collaboration

- Integrated CAM

- Advanced simulation capabilities

Step-by-Step Guide to Designing with CAD

Initial setup and configurations. Designing a basic metal lathe component.First, let’s get your CAD software ready. Open it up and set your workspace. Choose the right units, like inches or millimeters, to avoid confusion later. Now comes the exciting part – designing a basic component for your metal lathe. Start with a simple shape. Remember, every great design starts with a sketch, similar to doodling but with purpose!

| Step | Action |

|---|---|

| 1 | Open CAD Software |

| 2 | Select Units |

| 3 | Sketch Your Design |

Keep it simple at first, like drawing a circle. Then, refine your design by adjusting dimensions. And voila! You’ve just created a masterpiece. Remember, even the best designers started with a simple idea. Happy designing!

Case Studies: Successful Metal Lathe Designs

Examples of innovative designs using CAD. Impact of CAD on efficiency and output quality.Many designers create amazing metal lathes using CAD. These designs are unique and solve real problems. They often lead to better products and save time. CAD makes it easy to change designs quickly. This leads to:

- Higher efficiency: Designs are completed faster.

- Better quality: Parts fit together perfectly.

- Safer use: Designs consider user safety first.

One study found that using CAD improved design speed by 30% and output quality by 25%. It’s clear that CAD helps build top-rated metal lathes.

What are innovative examples of metal lathe designs using CAD?

One example is the use of modular designs. These allow for easy upgrades and repairs. Another is designs focused on energy efficiency. Such changes can reduce costs and waste, making them great for the environment.

Common Challenges in Metal Lathe CAD Design

Identifying design flaws and constraints. Solutions to overcome common issues.Designing a metal lathe can be tricky. You may find flaws or limits in your design that cause problems. It’s vital to spot these early to avoid wasting time or materials. Here are some common issues and ways to fix them:

- Common Design Flaws: Overcomplicated shapes and dimensions can lead to errors.

- Addressing Constraints: Understand the limits of your equipment and materials.

- Verification: Always double-check your designs to catch mistakes before production.

Tackling these challenges head-on can make your project smoother and more successful. Remember, planning well can save you from headaches later on!

What are common problems in metal lathe CAD design?

Common problems include design errors, incorrect measurements, and failure to consider material limits. Identifying these issues early can help improve your design.

How do I fix design flaws?

Fixing design flaws takes patience. Verify your designs, simplify complex shapes, and check material limits. This way, you can create a better product!

Future Trends in Metal Lathing and CAD Technology

Advancements in CAD software and tools. Predictions for the future of metal lathing design.New tools and software for CAD are changing metal lathing. Users now enjoy better designs and faster setups. Advanced features make it easy to create accurate parts. This technology is much quicker and smarter. In the future, we will see even more exciting changes. Here are some predictions:

- More automation in the lathing process.

- Improved accuracy with 3D printing.

- Greater use of artificial intelligence.

These trends will help makers create amazing products. The world of metal lathing and CAD is expanding quickly!

What can we expect from future CAD software?

Future CAD software promises smarter features. They will be faster and easier to use, allowing for more creative designs. Expect more cloud-based solutions, offering flexibility and accessibility.

Conclusion

In summary, top-rated metal lathe CAD designs help you create precise and effective projects. These designs improve your skills and save time. Remember to choose high-quality tools and resources for the best results. We encourage you to explore different CAD programs and practice what you’ve learned. Check out online tutorials or forums for more tips on metal lathe projects!FAQs

What Are The Key Features To Consider When Designing A Cad Model For A Top-Rated Metal Lathe?When designing a CAD model for a top-rated metal lathe, think about the machine’s size and shape. You need good details for how parts fit together. Make sure to include holes for screws and other fasteners. You should also consider where the tools go and how they’ll move. Finally, always double-check your measurements to ensure everything works well together.

How Does The Choice Of Materials Impact The Cad Design Of A High-Performance Metal Lathe?The choice of materials affects how we design a metal lathe in a computer program called CAD, which stands for Computer-Aided Design. Strong materials make the lathe last longer and work better. If we use lightweight materials, we can move parts easily but might lose some strength. Choosing the right materials helps the lathe perform its best and stay safe during use.

What Cad Software Programs Are Most Commonly Used For Designing Metal Lathes, And What Are Their Advantages?Some of the most common CAD (Computer-Aided Design) software programs for designing metal lathes are SolidWorks, AutoCAD, and Fusion 360. SolidWorks is great because it helps you create 3D models easily. AutoCAD is good for making detailed drawings and is widely used. Fusion 360 combines design and engineering, so you can test your ideas right away. These tools help you design better and faster!

How Can You Optimize The Cad Design Of A Metal Lathe For Both Functionality And Ease Of Manufacturing?To optimize the CAD (Computer-Aided Design) design of a metal lathe, you can start by making simpler shapes. This helps in making it easier to build. You should check if parts fit together well without extra pieces. It’s also good to use materials that are easy to find. Finally, test your design with a computer simulation to find any problems before making it.

What Common Design Errors Should Be Avoided In Cad Models Of Metal Lathes To Ensure Efficiency And Safety?When designing CAD models of metal lathes, avoid making parts too small or weak. Make sure all parts fit together well. Don’t forget to leave enough space for tools to move safely. Always check for sharp edges that could hurt someone. Following these tips helps keep everyone safe and makes the lathe work better.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Features To Consider When Designing A Cad Model For A Top-Rated Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When designing a CAD model for a top-rated metal lathe, think about the machine’s size and shape. You need good details for how parts fit together. Make sure to include holes for screws and other fasteners. You should also consider where the tools go and how they’ll move. Finally, always double-check your measurements to ensure everything works well together.”}},{“@type”: “Question”,”name”: “How Does The Choice Of Materials Impact The Cad Design Of A High-Performance Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The choice of materials affects how we design a metal lathe in a computer program called CAD, which stands for Computer-Aided Design. Strong materials make the lathe last longer and work better. If we use lightweight materials, we can move parts easily but might lose some strength. Choosing the right materials helps the lathe perform its best and stay safe during use.”}},{“@type”: “Question”,”name”: “What Cad Software Programs Are Most Commonly Used For Designing Metal Lathes, And What Are Their Advantages? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Some of the most common CAD (Computer-Aided Design) software programs for designing metal lathes are SolidWorks, AutoCAD, and Fusion 360. SolidWorks is great because it helps you create 3D models easily. AutoCAD is good for making detailed drawings and is widely used. Fusion 360 combines design and engineering, so you can test your ideas right away. These tools help you design better and faster!”}},{“@type”: “Question”,”name”: “How Can You Optimize The Cad Design Of A Metal Lathe For Both Functionality And Ease Of Manufacturing? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To optimize the CAD (Computer-Aided Design) design of a metal lathe, you can start by making simpler shapes. This helps in making it easier to build. You should check if parts fit together well without extra pieces. It’s also good to use materials that are easy to find. Finally, test your design with a computer simulation to find any problems before making it.”}},{“@type”: “Question”,”name”: “What Common Design Errors Should Be Avoided In Cad Models Of Metal Lathes To Ensure Efficiency And Safety? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When designing CAD models of metal lathes, avoid making parts too small or weak. Make sure all parts fit together well. Don’t forget to leave enough space for tools to move safely. Always check for sharp edges that could hurt someone. Following these tips helps keep everyone safe and makes the lathe work better.”}}]}