Have you ever watched a skilled craftsman turn raw metal into beautiful shapes? It’s fascinating! One tool that makes this possible is the metal lathe. But did you know that you can make a traditional metal lathe even smarter? Yes, that’s where training metal lathe CNC retrofit comes in!

Imagine transforming an old lathe into a high-tech machine that works like magic. Many people think it’s too complicated, but it can be easy and fun. With CNC retrofit, you get to experience the true power of automation in metalworking.

This article will guide you through this exciting journey. You’ll learn how to upgrade your lathe and why it matters. Whether you’re a hobbyist or a pro, the world of CNC retrofitting holds amazing possibilities. So, are you ready to discover how to unlock the full potential of your metal lathe?

Training Metal Lathe Cnc Retrofit: A Comprehensive Guide

Understanding Training Metal Lathe CNC Retrofit

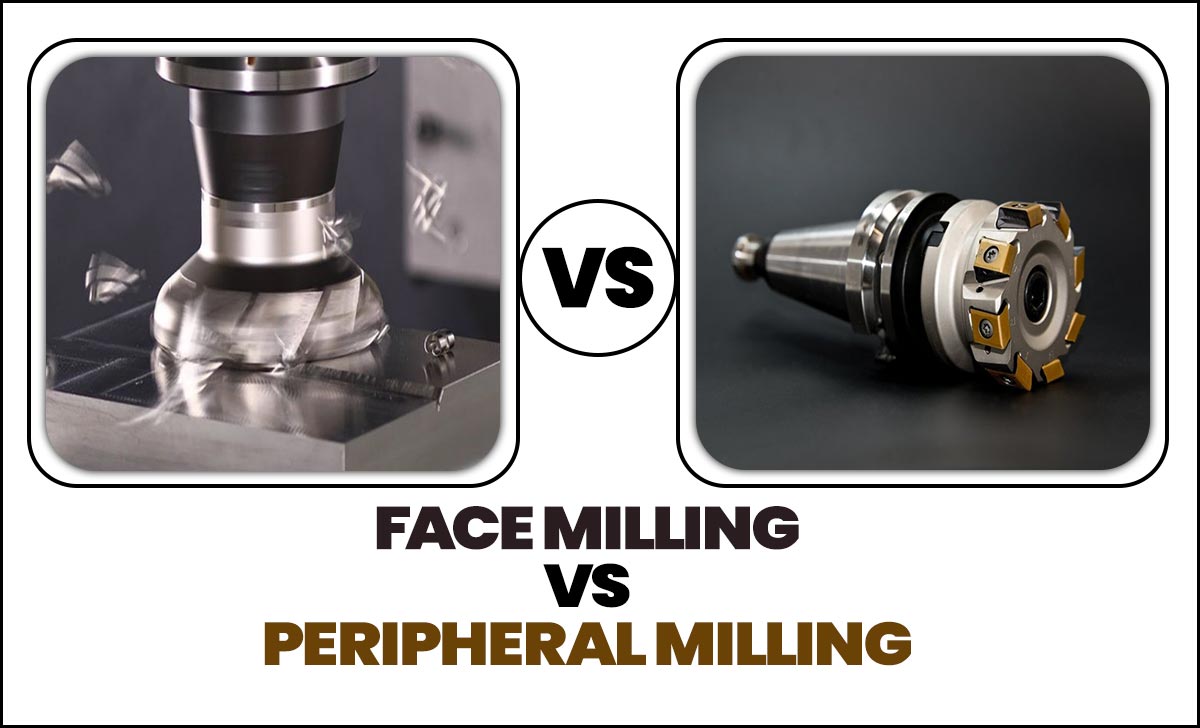

Training on metal lathe CNC retrofit helps improve machining skills. This process allows you to upgrade older machines with new technology. Imagine transforming a traditional lathe into a modern CNC tool! You learn to control precision and efficiency, boosting productivity. This upgrade can save costs while increasing capabilities. If you’re passionate about machining, retrofitting can open new doors for creativity and projects. Why not explore this exciting opportunity?Understanding CNC Retrofit Technology

Definition and explanation of CNC retrofitting for metal lathes.. Benefits of retrofitting compared to traditional CNC systems..CNC retrofitting transforms older metal lathes into modern machines. It upgrades the controls and software, making them smarter without needing a new machine. Imagine turning a classic car into a flashy sports car! Retrofitting helps save money while boosting performance. Compared to traditional CNC systems, retrofitted lathes often have shorter learning curves, require less maintenance, and offer better precision. Plus, you get to keep your old friend (the lathe), and that’s a win-win!

| Feature | Traditional CNC Systems | Retrofitted CNC Lathes |

|---|---|---|

| Cost | Higher | Lower |

| Learning Curve | Steep | Shallow |

| Maintenance | Frequent | Less |

| Precision | Standard | Improved |

Preparing Your Metal Lathe for Retrofit

Steps to assess the current condition of your lathe.. Safety precautions to take before starting the retrofit process.. “`htmlBefore starting your retrofit adventure, check your lathe’s health. Is it rusty? Do the parts move smoothly? These checks can save time later. Also, don’t forget to wear safety gear. No one wants metal shavings in their eyes! Here are some steps to follow:

| Steps | Actions |

|---|---|

| Inspect the Condition | Look for rust, damage, or anything else odd. |

| Test the Movement | Ensure the lathe works smoothly without strange noises. |

| Check for Safety Features | Make sure all safety guards are in place. |

Using proper locks and unplugging the machine is crucial. It’s always better to be safe than sorry. Think of it like protecting your favorite sandwich from ants: preventive measures matter!

