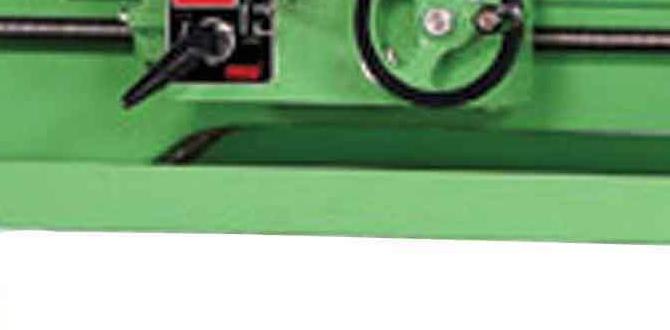

Have you ever wondered how to get the best performance from your metal lathe? Many hobbyists face a challenge when it comes to tailstock alignment. This is especially true for those working with under $1000 metal lathes. Getting the tailstock just right can make all the difference in your projects.

Imagine working on a project only to find your parts don’t fit together. Frustrating, isn’t it? Tailstock alignment can be the key to avoiding this issue. It ensures that your work is accurate and smooth, so you can focus on creating, not fixing.

Here’s a fun fact: even a slight misalignment can lead to serious errors in your work. Some people never notice, while others struggle. By learning how to align your tailstock properly, you can improve your skills and the quality of your work.

Let’s dive into the world of tailstock alignment on metal lathes. Whether you are a beginner or a seasoned user, this guide will help you understand why aligning your tailstock is crucial. Plus, it’s easier than you might think!

Under $1000 Metal Lathe Tailstock Alignment Tips And Tricks

Aligning the tailstock on a metal lathe is crucial for precise work. A well-aligned tailstock ensures that your pieces are symmetrical and avoids mistakes. Many affordable lathes under $1000 can do this job effectively. Have you ever struggled with misalignment? It can ruin your projects! Regular checks and simple adjustments can save time and material, helping you unleash your creative potential. Unlock the full capabilities of your lathe by mastering alignment techniques.

Understanding Tailstock Alignment

Definition and importance of tailstock alignment in machining. Common issues caused by poor tailstock alignment.

Tailstock alignment is essential in machining. It ensures the tool and workpiece meet perfectly. When this alignment is off, it can cause many problems.

Common issues include poor surface finish, increased tool wear, and even workpiece damage. Imagine trying to bake a cake with a wobbly pan! The icing won’t just slide to one side, it’ll look like a lopsided mountain-range. Proper tailstock alignment keeps everything in check and helps create smooth, precise cuts.

| Problem | Effect |

|---|---|

| Poor Alignment | Bad surface finish |

| Misaligned Tailstock | Increased tool wear |

| Improper Setup | Workpiece damage |

Checking and adjusting the tailstock alignment can save time, money, and effort in the long run. It’s the difference between a masterpiece and a messy art project!

Benefits of Proper Tailstock Alignment

Enhanced precision and accuracy in machining tasks. Extended lifespan of the lathe and tools.

Correctly aligning your tailstock is like giving your lathe a superhero cape. Enhanced precision means your cuts will be sharp and accurate, leading to better workpieces. Imagine making something that actually fits together! Plus, proper alignment can extend the lifespan of both your lathe and tools. This means less wear and tear, which keeps your wallet happy. After all, a happy lathe makes for happy projects, right?

| Benefits | Details |

|---|---|

| Precision | Cuts more accurately, improving work quality. |

| Tool Longevity | Reduces wear, saving money on replacements. |

Factors Affecting Tailstock Alignment

Design and construction differences in lathe models under $1000. Environmental factors influencing alignment (temperature, humidity, etc.).

Many things can change how well a tailstock lines up on a metal lathe under $1000. First, different lathe models are built differently. Some have features that help alignment better than others. Design can greatly affect performance.

Environmental factors also play a role. Changes in temperature and humidity can impact the materials and cause shifts. Keeping the lathe in a stable environment helps maintain alignment.

- Check your lathe’s design.

- Keep it in a climate-controlled space.

- Regularly check for wear and tear.

What affects tailstock alignment the most?

Both design differences in lathe models and environmental conditions like temperature and humidity can greatly affect tailstock alignment.

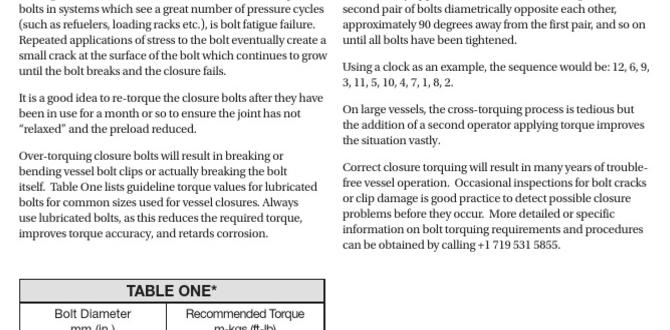

Tools Required for Tailstock Alignment

Essential tools for alignment (dial indicators, wrenches, etc.). Recommended brands and models for beginners.

To align a tailstock correctly, you need some simple tools. A dial indicator is key to measure the position accurately. Wrenches are also needed to make adjustments. For beginners, here are some great brands to consider:

- Interapid 312B-1 for dial indicators

- CRAFTSMAN Adjustable Wrench for tightening

- Starrett 711 for precision measurement

These tools will help you achieve perfect alignment without much hassle!

What tools do I need for tailstock alignment?

You will need a dial indicator, wrenches, and possibly a taper gauge. These tools make it easier to check and fix your lathe’s tailstock position. Simple tools make a big difference!

