Have you ever wanted to create cool metal parts but thought it was too expensive? Imagine designing a metal lathe that costs under $1000! Many people believe that high-quality tools are out of reach. But what if I told you that building your own metal lathe could be fun and affordable?

Metal lathes are amazing machines. They help you shape metal into beautiful pieces. Whether you want to make parts for a robot or a special gift, a good lathe can do it all.

Now, think about the idea of a CAD design. It stands for Computer-Aided Design. This means you can plan your metal lathe on a computer before you even start building. Do you see how exciting that is? You’ll be able to visualize your project and make changes easily!

In this article, we’ll dive into the world of under $1000 metal lathe CAD design. Get ready to explore tips, tricks, and the best tools to make your project a success!

Affordable Metal Lathe Cad Design Under $1000 Options

Discovering Metal Lathes Under $1000 with CAD Design

Finding a metal lathe under $1000 can seem challenging. Many people wonder if they can create professional-quality designs at home without breaking the bank. CAD design software plays a huge role in this process. It helps users visualize their projects and check measurements before starting. Imagine making your own tools or parts! With affordable lathe options, hobbyists can unleash their creativity and bring their ideas to life. Who knows? You might just discover a new passion!Understanding Metal Lathes

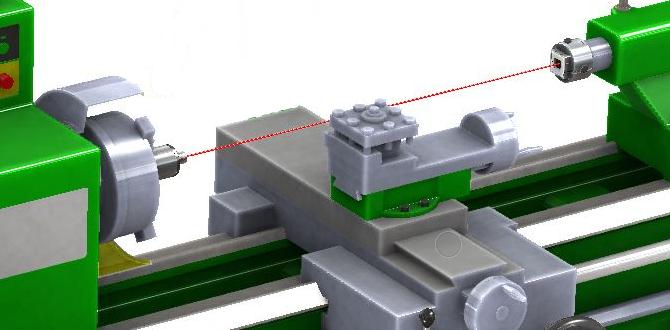

Definition and application of metal lathes in manufacturing and design. Key components of a metal lathe and how they function.Metal lathes are tools used to shape metal. They spin metal pieces while a cutting tool removes material. This process makes parts for machines and vehicles. Key parts of a metal lathe include:

- Headstock: Holds the spinning metal piece.

- Tailstock: Supports the other end of the metal piece.

- Carriage: Moves the cutting tool back and forth.

- Bed: The base where everything is mounted.

Each part plays an important role. They work together to create precise shapes, helping in manufacturing and design.

What Can Be Made with Metal Lathes?

Metal lathes can make various items like gears, shafts, and tools. They are valuable in factories and workshops, allowing creative designs to come to life.

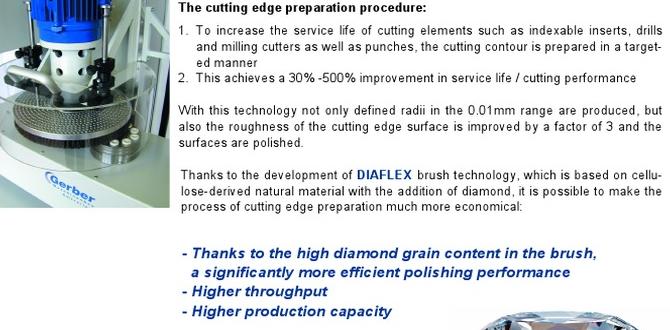

Benefits of Using a Metal Lathe for CAD Design

Advantages of precision and accuracy in CADbased projects. Versatility of metal lathes in various materials and design types.Using a metal lathe for CAD design can make projects a breeze! First off, precision is key. The lathe helps you create parts that fit together perfectly, just like a puzzle. This means fewer mistakes and more happy dances when everything works! Plus, a metal lathe is as flexible as a gymnast. It can handle different materials like wood, metal, or plastic, and adapt to various designs. So, whether you’re making toy parts or fancy gadgets, it’s got your back. In short, it’s a creative helper that takes your ideas from sketch to reality!

| Benefit | Description |

|---|---|

| Precision | Creates accurate parts that fit perfectly. |

| Versatility | Can work with different materials and design types. |

Top Features to Look for in a Metal Lathe under $1000

Size, weight, and portability considerations. Motor power, speed settings, and torque for CAD applications.Choosing a metal lathe can feel like searching for a needle in a haystack, especially under $1000. First, consider its size and weight. A lighter lathe can be easily moved around your workspace. Next, check motor power and speed settings. You’ll want a strong motor for those CAD applications. More speed settings equal more versatility, but don’t forget torque! A lathe with good torque makes cutting easier. Here’s a quick comparison:

| Feature | Importance |

|---|---|

| Size & Weight | Easy to move |

| Motor Power | Stronger cuts |

| Speed Settings | More options for projects |

| Torque | Better at cutting |

With these features in mind, you’ll find a metal lathe that fits your needs perfectly—no magician required!

