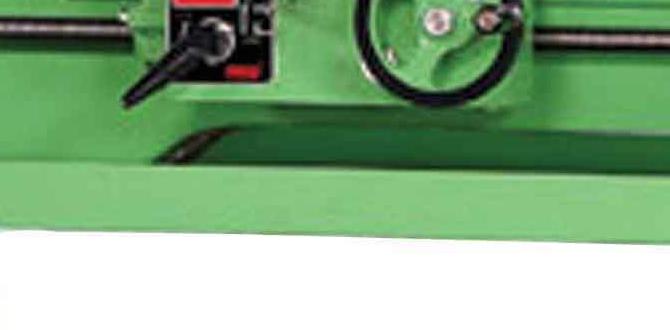

Have you ever watched a lathe in action? It’s fascinating to see metal slowly transformed into something useful. The process can seem complicated, but it doesn’t have to be. In this article, we’ll explore training metal lathe power feed. This essential skill can make your work much easier and faster.

Imagine using a machine that does most of the hard work for you. That’s what power feed does on a metal lathe. It helps you move the cutting tool smoothly and evenly. This means cleaner cuts and less effort on your part. Isn’t that exciting?

Many beginners feel unsure about using power feed. They often wonder how to start. But don’t worry! With the right training and guidance, anyone can master it. Knowing how to set it up and operate it will boost your confidence and skills.

Did you know that metal lathes have been around for centuries? They have evolved a lot over time. Today, they are powerful and precise machines. Learning about their features can turn you into a skilled user. Let’s dive into the world of metal lathe power feed and discover its secrets!

Training Metal Lathe Power Feed: Mastering Precision Machining

Training Metal Lathe Power Feed

Learn about the benefits of using a power feed on a metal lathe. This feature makes it easier to create precise cuts without tiring hands. Imagine finishing a project faster and with more accuracy. A power feed can help you adjust speeds for different materials, ensuring better results. Plus, it’s a valuable skill to master in machining. Simple steps and tips can make using a power feed fun and rewarding. Dive into this essential tool to improve your machining experience!Benefits of Using Power Feed in Metal Lathes

Increased efficiency and productivity. Enhanced precision and quality of work.Using a power feed on metal lathes can really boost your work! It helps you cut faster, which means more time for snacks. With steady movement, your pieces are more precise and look great. Who knew that a little machine magic could make you the town’s metalworking superstar? Plus, it cuts down on tired hands. So, less achy wrist and more happy crafting!

| Benefits | Description |

|---|---|

| Increased Efficiency | Work faster and finish more projects. |

| Enhanced Precision | Cut with better accuracy for a polished finish. |

Setting Up Power Feed on Your Metal Lathe

Stepbystep guide to installation. Common pitfalls to avoid during setup.Setting up power feed on your metal lathe is exciting! First, gather your tools and the machine parts. Follow these steps:

- Turn off the lathe and unplug it.

- Attach the power feed unit to the lathe carefully.

- Connect the wiring according to the manual.

- Check for loose parts.

- Power it on and test the feed slowly.

Avoid these common pitfalls:

- Don’t rush the setup.

- Make sure all screws are tight.

- Double-check the wiring connections.

With patience and care, your power feed will work smoothly!

What should I check first during setup?

Begin by ensuring your machine is powered off. Then, check all parts for damage. This step helps prevent any issues during setup.

Operating a Metal Lathe with Power Feed

Best practices for effective usage. Tips for adjusting speed and feed rates.Using a metal lathe with power feed can feel like magic. To get the best results, keep these tips in mind. First, always check the speed and feed rates. Too fast? You might get a metal smoothie instead of a shiny part! Adjust the speed so that your lathe hums like a happy bee.

Second, practice makes perfect. Test out different settings on scrap metal. Think of it as a fun game of “What’s That Noise?” Lastly, always wear safety gear. It’s better to be safe than sorry—and less likely to lose a finger to flying metal shavings!

| Speed (RPM) | Feed Rate (IPR) |

|---|---|

| 300 | 0.005 |

| 600 | 0.010 |

| 900 | 0.015 |

Troubleshooting Common Issues with Power Feed

Identifying common problems and their solutions. Maintenance tips for optimal performance.Power feed problems can be pesky, but don’t worry! Here are some common issues you might face, and simple fixes for each. If the feed slows down, it might need lubrication. Give it a good oiling! Another problem could be slipping gears—tighten them up, and you’re good to go.

| Common Problem | Solution |

|---|---|

| Slow Feed Rate | Lubricate the moving parts. |

| Slipping Gears | Tighten the gear settings. |

| No Power | Check power connections. |

For smooth operation, perform regular maintenance. Clean parts often, and inspect for wear. Remember, a happy lathe makes happy projects. Keep your wits sharp, and your lathe will be too! It’s like giving it a spa day—everyone loves that!

