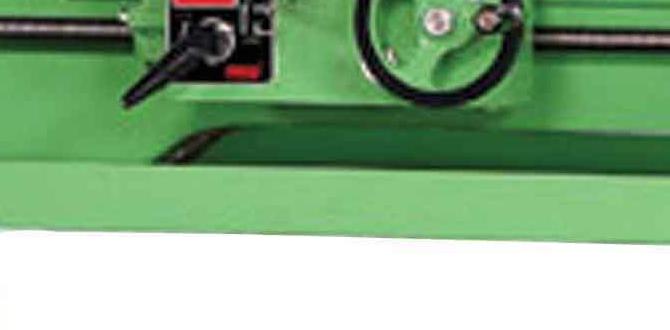

Have you ever thought about making your own tools or parts? With a metal lathe, you can do just that! Finding an under $1000 metal lathe drive system can be a game changer for hobbyists and professionals alike.

Imagine crafting custom pieces for your projects at an affordable price. It sounds exciting, right? Many people dream of working with metal but think it’s too expensive. But guess what? A quality metal lathe drive system can fit into your budget!

Here’s a fun fact: Even beginners can start using a metal lathe with the right tools. You don’t need to spend a fortune! An affordable metal lathe allows you to explore your creativity and inventiveness. Isn’t it thrilling to think what you can create?

Join us as we dive deeper into the world of metal lathes under $1000. Get ready to discover options that open up a new world of possibilities!

Affordable Metal Lathe Drive Systems Under $1000

Discovering the Under $1000 Metal Lathe Drive System

Looking for an affordable metal lathe drive system? You can find options under $1000 that are perfect for hobbyists and small projects. These systems often feature solid construction and good performance. Imagine turning wood or shaping metal easily! Many users appreciate their value and reliability. Furthermore, a well-chosen drive system can enhance your workshop’s capabilities without breaking the bank. So, why not explore these budget-friendly tools? Your next creative project awaits!Understanding Metal Lathe Drive Systems

Definition and function of a drive system in metal lathes. Importance of drive systems for precision machining.A drive system in a metal lathe moves the cutting tool or workpiece. It helps in spinning the material while cutting it into shape. This system is very important for precision machining. A good drive system enables accurate cuts and smooth finishes.

Some key functions include:

- Power transmission to the spindle

- Controlling speed and torque

- Ensuring stability during operations

Without a proper drive system, a lathe cannot work well. It may lead to errors or bad quality of work.

What is the importance of drive systems in metal lathes?

The importance of drive systems lies in their role in enhancing accuracy. They allow the lathe to function efficiently, which is crucial for high-quality results. With a reliable drive system, you can create parts that fit together perfectly.

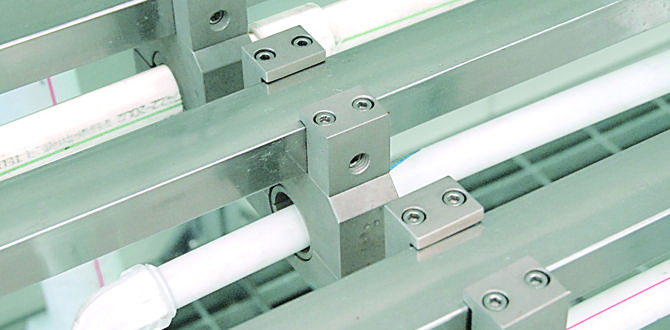

Key Features to Consider When Selecting a Drive System

Torque, speed control, and power ratings. Construction quality and durability.Choosing the right drive system is essential for your metal lathe. Here are some key features to think about:

- Torque: Good torque means more power for tough jobs.

- Speed Control: You need adjustable speed for different materials.

- Power Ratings: Higher ratings often mean better performance.

- Construction Quality: Look for sturdy materials to ensure longevity.

- Durability: A strong build can handle heavy workloads without breaking.

These features will help you pick a tool that lasts and works well.

What is torque in a metal lathe drive system?

Torque is the twisting force that helps the lathe turn materials. More torque allows the lathe to cut through harder items easily.

Why is speed control important?

Speed control helps you adjust how fast the lathe spins. This is key for working with various materials.

What should I know about construction quality?

High construction quality means better durability and less chance of failure. A well-built drive system can last much longer.

