Have you ever looked at a metal lathe and thought, “How can I make this better?” If so, you’re not alone. Many hobbyists and professionals want to upgrade their machines. A top-rated metal lathe CNC retrofit might be just what you need. It can transform an ordinary lathe into a high-tech marvel.

Imagine working on a project and needing precision. A CNC retrofit can help you achieve that. You can create intricate designs with ease. Did you know some of the best retrofits can even improve your lathe’s speed? This means you’ll get more done in less time.

Have you ever wished for smoother cuts or better accuracy? Many users rave about the results after upgrading. They find it easier to tackle complex projects. It’s almost like having a brand-new machine! Following this article, you will learn how to choose the best options for your needs.

So, are you ready to discover the world of CNC retrofits? Let’s dive in and find out how the top-rated metal lathe CNC retrofit can change your workshop experience for the better!

Top Rated Metal Lathe Cnc Retrofit Options For Upgrade

Top Rated Metal Lathe CNC Retrofit

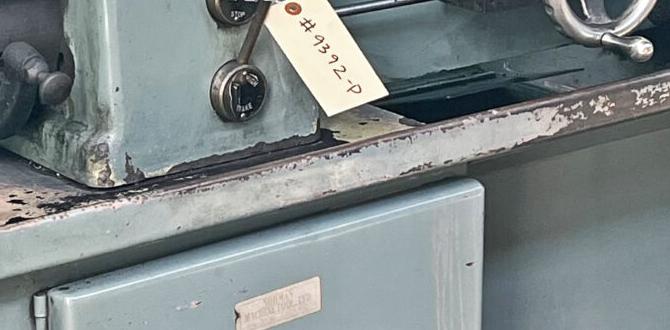

Imagine transforming your old metal lathe into a high-tech CNC machine. A top rated metal lathe CNC retrofit can do just that. These upgrades offer precision and efficiency, helping hobbyists and professionals alike make better parts. With various options available, you can find a retrofit that fits your needs and budget. Did you know that retrofitting can save you money compared to buying new? Explore the possibilities of upgrading your machine for remarkable results!Understanding CNC Retrofitting

Definition of CNC retrofitting. Benefits of retrofitting a metal lathe.CNC retrofitting is like giving your old metal lathe a new pair of running shoes. It updates the machine with new technology for better performance. This means you can make more accurate parts without the hiccups of the past. Think of it as upgrading from a flip phone to a smartphone—suddenly, everything is quicker and cooler! The benefits include increased precision, improved efficiency, and cost savings. It’s a win-win situation!

| Benefits | Details |

|---|---|

| Increased Precision | Get perfect parts every time! |

| Improved Efficiency | Spend less time fixing and more time creating! |

| Cost Savings | Save money by extending machine life! |

Criteria for Selecting the Best CNC Retrofit Kits

Key features to look for in a kit. Comparison of different CNC control systems.Selecting the right CNC retrofit kit can feel like picking a favorite ice cream flavor—so many tasty options! Focus on key features like ease of installation, compatibility with your existing equipment, and good customer support. Don’t forget to compare different CNC control systems too; some may offer fancy features while others keep it simple. Check this out:

| Control System | Features | Price |

|---|---|---|

| System A | Easy setup, user-friendly | $299 |

| System B | Advanced features, great support | $499 |

| System C | Basic, cost-effective | $199 |

With these criteria in mind, you’ll pick the best kit faster than a kid chasing an ice cream truck!

Top Rated CNC Retrofit Kits for Metal Lathes

Product reviews of toprated kits. Pros and cons of each retrofit kit.When it comes to upgrading your metal lathe, choosing the right CNC retrofit kit can feel like picking a favorite candy. Here’s a peek at the top-rated kits that can boost your machine’s skills! CNC Fusion Kit is popular for its ease of use but may lack power for heavy jobs. Convert My Old CNC shines with accuracy but is a bit tricky to set up. Check out the comparison table below!

| Kit Name | Pros | Cons |

|---|---|---|

| CNC Fusion Kit | Easy installation | Not powerful for heavy jobs |

| Convert My Old CNC | Very accurate | Tricky setup |

Upgrade wisely, so your lathe can do its happy dance every time you start it up!

Installation Process of CNC Retrofit Kits

Stepbystep installation guide. Common challenges and solutions during installation.Installing a CNC retrofit kit can be a fun project! Here’s how to do it step by step:

- First, gather all your tools and the retrofit kit.

- Next, unplug your machine for safety.

- Then, remove old parts carefully.

- Install the new components according to the manual.

- Lastly, connect everything and test it out!

Some challenges may arise, like aligning parts or software issues. If you face alignment problems, double-check measurements. For software hiccups, ensure you follow the setup guide closely. Study your machine to make adjustments as needed.

What are common issues with CNC retrofit kits?

Common issues include alignment problems and software glitches. Both can slow down your project. Use your manual to troubleshoot. Patience is key during this exciting upgrade!