Safety Considerations When Using Power Feed

Essential safety gear and practices. Recognizing and mitigating hazards.Using a metal lathe with power feed can be fun, but safety is super important! Always wear protective goggles, gloves, and ear protection. These will help keep your eyes, hands, and ears safe from flying chips and loud noises. Look at your workspace. Keep it clean and clear of clutter. Hazards can hide under that extra coffee cup! And remember, never wear loose clothing that can snag. Your lathe isn’t a fashion show!

| Safety Gear | Why It’s Important |

|---|---|

| Protective Goggles | To shield your eyes from debris |

| Work gloves | To protect your hands from sharp edges |

| Ear Protection | To reduce noise exposure |

Always be aware of your surroundings. If something doesn’t feel right, stop and double-check your setup. It’s better to take a moment than to become part of a “tale of the clumsy lathe”! In doing so, you’ll stay safe and make your training smoother.

Training and Skill Development Resources

Recommended courses and workshops for lathe training. Online resources and tutorials for further learning.| Resource Type | Recommended Options |

|---|---|

| Courses | Metalworking Basics, Advanced Lathe Skills |

| Workshops | Local Maker Spaces, Community Colleges |

| Online Tutorials | YouTube, Skillshare, Udemy |

Learning how to master a metal lathe can be as fun as baking cookies (minus the calories!). Check out courses like Metalworking Basics or Advanced Lathe Skills to get started. Local workshops at community colleges or maker spaces are helpful too. For those who prefer the comfort of home, online tutorials from platforms like YouTube or Skillshare are your best friends. Remember, practice makes perfect, and it’s way less messy than trying to bake without a recipe!

Conclusion

In conclusion, using a power feed on a metal lathe makes your work easier and more accurate. You’ll save time and achieve smoother finishes. Remember to practice safely and learn proper techniques. Explore user manuals and online tutorials for more tips. With patience and practice, you’ll master your lathe and create amazing projects!FAQs

Sure! Here Are Five Related Questions On The Topic Of Training For Metal Lathe Power Feed:Sure! When using a metal lathe with power feed, it’s important to learn how it works. You should understand how to adjust the speed and direction. Always wear safety gear like goggles. Practice with a helper so you can learn together. It can be fun and great for making cool shapes with metal!

Sure! Please provide me with the question you’d like me to answer.

What Is The Primary Function Of A Power Feed In A Metal Lathe, And How Does It Enhance Precision Machining?A power feed helps move the cutting tool automatically in a metal lathe. This means you don’t have to push it by hand. It makes the machine work smoothly and evenly. With power feed, we get better cuts and more accurate shapes. This helps us make parts that fit together perfectly!

What Are The Safety Precautions That Should Be Observed During The Operation Of The Power Feed On A Metal Lathe?When using the power feed on a metal lathe, always wear safety glasses to protect your eyes. Keep your hands and clothes away from the spinning parts. Make sure the area is clean and free from clutter, so you don’t trip. Always follow the machine’s instructions and ask for help if you’re unsure. Lastly, never reach over the machine while it’s running.

How Do You Properly Set Up And Calibrate The Power Feed Mechanism For Different Machining Tasks On A Metal Lathe?To set up the power feed on a metal lathe, start by checking the machine’s manual. This tells you how to adjust the settings. Next, choose the right speed for the material you’re using. Then, set the feed rate, which controls how fast the tool moves. Finally, test it on a scrap piece to see if everything works well. Adjust as needed!

What Are The Common Troubleshooting Steps For Addressing Issues That Arise With The Power Feed System In A Metal Lathe?To fix problems with the power feed system in a metal lathe, start by checking the power source. Make sure the machine is plugged in and the switch is on. Next, look for any loose wires or connections and tighten them if needed. You should also check the gears to see if anything is stuck. If it still doesn’t work, ask an adult for help.

How Does The Choice Between Manual And Power Feed Impact The Feed Rates And Surface Finish Of Machined Parts In Metalworking?When you use a manual feed, you control the speed yourself. This can be slower and less smooth, which might leave rough finishes. With a power feed, the machine moves automatically, usually faster and more evenly. This helps make better surfaces on the parts we want to create. So, picking power feed often gives nicer results!