Have you ever wondered how some metal lathes run so smoothly? The secret often lies in their drive systems. A top-rated metal lathe drive system transforms raw metal into precise shapes. But what makes one drive system better than another? You might be surprised at the differences.

Imagine stepping into a workshop. You see machines whirring and sparks flying. The sound of metal cutting is music to many makers’ ears. But to achieve that perfect cut, you need reliable equipment. That’s where a quality lathe drive system steps in. It plays a huge role in ensuring the machinery functions well.

Many people don’t know this, but the drive system can impact your work quality significantly. A good system makes turning metal even easier. In this article, we will explore what makes a metal lathe drive system top-rated. You’ll learn about the features that matter most and how they can help you achieve your best work. Get ready to dive into the world of metal lathes!

Top Rated Metal Lathe Drive System: Choosing The Best Options

Top Rated Metal Lathe Drive System

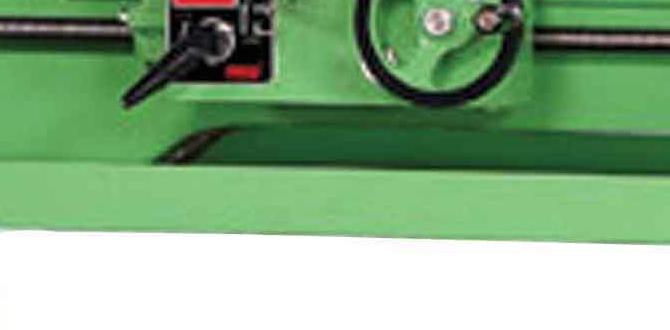

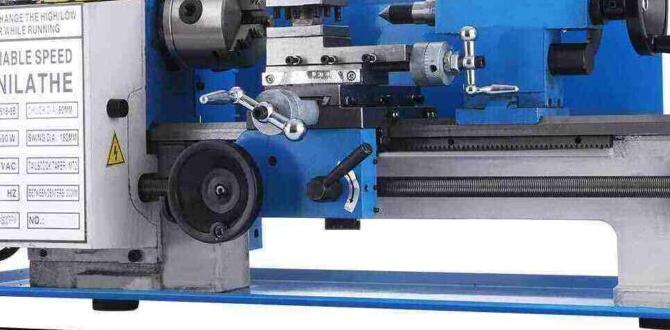

Looking for a powerful and reliable metal lathe drive system? Discover how the top-rated options offer smooth operation and excellent torque. These systems help you create precision parts with ease. Many users appreciate the efficiency and durability of these machines. Did you know that a good drive system can extend the life of your lathe? Choosing the right one can significantly improve your crafting experience and output quality. Unlock your creativity today!Understanding Metal Lathe Drive Systems

Explanation of what a metal lathe drive system is. Importance of drive systems in metalworking processes.A metal lathe drive system spins the lathe, helping cut and shape metal into cool designs. Imagine a roller coaster for metal! These systems are super important in metalworking because they control speed and torque. If not for them, our metal projects might look like a wobbly jigsaw puzzle instead of a shiny masterpiece. A good drive system keeps everything smooth and precise, like a dance partner who knows all the right moves!

| Drive System Component | Function |

|---|---|

| Motor | Powers the lathe |

| Pulley | Transfers motion and speed |

| Belt | Connects motor to the spindle |

Key Features of Top Rated Metal Lathe Drive Systems

Power and torque specifications. Types of drive systems (belt, gear, electronic).Metal lathe drive systems are like the heart of your machine. They need to be powerful! The power and torque specs matter a lot. Higher torque helps cut tough materials smoothly. Drive systems come in three main flavors: belt, gear, and electronic. Each type has its own quirks. Belts are quiet but may slip, gears are strong but noisy, and electronics offer precision without the hiccups. It’s like choosing between a bicycle, a go-kart, or a spaceship! Pick wisely!

| Type | Pros | Cons |

|---|---|---|

| Belt Drive | Quiet operation | May slip under heavy load |

| Gear Drive | High torque | Can be noisy |

| Electronic Drive | Precise control | Can be expensive |

Benefits of High-Quality Drive Systems in Metal Lathes

Enhanced precision and accuracy in machining. Increased durability and longevity of the lathe.Using a top-notch drive system in metal lathes can make all the difference. First, it enhances precision and accuracy, meaning your projects will turn out just right. Think of it like having a steady hand while drawing a picture—no messy lines! Also, these high-quality systems boost the durability of your lathe, helping it last longer. It’s like using a sturdy, well-made backpack instead of a flimsy one that falls apart during a hike. Trust us, your future self will thank you!

Factors to Consider When Selecting a Drive System

Compatibility with existing equipment. Maintenance and support options.Choosing the right drive system is important. First, check if it works well with your existing equipment. You don’t want to buy something that can’t connect or fits poorly. Next, think about maintenance and support options. Good support makes life easier if you face issues later. A reliable system can save you time and trouble.

What should I check for compatibility?