Comparative Analysis of the Best Metal Lathes under $1000

Review of top models and their specifications. Pros and cons of each model based on user needs and budget.Finding the right metal lathe under $1000 can feel like searching for buried treasure. Let’s explore some top models to help you out. Each lathe has unique features, so your choice depends on what you need. Here’s a quick look:

| Model | Specifications | Pros | Cons |

|---|---|---|---|

| Mini Lathe 7×14 | 7″ swing, 14″ bed | Compact size, great for beginners | Limited capacity for large projects |

| Central Machinery 46791 | 12″ swing, 36″ bed | Powerful motor, versatile | Heavy and not very portable |

| Grizzly G8688 | 8″ swing, 16″ bed | Good accuracy, great build | Noise level can be annoying |

Each option has its quirks, kind of like your pets! The best choice depends on your needs and budget. So, happy lathe hunting!

Tips for Choosing the Right Metal Lathe for Your Projects

Factors to consider based on skill level and project requirements. Importance of warranty, customer support, and community reviews.Choosing the right metal lathe is important for your projects. Start by thinking about your skill level. Beginners may need simpler models. Check project requirements to find the best fit. Make sure it has a good warranty. A solid warranty shows the company believes in their product. Explore customer support options. Good support can help when you have questions. Lastly, read community reviews. They share real experiences that can guide you.

What should I consider when choosing a metal lathe?

Look for these key factors:

- Skill level: Choose a lathe that matches your abilities.

- Project requirements: Find one that fits what you want to do.

- Warranty: A good warranty gives peace of mind.

- Customer support: Reliable help is a must.

- Community reviews: Learn from others’ experiences.

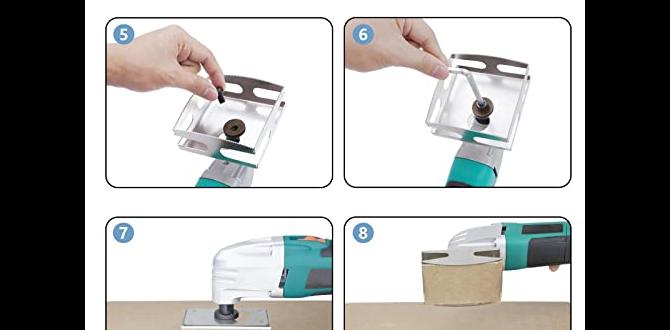

Setting Up Your Metal Lathe for CAD Design

Stepbystep setup process for beginners. Essential accessories and tools to enhance functionality.Getting your metal lathe ready for CAD design is like preparing for a fun adventure! First, make sure you have a good workspace. Keep it clean and bright; nobody likes working in a dark cave! Next, think about essential tools like cutting tools, tool holders, and a nice chuck. These will help your lathe work better. Here’s a quick checklist to get you started:

| Essential Tools | Purpose |

|---|---|

| Cutting Tools | Shape your metal like a pro! |

| Tool Holders | Keep things in place! |

| Chuck | Secure your materials! |

Finally, always double-check your setup. A small mistake can turn your masterpiece into metal confetti! With the right steps and tools, you’ll be a CAD designing whiz in no time!

Common Mistakes to Avoid When Using a Metal Lathe

Typical pitfalls in CAD design projects with metal lathes. Tips for ensuring safety and efficiency during operation.Many beginners dive into metal lathes without a clue. This can lead to big problems! Not checking the CAD design can cause ugly mistakes. Always double-check your measurements; a small error can cause a big crash! Also, remember to wear safety gear. Losing a finger just isn’t cool, even if you like metal art! Lastly, test run at a slow speed before going full blast. Speed thrills, but safety kills!

| Common Mistakes | Tips to Avoid |

|---|---|

| No CAD checks | Double-check all designs |

| Forget safety gear | Always wear safety glasses and gloves |

| Ignoring speed | Start slow before speeding up |

Resources for Learning and Mastering Metal Lathe CAD Design

Online courses, tutorials, and books for skill enhancement. Recommendations for forums and communities for ongoing support.Many resources can help you learn metal lathe CAD design. Online courses are a great start. Look for tutorials on sites like YouTube. Books can provide in-depth knowledge. Start with beginner-friendly titles. Joining forums can offer support and ideas. Connecting with other learners makes a difference. Here are some good options:

- Online Courses: Coursera, Udemy

- Tutorials: YouTube channels like ‘CAD in Black’

- Books: “Mastering CAD” or other beginner guides

- Forums: Reddit, CAD forums on Facebook

What are some places to find help with metal lathe CAD design?