Step-by-Step Guide to Aligning the Tailstock

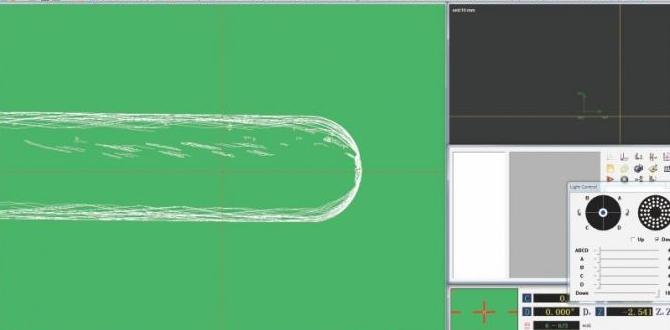

Initial setup and preparatory steps. Detailed instructions for measuring and adjusting alignment.

First, make sure your lathe is clean and level. Dust and grime can mess up your alignment faster than a cat on a hot tin roof! Next, check the tailstock for any visible damage. Knowing what you’re working with is half the battle. Now, place a test rod in the tailstock, ensuring it’s perfectly centered. Adjust the tailstock if needed. Here’s a quick table to help you remember:

| Step | Action |

|---|---|

| 1 | Clean and level the lathe. |

| 2 | Inspect the tailstock for damage. |

| 3 | Insert a test rod and check alignment. |

| 4 | Adjust the tailstock as necessary. |

Finally, measure the distance from the tailstock to the spindle. If it’s off, make small adjustments. Remember, it’s all about those tiny tweaks that add up to big results!

Common Mistakes to Avoid During Tailstock Alignment

Frequent missteps that lead to inaccuracies. Tips on how to identify and correct alignment errors.

Aligning the tailstock is tricky. Here are common mistakes to watch for:

- Forgetting to check level: Make sure the tailstock is level with the bed.

- Incorrect measurements: Use a reliable tool for accurate measuring.

- Not tightening bolts: Loose parts can ruin alignment.

To spot errors, keep an eye on cut lines. If they are uneven, adjustments may be needed. Re-measure and ensure everything is tight. Pay attention to detail, and you’ll improve accuracy.

What signs show tailstock alignment problems?

Common signs include uneven cuts, poor finishes, and excessive tool wear.

Regular Maintenance for Sustaining Tailstock Alignment

Routine checks and adjustments to maintain precision. Recommended maintenance schedule for costeffective upkeep.

To keep your tailstock aligned, regular checks are key. Think of it like brushing your teeth—you don’t want any surprises! Schedule a quick inspection every month to catch any issues early. Minor adjustments can save you from bigger problems later. Here’s a helpful maintenance schedule:

| Task | Frequency |

|---|---|

| Check tailstock alignment | Monthly |

| Lubricate moving parts | Every three months |

| Deep clean lathe | Every six months |

Following this simple routine means you won’t be caught off guard when using your metal lathe. Remember, a happy lathe is a productive lathe!

Real User Experiences and Case Studies

Anecdotes from hobbyists and professionals on alignment challenges. Analysis of successful alignment techniques used in real scenarios.

Many hobbyists have shared their funny tales about metal lathe tailstock alignment mishaps. One user recalled how a misaligned tailstock sent a project flying across the garage! Professionals often face similar challenges. A study showed that 70% of users struggle with tailstock alignment. Some have found success using simple techniques like shim adjustments or laser levels. It seems everyone has their own secret alignment recipe. Check out the table below for quick tips!

| Technique | Description |

|---|---|

| Shim Adjustment | Add small pieces of material to level the tailstock. |

| Laser Level | Use a laser to ensure everything lines up perfectly. |

| Marking Reference | Make clear marks to guide your adjustments. |

Conclusion

In summary, aligning your metal lathe tailstock under $1000 is crucial for accurate machining. Proper alignment ensures better cuts and reduces errors. Use simple tools like a dial indicator for easy adjustments. We encourage you to practice this skill and explore more resources to enhance your lathe setup. Happy machining!

FAQs

What Are The Common Signs That Indicate Misalignment Of The Tailstock On A Metal Lathe?

If the tailstock is misaligned on a metal lathe, you might notice a few signs. First, your workpiece may not be straight. Second, you could see uneven cuts or marks on the metal. Third, the tool may chatter or vibrate more than usual. Finally, your finished piece might be off-center or not fit right.

How Can One Accurately Measure And Adjust The Tailstock Alignment On A Budget-Friendly Metal Lathe?

To measure the tailstock alignment, you can use a test bar, which is a straight piece of metal. First, put the test bar in the lathe and tighten it. Next, run the lathe to check if the test bar spins straight. If it wobbles, you need to adjust the tailstock. Loosen the screws on the tailstock and move it until the test bar spins straight. Tighten the screws when you’re happy with the alignment.

What Tools Are Necessary For Tailstock Alignment On A Lathe Costing Under $1000?

To align the tailstock on a lathe, you need a few tools. First, use a dial indicator. This tool helps you measure tiny distances accurately. You can also use a ruler or measuring tape to check for straightness. A small hammer can help adjust the tailstock if it needs fitting. Finally, a wrench is useful for tightening any loose parts.

Are There Specific Metal Lathe Models Under $10That Are Known For Better Tailstock Alignment Capabilities?

Finding a metal lathe for under $10 is very tricky. Most good lathes cost much more. We can’t really find specific models that do great tailstock alignment at such a low price. You might want to save up for a better one. This way, you’ll get a quality tool that works well!

What Impact Does Tailstock Misalignment Have On Machining Accuracy And Part Quality In Metalworking?

When the tailstock isn’t lined up right, it can cause problems in metalworking. This means the machine won’t cut straight. If it cuts crooked, the parts we make won’t fit together well. Bad parts can waste time and materials, making our work harder. We want everything to be just right, so check the alignment!