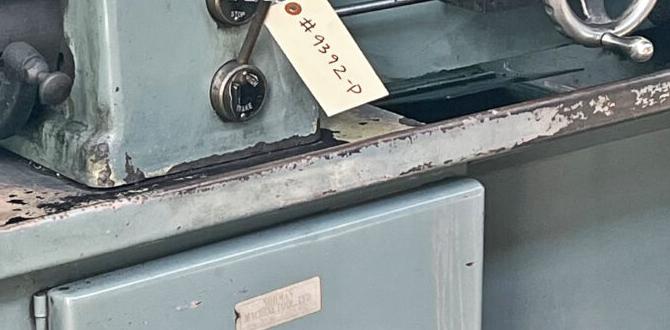

Top Metal Lathe Drive Systems Under $1000

Detailed comparison of the best options available. Highlight unique features and specs of each model.Finding the best metal lathe drive systems under $1000 can be exciting! Let’s look at some top choices. Each model has its unique features.

- Model A: Offers a high-torque motor and variable speed control.

- Model B: Known for its sturdy build and easy setup. Perfect for beginners!

- Model C: Comes with advanced safety features, keeping users safe while working.

Each of these options promises great performance without breaking the bank. Choose based on your needs!

What features should I look for in a metal lathe drive system?

Look for durability, speed settings, and safety features. These factors will help you pick a perfect model for your projects!

Installation and Setup Tips for Beginners

Stepbystep guide for installing a drive system. Common pitfalls and how to avoid them.Installing your metal lathe drive system can be exciting! Follow these simple steps to get it right. Start by reading the manual carefully. Next, gather all your tools. Then, place the drive system in a stable area. Make sure everything lines up correctly. Tighten screws gently, and check for any loose parts before starting.

Watch out for common mistakes:

- Forgetting to level the machine.

- Overtightening screws, which can cause damage.

- Not checking the belt tension.

If you follow these tips, you will avoid headaches. Soon, you’ll be on your way to creating amazing projects!

What are the best practices for setting up a drive system?

Always read the instructions closely and ensure all components are securely attached. This will help prevent accidents and improve performance.

Maintenance Best Practices for Longevity

Routine maintenance tasks to ensure optimal performance. Troubleshooting common issues.To keep your metal lathe humming happily, routine maintenance is key! Simple tasks like checking the oil and cleaning dust can work wonders. No one likes a grumpy lathe, right? If something goes wrong, don’t panic. Many troubles are easy to fix. Here’s a handy table for quick reference on what to check:

| Task | Frequency | Common Issues |

|---|---|---|

| Oil Check | Weekly | Low oil can lead to overheating |

| Cleaning | After each use | Dust may affect performance |

| Check Belts | Monthly | Wear and tear can cause slipping |

Being proactive is your best friend. Remember, a little love goes a long way in enhancing your lathe’s life!

User Experiences and Reviews

Summarized feedback from users of various systems. Realworld performance insights.Users share many thoughts on various metal lathe drive systems. Overall, they appreciate how affordable these systems are. Many say they work well for most projects. Here are some common points from users:

- Easy Setup: Most users find installation simple.

- Stable Performance: Many enjoy steady and smooth operation.

- Durability: Users mention long-lasting materials.

Some users report minor issues but state they can be fixed easily. This shows these systems can be great for hobbyists and small businesses alike.

What do users generally think of these systems?

Overall, users feel positive about their choices. Most mention they received good value for their money. Many satisfied users say they recommend these systems to friends. It’s clear that many enjoy using their metal lathes for different projects.

Cost-Effectiveness and Value Assessment

Analyzing performance versus cost in budget drive systems. Longterm value considerations for budget buyers.Finding the right metal lathe drive system can feel like finding a needle in a haystack. You want performance without breaking the bank. Many systems under $1000 can still deliver strong results. Think of it like buying a sandwich: some are just bread and a sad little slice of cheese, while others are packed with flavors and toppings. Look for a system that balances quality and cost. Over time, a reliable system can save you money. Investing in something durable can be a wise choice!