You can find help on YouTube, Coursera, and Reddit. Online platforms and communities share tips and answer questions.Conclusion

In summary, a metal lathe under $1000 is a great option for beginners. It offers good quality for affordable prices. You can create impressive CAD designs with practice. Start by researching models that fit your budget. Explore tutorials and guides to enhance your skills. With the right tools and knowledge, you can make amazing projects. Happy crafting!FAQs

Here Are Five Related Questions On The Topic Of Under $10Metal Lathe Cad Design:Sure! Using a metal lathe means you can shape metal objects. CAD stands for Computer-Aided Design. It helps you make designs on a computer. You can often find free or low-cost CAD software to create your designs. With a little practice, you can make cool projects for under $10!

Sure! Please provide the question you want me to answer.

What Are The Key Features To Consider When Designing A Metal Lathe In Cad Software For A Budget Of Under $1000?When designing a metal lathe in CAD software for under $1000, you should focus on some key features. First, check the lathe’s size and weight. A smaller, lighter lathe is easier to use and move. Next, look for adjustable speed settings; this helps you work with different types of metal. Lastly, consider the tools you need; make sure they fit within your budget.

How Can One Optimize A Cad Design Of A Metal Lathe To Ensure Functionality While Adhering To A Budget Constraint?To improve a CAD design of a metal lathe while staying on budget, you can start by using simpler shapes. This can save material and make it cheaper. Next, choose cost-effective parts that still work well. We should also check if we can do things like assembling parts differently to cut costs. Finally, test the design with a small model before making the final one. This way, we can fix problems without wasting money.

What Types Of Materials Are Suitable For A Cost-Effective Metal Lathe Design, And How Can These Be Represented In Cad?You can use wood, steel, or aluminum for a cost-effective metal lathe. Wood is easy to work with, while steel and aluminum are strong. In CAD, which stands for Computer-Aided Design, you can draw the lathe shapes easily. You can pick the materials and colors in the software to see how it will look. This way, you can design it just right!

What Cad Software Options Are Available That Cater Specifically To The Design Of Metal Lathes In The Under $10Price Range?You can find some CAD software options for designing metal lathes that are free or very cheap. One great option is Tinkercad. It’s easy to use and you can design simple models online. Another choice is SketchUp Free, which is also fun and user-friendly. These tools help you learn and create without spending much money!

How Can Structural Integrity And Safety Be Incorporated Into A Metal Lathe Cad Design Without Exceeding The $10Budget?To keep our metal lathe safe and strong, we can use good design choices. We should make thick parts where there is a lot of pressure and use strong shapes like triangles. For under $10, we can pick affordable materials and simple designs. We can also add safety features like covers to prevent accidents. This way, we can create a safe and sturdy lathe without spending too much money.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Under $10Metal Lathe Cad Design:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Using a metal lathe means you can shape metal objects. CAD stands for Computer-Aided Design. It helps you make designs on a computer. You can often find free or low-cost CAD software to create your designs. With a little practice, you can make cool projects for under $10!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Features To Consider When Designing A Metal Lathe In Cad Software For A Budget Of Under $1000?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When designing a metal lathe in CAD software for under $1000, you should focus on some key features. First, check the lathe’s size and weight. A smaller, lighter lathe is easier to use and move. Next, look for adjustable speed settings; this helps you work with different types of metal. Lastly, consider the tools you need; make sure they fit within your budget.”}},{“@type”: “Question”,”name”: “How Can One Optimize A Cad Design Of A Metal Lathe To Ensure Functionality While Adhering To A Budget Constraint?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To improve a CAD design of a metal lathe while staying on budget, you can start by using simpler shapes. This can save material and make it cheaper. Next, choose cost-effective parts that still work well. We should also check if we can do things like assembling parts differently to cut costs. Finally, test the design with a small model before making the final one. This way, we can fix problems without wasting money.”}},{“@type”: “Question”,”name”: “What Types Of Materials Are Suitable For A Cost-Effective Metal Lathe Design, And How Can These Be Represented In Cad?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use wood, steel, or aluminum for a cost-effective metal lathe. Wood is easy to work with, while steel and aluminum are strong. In CAD, which stands for Computer-Aided Design, you can draw the lathe shapes easily. You can pick the materials and colors in the software to see how it will look. This way, you can design it just right!”}},{“@type”: “Question”,”name”: “What Cad Software Options Are Available That Cater Specifically To The Design Of Metal Lathes In The Under $10Price Range?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can find some CAD software options for designing metal lathes that are free or very cheap. One great option is Tinkercad. It’s easy to use and you can design simple models online. Another choice is SketchUp Free, which is also fun and user-friendly. These tools help you learn and create without spending much money!”}},{“@type”: “Question”,”name”: “How Can Structural Integrity And Safety Be Incorporated Into A Metal Lathe Cad Design Without Exceeding The $10Budget?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep our metal lathe safe and strong, we can use good design choices. We should make thick parts where there is a lot of pressure and use strong shapes like triangles. For under $10, we can pick affordable materials and simple designs. We can also add safety features like covers to prevent accidents. This way, we can create a safe and sturdy lathe without spending too much money.”}}]}