Cost Analysis of CNC Retrofitting

Breakdown of expenses involved. Longterm savings versus initial investment.CNC retrofitting can be expensive but worth it. Breaking down costs helps understand the value. You’ll need money for parts, tools, and labor. Here’s a quick list of expenses:

- Initial parts like motors and sensors

- Software for controlling the machine

- Labor for installation and setup

The good news? Long-term savings can offset the high starting cost. Reduced energy use and fewer mistakes lead to fewer repairs. Smart spending now means more money later!

What are the long-term benefits of CNC retrofitting?

The long-term benefits include improved precision, increased speed, and lower maintenance costs. These factors save time and money over time.

Key factors in cost analysis:

- Improved productivity

- Less waste of materials

- Longer machine lifespan

Real-world Applications and Case Studies

Success stories from manufacturers. Industries benefiting from CNC retrofitting.Many manufacturers have seen great success by retrofitting their metal lathes to CNC systems. This upgrade helps them work faster and more accurately. One manufacturer, XYZ Corp., reported a 30% rise in productivity after making the switch. Industries like automotive and aerospace especially benefit from this tech. They can produce complex parts without losing their sanity or their tools!

| Industry | Benefit |

|---|---|

| Automotive | Faster production |

| Aerospace | Higher precision |

| Medical Devices | Quality assurance |

CNC retrofitting has truly become a game-changer, making it easier for these sectors to keep up with demand while maintaining quality. Remember, less time wasted means more time for coffee breaks!

Maintenance and Support for CNC Retrofits

Importance of regular maintenance. Resources for technical support and troubleshooting.Keeping your CNC retrofit in top shape is like brushing your teeth—important to avoid bigger problems! Regular check-ups prevent breakdowns and keep everything running smoothly. Look for clogs, loose wires, and dust bunnies hiding in corners! If things go wrong, don’t panic! There are plenty of technical support options available. Websites, forums, and even your neighbor who knows a thing or two about machines can help.

| Resources for Support | Contact Information |

|---|---|

| Online Forums | www.cncsupport.com |

| Technical Support Hotline | (555) 123-4567 |

| Local Workshops | Check community centers |

Future Trends in CNC Retrofitting

Emerging technologies in CNC retrofitting. Predictions for the future of metal lathes and CNC technology.New tools and ideas are changing how we fix CNC machines. Many exciting technologies are on the horizon, like smart sensors. These can help machines work better and save energy. Predictions show that metal lathes will get faster and more precise. Companies might even use artificial intelligence to help with designs. Below are some key trends to watch:

- More automation in machine setups.

- Better user interfaces for easier control.

- Integration with cloud technology for data sharing.

How will CNC retrofitting improve technology?

The future of CNC retrofitting looks bright. With new advancements, machines can become more efficient and smarter. This means better products and happier workers.

Conclusion

In summary, a top-rated metal lathe CNC retrofit can transform older machines into modern powerhouses. You gain precision and efficiency, making your projects easier. Always research and read reviews to choose the best retrofit for your needs. Dive deeper into online guides and forums for tips, so you can enhance your skills and enjoy your metalworking journey!FAQs

What Are The Key Features To Consider When Selecting A Cnc Retrofit Kit For A Metal Lathe?When choosing a CNC retrofit kit for a metal lathe, think about a few important things. First, check if the kit fits your lathe model. Next, look for easy-to-use software that helps you control the machine. Also, consider the quality of the parts. Strong and durable parts will last longer. Finally, think about getting good customer support in case you need help.

How Does Retrofitting A Traditional Metal Lathe With Cnc Capabilities Enhance Its Performance And Precision?Retrofitting a traditional metal lathe with CNC, which means Computer Numerical Control, makes it much better. You can program it to cut metal in very precise ways. This means each part is the same and fits better. It also helps you finish tasks faster, so you can make more pieces in less time. Overall, it improves how the lathe works and how accurate it is!

What Are Some Top-Rated Cnc Retrofit Kits Currently Available For Metal Lathes, And What Sets Them Apart?Some top-rated CNC retrofit kits for metal lathes include the Siemens Sinumerik, CNC4PC, and LinuxCNC. These kits help your lathe become fully automatic and easier to use. The Siemens kit is known for its easy setup and great support. CNC4PC stands out for its affordable price and extra features. LinuxCNC is free and flexible, perfect if you want to customize your machine.

What Are The Steps Involved In The Retrofitting Process Of A Metal Lathe To Cnc?To retrofit a metal lathe to CNC, you first need to gather your tools and parts. Then, remove the old parts from the lathe. Next, you install the new computer parts and motors. After that, connect everything to a computer so you can control it. Finally, test the lathe to make sure it works well.

How Can Users Ensure Compatibility Between Their Existing Metal Lathe And The Chosen Cnc Retrofit Components?To make sure your metal lathe works with new CNC parts, first check the size and shape of your lathe. Look at the parts you want to buy and see if they fit. It’s also good to read the instructions from both your lathe and the new parts. Lastly, ask other users for advice or search online for tips. This way, you can avoid any problems when putting everything together.