| Feature | Cost-Effective System | High-End System |

|---|---|---|

| Initial Price | Under $1000 | Over $1000 |

| Durability | Good | Excellent |

| Performance | Reliable | Exceptional |

| Long-Term Value | High | Very High |

Future Trends in Metal Lathe Technology

Innovations on the horizon in drive systems. How advancements may impact budget options in the future.New ideas are coming in metal lathe tech! Future drive systems may use super smart motors that could cut energy costs. Imagine saving bucks while making cool projects! Budget-friendly options under $1000 are likely to improve as technology advances, making lathes accessible for everyone. They’ll be faster and easier to use. Who knew metal lathes could become the superheroes of workshops? Here’s a quick look at some future-driving innovations:

| Innovation | Description |

|---|---|

| Smart Sensors | Help monitor and adjust speed automatically. |

| Energy Efficient Motors | Reduce power use while boosting performance. |

| DIY Upgrades | Cheaper parts for easy upgrades. Fun times! |

Conclusion

In summary, finding a metal lathe drive system under $1000 can be rewarding. These lathes offer great value for beginners and hobbyists. They provide essential features without breaking the bank. If you’re looking to start your metalworking journey, consider your needs and do thorough research. Explore online reviews to find the best options for you. Happy turning!FAQs

What Are The Key Features To Look For In A Metal Lathe Drive System Under $100When looking for a metal lathe drive system under $100, check for a strong motor. A good motor helps the lathe turn smoothly. You also want it to have different speeds. This lets us choose how fast we work. Lastly, make sure it’s easy to set up and use. This will help us start our projects quickly!

How Do The Performance And Capabilities Of Budget Metal Lathe Drive Systems Compare To Higher-End Models?Budget metal lathe drive systems are simpler and less powerful than higher-end ones. They can handle basic tasks, but might struggle with tougher jobs. Higher-end models work faster and can make more precise parts. If you only need a lathe for simple projects, a budget one could be fine. But for serious work, a higher-end model is better.

What Maintenance Practices Should Be Followed To Ensure The Longevity Of An Affordable Metal Lathe Drive System?To keep your metal lathe drive system working well, you should clean it often. Dust and chips can get stuck in the parts. Check and tighten any loose screws or belts. Also, oil the moving parts to help them work smoothly. Finally, always follow the instructions that come with your lathe for the best care.

Are There Any Specific Brands Or Models Of Metal Lathe Drive Systems Under $10That Are Particularly Recommended By Users?Finding metal lathe drive systems for under $10 is very hard because most are more expensive. Users often suggest checking out small tools from brands like Harbor Freight or Grizzly. You can find deals on smaller models at these stores. Remember to read reviews to see what other people think before buying!

How Can I Enhance The Performance Of A Budget Metal Lathe Drive System Through Upgrades Or Modifications?You can make your budget metal lathe better in a few ways. First, check the belts and change them if they are worn. You can also add a better motor for more power. Finally, clean and oil the parts regularly to keep everything running smoothly. These small changes can help your lathe work much better!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Features To Look For In A Metal Lathe Drive System Under $100 “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When looking for a metal lathe drive system under $100, check for a strong motor. A good motor helps the lathe turn smoothly. You also want it to have different speeds. This lets us choose how fast we work. Lastly, make sure it’s easy to set up and use. This will help us start our projects quickly!”}},{“@type”: “Question”,”name”: “How Do The Performance And Capabilities Of Budget Metal Lathe Drive Systems Compare To Higher-End Models? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Budget metal lathe drive systems are simpler and less powerful than higher-end ones. They can handle basic tasks, but might struggle with tougher jobs. Higher-end models work faster and can make more precise parts. If you only need a lathe for simple projects, a budget one could be fine. But for serious work, a higher-end model is better.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Followed To Ensure The Longevity Of An Affordable Metal Lathe Drive System? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your metal lathe drive system working well, you should clean it often. Dust and chips can get stuck in the parts. Check and tighten any loose screws or belts. Also, oil the moving parts to help them work smoothly. Finally, always follow the instructions that come with your lathe for the best care.”}},{“@type”: “Question”,”name”: “Are There Any Specific Brands Or Models Of Metal Lathe Drive Systems Under $10That Are Particularly Recommended By Users? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Finding metal lathe drive systems for under $10 is very hard because most are more expensive. Users often suggest checking out small tools from brands like Harbor Freight or Grizzly. You can find deals on smaller models at these stores. Remember to read reviews to see what other people think before buying!”}},{“@type”: “Question”,”name”: “How Can I Enhance The Performance Of A Budget Metal Lathe Drive System Through Upgrades Or Modifications? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can make your budget metal lathe better in a few ways. First, check the belts and change them if they are worn. You can also add a better motor for more power. Finally, clean and oil the parts regularly to keep everything running smoothly. These small changes can help your lathe work much better!”}}]}