Make sure the drive system fits with your tools. Check sizes and types. Look for a design that matches your needs.

Always consider:

- Size and shape.

- Power requirements.

- Connection types.

Why is maintenance important?

Regular care keeps your drive system running. It helps avoid future breakdowns. Support options help you fix problems quickly.

Look for:

- Easy-to-find parts.

- Good customer service.

Common Issues and Troubleshooting Tips

Identifying typical problems in drive systems. Stepbystep troubleshooting solutions.Metal lathe drive systems can sometimes hit a bump in the road. Common issues might include strange noises, inconsistent speeds, or even a stubborn machine that just won’t turn on. The first step in troubleshooting is to check the power supply—make sure everything is plugged in! If it’s still acting up, look for loose belts or damaged wiring. Remember, every time you reach for the tool, double-check your connections or face the wrath of the stubborn lathe! Here’s a handy table to help you identify and solve some common problems:

| Issue | Solution |

|---|---|

| No power | Check the power source and connections. |

| Strange noise | Inspect the belts and bearings. |

| Speed issues | Adjust the speed settings and check for wear. |

| Constant stopping | Look for overheating parts or stress on the motor. |

Maintaining Your Metal Lathe Drive System

Regular maintenance practices to ensure optimal performance. Signs indicating the need for professional servicing.Keeping your metal lathe drive system in great shape is like giving it a spa day. Regular maintenance ensures everything runs smooth as butter! Check for loose belts and oily spots. If you hear funny noises, it might be time to call for help. Be on the lookout for signs like strange vibrations or if your lathe starts behaving like a cat on a hot tin roof. Remember, a well-cared-for machine lasts longer and works better. Happy turning!

| Signs of Trouble | Action Needed |

|---|---|

| Strange noises | Check for loose parts |

| Vibrations | Inspect the drive system |

| Inconsistent performance | Consider professional help |

FAQs About Metal Lathe Drive Systems

Answers to commonly asked questions. Clarifying misconceptions about drive systems.Many people have questions about metal lathe drive systems. Here are some answers to clear up confusion:

What is a metal lathe drive system?

A metal lathe drive system is a setup that powers and controls the lathe. It helps shape metal into different forms.

Is a more expensive drive system always better?

No, not always. Some expensive systems may have extra features. But your needs and skills matter most.

How do drive systems affect my work?

Drive systems affect speed and precision. A good system helps you create better, more accurate pieces.

What are the common types of drive systems?

- Direct Drive

- Belt Drive

- Gear Drive

Understanding these basics will help you choose the right system for your projects.

Conclusion

In conclusion, a top-rated metal lathe drive system offers power and precision for your projects. It helps you shape metal with ease and accuracy. When choosing one, consider speed, durability, and features. We encourage you to explore reviews and guides to find the best fit for your needs. Start your journey into metalworking and enjoy the creative possibilities!FAQs

Sure! Here Are Five Related Questions On The Topic Of Top-Rated Metal Lathe Drive Systems:Sure! Here’s a simple answer. A metal lathe drive system helps machines shape metal. It turns the metal slowly so we can cut or smooth it. Top-rated systems are strong and work well. They help make our projects better and faster. Using a good drive system is important for making neat and precise shapes.

Sure! Please provide me with the question you’d like me to answer.

What Are The Key Features To Look For In A Top-Rated Metal Lathe Drive System?When looking for a top-rated metal lathe drive system, you should check for a strong motor. A strong motor helps cut metal easily. You also want easy speed controls, so you can change how fast it works. Good quality parts make the machine last longer. Finally, look for a system that is simple to use.

How Does The Drive System Impact The Overall Precision And Performance Of A Metal Lathe?The drive system of a metal lathe helps turn the metal piece smoothly. If the drive system is strong and steady, it makes better cuts. This means you get more exact shapes and sizes. When the machine runs well, it can work faster, saving you time. So, a good drive system is very important for making quality pieces.

What Are The Advantages Of Using A Direct Drive Versus A Belt Drive System In Metal Lathes?Direct drive systems are simpler and more compact. They give you more power right away when you need it. With fewer moving parts, they are often easier to clean and fix. Belt drive systems can slip, but direct drives work smoothly. Plus, direct drives can be quieter, so you can work without too much noise.

How Do Different Power Ratings Of Drive Systems Influence The Capability And Applications Of Metal Lathes?The power rating of a drive system on a metal lathe shows how strong it is. A higher power rating means the lathe can cut through tougher materials. This lets us make bigger and more complex shapes. Lower power ratings work well for softer materials or smaller projects. So, the power rating helps us choose the right lathe for the job we want to do.

What Are Some Of The Best Brands Or Models Of Metal Lathe Drive Systems Currently Available On The Market?Some of the best brands for metal lathe drive systems are Grizzly, Jet, and Northwood. Grizzly makes strong and reliable machines. Jet has great features and is easy to use. Northwood is known for high quality and good performance. You can find these brands at many tool shops or online.