“`Step-by-Step CNC Retrofit Procedure

Detailed process for installing the retrofit kit on a metal lathe.. Common challenges faced during installation and how to overcome them..Installing a retrofit kit on a metal lathe can feel like building furniture from IKEA—lots of pieces and confusing instructions! Start by removing old parts carefully. Next, follow the steps in your kit, making sure to align everything perfectly. A quick tip? Check twice before you screw. Common challenges include misalignment and missing tools, but don’t worry! Using a friend or a trusty video guide can really help. Once you finish, give yourself a high-five; you’ve earned it!

| Challenge | Solution |

|---|---|

| Misalignment | Double-check your measurements. |

| Missing tools | Make a checklist before starting. |

With patience and a bit of humor, you’ll master that CNC retrofit like a pro! Remember, a good laugh can make any task easier.

Software Considerations for CNC Retrofits

Types of software compatible with CNC retrofitting.. Instructions on how to configure and optimize the software for best performance..Choosing the right software for your CNC retrofit is key to smooth sailing. Some popular types include G-code interpreters, CAM packages, and control software. These tools help your machine understand how to behave. To make sure everything runs like a well-oiled machine, focus on configuring settings like speed and acceleration. It’s like tuning a guitar – a little twist here and there can make a big difference. Here’s a simple table to get you started:

| Software Type | Description |

|---|---|

| G-code Interpreter | Translates commands into machine movement. |

| CAM Package | Helps design and plan manufacturing steps. |

| Control Software | Directly manages machines and operations. |

Remember, the right software will have your CNC machine running like a champion, ready to tackle any challenge with a wink and a grin!

Training and Skill Development for Operators

Recommended training programs for operators using retrofitted CNC lathes.. Importance of ongoing education and skill enhancement in CNC machining..Learning to operate retrofitted CNC lathes is like learning to ride a bike—with a twist! It’s essential to enroll in recommended training programs tailored for operators. Hands-on training helps develop strong skills, which is key in CNC machining. Plus, ongoing education keeps your skills sharp and your brain buzzing. You wouldn’t drive a car without knowing the rules of the road, right? So, here’s a quick look at some training options:

| Training Program | Duration | Key Features |

|---|---|---|

| Basic CNC Operations | 4 weeks | Intro to CNC, Safety, Basic Setup |

| Advanced Machining Techniques | 6 weeks | Complex Shapes, Materials, Tooling |

| Ongoing Skill Workshops | Monthly | Updates on Tech, Troubleshooting |

Investing in your skills today will pay off tomorrow. Remember, a well-trained operator is like a superhero in the workshop! Keep learning, and you’ll turn those lathes into magic-making machines.

Best Practices for Maintenance and Troubleshooting

Routine maintenance tips to ensure longevity and performance of retrofitted lathes.. Troubleshooting common issues that may arise postretrofit..Keeping your retrofitted lathe in top shape is important for good performance. Regular maintenance will help you avoid problems. Check the machine oil often. Clean the parts regularly to prevent dust build-up. Tighten any loose screws to keep everything secure.

- Inspect cables for wear.

- Lubricate moving parts as needed.

- Calibrate settings at least once a month.

If issues arise, first check software settings. Misalignment and noise may mean a part needs fixing or replacing. By following these steps, you can enjoy a long-lasting and efficient machine.

How can I identify common issues with my lathe?

Check for strange noises, vibrations, or error codes on the display. Also, monitor the quality of your cuts. Changes in this can signal a problem with the machine.

What tools do I need for maintenance?

- Oil can for lubrication.

- Wrench for tightening bolts.

- Cleaning cloths to remove dust.

Cost Analysis: Is a Retrofit Worth It?

Breakdown of costs associated with retrofitting versus purchasing new machinery.. Factors to consider in calculating return on investment (ROI)..Deciding whether to retrofit your machinery or buy new can feel like picking ice cream flavors—so many choices! First, let’s break down costs. Retrofitting is often cheaper than splurging on shiny new gear. Still, you must consider things like installation and how long it will last.

| Cost Breakdown | Retrofitting | Buying New |

|---|---|---|

| Initial Cost | $2,000 | $10,000 |

| Installation | $500 | $1,000 |

| Maintenance (yearly) | $200 | $400 |

Next, think about your return on investment (ROI). If you retrofit, you save money and keep your old buddy running. But, if you buy new, you might get fancy features. It’s a lot like choosing between a trusty bicycle and a shiny new scooter. Which one will take you further? Choose wisely!

Success Stories of CNC Retrofit Projects

Examples of successful retrofit implementations in various industries.. Lessons learned and insights gained from these case studies..Many industries have tackled CNC retrofit projects with amazing results. One factory boosted its production by 50% after updating old machines, proving that new tech can work wonders. Another example comes from a small workshop that turned a struggling lathe into a powerful tool, saving money and time. Key lessons include the importance of planning and training. Remember, **adaptability is key**; if a lathe can evolve, so can you!

| Industry | Success Rate | Lessons Learned |

|---|---|---|

| Automotive | 50% | Plan Ahead |

| Woodworking | 40% | Train Operators |

| Aerospace | 60% | Embrace Change |

Conclusion

In conclusion, retrofitting a metal lathe for CNC can boost your machining capabilities. It makes your work easier and more precise. You can save time and money by upgrading instead of buying new machines. If you’re eager to learn more, consider exploring guides or videos on CNC retrofitting. Taking the next step can greatly improve your skills and projects!FAQs

What Are The Key Components Needed For A Successful Cnc Retrofit Of A Metal Lathe?To successfully retrofit a metal lathe with CNC, you need a few key parts. First, get a good computer to control the machine. Next, you’ll need special motors that move the lathe parts accurately. You will also need sensors to help measure the parts being worked on. Lastly, you need software to make it all work together.

How Do You Choose The Right Cnc Controller For Your Metal Lathe Retrofit Project?To choose the right CNC controller for your metal lathe, first think about what you need it to do. Check if it fits your lathe’s size and type. Look for one that works well with your computer software. You should also see how easy it is to use. Finally, read reviews to find out what others like or dislike about it.

What Are The Common Challenges Faced During The Retrofitting Process Of A Metal Lathe To Cnc, And How Can They Be Overcome?When we change a metal lathe to a CNC machine, we face some challenges. First, fitting new parts can be tricky because they need to be just right. We can solve this by measuring carefully and using the right tools. Also, programming the machine takes time and practice. We can overcome this by learning from guides or asking experts for help.

What Are Some Best Practices For Calibrating And Tuning A Retrofitted Cnc Metal Lathe To Ensure Precision And Accuracy?To make your CNC metal lathe work better, start by checking its level. Use a spirit level to ensure it’s straight. Next, measure the cutting tools for size and shape. It’s also important to adjust the software settings to match your tools. Finally, do test cuts and adjust until you get perfect shapes.

What Are The Cost Implications Of Retrofitting A Metal Lathe For Cnc Operation Versus Purchasing A New Cnc Lathe?Retrofitting a metal lathe costs less than buying a new CNC lathe. You save money by using your old machine. But, retrofitting can take time and might need extra parts. A new CNC lathe works right away but costs a lot more. We should think about how often we will use the machine to decide what’s best.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Components Needed For A Successful Cnc Retrofit Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To successfully retrofit a metal lathe with CNC, you need a few key parts. First, get a good computer to control the machine. Next, you’ll need special motors that move the lathe parts accurately. You will also need sensors to help measure the parts being worked on. Lastly, you need software to make it all work together.”}},{“@type”: “Question”,”name”: “How Do You Choose The Right Cnc Controller For Your Metal Lathe Retrofit Project? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right CNC controller for your metal lathe, first think about what you need it to do. Check if it fits your lathe’s size and type. Look for one that works well with your computer software. You should also see how easy it is to use. Finally, read reviews to find out what others like or dislike about it.”}},{“@type”: “Question”,”name”: “What Are The Common Challenges Faced During The Retrofitting Process Of A Metal Lathe To Cnc, And How Can They Be Overcome? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we change a metal lathe to a CNC machine, we face some challenges. First, fitting new parts can be tricky because they need to be just right. We can solve this by measuring carefully and using the right tools. Also, programming the machine takes time and practice. We can overcome this by learning from guides or asking experts for help.”}},{“@type”: “Question”,”name”: “What Are Some Best Practices For Calibrating And Tuning A Retrofitted Cnc Metal Lathe To Ensure Precision And Accuracy? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make your CNC metal lathe work better, start by checking its level. Use a spirit level to ensure it’s straight. Next, measure the cutting tools for size and shape. It’s also important to adjust the software settings to match your tools. Finally, do test cuts and adjust until you get perfect shapes.”}},{“@type”: “Question”,”name”: “What Are The Cost Implications Of Retrofitting A Metal Lathe For Cnc Operation Versus Purchasing A New Cnc Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Retrofitting a metal lathe costs less than buying a new CNC lathe. You save money by using your old machine. But, retrofitting can take time and might need extra parts. A new CNC lathe works right away but costs a lot more. We should think about how often we will use the machine to decide what’s best.”}}]}